-

Posts

3,155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Forming a rabbet

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

If you go the route of replacing the stem and keel, my FET method will work. You can see in my Resolution build where I replaced the stem and keel, but I didn't have the FET, I used an added strip to form the rabbet -

Forming a rabbet

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Dave , after looking at your build log I have to ask, is the stem and keel part of the backbone? If so, my method of using the FET for the rabbet in the stem area probably would not work after all. -

Forming a rabbet

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Dave , I actually used the Proxxon FET to form a rabbet on the MS 1:48 longboat, including the stem/bow. I'll have to get back to you later with some pics. -

Cordless Micro Drills

Gregory replied to CLovehitch's topic in Modeling tools and Workshop Equipment

Along with what Bob is saying, I don't see that being much more useful than a pin vise. It is going to stall very easily and the tool selection is very limited compared to devices with a 1/8 collet sharing the Dremel type tools. While not cordless, I have found this to be very useful for light work. It weighs in at 6.8 oz, so is very easy to use. Dremel 2050-15 Stylo It also takes the Dremel keyless chuck eliminating the need to change collets for the smallest drill bits on up to 1/8 for all Dremel type accessories. -

Jiggling or Nibbling

Gregory replied to CLovehitch's topic in Building, Framing, Planking and plating a ships hull and deck

-

Jiggling or Nibbling

Gregory replied to CLovehitch's topic in Building, Framing, Planking and plating a ships hull and deck

The Jiggling or Nibbling didnt show up till late 18th century.. The hook method that Allan illustrated may have been used. -

Split ring making process

Gregory replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

While I'm sure soldering produces a great result it introduces a another set of tools, materials and skill set, and the result requires blackening. It might fit better in another topic, as the one who requested help said: -

Split ring making process

Gregory replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

Thanks for starting this. I have struggled with making these look good. I really like CPDDET's fine cut-off disks.. I now have some on order. Like everything he does, Chuck makes it look so easy. He's probably made thousands of these. If only he would start selling them.. -

Split ring making process

Gregory replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

Coating with CA might work as well. -

From the link: "The Ropewalk Machine itself is no longer available"

-

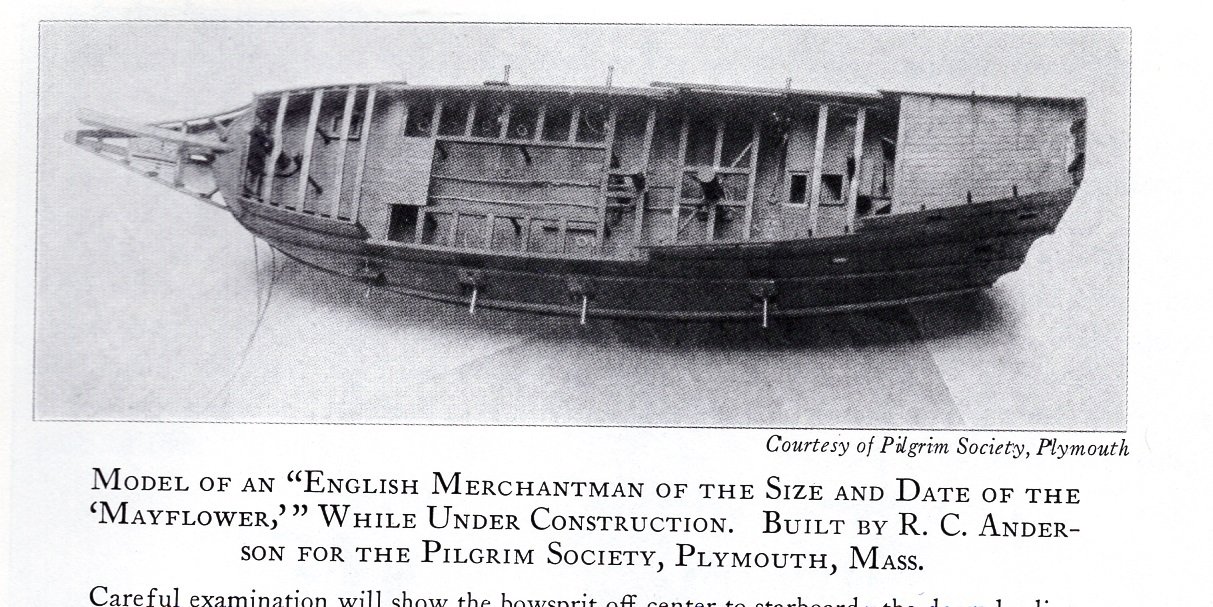

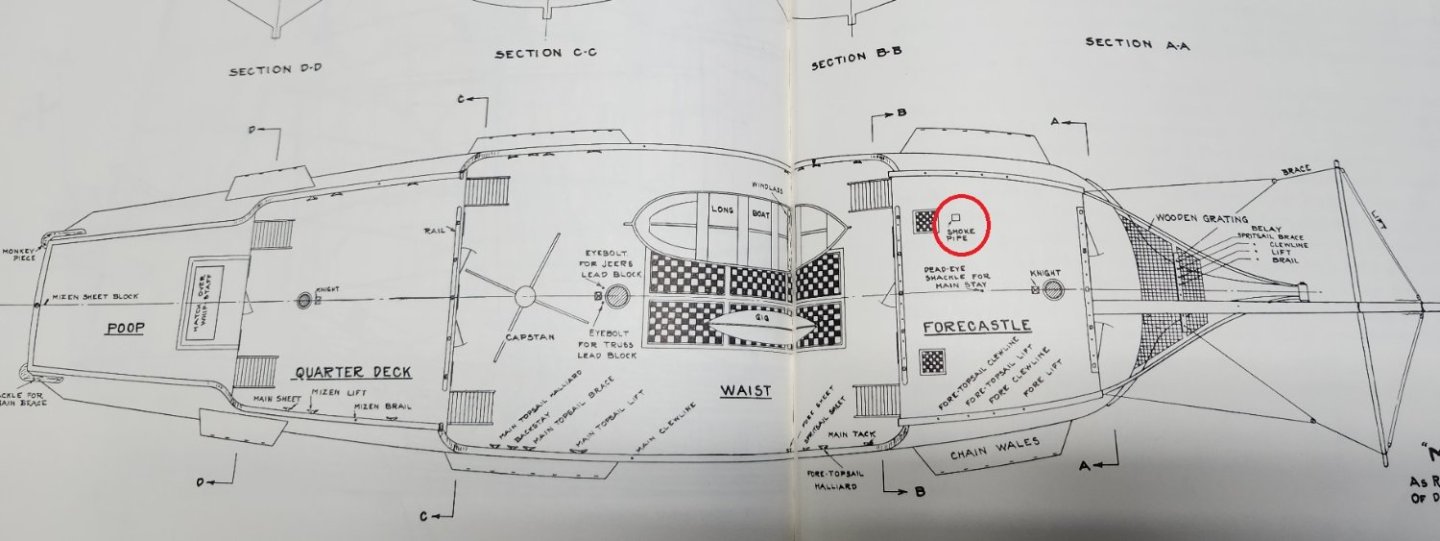

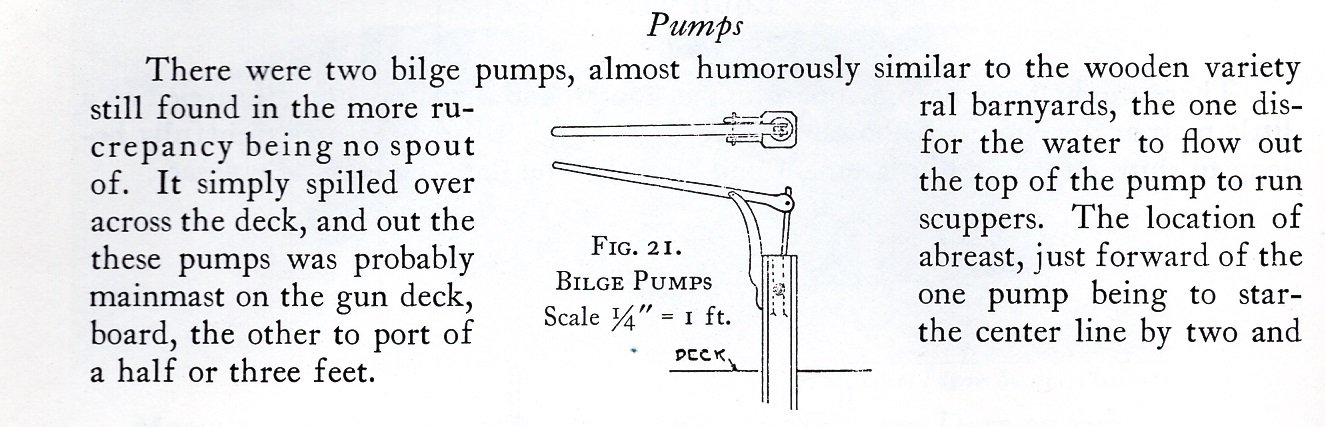

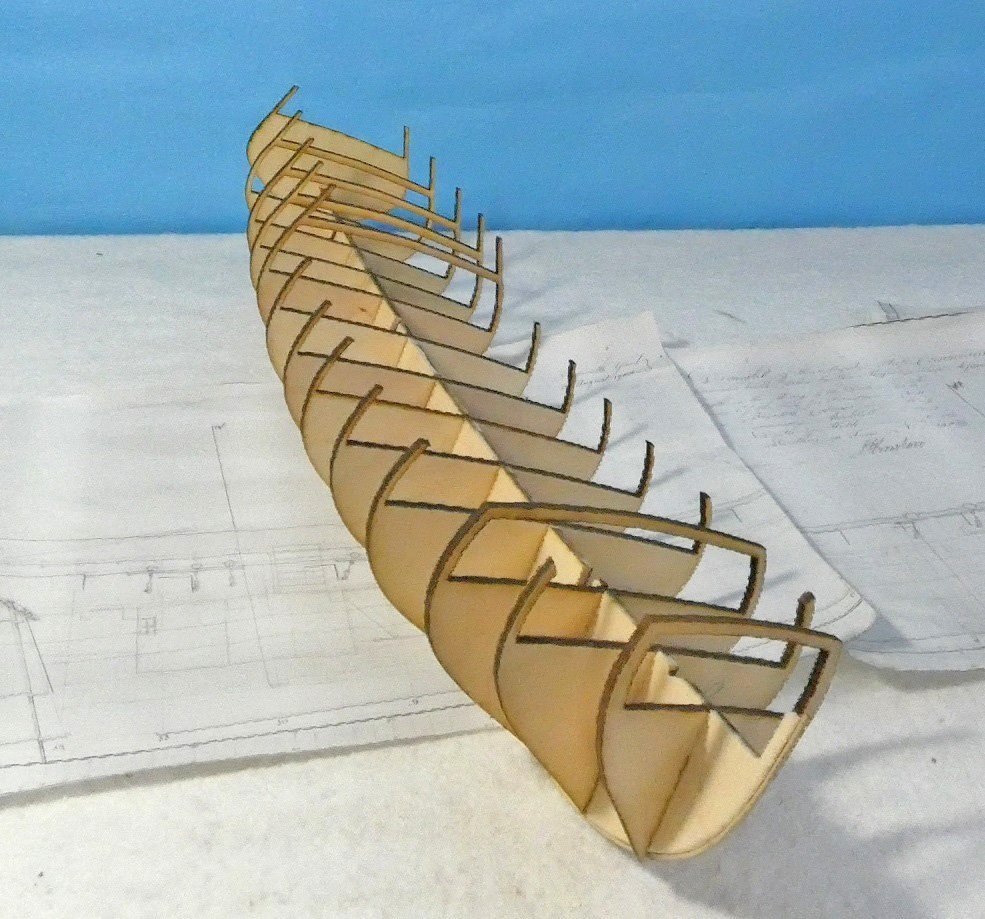

In the book " The Frigate Constitution And Other Historic Ships " F. Alexander Magoun has a chapter on the Mayflower. The information seems to be based on standards for similar vessels, with no mention of documented facts, but he speaks of some features as if they are facts. He offers a plan for the deck. I have circled where he shows the ' Stove Pipe ' However, he wrote of a 'galley' that must be under the forecastle deck show above. This is what he writes about the pumps. The ' gun deck ' would have been below what he shows as ' The Waist ' in the plan above, so the pumps he describes would not have been visible if your model is similar. Here is what he says about the capstan. It seems unlikely that the bars would have been mounted permanently, but others may know if it was in fact the practice on these type of boats. There is no mention of a binnacle, so it is possible just a compass in a box was used as needed. In lieu of other trusted sources, I think you will be safe in following these suggestions, and making it look good to satisfy your goal. I notice in the image Allan provided you can see the kettle and pumps as Magoun describes, but with the capstan forward of the main mast.

-

Typically on kits, the strength of the bulkhead gunwales extensions come from the planking; inside and out. You should see the ModelShipways Rattlesnake. I have stopped counting how many I have had to replace. They are only 1/8" @ 1:48. Additionally, reinforcing those pieces can interfere with gun port framing.

-

Makes no difference to me.. What matters, is how oakheart wishes to proceed.. There seems to be a lot of differences of interpretations of these ship's boat plans. Some seem to worry about the smallest detail, but I have yet to see anyone model the details of transom construction. Most seem content to show it as one big piece, when it surely wasn't built that way. I plan to address this with my build.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.