-

Posts

9,598 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Lad

-

Ollie, In the mid to late 19th century, ratlines were 12 to 18 inches apart. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Setting flags - which way does the wind blow?

Jim Lad replied to rodgerdodger's topic in Masting, rigging and sails

Another minor point regarding ships at anchor. They may not be riding to the wind, but to the tide, or a combination of both, depending on the relative strengths of wind and tide, so flags on an anchored ship could still be blowing in any direction. John -

HMS Ocean 1898 by tozbekler

Jim Lad replied to tozbekler's topic in - Build logs for subjects built 1851 - 1900

That looks like it will be an interesting build. John -

Thanks Pete and Bob! Bob - If I leave the camera at the museum I then have two problems - 1) How do I transfer the photos to my computer, and 2) I've been using my wife's camera as mine is a bit big and bulky to take in! John

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Ollie, I think she'll look better with no sheer-pole! Good to see that you've rigged the top rope. These little ships were ridiculously "over hatted" as the 19th century sailing ship men said - over rigged for us mere mortals - they needed to be able to get the top hamper off pretty quickly if the wind started to blow up too much. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

You're making a great job of her, Popeye! John

- 165 replies

-

- united states

- revell

-

(and 1 more)

Tagged with:

-

Thanks very much for the encouragement, folks! John

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

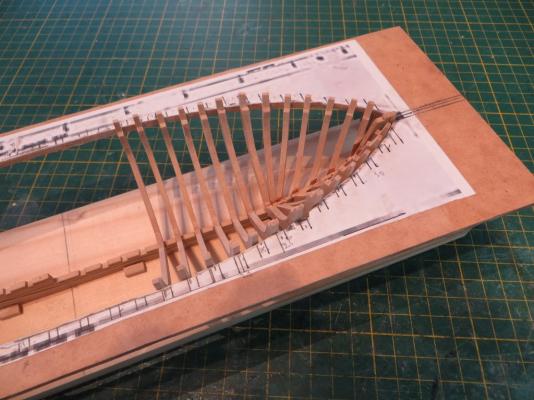

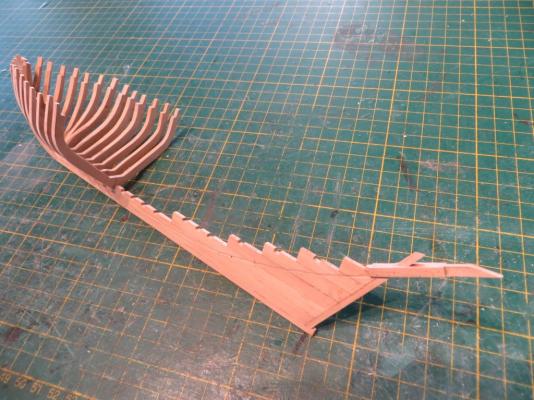

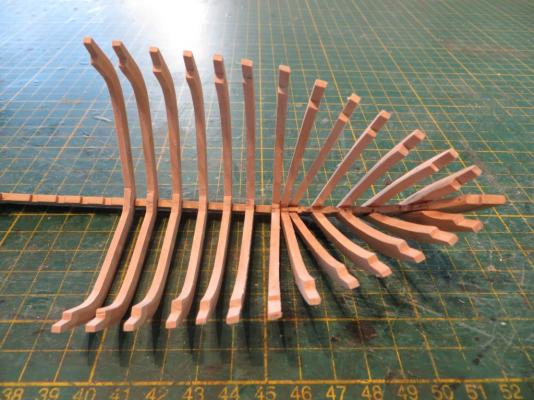

Well, it's been a lonnnnnnnnnnng time since I've posted an update. This is partly due to the fact that not a lot of progress has been made, partly because I've missed a couple of days at the museum and also partly due to the fact that I keep forgetting to take my camera with me when I go in to the museum! A few more frames have been raised and hopefully the framing will go a little more quickly from now on. I'm finally at the stage where the remainder of the frames are rough cut, so while I'm waiting for glue to dry on one frame I can be finishing the next one ready for fitting. A couple of frames are going to need adjustment at the fairing stage as, for some unknown reason they're slightly too long - but too long is easy to cut down at the final fairing stage. John

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

James Craig by blueyAU - FINISHED

Jim Lad replied to blueyAU's topic in - Build logs for subjects built 1851 - 1900

Hope you're going to get on with it, Bluey. She's a nice looking ship, and that looks a very nice model of her. John -

Ollie, The 'lanyard strip' is called a sheer-pole. It's main purpose was to stop the deadeyes from twisting or, as Tom has said, in a ship with the shrouds set up with bottle screws, it was used to lock the screws. When fitted, it should sit right down on the tops of the deadeyes but is lashed in the manner shown in the kit plan photo. With regard to the Mermaid, the contemporary paintings don't show a sheer-pole, and I'd be surprised to see them on a ship of this size and period. If you really want to fit them, yours looks a little over scale. By the way, when you come to the ratlines, note that the contemporary painting show them as being on the forward three shrouds only. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Nice to see the rigging started, Ollie - and it's looking really sharp! John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Great to see the final result turned out so well, Popeye - and that you came up with an answer to the problem. John

- 165 replies

-

- united states

- revell

-

(and 1 more)

Tagged with:

-

Harriet McGregor by Boccherini

Jim Lad replied to Boccherini's topic in - Build logs for subjects built 1851 - 1900

Nice bit of blacksmithing on the bollards, Grant! John -

Ollie, A half hitch on the cleat to secure the fall and then the end coiled and the coil dropped over the cleat. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

What? Not made of brass? Very nice, Michael! John

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.