-

Posts

1,655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

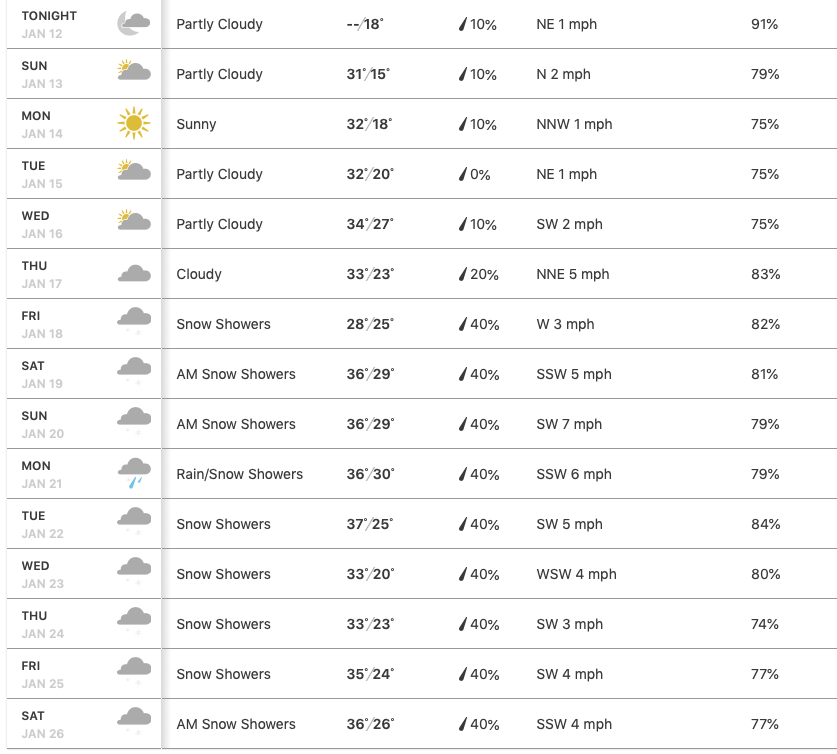

Thanks, Mark, I am happy to share what I learn, including mistakes and missteps. Druxey, your comment about parallel light rays makes sense, particularly with the fine detail I am hoping to make. I have a potential window for the sun on Monday, the only day for the next 15 days (see the weather forecast below; it reminds me of when I lived in London in the mid 70s to mid 80s). I will see if I can get everything ready by then. If not, or if the weather projection is wrong about Monday, then I am looking at a long delay... Or maybe I can send my metal blank to one of you who sees the sunshine more often! It will only take 15 seconds of exposure on each side.😊 No, that won't work because it needs to be developed very soon afterwards... Best wishes, Mark

-

Hi druxey, The exposure part has me nervous. The instructions from Micro Mark say it can be exposed either by sunlight (noon, on a bright, cloudless day for 15 seconds each side), or a 60 watt incandescent bulb for 10 minutes each side, with the bulb 4" from the surface. However, earlier in the paragraph it says a 100 watt bulb. My part of the country hasn't seen a bright, cloudless day in some time (yesterday was completely fogged in). So I was reconciled to using the light bulb. But 100 watt or 60 watt? I think I will call Micro Mark on Monday to get further guidance. What happens when we can't buy incandescent bulbs for love or money? Does an LED bulb give off UV the same as an equivalent incandescent bulb? The eighteenth century model builders didn't have to worry about things like this! Mark

-

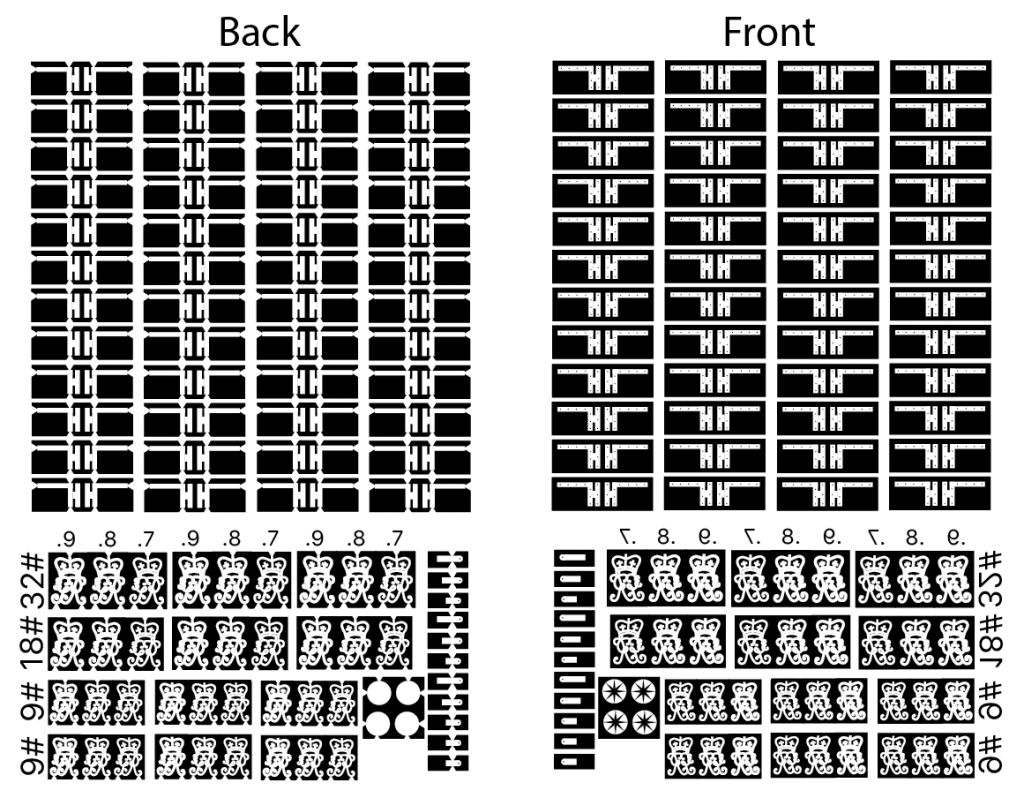

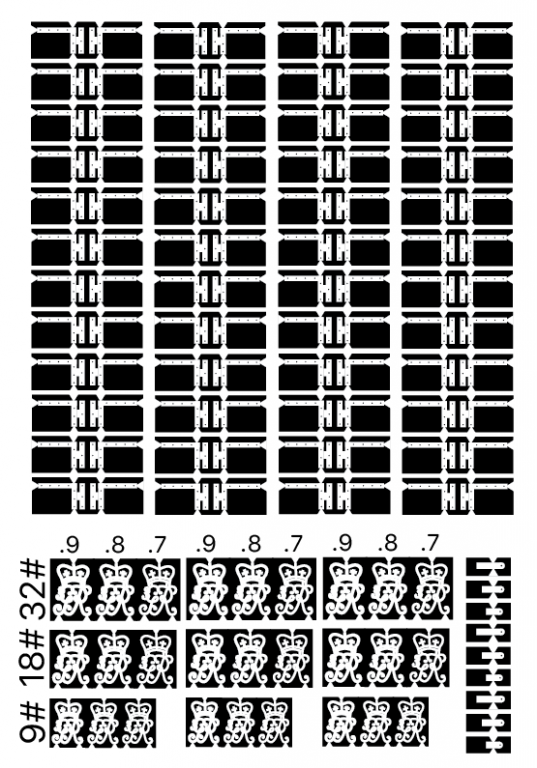

Alan, too right about remembering to come back! I put off rebuilding the cannon for several years (admittedly, retiring and moving slowed down my ship production time). At the risk of making too many boring postings, I thought others might find interesting my first explorations of photo etching as I proceed. I am using the Micro-Mark Pro-etch system from their catalog. The following is what I understand will happen: The system will chemically etch metal wherever it is not protected by a photoresist mask. The mask has to be applied to both sides of the metal, otherwise it would just eat through the metal from the back irrespective of what mask was placed on the front. Where the masks are the same on both sides, the metal will be etched all the way through. Where the masks are different, the etch will only go halfway through, leaving a depression on one side. To create the photoresist mask, artwork is created for both sides of the metal, each the mirror image of the other so the two sides line up precisely. This involves making the artwork for one side, then creating a mirror image for the other. The artwork will then be used as a mask to expose the photoresist on the metal to UV light, white areas protecting the photoresist material and therefore protecting the metal underneath from etching, and the black areas eating away the resist and therefore allowing the metal in these locations to be etched. Using Adobe Illustrator, I drew the artwork, then created a mirror image for the mask on the other side. Looking at the door hinges, I created black dots for bolt locations on the front side, and removed these on the back side so they will not etch all the way through. Similarly, I added white triangles on the back side to hold the pieces in place when the etch is completed; these thinner parts will be cut through just like cutting parts from sprues in plastic models. I need to rig a dark interior room with a yellow light so I can work with the photo resist and not expose it to UV light until everything is ready to go. The exposure to develop the resist is done with a 60 watt incandescent bulb (fortunately, I still have one in my old drafting light). Many unknowns still to go! Mark

-

Hi Doris, I have long admired those dolphin supports in contemporary models, and have vaguely thought about making something like that for my own project. I look forward to seeing how you make these! Mark

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Bob, thank you very much for your comments. As you can see, I am very often learning as I go along. And many of the great builders on this website have taught me more than I would ever would have discovered for myself. Learning from a lot of mistakes has also helped! Sometimes when the mistakes are really bad, I put those aside for a while and go onto something else to get my confidence back, and then revisit the mistake to try another approach. I tried making the cannon several years ago, and was quite discouraged by the outcome. A few years later, I have renewed energy to do it better. Mark

-

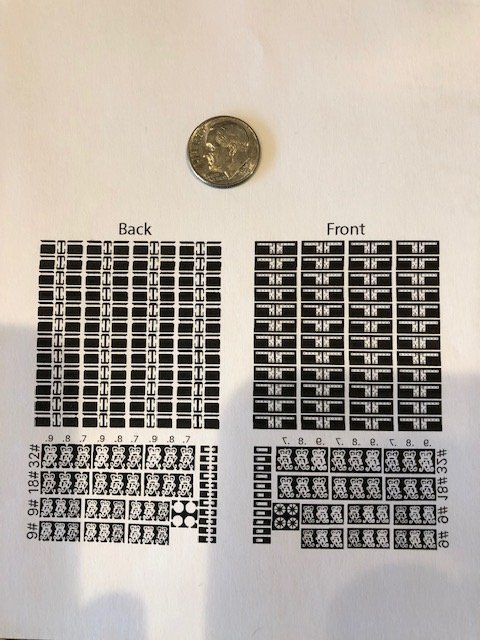

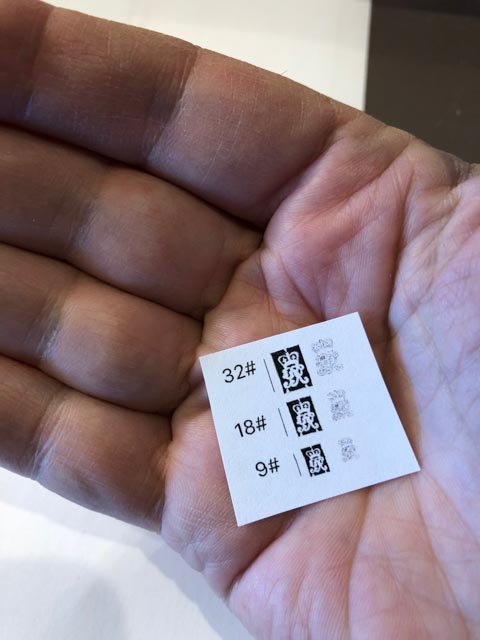

Hi Greg, Yes, that is my plan. I have made several of each in case I screw up attaching to the master cannons, and also to see what happens with different thicknesses of lines. I am not yet sure just how much the Micro Mark etching kit will resolve down to these fine lines. And as long as I have to use up a 3X3 sheet, I might as well fill it up! Mark

-

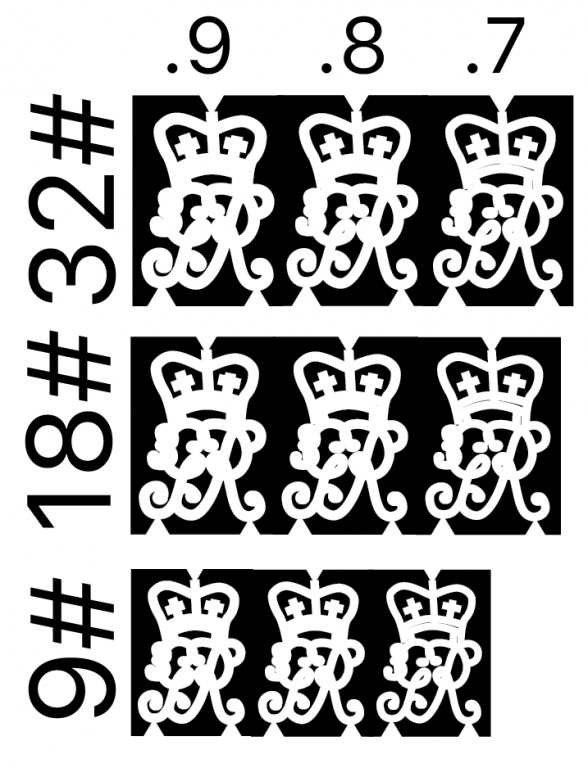

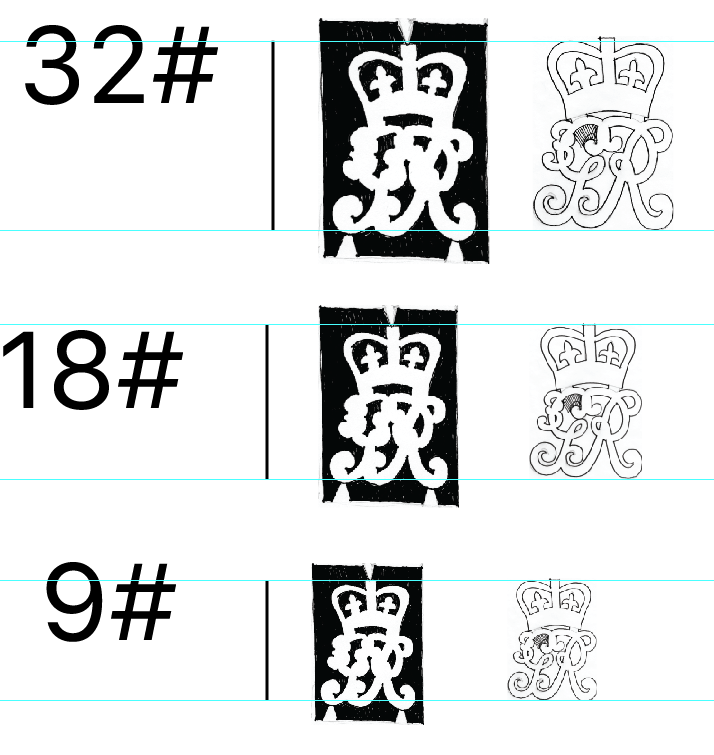

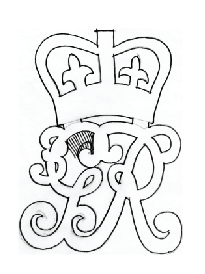

Hi everyone, I spent a little more time in Adobe Illustrator, trying to get cleaner drawings of the king's cyphers for photo etching. Once I got the hang of the pen tool, I was able to draw the forms rather than filling in the backgrounds (my previous attempt). And this allowed me to vary the thickness of the lines. Since I don't know how well the photo etch will deal with fine detail, I will try a couple with different thicknesses of line, hoping some good ones come out of the mix. Thinking about other metal objects that would be 5/16" thick real size to fill up the sheet, I have drawn up the door hinges for all of the partitions. I also drew some vent fields for the cannon. Can anyone think of other metal objects this thin, while I am at it? I thought about the compass. The etching process is supposed to etch from both sides, which means that there can be recessed parts not cut through all the way depending on how the art is arranged. Maybe cut the compass rose into one side? Not sure how I would color that to pick out the raised parts later. Maybe the pump rhodings? Mark

-

Thank you, Jorge, druxey and Doris for your kind comments. And Doris, again I am amazed what you can do with clay, now that I have tried and failed to create details like you have done for your projects. Drawing the cyphers for photo-etching is proving to be challenging, given their size. Working in Adobe Illustrator, I discovered that they need to be fattened up, or the fine lines just disappear when shrunk down to scale. I don't know yet how fine the Micro Mark photo-etch paper will resolve either, so a little experimentation in in order now. Mark

-

Hi everyone, Cannon masters finally done. Here are the four guns of the Bellona: 32# on the gundeck, 18# on the upper deck, 9# long on the forecastle, and 9# short on the quarterdeck. Now on to the king's cypher. I have even additional appreciation for Doris's amazing work with clay. I was not able to get anywhere close to her skill trying to make the cyphers that way. So I will try my Micro Mark photo etching kit and see how well I can do with that. The chemicals were way out of date, so waiting for renewed stock in the mail. Mark

-

Michael, Your closeup photos look as much like a full scale vessel as any I have ever seen. Spectacular craftsmanship! Mark

- 2,215 replies

-

Hi Michael, Just catching up. Everything is looking wonderful, and I am particularly impressed with your machining and metal working. It all seems impossibly difficult until you demonstrate it, which makes it even more magical! Mark

- 2,215 replies

-

Those shipworkers can sometimes get a little frisky! Mark

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Alan, I look forward to seeing what he has done, if possible. Druxey and Michael, thanks for the additional advice on the pewter. The pewter I bought from a jewelry supply in Denver, and which led to disappointing casting the first time around, is labeled R98. Online I discover that it is 98% tin, 1.5% bismuth, and .5% copper. It melts at 466 degrees and pours at 590 degrees. The better looking pewter from Micro Mark is Type 280, which is only listed as a mix of tin and bismuth without proportions. It melts at 280 degrees. So the pewter that led to disappointing results for my model had copper and a much higher melting point. I wonder what advantages it brings to jewelry making? Thanks, Greg and MIchael, for the comments on my window view. We moved to the countryside to get closer to nature and a slower pace of life; but I am still getting used to the idea of bears and mountain lions that sometimes roam around near us. I am beginning to think that I like nature best when looking at it out of a shop window! Mark

-

Hi Alan, Hmm, sculpting in liquid metal. I'll give that some thought. Does he have any pictures of work so far? My new pewter just arrived from Micro Mark. It looks significantly more refined that the stuff I got at a jeweler's supply place in Denver many years ago. Here is a photo of the pewter I got from Micro Mark on the right, and the old stuff on the left. The old stuff looks discolored and much rougher. Now it could have been the moulds they were cast into, but the Micro Mark material looks much cleaner and close-grained. I am hopeful this might have been my problem with casting in the past. We will see! Mark

-

Thanks, Greg and Mark, for your kind comments, and thanks to everyone for likes. Greg, I don't think I am a threat to commercial cannon manufacturers, at my rate of speed... I started thinking about making the King's cyphers, and assumed I would make these with Micro Mark's photo etch kit. I may still. But I realized that I only need to make 4 cyphers for the four master patterns, with perhaps some duplicates for mistakes. So then I thought that I might as well make other metal parts at the same time, to avoid wasting a sheet of photo etch on just four small parts. But then I noticed that the metal in the kit is only .005" thick, which at 3/16" scale is 5/16" at full size. I looked through David Antscherl's and Greg's Fully Framed Models series for an inventory of metal parts needed, and the only other parts I could find that thin are door hinges in the various cabin partitions. So photo-etch looks pretty inefficient in the big scheme of things for my project. I will try a few other ideas, like Doris's use of modeling clay, or David Antscherl's suggestion of piping glue through a hypodermic needle. I welcome any other ideas! 2 of these will be 3/16" long and the other 2 will be 5/32" long. Best wishes, Mark

-

Mark, I can only admire from afar your skill in understanding and tweaking hardware. When my son was 21 he successfully built his own computer, with no previous experience or training; I still secretly believe aliens landed to help him, but what do I know?😊 Great to see what you are doing with it. Best wishes, Mark

-

Thank you, Doris, those are beautiful cannon. You have inspired me to try the modeling clay before getting into photo etch. Mark

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Doris, Astonishing small detail. Beautiful! I apologize if I missed this, but have you ever made the King's cypher or emblem for a cannon? I was about to start on photo-etching these for my project, but your tiny guns made me think that there might be another way. Best wishes, Mark

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

hi Mark, I must have missed it somewhere, I apologize; what laser cutter are you using? Mark

-

Hi everyone, I finally managed to turn a good 32# master. The button still needs a little cleaning up, but here it is. Mark, you are right. Even with the drawings and turning recipes worked out, It took me all day to turn this one cannon. I am sure I would get a little faster for each if I tried to turn them all, but 74 would be a long time turning. I have nothing but the greatest respect for those of you who turned individual guns. I was relieved to see that the ship's cat was guarding the ship while I was at the gun foundry... Best wishes, Mark

-

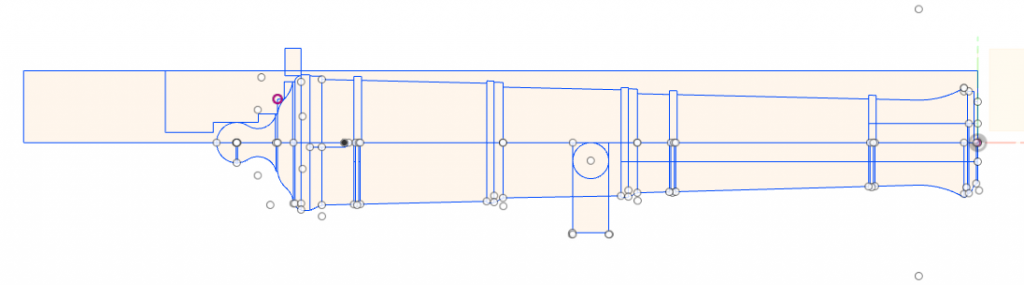

Hi Mark, I will talk to Sherline, see what they have to say. I may not be able to afford it, but at least I will know what is possible or not. Paul, well spotted. My original drawing concerned only the lathe turning, so I located the trunnion on the center line of where the bore would be located so I could dimension the bore itself. But I have now decided initially to locate the trunnion from the finished muzzle face in the mill, when I first drill the hole. To help with this, I have relocated the trunnion to its proper location in the drawing below. The cannon I showed all had the trunnion drilled in correct position. One of the pictures I posted shows first drilling with a center drill, the only way I know to drill a hole off center on a cylinder that will prevent the drill from creeping. So far, it has worked very well. I will be happy to post my experiments with casting. Recording the process will help keep me organized! Happy new year! Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.