Greg Davis

-

Posts

339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Greg Davis

-

-

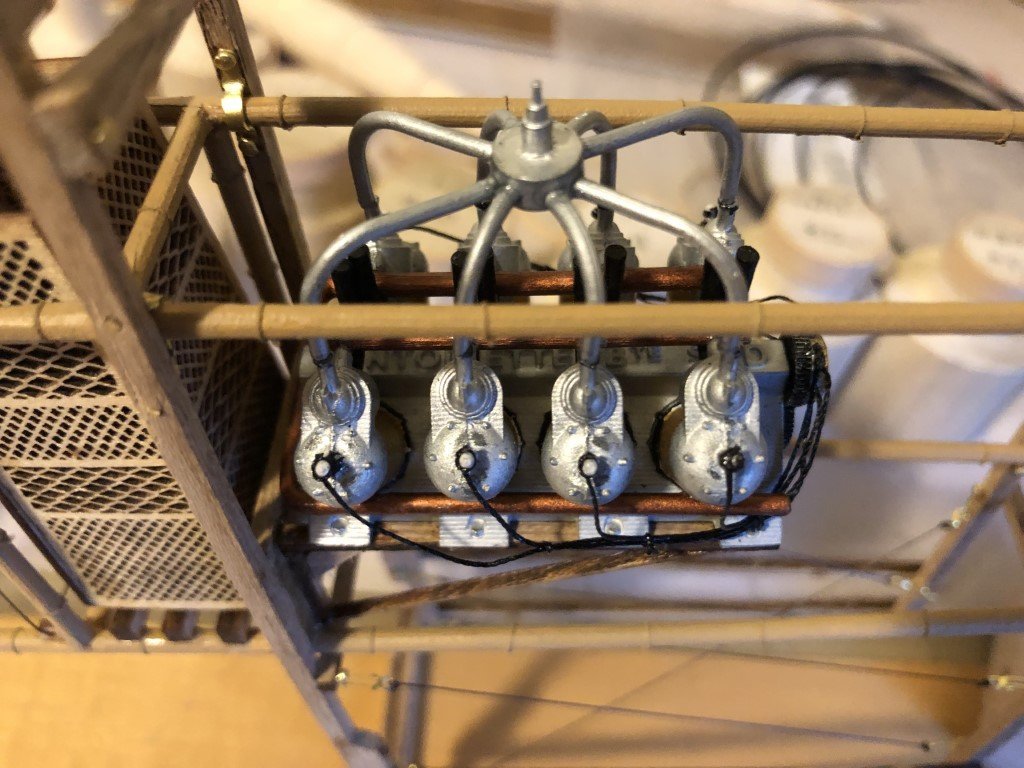

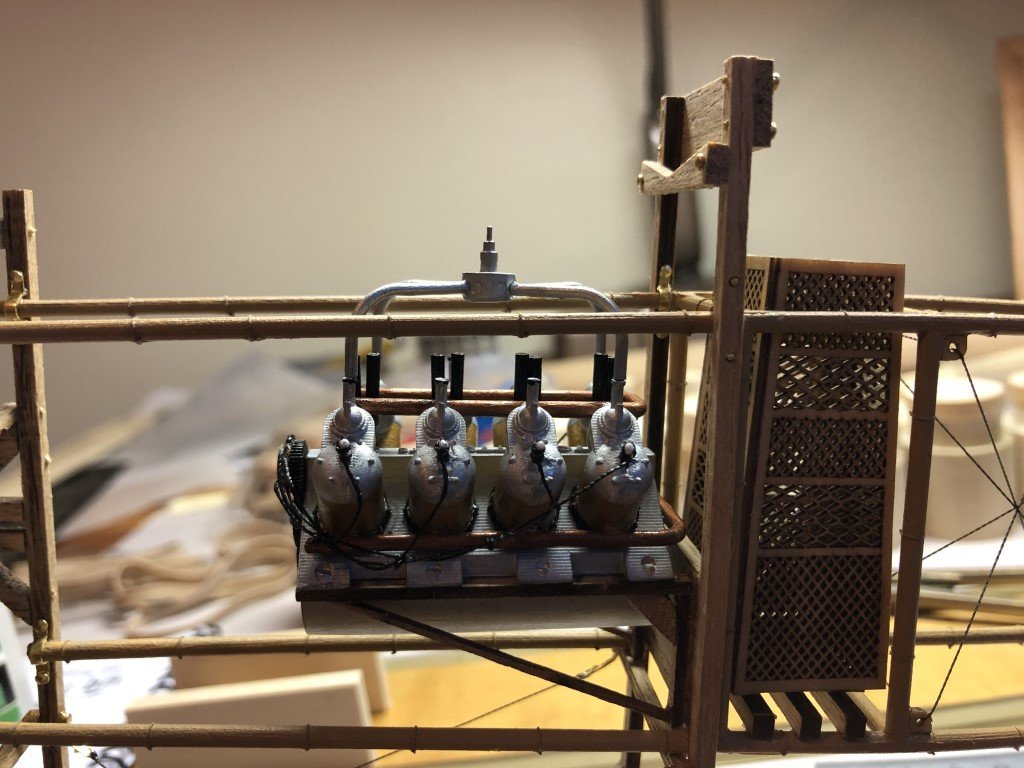

Just finished installing the fueling tubes to the middle four cylinders - pretty tedious work.

Now it needs some copper paint to be finished with the engine installation.

- mtaylor, Diver, GrandpaPhil and 8 others

-

11

11

-

I hope there are no limits on the number of build logs one can have open at any particular time!

I'm trying to make more bench space to get back to may 'main project' - a scratch-built model of L'Invention 1799 based on G. Delacroix's amazing ANCRE monograph. Unfortunately, I have a problem with starting models and not always finishing them directly. So lately it had been pointed out to me, by the resident space allocator, that I don't need more space, I just need to finish a few projects to reclaim the space I need. I concede that this is a truth. There are at least two models, well along that could / should be finished. Once done a good deal of space will open up again. This is a picture of the two as they sat a few days ago:

In the back is the Corel model of La Couronne that I purchased in 2011 and started in 2020. In the foreground is the Amati model of the 1753 xebec Sciabecco; purchased and started in 2015.

With the help of this log, I hope to make some steady progress and finish the Sciabecco in tandem with my Santos-Dumont 14bis airplane kit build and my Santos-Dumont No18 Hydroplane scratch build project. Big hopes, but I figure something a retired person can achieve.

Unfortunately, I don't have any photographs of the early stages of the Sciabecco build so I will try to provide some background in a written form. I believe the key aspects wood be that

- The plywood keel assembly was replaced with one made of cherry so that the ply's in the stem and stern would not be visible when finished

- The lower deck was extended / planked past the gratings on the upper deck

- The gratings were glued to the false deck prior to planking and then sanded flush with the deck. The instructions call for the gratings to be added on top of the deck planking.

- The large stern grating is made from cherry (this was my first try at making my own grating) and replaces a plastic grating that had spaces too large for the model.

Over the last couple of days I have been adding the quick stuff to the bulwarks and getting this material painted to match the interior paint.

The first layer of planking was pretty well done, so it shouldn't take much time to prep the model for the second layer. It may get up to 50 degrees (F) here tomorrow - that would be just fine to sit out back for a while and smooth out the hull.

At some point I'll open a log for La Couronne - it will be great to get that one done also. I really like the rigging of that time period.

-

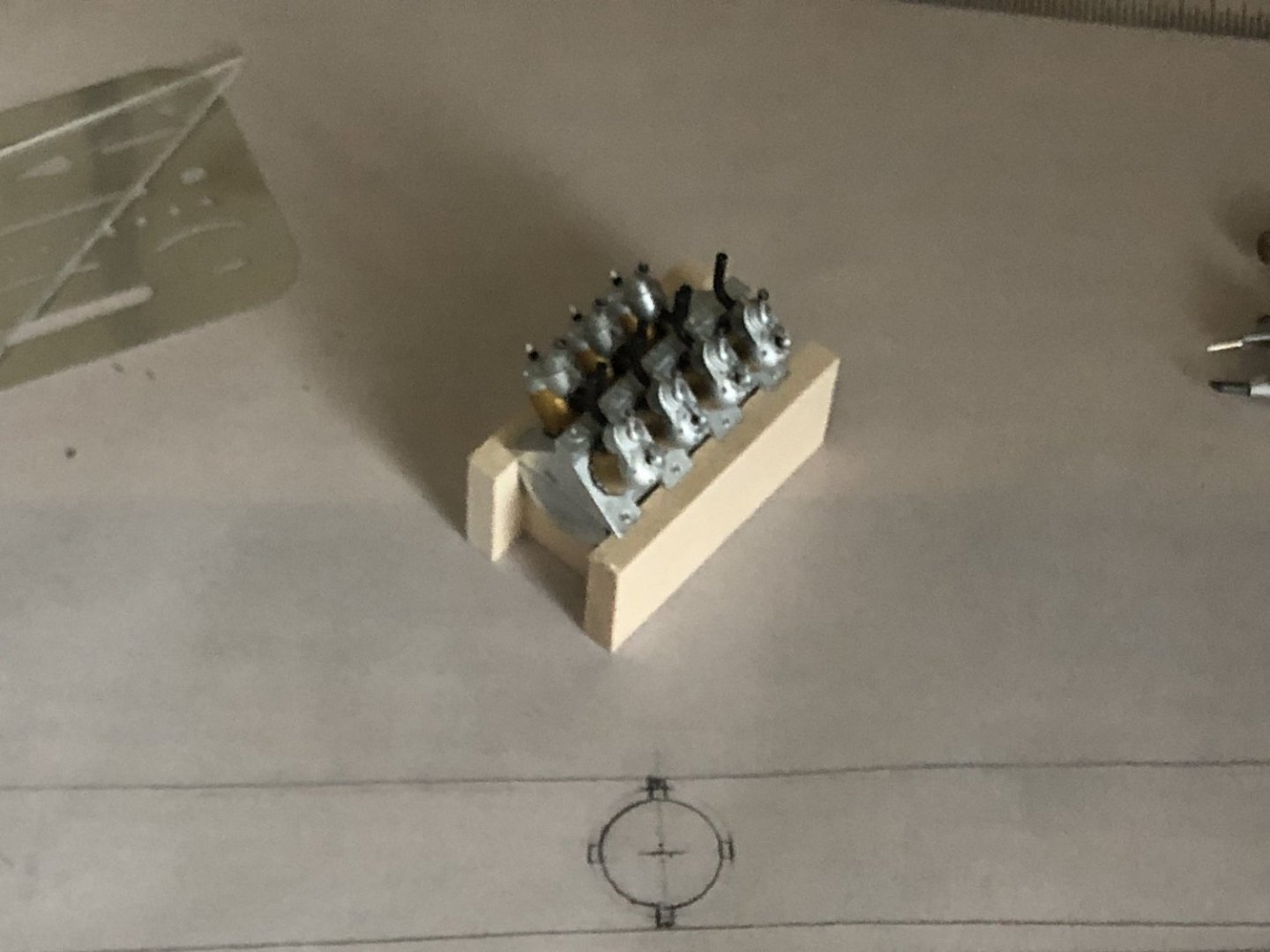

Yesterday I made a small jig to help assemble the fuel distributor. First I marked the pattern of where the parts would attach to the engine by placing a small sheet of vellum over the cylinders on my engine. I then taped the pattern to a piece of wood and drilled 1/16" holes where each tube would go. Figured out where each of the eight tubes were to fit (not quite the way the instructions seem to indicate). As with George's experience, the castings needed to be reduced a bit (close to 1mm) to fit the carburetor(?) correctly. Also it might be noted that for the pieces to come together correctly, the carburetor needs to be aligned with its casting molding line parallel to the engine block.

At first I was going to put all 8 fuel tubes in place using the jig, but then I got worried about pulling the assembly free so I stopped at the four longest ones and waited overnight before extracting the assembly.

I then fit this assembly to the top of the engine. Two of the fuel tubes needed to be shortened for the assembly to sit level on the four cylinders. I also needed to make a few small adjustments to get a better alignment of the tubes to the cylinders. Through a series of very small bends using two pairs of pliers I got everything to match as best possible. And just as George said - working on this assemble is a royal pain!

At this point I decided to permanently attach the engine to the engine mounts and then attach the partial fuel system to the engine.

I'll fit and install the remaining four tubes with this much in place.

- Old Collingwood, Canute, Freebird and 6 others

-

9

9

-

5 hours ago, George Ramey said:

Greg

I'm worried about trying to remove the distribution system since that process was a royal PIA. I'll study fitting as much as brass parts on the installed forward cockpit and installing as many aft cockpit brass on the loose aft cockpit where only the rigging is left. Could be a pipe dream though. My missing forward cockpit parts are due to arrive next Tuesday, a much better response than your carb. I guess they must have ordered a few since that was a common shortage.

George

George -

Completely understandable - I totally understand where you are coming from! Good luck!

I received the (no longer needed) cockpit parts in the mail today, so it will undoubtedly be the case that yours arrive soon.

Greg

- mtaylor, Canute and Old Collingwood

-

3

3

-

3 hours ago, George Ramey said:

Oh my. I on the finishing stages of the engine build and am installing the plug wires. I'm using black thread instead of the thick beige stuff in the kit because it seemed to be too thick. Fuel distribution is complete so I'm worried about the engine installation. Do you think it is feasible to install the engine after the front cockpit structure and install the aft cockpit structure afterwards? I'm thinking I could splay the fuselage bamboo to install the engine and install the aft cockpit next. Your engine and cockpit area look great. I hope mine can look as good,

Attached is an engine photo. Not real enthused about my fuel distribution installation. I made a jig to install the first two pipes based on measured dimensions on the two carbs farthest apart and installed that first. then each tube was individually fitted which required some tube trimming. The problem I discovered was that the carbs are not positively located on the block due to the very slight block counterbore so the carb cannot be really positively located. Also, there will be be slight clocking differences so that throws the pipe location slightly off.

I made a crude engine stand out of scrap balsa which has helped working on the engine

George

Looking really nice!

I would give your idea of putting the engine in place and then closing up / finishing the backend some thought. My initial thoughts considering the pro's and con's seem to be having to disassemble the fuel system vs having the backend of the plane heavy as you rig the undercarriage / complete the nacelle. I found that undercarriage rigging to be a little challenging because the brass turnbuckles are really fragile. I had to come at the work from a lot of angles and appreciated that the structure was light weight at the time. If you can get the fuel system off in one piece that may be the 'safest' way to go.

Looks like we made similar engine stands!

-

A good portion of the engine is complete. Here it is sitting on the engine mounts, but not permanently attached. The fuel distribution system that goes on top still needs to be built. It needs to be attached after the engine is in place for good because there is not enough room to maneuver the complete structure in place. In fact there is a good deal of tipping and turning just to get this much of the power plant in.

- hof00, king derelict, mtaylor and 5 others

-

8

8

-

Replacement cylinder arrived in the mail today!

Time to get out a file to clean it up and then paint it to match the other seven that are already in place.

- Canute, Jack12477, Old Collingwood and 7 others

-

10

10

-

30 minutes ago, iMustBeCrazy said:

Working in Huon Pine makes me cry with every cut, every piece you can buy these days is salvaged.

You could try using plane shavings, a thick shaving would be about 0.2mm with very little wastage.

I think that could very well be my backup plan - thanks!

- mtaylor, Canute, FlyingFish and 2 others

-

5

5

-

Today the thickness sander got quite the workout thinning stock down to 0.35mm. Good to have the material ready - hope that I made enough. It was just a bit sad to see how much waste there was between using the table saw to get about 1.5mm thick sheets and then to sand the sheets down to almost nothing. Going to try extra hard to get the hoops right on the first try!

-

Today I prepared a set of forms for the hoops. I made these starting with poplar dowels with 1.5" and 1.125" diameter that I picked up at the local Menards.

Now it is time to make a lot of paper-thin wood to wrap around the forms.

- Ryland Craze, yvesvidal, KeithAug and 4 others

-

7

7

-

that would match well with the illustration

- mtaylor, Old Collingwood, Egilman and 1 other

-

4

4

-

Today I got notified that Model Expo has sent the replacement engine cylinder!

I think I got their attention this weekend by asking for a store credit as I had nearly given up on ever seeing the replacement part.

-

George

Thanks for sending the pics - looks really nice!

Greg

- Old Collingwood, Canute, mtaylor and 1 other

-

4

4

-

On 2/5/2024 at 2:18 PM, George Ramey said:

Greg,

I'm still working on the canard and humming along and am at the axis stage where I'm doing the nose and have run into a mystery. On page 30 in the instructions I've just bonded Cn 1 to the bamboo. Is this really a butt joint glued with CA? Doesn't seem very strong but that's what I've done. Tried to drill a 1mm hole into Cn1 where the bamboo butts so I could pin the joint for strength but the material is too hard for my small drill bits to make much of an impact. Also, what is Cn2? It doesn't appear on the metal parts page and your build doesn't seem to show it either. You are right about the instructions being somewhat sketchy.

My bamboo treatment is the yellow ochre applied by hand using latex gloves where I dip my forefinger in the paint and rub it on after the nodes have been applied. This is followed by Diamond Glaze (by Judi-Kins available on Amazon) diluted with water to give it a slight sheen like bamboo.

I like your bamboo finish which makes it looks like an aged bamboo that really looks authentic.

George

George -

I did it as a butt joint as well - I added a fillet of CA between the three parts to reinforce the joint. Good question about the Cn2! I don't know, I just attached the nose to the Lt4 brass tubing (again with a butt joint). After the rigging lines were put in place I felt pretty good about the nose structure.

I'm not familiar with the Diamond Glaze product - I hope you like the result you have gotten!

Greg

- Canute, Old Collingwood, mtaylor and 1 other

-

4

4

-

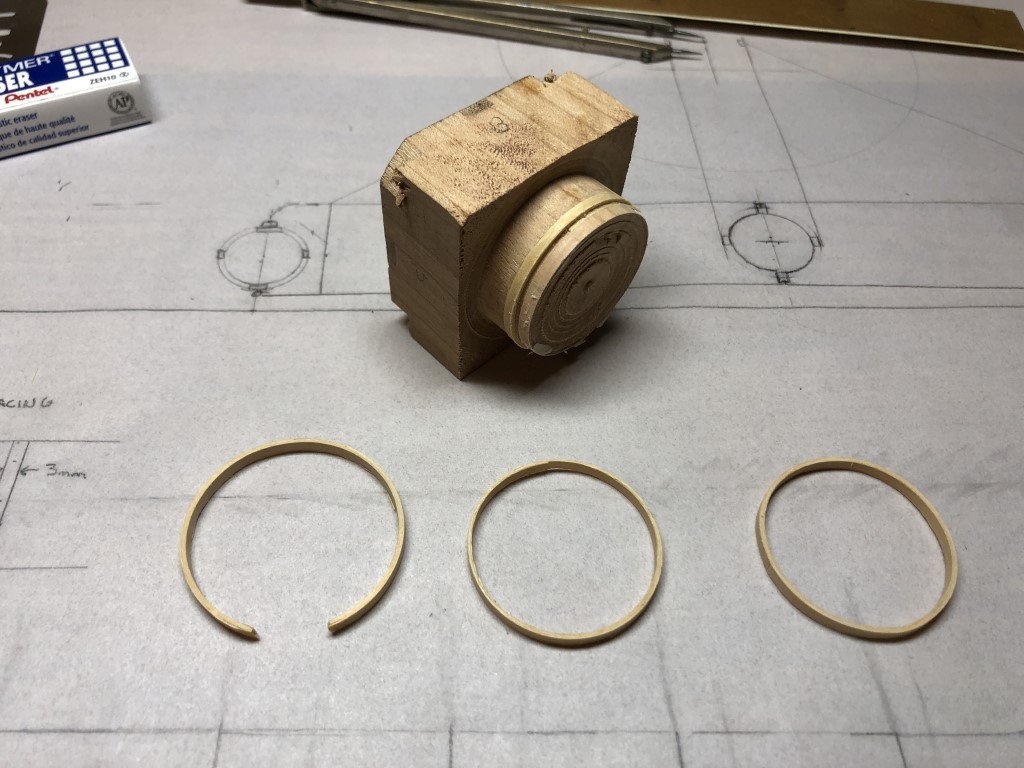

Two more tries and I think I have a method that will work. I was able to sand some C-boxwood down to 0.35mm with my Byrnes thickness sander. I then trimmed some strips off to use for the lamination. For the second try the wood was laid in a spiral - easiest to do, but I felt the inner bump was to extreme. I don't think I can reliably create a long bevel to get a smooth inner circle. So the third try is a three layer lamination were the seam from each layer is offset. I believe the result is worth the extra effort, especially considering there are less than 30 hoops to make - not much in comparison to framing a ship!

In this picture the hoop trials go from left to right: the broken two layer laminated 1st try, the inner bumped (at the top) 2nd try, and the three layer laminated 3rd try. The mold I used for the trials is above the hoops. I don't need to make a separate mold for each hoop as in some cases there are multiple hoops of the same diameter.

- Paul Le Wol, Canute, mtaylor and 6 others

-

9

9

-

The hoops are going to be 1mm thick and 3mm wide. I made a mold for what would be the largest diameter hoop 1.25in. Unfortunately, this first hoop experiment was not successful - it broke taking it off the mold. Other than that it looks nice!

I had made this hoop using two approximately 0.5mm thick pieces of boxwood, but after bringing the thickness of the hoop back to 1mm it was to thin near one of the layer joints and fell apart there. I was worried that this might happen. Now I am sure that there should be at least three layers in the laminations to guard against this type of separation. This will require me to make up some material that is around 0.35mm thick. This will be a new challenge for me. In the past I was successful making sheets of 0.5mm cherry, so I'm hoping I can go a bit thinner with the Castello boxwood.

- mtaylor, GrandpaPhil, davyboy and 4 others

-

7

7

-

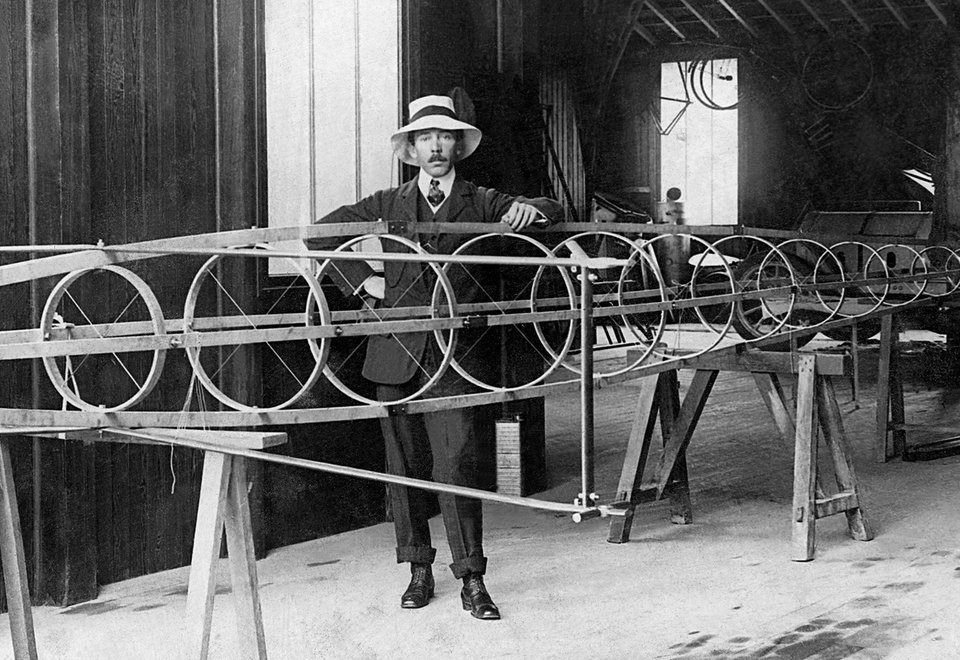

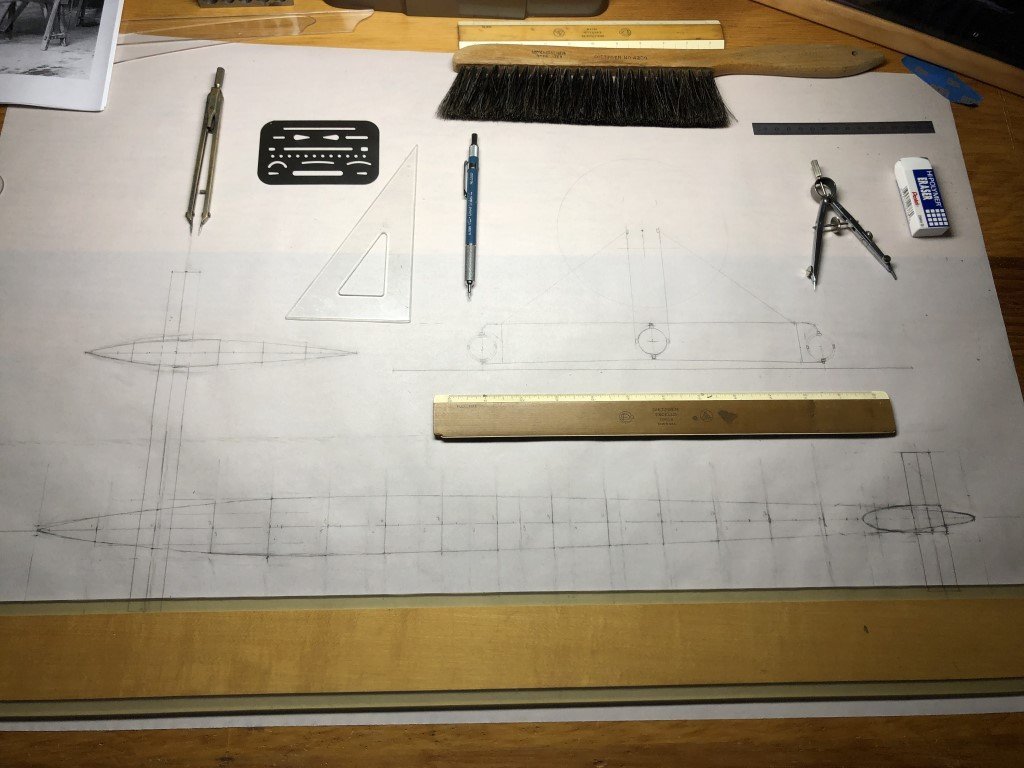

Toward the end on last year, I became acquainted with a boat that Alberto Santos-Dumont built in 1907. The boat - the No 18 hydroplane, was Santos-Dumont's only watercraft; the rest of his many notable creations were aeronautical in nature. He built and flew many balloons and dirigibles, but may be best known for the 14bis - credited to be the first plane to take off under its own power and flown publicly in Paris. For many years, in Europe and in Brazil (his home country) Santos-Dumont was credited as the first to fly an airplane. Santos-Dumont was independently wealthy and thus had the means to pursue his desire to build and fly heavier than air crafts. Most of his creations where constructed in France where his main residence was located for many years. He also liked a challenge, often associated with a bet. The No 18 hydroplane came about due to a bet that asked for the first boat to achieve 100km/hr along a course on the Seine (averaged over two directions).

No plans for the No18 are know to exist; in fact Santos-Dumont destroyed many plans and notes in 1918 after being accused of spying for the Germans. It is most likely that the plans and associated building notes for the No18 were destroyed at that time. Over in the 'Discussions for Ship Plans and Project Research' portion of MSW I have posted more about the boat and my quest for information. Fortunately, with positive encouragement from MSW members and a number of helpful contacts I have been able to collect enough reliable information that I am confident that a quality model of the No18 hydroplane can be created. This is what I aim to do.

Mostly based on published articles and historical photographs, I have been able to draft plans to build a model in the scale 1:16. The model will be just over 24" long, the main hydrofoil gives a width of about 15", and the height will be about 8". The original was 10m long, 6m wide and had a propeller with a 2.1m diameter. Power was provided by an Antoinette V16 engine.

The model will show interior detail of the boat's structure. I have chosen Costello boxwood for the wood structures within the model.

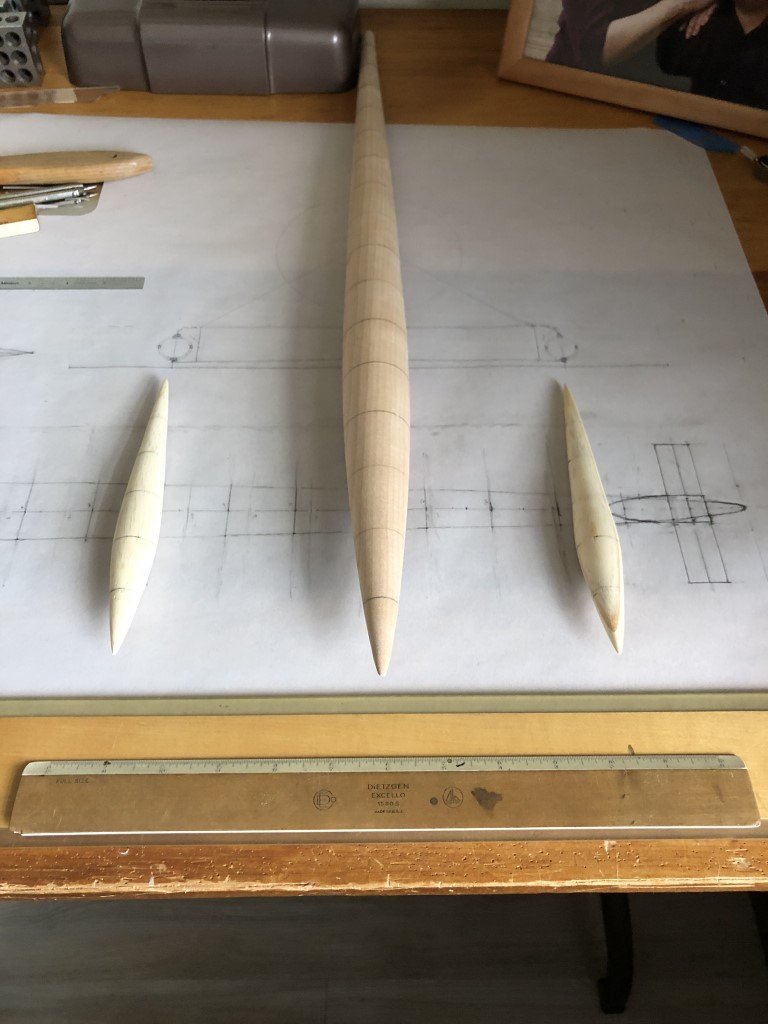

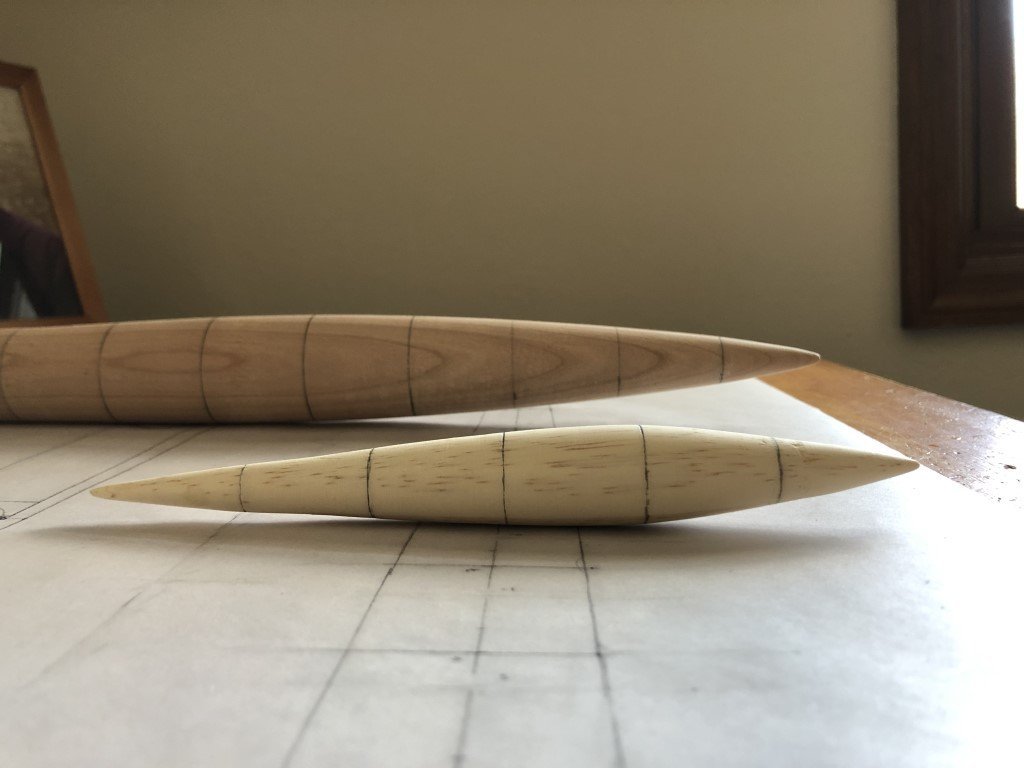

To get started / validate my drawings in some manner, I decided to create a mockup of the main pontoon and the two outrigger nacelles.

The shapes look good to me, so now I will be focusing on making the cross-sectional hoops that hold the shape of these three objects. There are 17 hoops to be make for the main pontoon and 5 for each nacelle. I plan on using a lamination method for the hoops - so making some thin strips of wood and a molds for the hoops will be the first tasks. While I'm working on the hoops, I will be thinking about how to make a jig that will keep them in place as the longitudinal stringers are attached to each.

-

3 hours ago, George Ramey said:

My wings are basically complete and the basic fuselage is done with the basket installed. Had to remove two of the bottom crosspieces supporting the basket because the basket would wedge itself in but not quite (by about .02") get inserted. Found out why I ran short of the 1.5mm bamboo rods; I made 6 each left and right ribs, not three. I interpreted "build 6 identical wing panels" to mean 6 each side since the plans showed a showed a left and right wing template. Substituting the Midwest products 1/16 dowels for the shortages.

Built the cockpit rear, but like you, I am short the fl01 sheet for the cockpit front. After a week and a half and a gentle reminder, I received confirmation that my request is "processing". I will work on the canard while waiting for the missing part.

Good luck with the carb. If my parts request drags on, I'll build my own like you.

George

George -

Sounds like you are making great progress - post a pic or two!

I had the same issue with the basket; it was a really tight fit, so I put the crosspieces in after the basket was inside the fuselage.

The instructions are challenging / ambiguous at times. I'm pretty sure that I will be replacing many of the ribs that are between the wing panels because I don't like how the bamboo didn't keep the airfoil shape. I'm going to use basswood for the replacements. I took some 1/16" square basswood and passed it thru a drawplate to round off the edges. After painting and putting the nodes on they should match the rest of the material.

Good luck with the canard.

My parts requests have been 'processing' for since the end of November for the cockpit parts and mid-December for the cylinder. I hope that you get your parts quickly and don't need to experience such a delay.

Greg

- Old Collingwood, Jack12477, mtaylor and 2 others

-

5

5

-

-

25 minutes ago, Keith Black said:

Greg, check out the below. These folks are out of New Zealand, their products are gorgeous and very pricey. The third link is their 1:72 boats which is as close to your 1:80 scale that they sell. Search through all the boats, you might find something that would work for you. i've not bought from them but I'm very tempted, let me know what you think.

https://micromaster.co.nz/collections/royal-navy-ships-boats

https://micromaster.co.nz/collections/royal-navy-ships-boats/1-72-scale

There's also Cornwall Model Boats in the UK. Very nice folks, I've ordered from them several times.

https://www.cornwallmodelboats.co.uk/acatalog/aeronaut-liferafts.html

Keith

Thank you for the links - the micromaster boats are amazing, but there is no way I'm spending > $250 on boats to give away! They must have a pretty nice 3-D printer. I've recently thought about getting a 3-D printer for making some parts myself. I haven't been able to determine what a minimal outlay for reasonable results would be. There are so many printers on the market.

I've already been thru the Cornwall site a few times and didn't see what I wanted. I've ordered from them previously and, like you, have had good experiences.

Thanks again,

Greg

-

Braces have been taken care of. No more rigging planned at this point.

I'll be setting the main assembly aside for a while; hopefully in a safe place! I'm looking to have the project complete for when it warms up and the snow / ice goes away - probably well into April. Likely on and off work till then.

Time to work out what the case will be made of. Currently thinking of using Cherry so the case can be darker in nature and complement the hull. Once the case of the base is done, I'll make the two cradle type mounts - these will be painted black and attached to the case base. Once the ship is mounted, I plan to add the anchors, either hanging or laying on the case base.

Additionally, I want the ship to have all 6 boats. The kit came with two cast boats that are the correct size for the upper deck. There should be two slightly shorter boats alongside the smoke stack and then two additional (even shorter) boats ahead of the foremast. I have searched the web countless times looking for boats that fit the need of this ship but have not been able to find anything that will work. Looks like I will need to fabricate them myself.

-

I set up the braces this evening. Tomorrow when I have natural light I will take another check that the lines are where they are suppose to be. Then I can complete the attachments to belaying pins and cleats.

-

Foresail and mainsail rigging done - I always like the three blocks that come together for this part.

Time to start with the braces.

- Keith Black and clearway

-

2

2

-

The last two spars are in with their respective rigging.

Now I can see just how much room this model will take up. Looks like it is turning into an acceptable display model!

The list of tasks to complete is shrinking:

- lower mast sail handling rigging

- braces

- anchors

- ship boats

- finishing touches

- display mounts

- display case

The launch date is coming into view!

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - Scale 1:16

in - Build logs for subjects built 1901 - Present Day

Posted

I have all of the hoop material for the main pontoon laid up on the formers. Three ply's for each. They were not too difficult to set up until the diameter dropped below 0.5" - the smallest one 0.30" was not fun.

I'll part off 3mm hoops on my lathe. Most I only need to cut one from but there are two pairs of hoops #4 & #7 and #5 & #6 that have the same diameter. For those I laid up wider strips of wood so that I can part two off each.

Still thinking about an assembly jig. This is what I am currently thinking of making:

There would be a 16 pieces of 1/8" hardboard cut to the above shape - one for each hoop. Each riser would be be made with the center of each hoop at the same height. The semi-circular cut out for each hoop's out diameter would top out 1.5mm lower than center to accommodate the 3mm side stringers. A notch would be cut at the bottom to accept the bottom (or top) stringer. To help keep the hoops stabilized thru the stringer installation, I will slice off a 3mm disk from each form to sit inside each hoop. This way I can press down / clamp the stringers without fear of breaking a hoop. A couple of tabs on each riser should keep the hoops / discs vertical.

An alternative would be to cut a more standard comb jig and keel support like those used for typical scratch built framed ships. For some (unknown) reason I'm more worried about getting all the necessary alignments to get the symmetrical / linear cigar shape.

Input certainly accepted!