-

Posts

9,598 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Lad

-

Well, Danny, if you're not making a silk purse, you're at least making a fine linen one! John

-

Aha! Back in the shipyard - great news, Augie! John

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

The country, type of ship and time period would help, mate! John

-

Nicely done, Ollie. A good finishing detail might be a painter spliced to that ringbolt forward and coiled down in the bottom of the boat. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Yep, lash 'em down, Ollie. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

HMS Druid by Krug - FINISHED - 1:48 - Hahn

Jim Lad replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Very nice indeed, Mark! John -

I agree with Tom - six oars would be better - and stow them with the blades facing forward as with your test oar in the photo. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

That boat's turned out well, Ollie. It was quite common for cutters to carry their boats on deck (less chance of damage that way) and as King clearly shows his boat on deck, then why not stow it here? You have a clear primary source for it being stowed on deck! John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

By the look of all that fiddling, it might have been just as quick to plank the entire gun deck in the first place! John

- 165 replies

-

- united states

- revell

-

(and 1 more)

Tagged with:

-

Perseverance pays off! Nicely done, Bob! John

- 420 replies

-

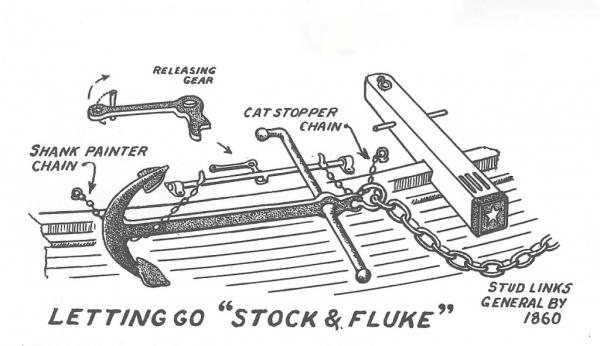

YES!! Progress!! Kats, Question 1: If the boats were stowed under the davits, it was common to simply drop the coil of the fall into the boat. If the boats were stowed elsewhere, then it was usual to turn the davits fore and aft and cross the falls, hooking the lower blocks onto the opposite davit. In this case, the falls would be coiled up on the cleat where they were secured. Question 2: If the anchors were stowed for sea, the cables would be unshackled and brought inboard and the anchors stowed on the forecastle. If ready for letting go, then they were either hung off the cathead with a slip or hung off 'stock and fluke' as in the drawing below. I would think a ship such as the Cutty Sark would let go 'stock and fluke'. John

- 237 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Every little bit you manage is a delight to see, Toni! John

- 1,449 replies

-

Plated Iron Hull

Jim Lad replied to Pete Jaquith's topic in Building, Framing, Planking and plating a ships hull and deck

Pete, It should work well providing it's thin enough for scale. Remember that you tug's hull plates would probably only have been 1/4 or 3/8 inch thick. John

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.