-

Posts

2,532 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

Thank you Glenn, Derek and DocRob. This is the model I've done that had crowsfeet and I too really like the look. I've now added the all of the stays and preventor stays. Here is an example of the blocks used in some of the rigging. These are for the fore topmast preventor stay. And here is the bocks in place for the fore topmast preventor stay. And some overall picture of the completed stays. Thanks for stopping by!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Fantastic planking Glenn. Your workmanship is second to none!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

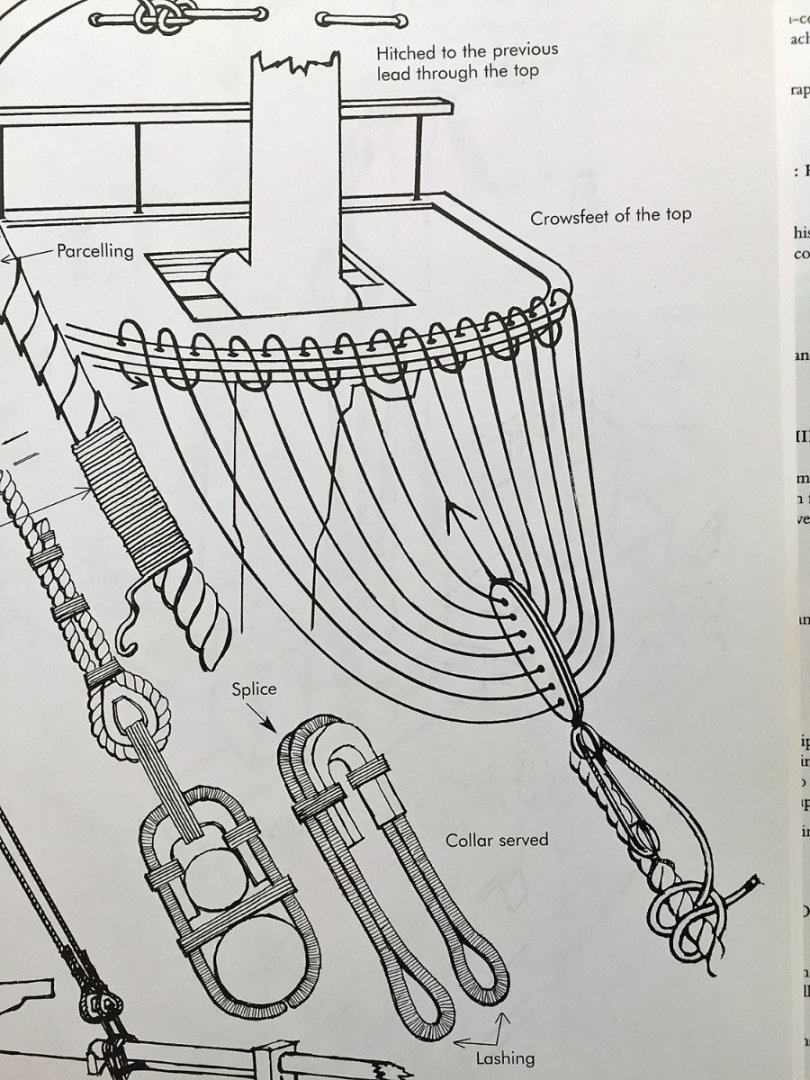

I've completed the fore and aft crowsfeet and I'm happy with how they came out. It was a lesson in patience and deep breaths but fun in a kinda sick way. Next there 7 more stays that need to be served and put in place.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice catch. For whatever reason I did a similar thing before. Much better to find it now than in the middle of planking.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you B.E. and Glenn. Thankfully I could find enough information in others build logs to get me through. Also thanks for all the likes. Much appreciated!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I've served the main and fore stays and mounted them per the plans. After reviewing other logs, (Glenn's DOK and Ron's Sphinx) plans and pictures I made my first attempt at rigging the crowsfeet. There were a few false starts, twisted and knotted line that had to be untangled numerous times, I finally completed the first of three crowsfeet. Thanks for stopping by!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Stunningly superb Chuck!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That's a fine start and welcome to the club!

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thats some fine work Ben! Very nice.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've started working on the five stays. The all of the stays have a mouse on them. I've seen others make the mouse from a dowel which I copied. I drilled a hole down the center just slightly larger than the line, sanded them to shape, cut them off and painted them. I then served the lines below where the mouse will be. I then made the eye seizing it and sliding the mouse into place. Here you see the fore preventor stay and mouse in place. Here are the fore and main preventor stays and the mizzen stay. Next I'll add the main and fore stays and then three sets of crowsfeet!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks Glenn. Yes, I've been looking at that and making a mouse for the stays. I found this for the crows feet.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The portside ratlines have all been tied and went much quicker than the starboard ones! Before I hang the yards I'll be working on all of the various stays and the crows feet. Having never done "crows feet" on to a stay should be a fun learning experience.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Glenn, B.E. and the other Glenn . I agree, it just takes me getting to it and staying focused. Hmmm wait a minute that's me about most things!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I've just completed the lower and upper ratlines on the starboard side. They aren't the best but I'm happy with them. Jim H. said that ratlines are therapeutic. By the time I finish tying all the knots for the port side I may need therapy!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I second that. Well worth the time spent!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Chuck, I've had the pleasure of see your Winnie in person and your design and workmanship is simply stunning. Ok just for grins and giggles I requisitioned (stole) the Admirals kitchen food scale and weighed my Winnie. She currently tips the scales at 5lbs 8ozs. (2.5kg). Might have to put her on a diet.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi B.E. I just got caught up with your wonderful work on the Sphinx. It was such a pleasure!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well, it's been almost two months I've been moving slow and unsteady. It's always tougher to get modeling time in the warmer weather but I'm not going to complain. It goes away too fast as it is. I served the upper shrouds and added them. A couple of miscues and a shroud or two were replaced but finally they are done. Next, I'll be doing the ratlines. Hopefully it will go smoother and a little bit quicker.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice work and I'm off to get some magnetic strip too!

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.