-

Posts

3,173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

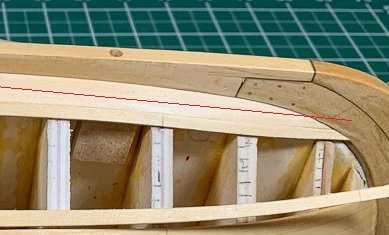

50% May or may not be enough. In the planking resources you will find that you should count the number of full planks amidships. Measure the space available at the bow and divide by the number of planks. If it looks like the planks at the bow are going to be too narrow then you may need a drop plank which will reduce the number of planks at the bow by one.

-

Size of Rope and Serving for Stropping blocks

Gregory replied to Peter6172's topic in Masting, rigging and sails

With regard to serving block strops, I would suggest it's a matter of getting it to look right rather than going with convention. At 1:65 scale you face some challenges. Some great examples of very detailed rigging, although at 1:48, is by Johann in his La Creole build. I will point to some of his stropping work, but the rest of his build has a lot of rigging detail. -

Tips on prepping masts, spars, etc for tapering

Gregory replied to Capella's topic in Masting, rigging and sails

Another option whether drilling or lathing, is to make the spar in two pieces which can be joined together after the tapering is done.. -

- 35 replies

-

- Constitution

- Revell

-

(and 1 more)

Tagged with:

-

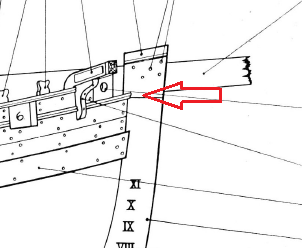

I skimmed through the instructions and see no purpose for that hole.. Perhaps Chris will chime in.. It doesn't show up in the AOTS book as a hole... It seems to coincide with some molding, but I can't tell to what extent the molding is modeled in the Vanguard kit..

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

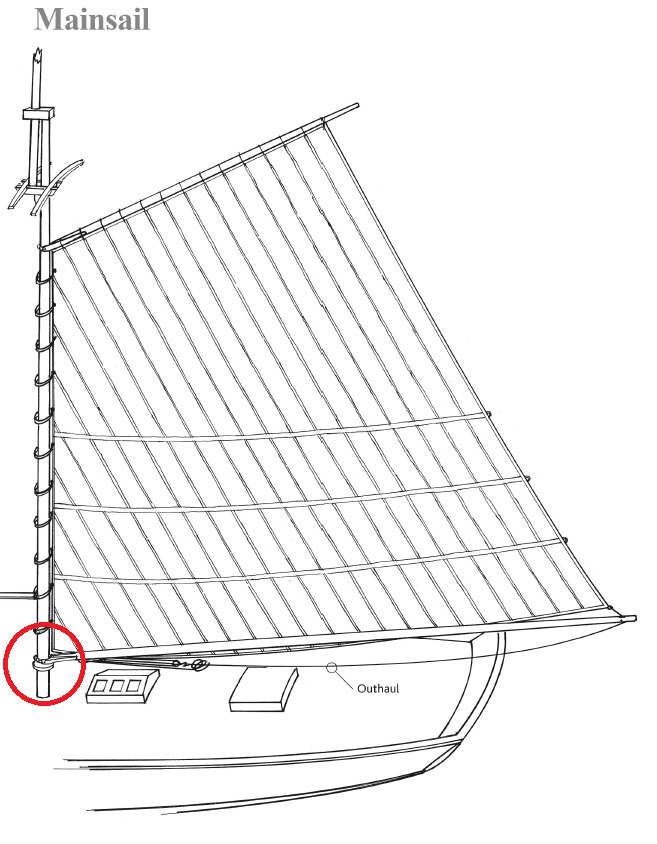

One more note about the ring on your foremast.. Your ring might be a misplaced shoulder for the main boom. The fore mast doesn't have a boom so the shoulder would be out of place there. P.S. If you haven't seen it already, a real nice log for this kit with a lot of detail is this one by Sam (SRC )

- 89 replies

-

- Enterprise

- first build

-

(and 2 more)

Tagged with:

-

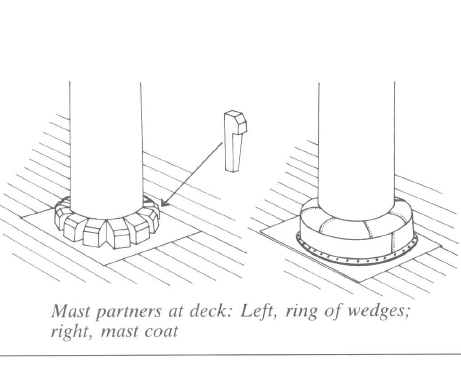

There was rarely if ever a continuous ring of material around the mast at the deck. What you usually see is a modeling convention. The mast coat might have been tarred canvas placed over a series of wedges. Here is an example decorative looking fitting from AgesOfSale Just use the ring on your mast, or cut another one to make some wedges to place around the base of the mast and embellish them as you see fit. Your shroud rigging at the channels really looks good..

- 89 replies

-

- Enterprise

- first build

-

(and 2 more)

Tagged with:

-

Very nice macro photography.. What camera are you using?

- 35 replies

-

- Constitution

- Revell

-

(and 1 more)

Tagged with:

-

Your New "cautionary tale" posterchild here!

Gregory replied to Valkyrja68's topic in New member Introductions

With everything I said, I think cloth can be used to good effect depending on the subject. If you take a look at my Mary, I am happy with the way the sails came out. They provide a look I was going for that had nothing to do with a concern that the stitching is way out of scale. I was just being preemptive, knowing there are those here who are prone to advise against sewn sails. I think you should explore your creative goals when it come to model ship building. -

Your New "cautionary tale" posterchild here!

Gregory replied to Valkyrja68's topic in New member Introductions

While not the final word, you will find the use of cloth, that requires sewing, is not well received here due to the challenges of achieving a scaled look. The weave of the cloth and the size of stitches detract from an otherwise finely detailed model. There are some models displayed with fairly decent cloth sails, but I don't recall anyone sharing technique to any extent. There is an excellent tutorial on making sails with silkspan to be found here: Considering this project ( Medway Longboat ) is 1:24 scale, it reflects the limitations of trying to get a good effect with cloth. I searched for 'cloth + sails' and got a few pages, but it remains to be seen what you might filter out of it.. https://modelshipworld.com/search/?q=cloth %2B sails&quick=1 -

Ancient anchor found in Yucatan.

Gregory replied to Eugenio Treviño's topic in Nautical/Naval History

Two or three hundred years is pre-historic as far as I'm concerned.. -

The SI plans ( which I haven't seen ) must have been derived from the NMM plans which are available at the link I provided above. The MS plans and the Mamoli plans which I have, match the NMM plans very closely as far as the general arrangement is concerned.

-

@Dave_E If you have decided to go with MS, I'm sure you have searched up some of the logs. I hope you found this one: It' stalled for now, but there is a lot of progress and some great examples of technique..

-

I have never seen a topic here where someone talked about " bashing " and had to explain what they meant. I could have missed it, though. Terms and languages, evolve. I always take " bashing " to mean adding something or improving (subjective ) on something that was not included in the kit.

-

Your New "cautionary tale" posterchild here!

Gregory replied to Valkyrja68's topic in New member Introductions

Post pictures in your log and I'm sure you get will plenty of help. We have many members who have built the Revell Connie. -

I am inclined to vote for the MS kit.. It will have the best plans and fittings in general. Try to catch it on sale when ModelExpo is having a ' free shipping ' add on.. Subscribe to their news letter. I don't know if you are aware of ModelExpo's policy of replacing any parts for any reason. it's a great reason to do business with them.

-

Your New "cautionary tale" posterchild here!

Gregory replied to Valkyrja68's topic in New member Introductions

A good thing to remember, is if you have a particular kit in mind, just run it by us here and we can tell you if it is not welcomed here for some reason. -

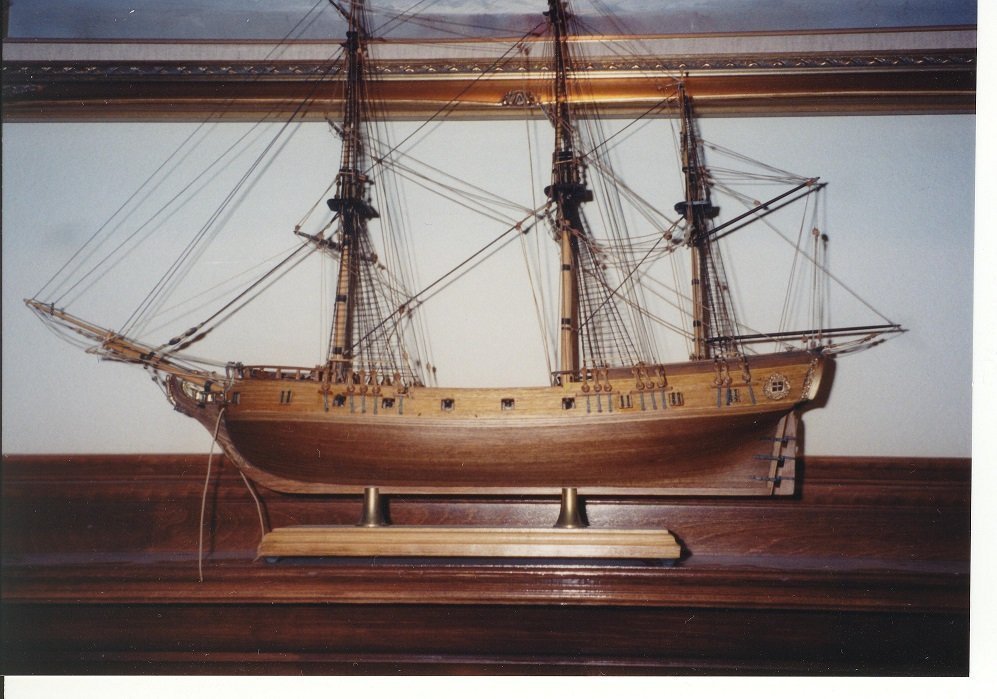

The Mamoli kit was my first wood kit over 25 years ago. No internet, so I relied on what I gleaned from Seaways Ships in Scale and several books I acquired. I found it to be a great learning experience. I just wasn't aware of the shortcomings of the kit because I didn't have anything to compare it to. Here it is, mostly finished. I gave the finished model to a relative, and have since recovered it in very bad shape. If I get around to doing a scratch POB model, this would be high on my list.. I think the ornamentation would be an interesting CNC wood carving project.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.