-

Posts

718 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Greg Davis

-

-

1 hour ago, BradNSW said:

Excellent progress. We look forward to watching these joints come together, step by careful step. IMO, they can make or break a model.

You are several months ahead of my latest project. The mobile shipyard is still working on frames. We did have a friend deliver a package of pearwood stock to our current campground, for the keel and rising wood.

So, workers here are already planning the steps and process for laying the keel and stem/stern pieces. I will continue to follow closely to glean what I can from your techniques and experience! Thanks for the great pictures and process descriptions!

And I will be doing the same. Safe travels!

Greg

-

8 hours ago, AnobiumPunctatum said:

It's not only the problem which David mentioned. It's also a simple problem working with wood (and also other materials). If you cut and grind your wooden parts 100% exactly to the line, your model keel will be 0.4 to 0.5 mm longer than planned (depends if you have 5 or 6 parts). The glue needs also some space. My experience say that you have to think on 0.1mm for every joint. If you add some thin paper for the caulking you need at minimum 0.15 to 0.2mm for the joint.

Especially at the keel this gives your model some extra length.

With manually cutted parts you can't avoid this.

All points well taken - expanding / contracting plans and wood, together with the fact lines on a drawing have width.

I won't be adding any paper for caulking and yes, glue does take up space. I hope to keep a good eye on the accumulated length / minimize the chance for expansion by keeping track of not just the dimensions of each individual part, but also that of assemblies. So here, the combined width of the apron / stem is as important as the width of the apron and stem individually.

Of course finishing individual parts to the exterior the associated plan lines will result in joined pieces to include the thickness of two copies of the lines from the plan plus space taken by glue - so one line width plus glue too much. Finishing individual pieces to where the plan line nearly disappears (on both sides of a joint) keeps the joined combined piece(s) dimensions closer to what the goal is.

Either way, assume if one had modeled a keel to be 850mm and ended up 0.5mm in excess of the overall keel length, the length for this assembly l will still be within 0.06% of the desired length [ (0.5 / 850) x 100 = 0.06% ] - for me, I'd call that a win!

-

I milled the scarf joining the apron and rising wood segment, then glued the pieces together and set them under glass for more than a day. My plan is to shape the fore side of the subassembly so it matches with the previously made section. Then I will shape the inner side followed by milling the more delicate scarf on the end of the rising wood piece.

-

Just a quick update:

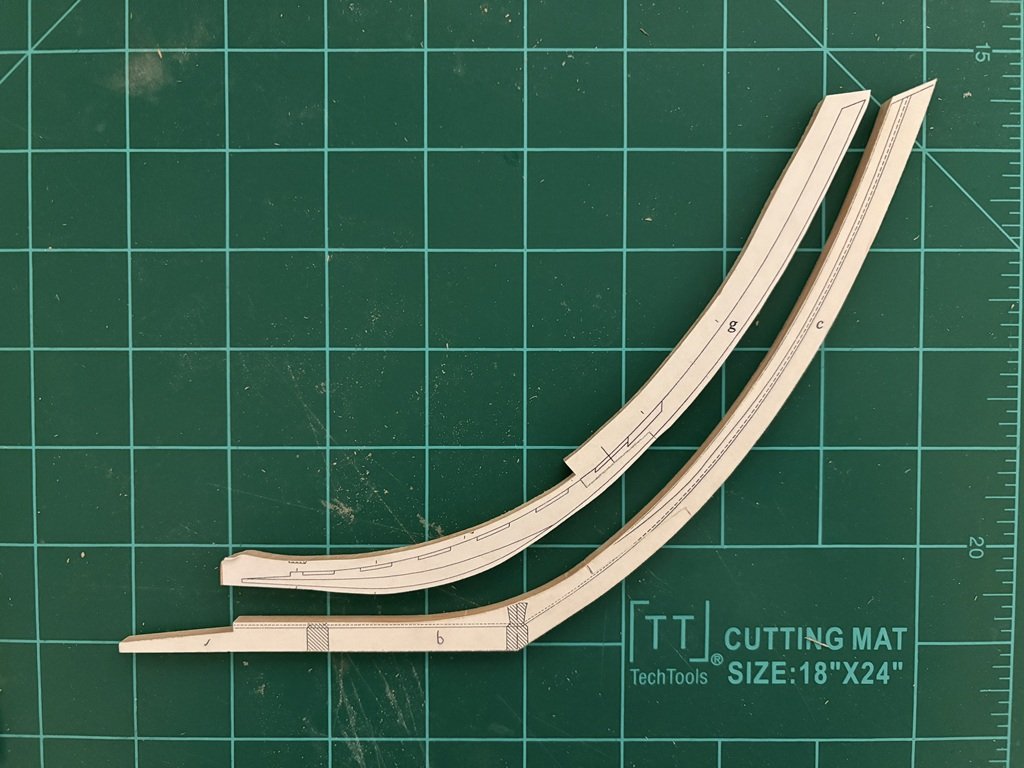

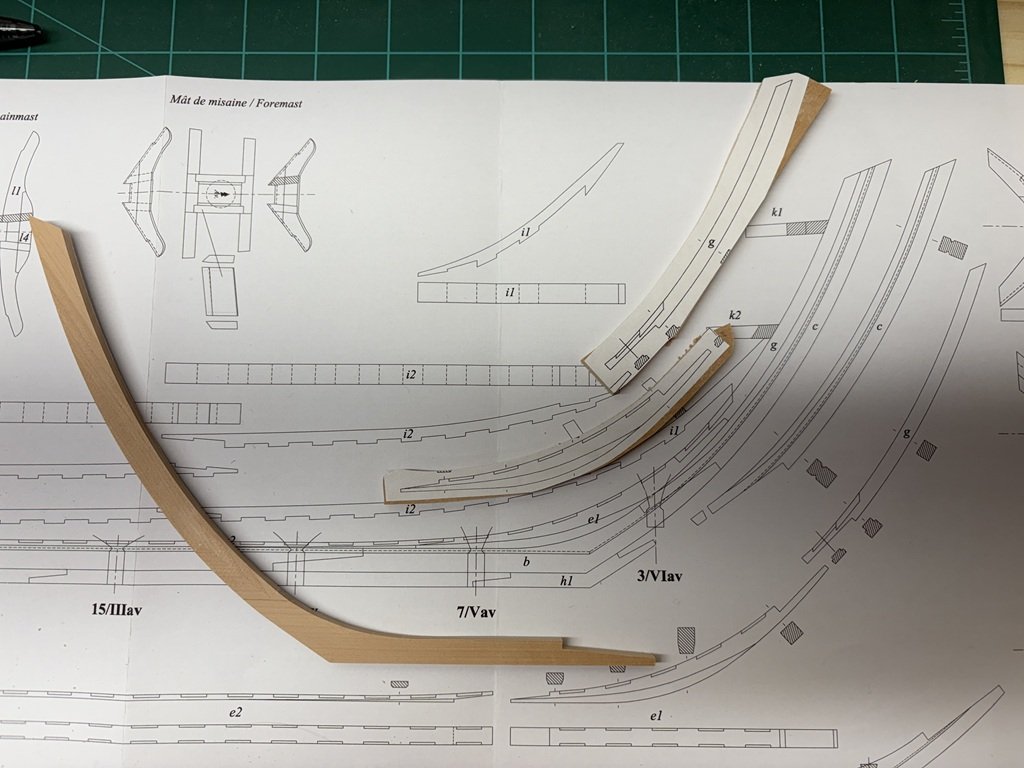

It's taken a few days but the fore-foot (b) and stem (c) are connected, shaped and ready to accept the apron (g) as well as the first section of the rising wood (e1). I expect that it will take quite a few more hours of careful shaping to get g and e1 nicely fayed to b and c. The fore-foot (h1) already is shaped to fit correctly to b (and to the next part of the false keel h2).

- druxey, No Idea, KARAVOKIRIS and 5 others

-

8

8

-

5 hours ago, druxey said:

The second solution is one I've used now for decades, since I discovered paper plans were a snare and delusion for accurate work. Sure, it's more work, but saves my sanity in the long run! The photo is the prelude to my current project, the South Carolina, ex L'Egyptian.

Fortunately we keep our house fairly well controlled in terms of temperature and humidity so I'm hoping that there is minimal dimensional changes going on here! For this project I will make use of the dimensions listed in the monograph as well as the plans.

I had read about your use of Mylar in your books and it may be wise for me to think in this direction for future projects. This certainly seems to be a situation where it would be valuable to have CAD files which don't appear to be available for ANCRE publications. But I do have a project in the wings that needs to be done in the next couple of years for a local non-profit. They want I model of a Mackinaw boat and I have agreed to make one for them. Still not sure what draught I will work from, but it appears that I will need to draw the plans myself - it could be a good introduction for me for working with Mylar.

I am very much looking forward to seeing the result of your current project; South Carolina (ex L'Indien?) is such a beautiful frigate!

Greg

-

-

Before refining the joints, the accumulated error in length of the keel was nearly 2mm over the ~80mm unit. After working more on the joints, I've reduced this to less than 0.5 mm; so I'm now within 0.6% of the plans. I concerned that if I go further, I may end up being off by more in the negative side / am I already in the area of contraction / expansion of the paper plans - what to do now?

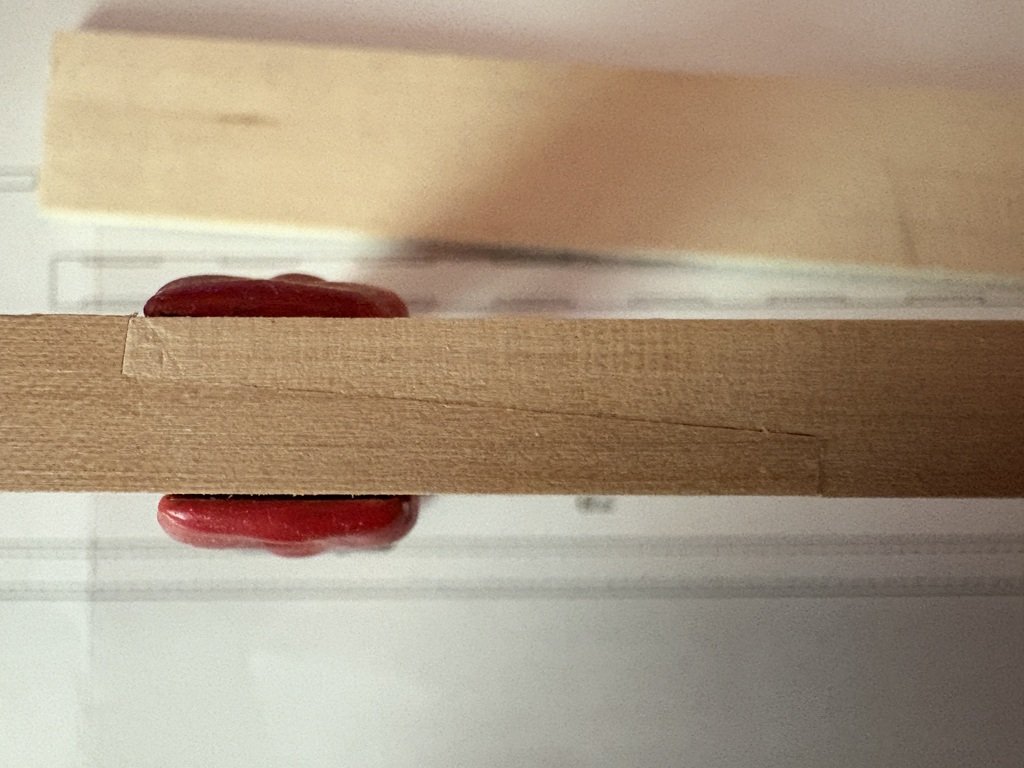

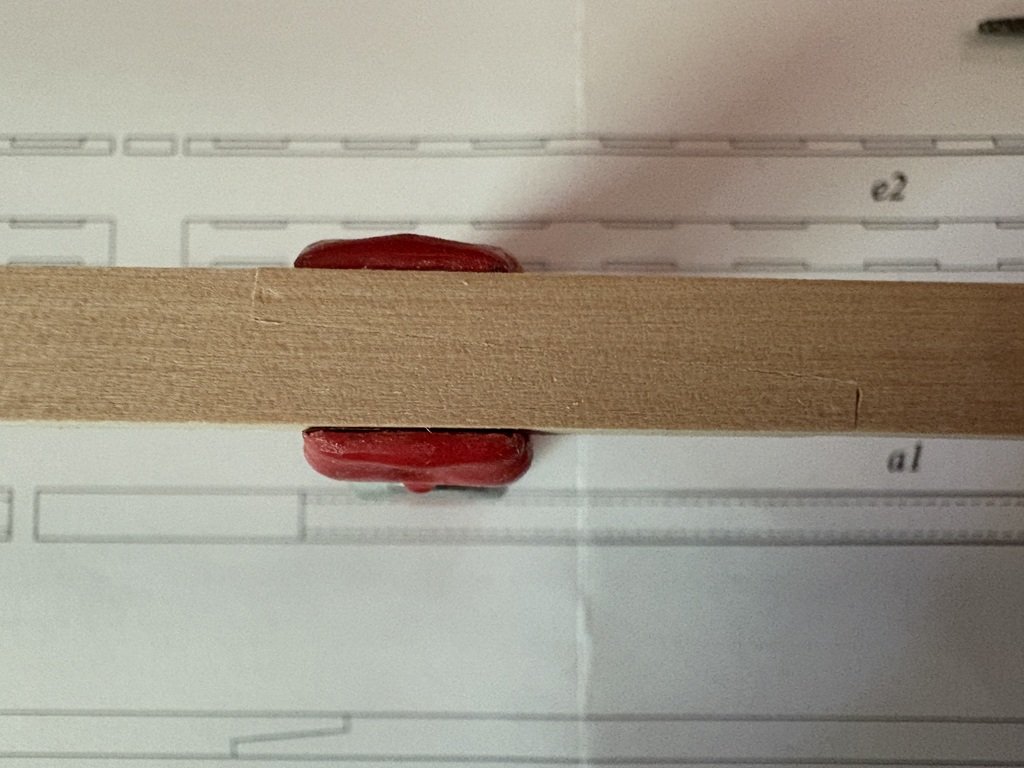

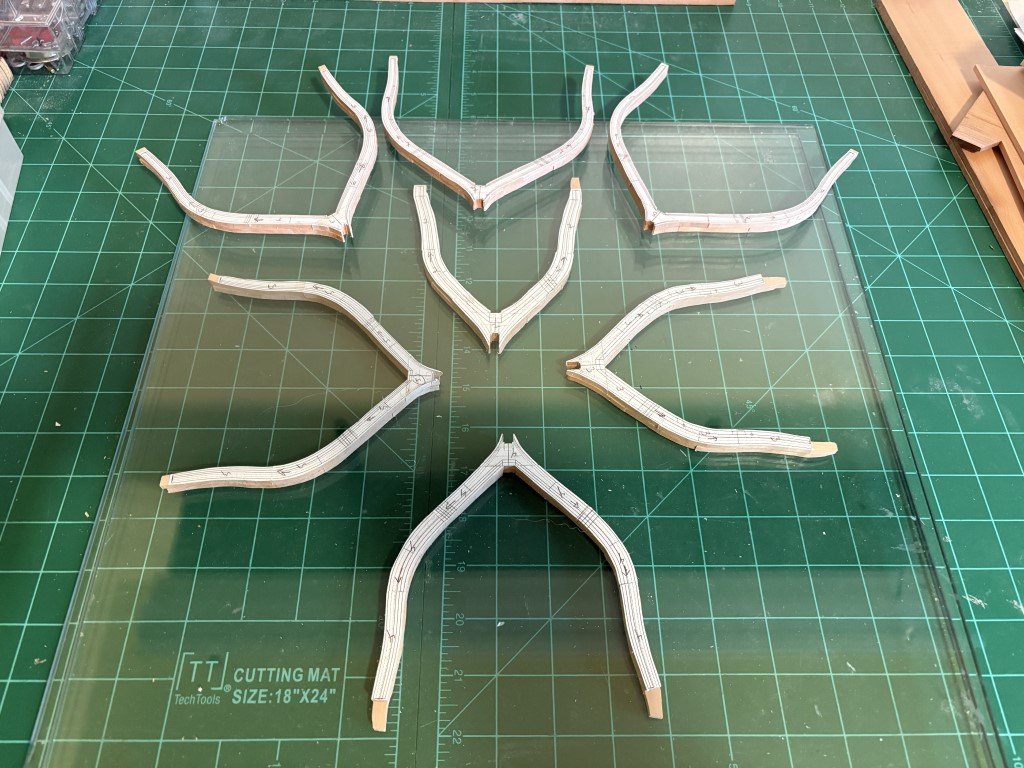

Here's what the 4 scarf joints that link the 5 pieces of the keel from fore to aft:

Next up some work on the false keel joints

-

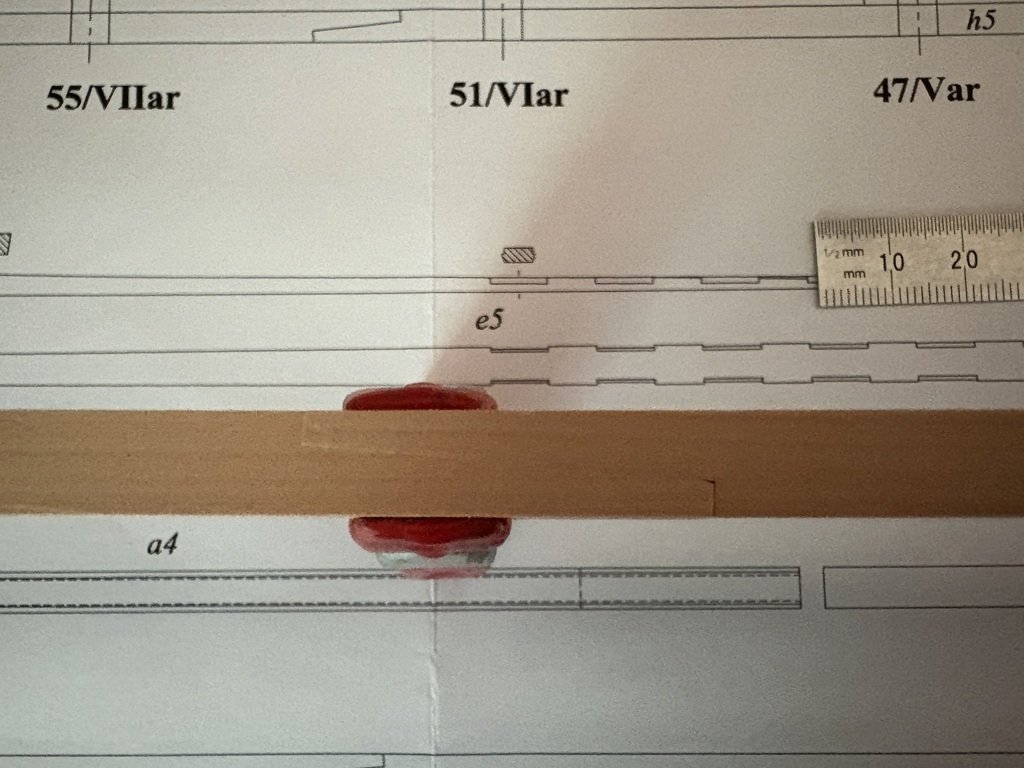

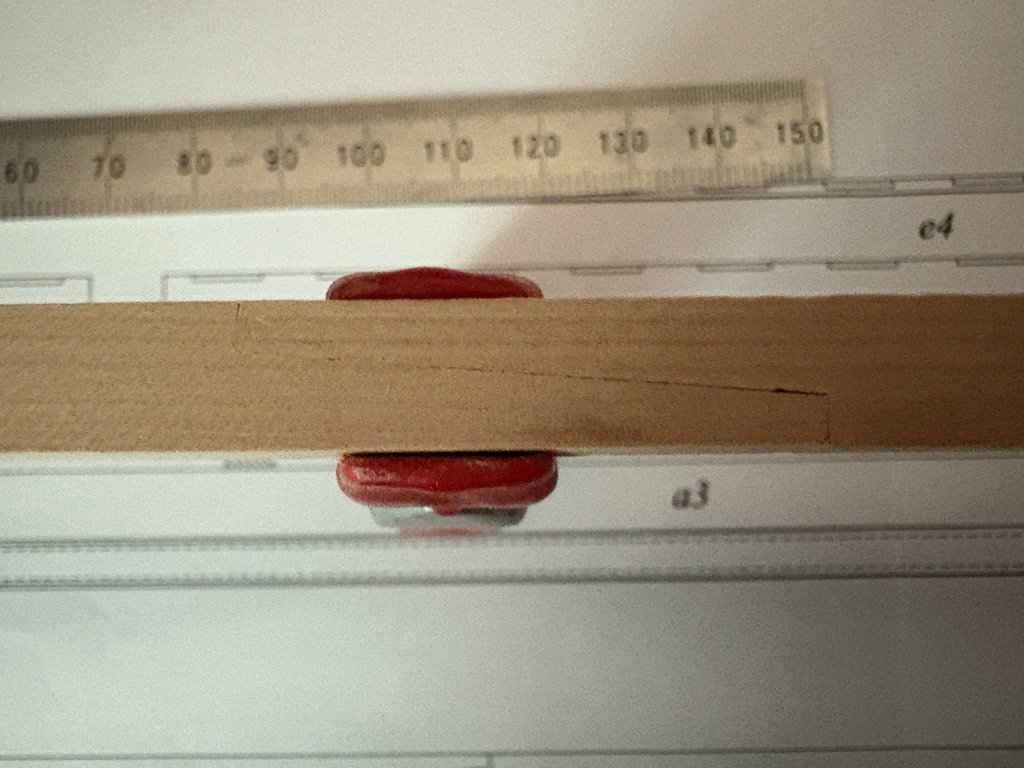

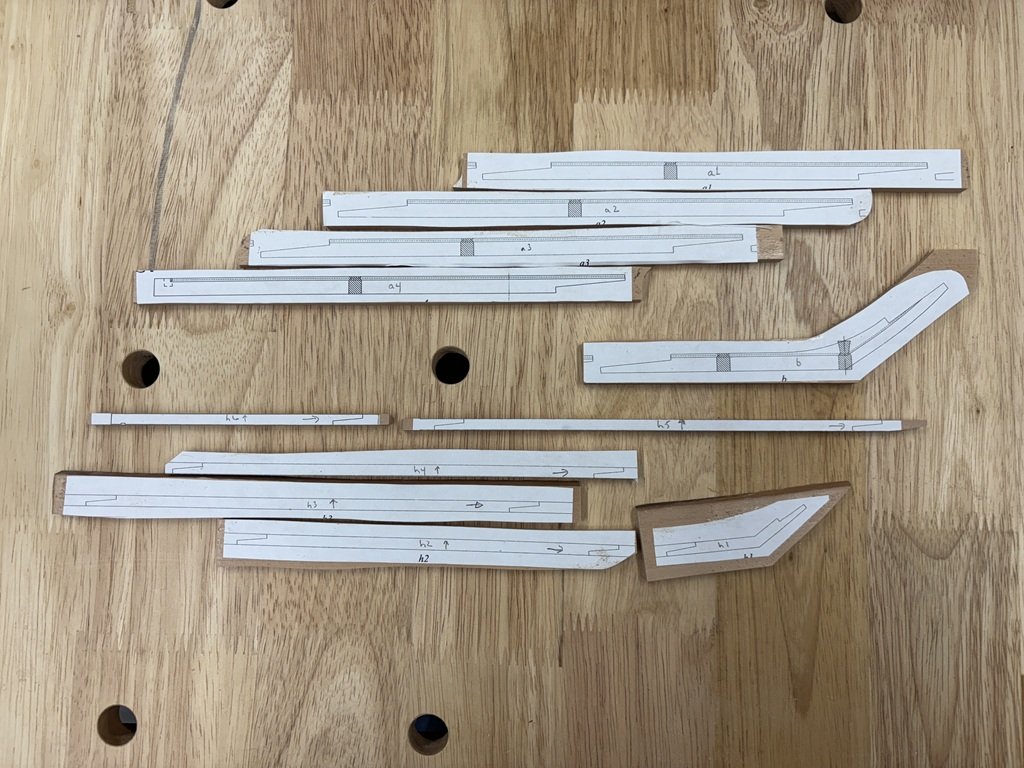

Milled the scarf joints and set the pieces all together:

Now they need to come back to my model room and get a little bit of final fitting!

- GrandpaPhil, druxey, KentM and 3 others

-

6

6

-

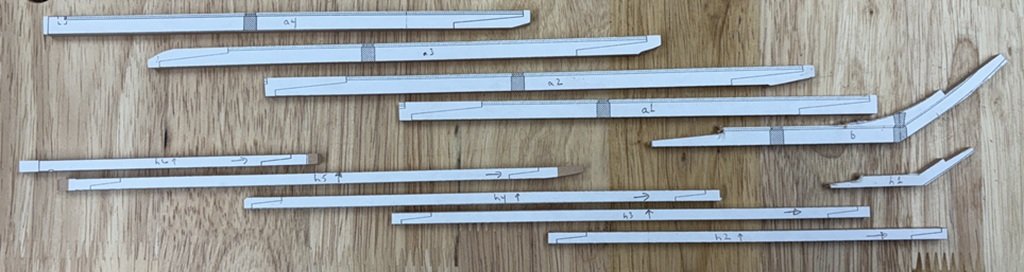

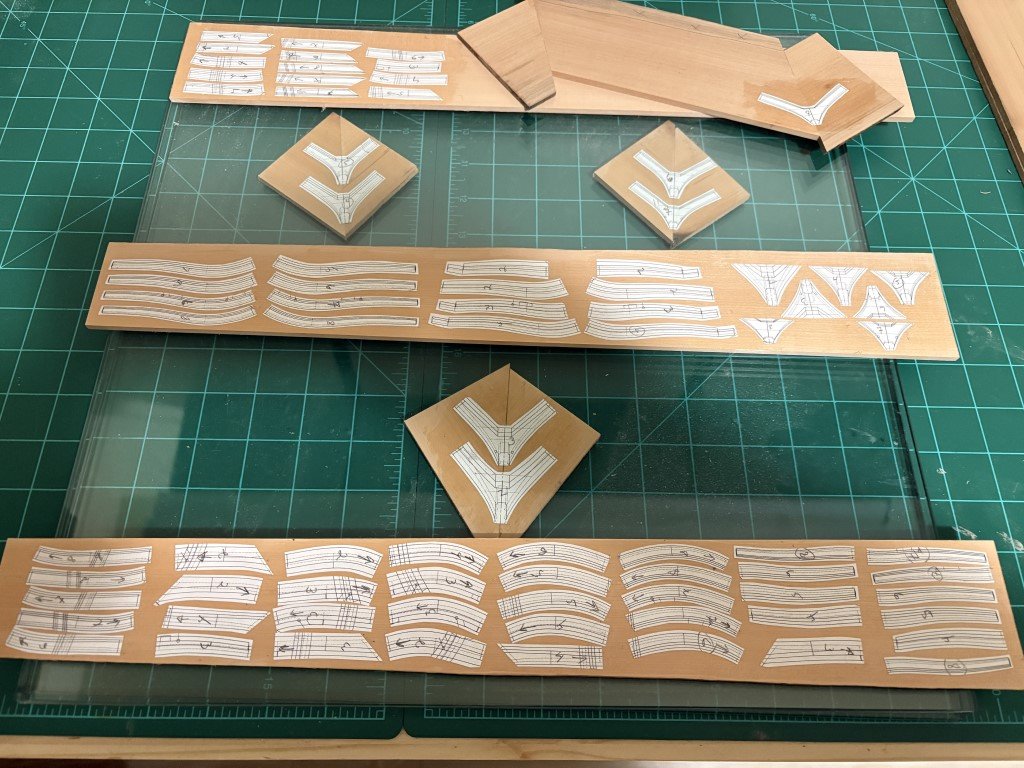

Finally all these parts have been milled to their proper dimensions (two pieces I didn't like my first attempt and remade them) - time to start in on the scarf joints!

Hopefully milling of the the joints go well so that this step doesn't need anymore redo's.

- BradNSW, GrandpaPhil, KentM and 2 others

-

5

5

-

On 6/4/2025 at 8:10 PM, BradNSW said:

I just discovered your excellent build log!

I'm excited because you are a few weeks ahead of my build of the bomb ketch Salamandre. This means I can see how you complete the steps I am about to start!!

Your frames look superb (I'm 75% through frame construction). I wait with anticipation to watch you mill and construct the keel.

Thanks for posting such detailed pictures and descriptions!

I'm glad you like what you are seeing here. I got a chance to see the work you have been doing as well - very impressive!

All the best,

Greg

-

After 'tuning-up' the mill a bit, I got a start on fabricating parts for the keel and false keel. I cut out paper templates that were quite wide in comparison to the parts in order to maximize my chances of keeping these long straight pieces nice and straight.

- JacquesCousteau, dvm27, No Idea and 7 others

-

10

10

-

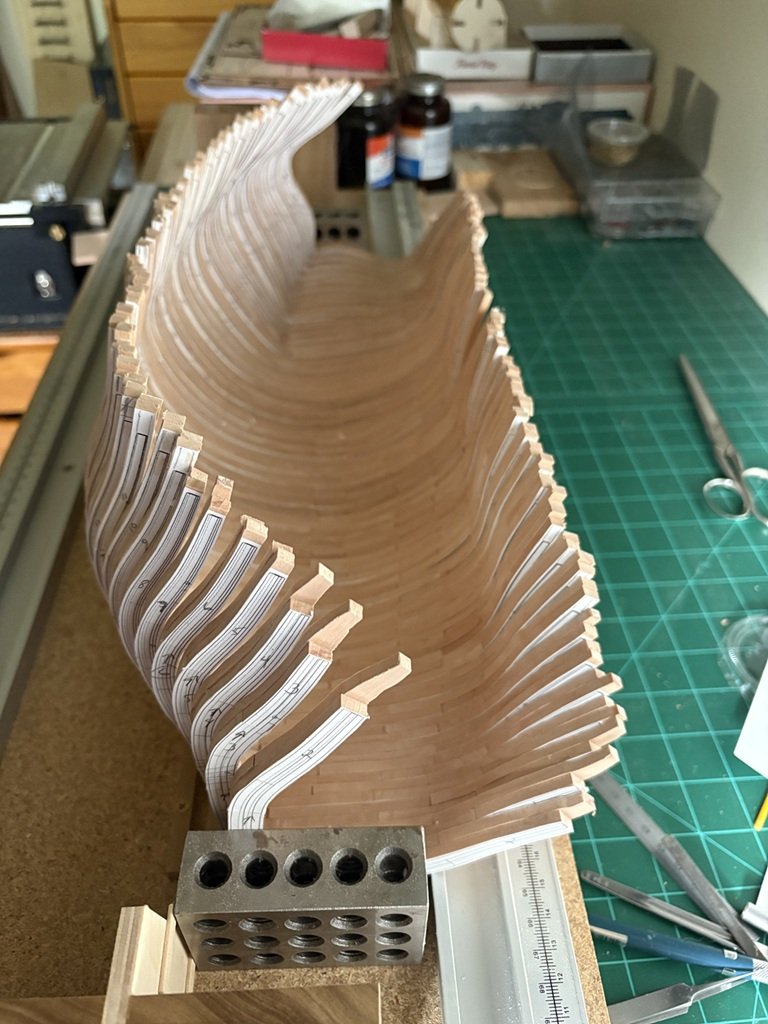

Here are all the full frames together - I think there is an unwritten rule that they need to be stacked up and photographed at this point:

-

1 hour ago, ChrisLBren said:

Nice work Greg ! Currently Im plowing thru my keel on La Renommee - its a challenge to get it right - lots of milling. Its much more interesting than the monotony of building frames. Look forward to seeing your progress

Thanks for dropping in, the complement, and for making your very nice build known to me!

Greg

-

-

A bit more progress - two more sheets of parts to cut out and I will have 180 pieces needed to assemble frames 43 thru 57.

The three sheets of wood in the foreground are 5.35mm thick - they are for the next phase: the keel structure.

- davyboy, GrandpaPhil, KARAVOKIRIS and 5 others

-

8

8

-

Most of the parts for frames 43- 50 are ready to cut out. Blanks for the two part floors are between glass plates drying flat. Photocopied patterns for all the parts for frames 51 - 57 are in the plastic tray ready to be rubber cemented to wood. I feel I'm getting rather proficient with the frame assembly line!

Looks like I also need to prepare a bit more 4mm thick material for the last 7 full frames - not going to make it with what I've already milled.

-

Frames 2 - 8 assembled. So frames 2 - 42 have been put together. I've made (a lot of) photocopies and am preently cutting out the patterns for the remaining full frame.

- KARAVOKIRIS, G. Delacroix, dvm27 and 7 others

-

10

10

-

Good deal of time at the scroll saw, followed by trimming ends on the Byrnes table saw, and milling of the slots for attaching to keel. So now I have a 'kit' for frames 2 - 8 to assemble!

I think 3 or 4 frames fit between my glass sheets for drying, so 2 - 3 days of work with these. Simultaneously, I can start building a kit for Type C frames 43 - 57. After that, it looks like I better get at the keel structure and make a building board / cradle for L' Invention. I am really looking forward to seeing the frames standing up in order giving a first impression of the hull shape!

- No Idea, Maxthebuilder, druxey and 8 others

-

11

11

-

First batch of Type C frame pieces are ready to go to the scroll saw.

These pieces will make up frames 2 to 8; the remaining C frames are 43 - 57. Once done, I believe that will be all of the full frames - 56 in total.

- Maxthebuilder, druxey, GrandpaPhil and 6 others

-

9

9

-

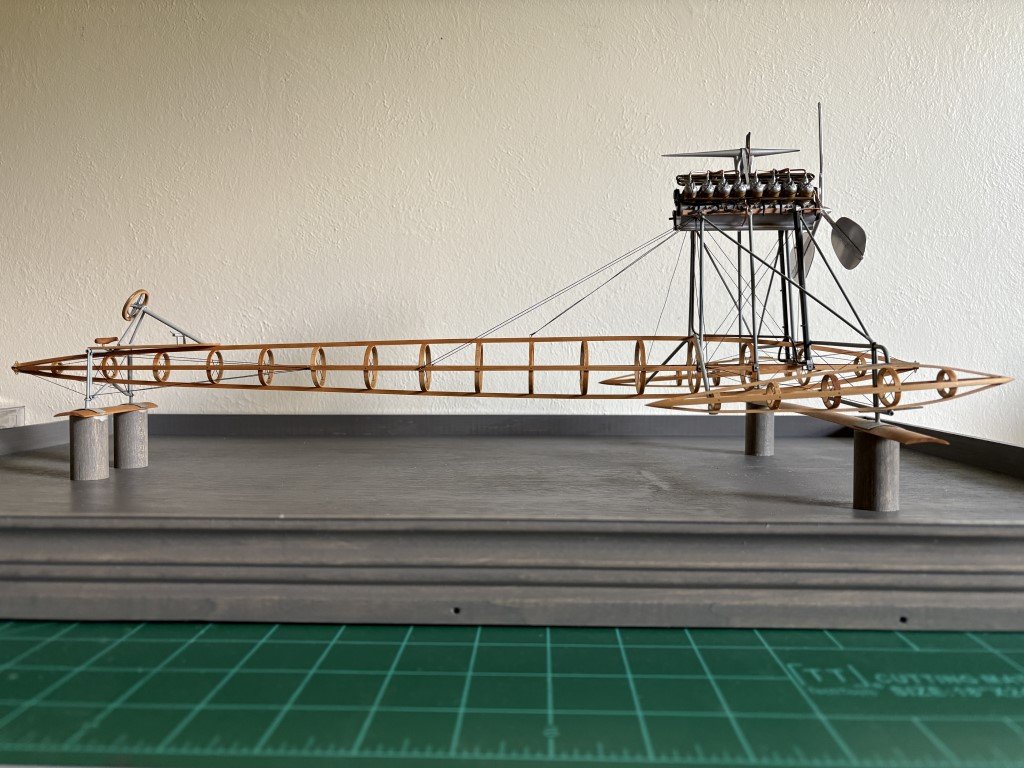

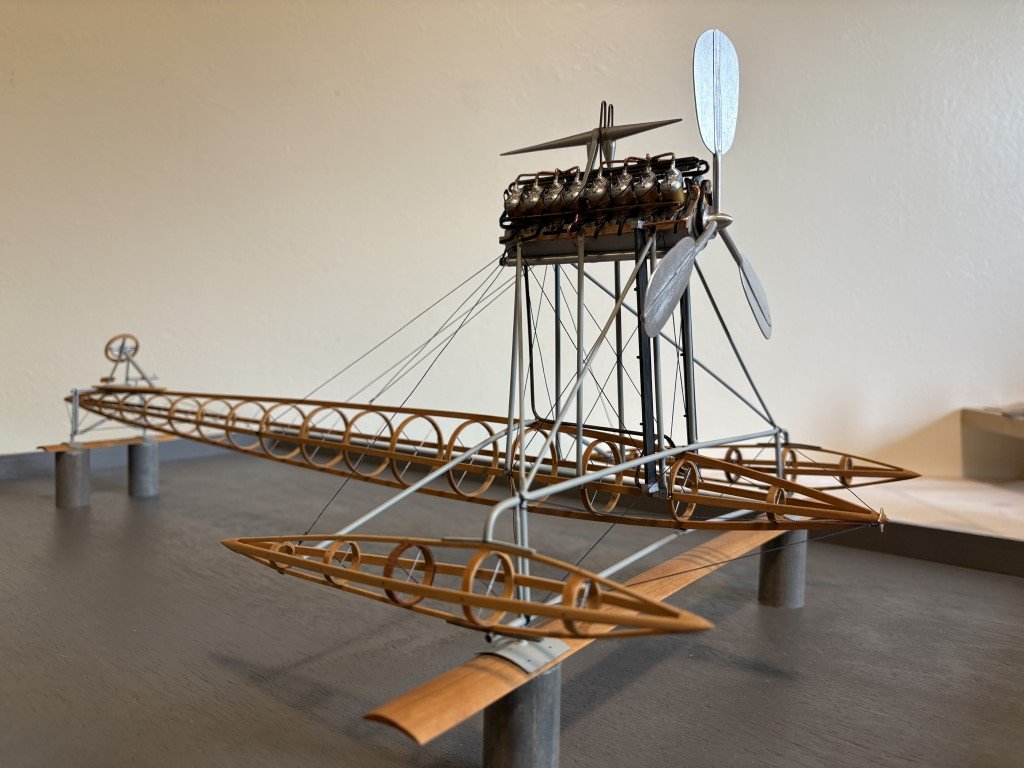

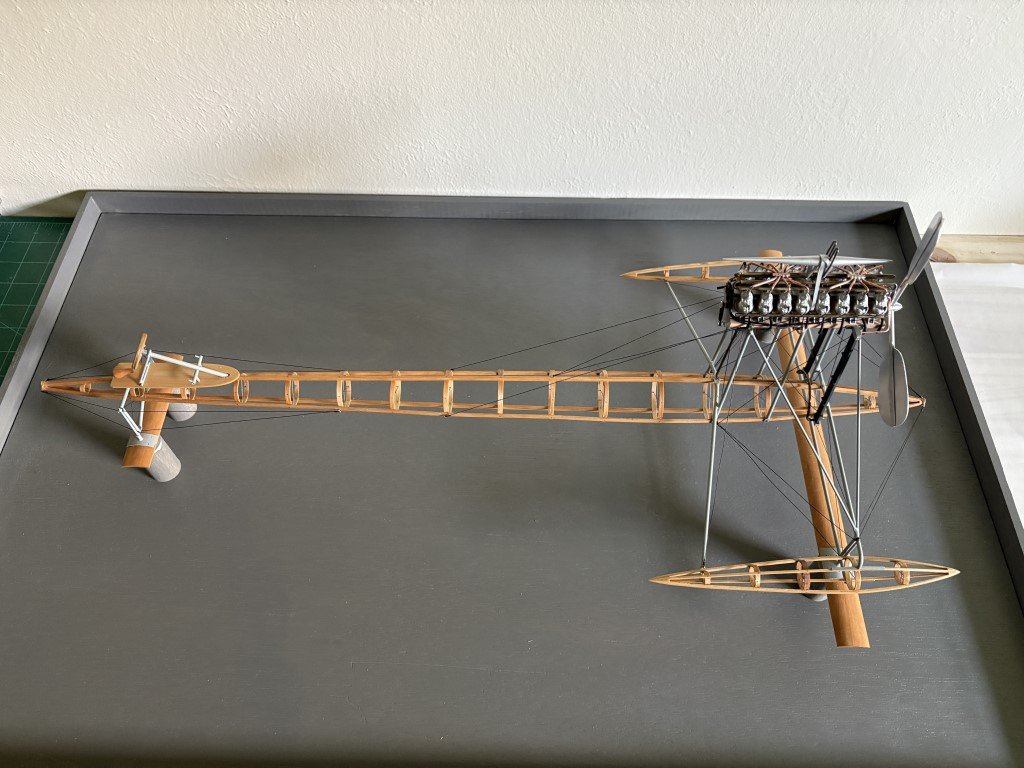

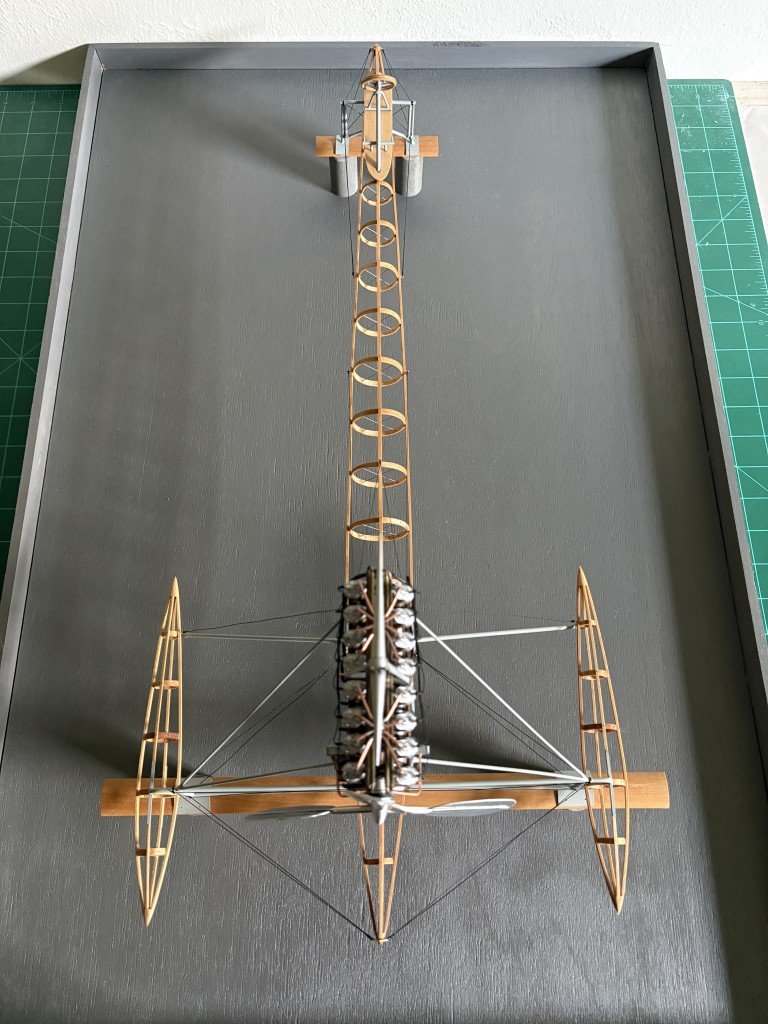

I know it has been quite a while - much longer than expected! The 'quick diversion' of building the Santos-Dumont 14bis turned into researching and building a model of the Santos-Dumont No 18 Hydroplane. But that is done and today I got out the Swiss Pear and started to mill enough wood to finish the remaining frames.

Looking forward to making frames and then a keel structure to place them on!

- Stavanger, No Idea, G. Delacroix and 5 others

-

8

8

-

First, I want to say thank you to everyone that spent time following this build and an especially big thanks for all that provided me with their views and information that I would not have otherwise been knowledgeable of.

Second, I have gotten back home from an enjoyable couple of days at the 48th Midwestern Model Ship and Boat Competition. This morning, I was quite satisfied to see the model had earned a gold award in the advanced category; but later in the day, things got even better when it was announced that the Santos-Dumont No 18 Hydroplane had been judged as Best of Show!

-

The model mounted on a display board now. I'm not sure I will add more to the model at this point; however, if 'new' information appears I am not opposed to modifying what has been done to this point.

Friday the Santos-Dumont No 18 hydroplane will get a ride to the 48th Annual Midwestern Model Ship and Boat Contest. Very interested in what kind of feedback I will receive - hope it is liked!

-

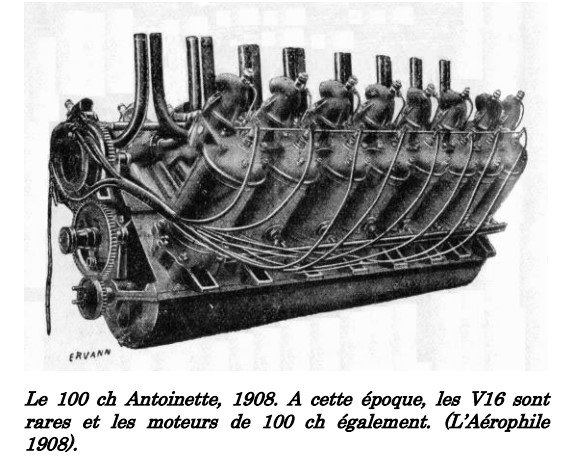

All ignition wires are in place and I believe I have done what I can wrt the engine.

All the woodwork for the case has been completed. Staining / finishing and then model installation followed by a couple of final details; however, for the most part I think I'm close to a finished (for now) situation.

- druxey, vossiewulf, iMustBeCrazy and 5 others

-

8

8

-

As I went to the other side, more boots went missing so I ordered more as a safety measure - it must of worked because a got 16 in place and have one left over before receiving the extras!

I've wired one side based on the following picture:

Here's the result:

Time to turn the boat around and complete the wiring.

L'Invention 1799 by Greg Davis - Scale 1:48

in - Build logs for subjects built 1751 - 1800

Posted

Here's the result of this week's work:

I felt that if I worked these joints anymore, the result would start to degrade; hence the decision to attach and move on to another piece.

Question: Is it wise to shape the cutwater at this point (and set it aside for a really long time)?