-

Posts

2,535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

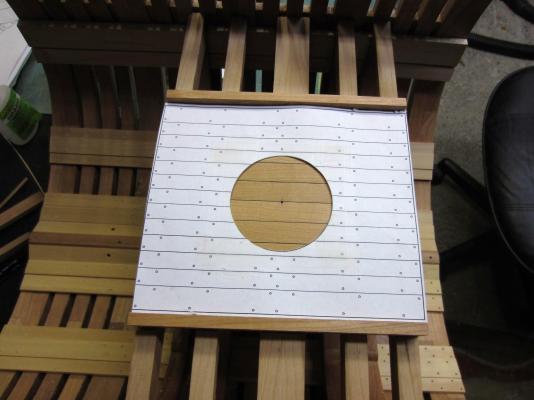

I’ve completed the second layer of decking for the mortar pit. I assembled it off the model again gluing black construction paper between the planks to simulate the caulking. The planks are a different width and did end up over lapping the lower decking most of the time. One seam lined up on each side so there shouldn’t be a concern with strength is it was that way in full scale. After I did the initial assembly I then marked the circle for the mortar and cut close to the line with the scroll saw. I then used the dremel with a sanding drum to finish it. I then glued the second decking to the first. I also have drilled it for the treenails After looking at the plans I noticed that between the top beams for the shot room, the deck beam, and the two layers of decking it would have been 3’ 4” thick on the actual ship! That’s a lot of support for what I assume to be a very heavy gun.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Ben, I’m glad to see that you have finished her.Very nicely done and it looks really great in the display case. Another point about switching back and forth between the “dark side” and the light is you could become deficient in Vitamin D if you stayed on the dark side too long!

- 147 replies

-

Oh my Augie. I just got caught up from what I missed while I was away and I LMAO while reading it all. Oh and by the way the planking looks really good too!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Well I’m back safe and sound and hope to relax a little doing some modeling this weekend. Thanks Paddy. Ben, Not as much as I missed MSW! Hi Grant and thanks. Thank you Craig, Hi Chuck. Thanks and it’s good to hear from you. Jeff, yes she is huge but I’m getting used to it now. There has been so much going on here at MSW over the last 8 days! I need to take a week off just to read all the posts. I’ll do my best the work shop is calling right now. Thanks again you all and it’s great to be back!!!!!!!!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Bob. I’m back in town and I just got caught up on your work. Everything looks to be going very well. You may have had doubts but the rest of us knew you would “nail it”. Oh by the way, isn't having a couple of teeth extracted, a little extreme way to get more modeling time? I hope you're feeling better.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

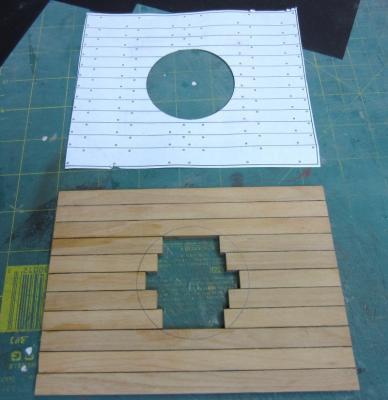

Hi Pete, Glad to hear you are enjoying it. Hi Bob, I wondered the same thing about the upper and lower planking but they are different widths so the majority of the planks overlap. It looks like that all but one plank on each side will be an overlap. Once I cut the planks and add the construction paper I’ll know for sure. As far as assembly of the second planking I will do it off model. I plan on using lengths just long enough to get into the circle and then cut it close with the scroll saw and finish with a drum sander. Again that’s the “plan”. As far as mouse world goes thanks for the hint. We always try to avoid the weekends whenever possible. Especially this being a holiday weekend. Well the Admiral is waiting so it’s Hi Ho Hi Ho and out the door I must go.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

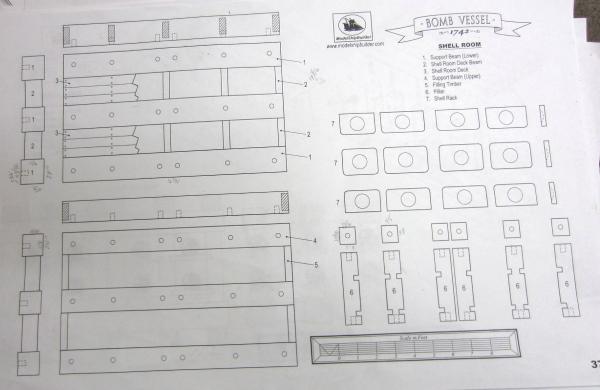

Thanks Michael and welcome aboard. I’ve cut and fit the mortar pit boundary timbers. Between these two timbers will be a first row of decking. It is cut from boxwood and the calking is simulated using black construction paper. Doing the pencil on the edges just looked too thin at this scale. Here I’ve cut out the plans showing the second layer of planking that will go right over the top of the first. You will notice that a nice circle is formed in the middle for the mortar. Seeing I don’t have a drill bit that big it should be interesting getting the hole round. Well this will be the last post for awhile. We are off to the land of oranges, alligators and a talking mouse with the grand kids. Should be interesting to see how steady my hand is when we get back. You all be good now while I’m away! No slacking off or rum rations will be cut!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hey Chris I hope you gave a great Birthday!

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Seeing some more of your fine work is a great way to start my day! Thanks.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

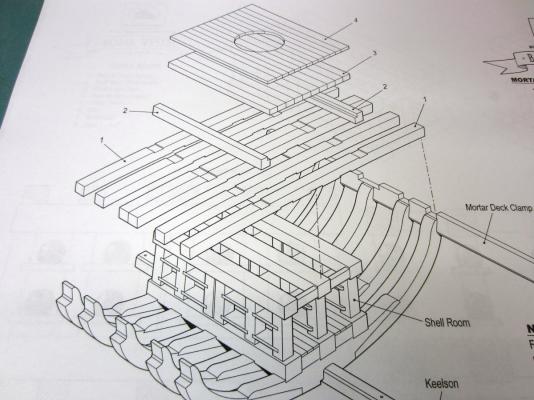

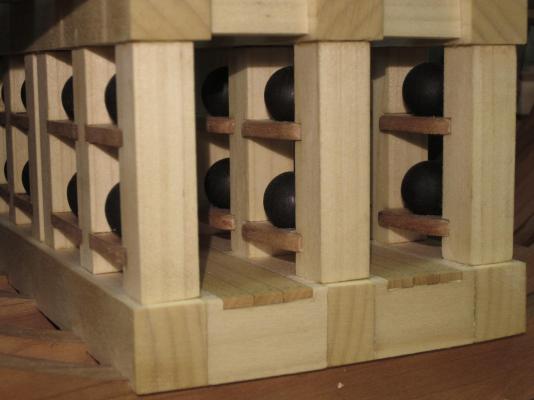

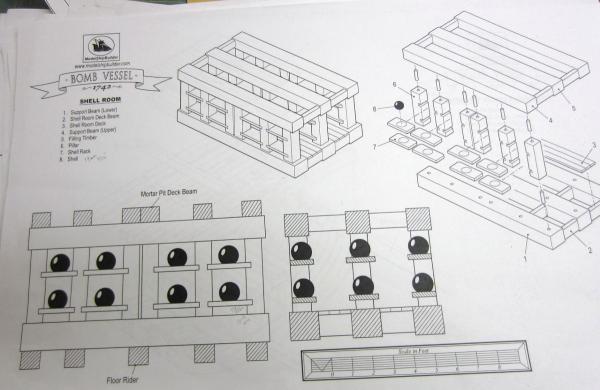

I’ve assembled the two other rows for the shell room, glued the cannonballs in place and set all three rows in place. I then added the top beams just like the bottom beams. Here you see the plans for the mortar pit beams and planking as well as the beams cut out as per the plans. The mortar pit beams have been cut and test fit into place on top of the shell room. The bottom of each beam is notched to fit over the top beams of the room. Here you see the notches cut into the tops of the mortar pit beam and ready to accept the mortar pit boundary timber. Thanks for stopping by!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks Joe, I'll keep the picture coming, that is when I remember to take them! Hi Grant, I am too brief sometimes. Sorry about that. I took a 3/8" (9.5mm) drill and used it to make a small depression in the center of the shelf. I then used 100 grit sandpaper on the tip of my finger and just kept turning it in the depression until I had it the way I wanted it. I then finished it with some 220 to smooth it out. Kinda like sticking you finger in your ear and twisting back and forth when it itches!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks Chris, It's great to hear from you. The cutting out of the parts and the assembling of the shell room is progressing. The shelves are made from cherry and the posts from poplar. Each shelf will have a depression sanded into it for the mortar shell to set in. Here you can see one row set in place for a test fit.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks Bob and Joe, It's sure different than anything else I've done and a nice change. It will be interesting to weight it when I'm all done as its getting heavy already.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Now that the floor riders are in I’ve started the floor for the shell room. All of the beams are cut from some white poplar I had kicking around. The beams and posts will be sealed with a natural stain prior to the application of wipe on poly. Here are the shell room floor beams test fit. And the completed floor with the beams and walkways which are made with boxwood.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Ouch, That really sucks. Well I guess you have something to look forward to doing during your visits.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Augie, You’re moving along nicely. The planking of most of the hull is straight forward. Just remember to pre bend the planks at the bow and stern like Chuck describes and you won’t have any problems. Might take a looooong time but no problems. Adrieke, The practicum it around 170 pages.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

The inboard hull planking below the motor deck clap has been installed. I still have to drill it for the treenails and then it’s on to building the home for the cannon balls. Here are the plans showing the assembly and it’s placement.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Ben, Yeah I thought it was kinda neat. I had set the sander next to it while getting more paper then thought it was a good reference to the size. Thanks Mark, I guess “different” would be the correct word. The size throws off what we are used to doing. When doing joints a little flick of a chisel or knife would fix a bad fit. Here a little off requires the removal of a ½” wide piece of wood! On the plus side there is a lot more to hang onto so the tips of my fingers have suffered less.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Well said Remco and your work is still an inspiration.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Miniature Spindle Sander

Rustyj replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Hi Chris, I've used a dremel in the dremel drill press for many a year and has worked well for small items. My brother made a raised bed for me but it is not necessary. It is an option for you until Jim Byrnes builds one. -

Hi Augie, Just got caught up and you are doing a great job. Just wonderful. I too am eagerly awaiting your planking but I am also very sympathetic too! Don’t fret it though. It may be a large task but your methodical approach and attention to detail will serve you well!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Ben, Thanks for your continued support. I’ve done a couple of admiralty style POF’s already and I’m not sure when I will do a full one again. So many things to build. Well the floor riders have been shaped and installed along with the motor deck clamps. I’ve also placed the first of the inboard planking between the keel and the deck clamps. The channel has been cut for the limber boards too. Seeing that the clamps and riders are installed the framing is stable enough to fair the outer hull now. So I took her outside and seeing she is so big I was able to use a palm sander I normally use on full size work to rough her in. Here you see one side has been done with 80 grit. I’ll work out to 220 grit for now.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.