-

Posts

2,535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

Spot on Augie! You are doing a great job and a Merry Christmas to you and yours.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

A Merry Christmas to you too Antony and good luck with the carving too.

- 209 replies

-

Thank you all for stopping by and for all of the likes. Hi Ben, Thanks. It’s really fun using multiple woods. Hello Jakob. Thanks for joining this motley crew and your kind words. The starboard side is now complete. Now it’s time to drill a lot of holes and make some treenails. No work or playing in the shop for the next couple of days. I also want to wish a Merry Christmas to everyone and their families here at MSW! See you again soon!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks for the tip Mike. Now I just have to “accidentally” tear a sheet so I can give it a try. Had a good stretch of time in the work shop. I have been planking above the wale. Very straight forward until I got to the sweep ports and gun port openings. Then I had to notch the plank. It was a slow process of take a little off, check, take a little more and recheck. After several times it worked out. Now its time to plank the starboard side and then a bunch of treenailing.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

I absolutely would Floyd. Just have to time it for when his wife is out!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Oh no I won't tell but if I run out of tee shirts I know where to go!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Very nice work Bob! I agree that planking the deck can be addictive. I find it a lot of fun and if you’re not careful you could spend the whole day doing it. Hmmm that doesn’t sound so bad does it? Also I don’t think you will have any problems nibbing those planks when the time comes. Have a Merry Christmas and enjoy the family and any sneak a ways you can get.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Gary. Your comments are always appreciated. Hi Bob, yep old tee shirts have almost as many uses as duct tape. Hi Bob H. I’m sure the tee shirt club is very large. One problem I have is that since I’m semi retired I don’t wear them out as fast as I once did. I’m afraid someday I may deplete my supply and have to use, gasp, new ones.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Chris, Yes there is one coat of satin wipe on poly on the wales and hull planking. I do it as much for the look as the protection. I have yet to try the danish or tung oil but I am thinking of trying that too.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks everyone for your comments and likes. Mike, Ttttthhhhhaaaaaannnnnkkkkksssssssssss. Hi Joe, thanks and I try to remember to take pictures. Sometimes I get so wrapped up in what I’m doing I forget to take them. Hey Grant, The main reason I chose the Fiebing Dye was that I saw and liked the results from others using it. Also for me there is not the smell associated with spirit based stains. Hi Rob, It is the same for the deck planking. I edge glue black construction paper to one edge, trim it tight and then glue the plank down. Repeat as needed.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks Tim. Hi Chris. I’ve played with it a bit. It is as thin as water. The best way I found to do it on something this large is to use a cut up cotton tee shirt. Using rubber gloves of course I dipped the tee shirt in the dye squeezed the excess out and then rubbed it in. At the ends I did tape it off and used a small brush to better control it. I’m very happy with the way it came out. After it dried I also installed three rows of planking below the wales. That is the extent of hull planking I will do.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Glenn, She’s looking very nice. Your work is as nice as it always was. The aluminum foil may be quicker but I don’t think it will have quite the same look. I do feel your pain though after cutting and placing the copper on the Constitution a few years ago and I still have a twitch from it. I really like the closed hatch look and thanks for continuing your posts too. I will use it as a reference once I get mine out of the closet. Have a Merry Christmas and a Happy New Year!

- 101 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

Thanks Floyd. It's really fun to do. Nothing really exciting to show all of you. I have cut the wales from cherry and installed them. Once they are sanded I will be coloring them black with Fiebings leather dye. This will be the first time I have used it so this might be interesting! I have depleted most of my ebony and will probably discontinue using it anymore. It’s bad for you, I’m not religious enough about wearing a mask and it’s just messy. As far as the rest of the planking goes I will be using Boxwood. The plans show planking only above the wales but I may put two or three rows below the wales too.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Rob, Thanks for the screw idea! Mike, As you said it will take a long time I think as some parts require the removal of 1/4" or more of material. That's a whole lot of sanding and filing. Ok the planking in board is complete. As I mentioned before I used red heart. I also cut some thin veneers to line the inside of the gun ports. I did not think far enough ahead for the sweep ports so they will be painted red to match. They are so small I don't believe anyone will know the difference. That is except for all of you.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks all for your comments. I have a drill press and haven’t thought about trying to turn something like this in it yet. I have done small stuff in it but as Augie says the size is an issue. The first issue would be cutting the block or dowel down to ½” so it would fit in the chuck. Then if that was successful I would need to get a good set of tools for turning which I now see are quite far ranging in price. I assume that in general terms cheaper is not better when purchasing these. But then I’ve seen sets for 200-300 hundred dollars. Mike, I too agree with Grant that “dark side” builds lend themselves to getting a lathe but I don’t stick to just scratch building either. There are several kits I want to build too. Although I will do some modifications to them…..Hmmmmmm. And then Floyd mentioned my weakness and that is I LOVE TOOLS. Crap, in my mind I’m getting nowhere. Anybody have a rich uncle?

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

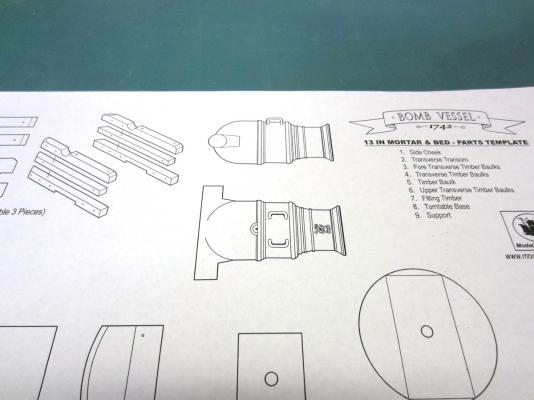

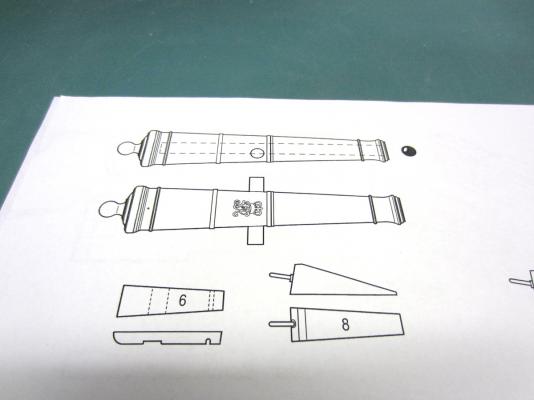

Again thank you all for stopping by. The deck has been tree nailed and I will have the inboard planking completed this weekend. I have been ignoring the 800 pound gorilla in the room. I now have to address it. So I’m finally looking ahead to the cannon and mortar. You see I do not own a lathe and I’m hard pressed to spend $400-$800 dollars just to make a couple of cannon. I’ve also looked at the less expensive lathes like Proxxon but that only does wood. If I spend that much should I spend more for a metal lathe but would the cost be justified and worth it and on and on my mind goes! One alternative was to see if I could commission someone to make them for me. As they are so big I’m thinking they could be turned out of boxwood or holly or some such close grained hardwood. I forgot to put a ruler on the plans but the cannon is 4 ½” long and ¾” wide. The mortar is 2 ¾” long and 1 ½” wide. Oh decisions, decisions, decisions!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Bob, Oh the things that end up inside our models while building them! That was a great recovery though and a really good idea on doubling the frames. Thanks.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Daniel, We were posting at the same time. Yeah I’ve envied all those spotless, well organized shops for years. But then once I walked into one of those they would never be the same again! I agree the aroma of the shop is something else but I also find that we are the only ones who truly appreciate it.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Greg. It would be an honor to clean up after you! Hi Michael and Grant, It just struck me as funny when Antony was talking about “clean build” and I knew I had all that cleaning to do. So it was fun to share with you all. Oh yeah when I first started building it was on a small table in the corner of the living room. You know I kept that a whole lot cleaner with the Admiral right there.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

OK you may have thought it was tongue in check when I said I had to clean the shop before I continued. You see I am the type who likes to spend as much time as possible working and I just jump from one step to the next. If what is on my desk isn’t needed for the next portion of the build I just push it aside and onward I go. Well seeing that there was no workspace left for me to start cutting the red heart for the inboard planking it was time to clean. So I just spent the last 3 hours cleaning and now it's be full steam ahead this weekend!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thank you Daniel. The build may be clean but I sure have got to clean up the shop before I can do anything else. I’ve been a little lazy when it comes to putting things away! As far as sealing the wood goes if I have finished a section and no more gluing will be done I apply a coat of MinWax Wipe on Polyurethane satin finish. This seals the wood and helps protect it. Also with so many nooks and crannies it would be really hard to apply later.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Antony, I just got caught up with your log and you are doing some outstanding work. Very well done and the look is so clean. I love it.

- 209 replies

-

Hi Chris, Of course they fit! It’s just a testament to the great care and patience you have put into building her. Very nicely done.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.