-

Posts

1,016 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by flyer

-

Hi Hamilton Those are indeed nice looking sails. My viewing distance might be a bit big but Bob looks at them from a point a few thousand miles closer and he agrees with me... Cheers Peter

-

The deck Back in the wharf I started deck laying. Although the quality of the wood provided by the kit was doubtful I decided to use it. I hope the imperfections in the kit will give a certain rustic charm (within small tolerances, of course). First A 5mm waterway plank was laid along the edges. The outer part of it will be covered by the spirketing. The heads of the deck planks are cut into the waterway 'on the go'. Caulking is imitated by painting the planks edges with a black marker. planking has begun first half of the fore deck is covered

-

OK Martin, I went back into the alps for a week of voluntary work. A few short breaks to enjoy the scenery were possible. (I know this is a bit off topic but just too beautiful not to share with those poor fellows which have to live on a seashore. ) the Matterhorn is just visible in the background

-

Hi Hamilton You could consider to glue the hems and pencil the stitches as I did on my Pickle. It's certainly easier than learning to be a seamstress and gives a good result. Somewhere in MSW you should find more information about glued sails. It would be a pity if your America should have to remain in harbour forever for want of sails. Cheers Peter

-

Hi Nils Wonderful benches and chairs. That you are reluctant to smear paint over those little gems, I understand very well. However those brass parts could stand out a bit of the rest which is all in original colour. Don't you think that you could just brush them lightly with a nearly dry paintbrush with some matte wood colour (after thoroughly cleaning them, of course)? Cheers peter

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Martin Very nice work. I like that chimney. It meets the standard of your galley stove and is even visible! But I'm afraid you have a tendency to leave the safe path of kit building and come under the influence of the dark arts of scratch building. This could lead to an even more creative language with a tendency to startle yourself again. Beware! Cheers peter

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

The finished rudder was used to mark the hinge positions on the sternpost. The hinges were made in a similar way with stripes of cartridge paper and eyepins. All was painted copper and the rudder provisionally hanged. In my opinion it looks as good as those cast parts from the kit and is quite easily done. raw material for the hinge first hinge in place the provisionally hanged rudder looks ok

-

Thank you, Eljiah! Hi Martin Good idea, we could make equinox another holyday. Cheers! A reason to leave the alps? Just too many cow droppings on your paths perhaps and the hunting season will open soon. Most of the time they shoot venison but you never know - they don't always really like us lowlanders up there. Hi Michael Thank you. Yes, if I want to fly I have to flap my own wings (my family name translates as 'bird'). I belong now to those happy retired gentlemen which have no time for anything. Honestly, sometimes I wonder where I used to find time for work. Cheers peter

-

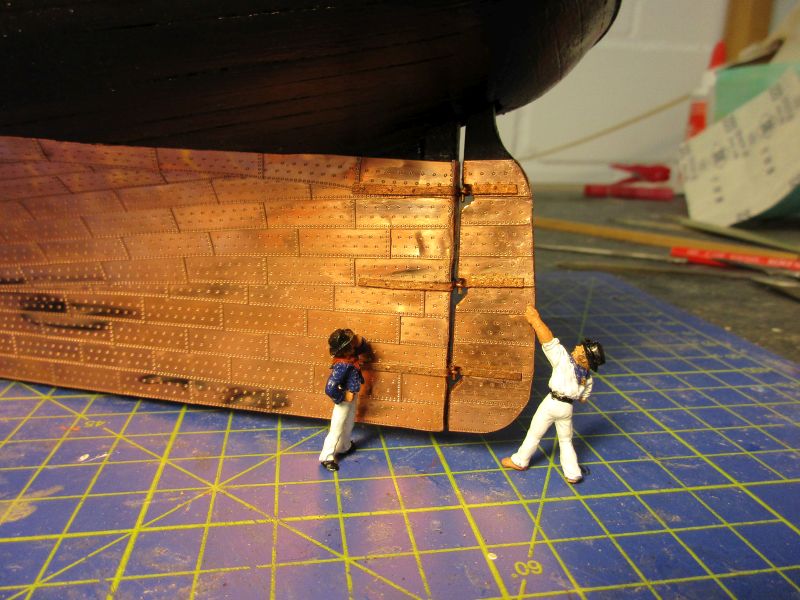

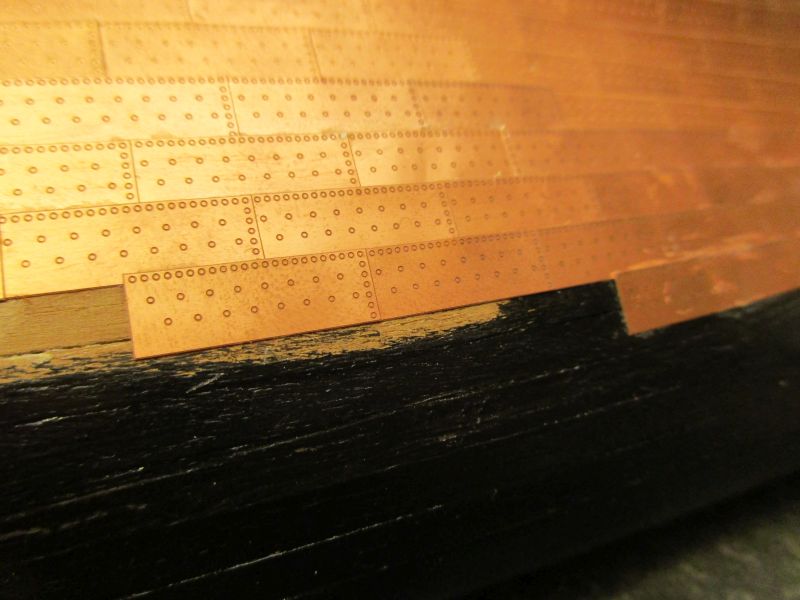

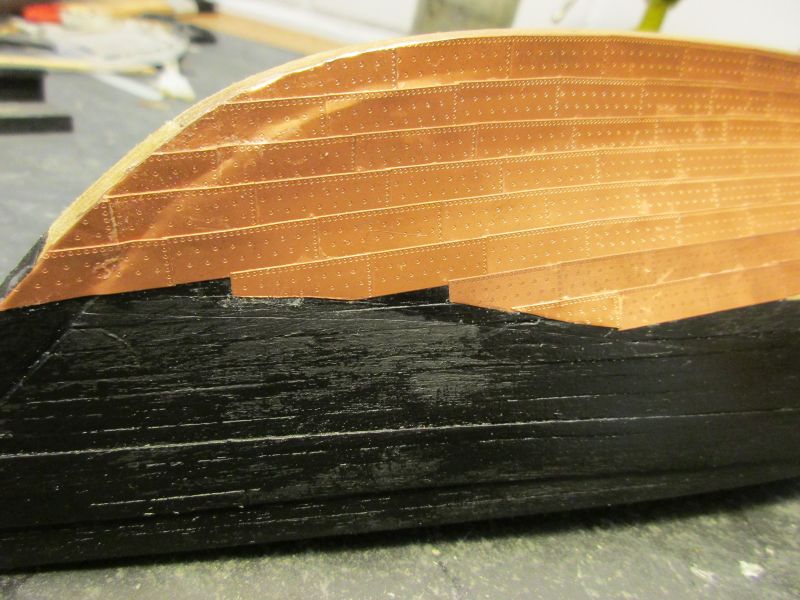

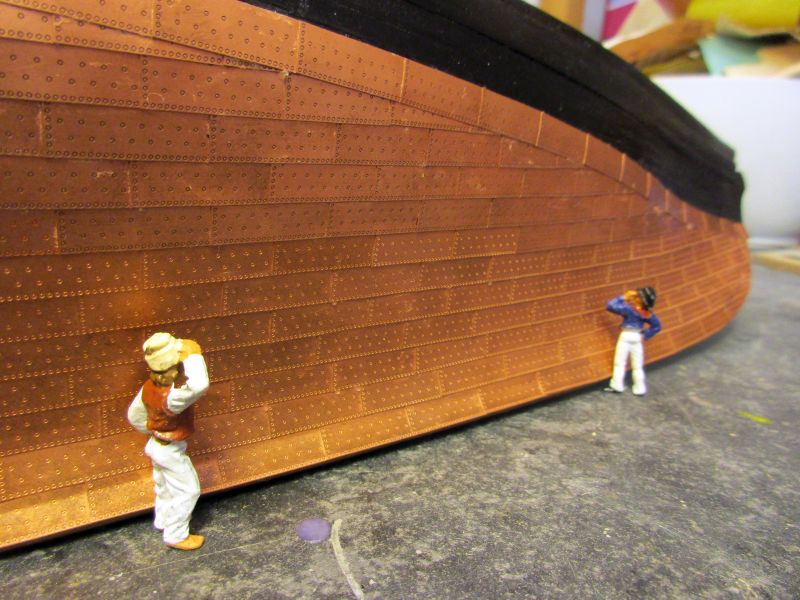

The coppering is now completed and the plates cleaned of glue stains and finger prints with a rotating brush. (A few plates were dislocated by the brush and had to be replaced - better now, when America still is in the wharf.) In the process the patina which is on the plates on delivery gives way to a bright shine but will be replaced over the months by a natural darkening through oxidation of the copper. A false keel will be bolted to the keel, that's the reason why I left off the copper under the keel. The copper will lose its shine over the next months a false keel will cover the underside of the keel coppering seems acceptable The Rudder As mentioned earlier the kit's rudder was replaced by a scratch built one and then coppered below the waterline. The kit's rudder hinges were clean cast parts but the opening was only about 3,5 mm and therefore useless. I decided to make new ones according to the method used on Pickle. The hinge was fabricated with a strip of cartridge paper with the nail heads represented by pushing a needle lightly into the reverse side. The pintle is made from a bended nail minus it's head. All is the glued in place and painted copper. Presently I'm trying to decide if the rudder needs (a) pendant(s). One picture I found showed a single pendant hanging from the taffrail similar to that on Endeavour. On the other hand they are not found on the America replica and I have no idea when they went out of fashion... kit's rudder and replacement coppered with first hinge in place kits hinge and parts for the new one: cartridge paper hinge, nail and raw pintle second hinge not yet painted

-

The weather is still too fine for long working hours and I spent some time travelling in Iceland and hiking in the Swiss alps. In both places the air is rather fresh and the beer fine. On Iceland most places are at sea level and easily accessible but the country is expensive and some flight hours away. In the Swiss alps on the other hand glaciers are at 2500m the air is rather thin (you need to cook your soft eggs for 7 minutes instead of 3 and hiking is a bit straining but I can reach most nice places with a 3 hours scenic train ride. But back to serious business... where America meets Europe... part of the Mid-Atlantic-Ridge on Iceland

-

Thanks Nils. Photo etched, yes, and they are also available in 1/72. BTW, your planking on KWdG looks fine as it is. I remember Queen Mary in long beach having quite prominent rivets as well. Cheers peter

-

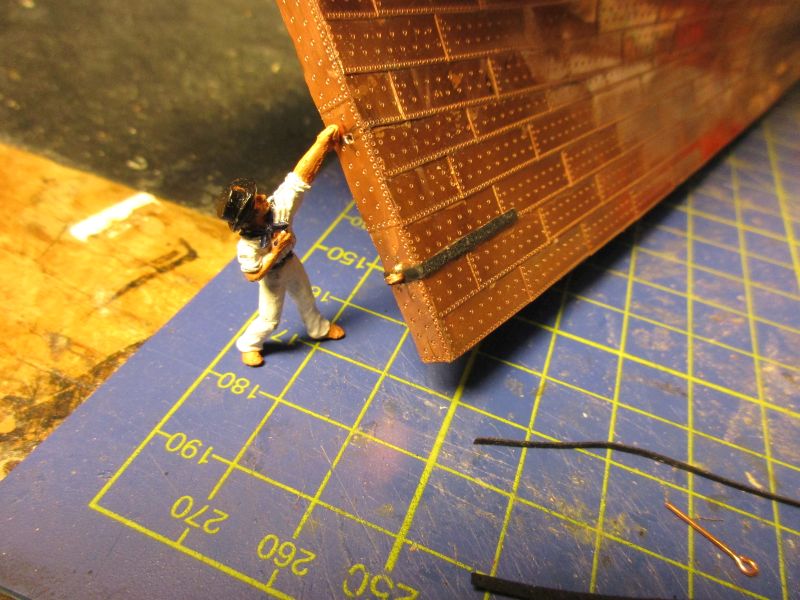

Finishing the hull The upper part of the hull was painted black and the coppering started. I use Amati copper plates. They come in sheets and the single plates can easily be broken off by bending them a few times both ways. Starting at the lower stern the plates were glued on, overlapping from stern to stem and from the keel to the waterline. Along the waterline a single line of plates gives a clean termination. This pattern follows the one used on USS Constitution and I think it should be adequate for America. Those Amati plates are meant to overlap. That's the reason for them being left and right. One line of nails on the upper and forward side is provided by the next plate overlapping the bald edges. The handicap of that system is the unfinished look of the terminating plates. I also like the way the nail heads are shown flat, running smoothly with the copper. I think the prototype should have looked this way (Constitution does) and not with those heavily protruding nail heads of the Caldercraft plates, somehow creating the image of a badly shaved hedgehog. overlapping of the plates, viewed from the bow the waterline has to be followed only roughly the plates are brought on in stripes, running aft to forward, each upper overlapping the lower one a dockyard worker holds one copperplate one side is finished - now the work starts all over again After finishing the larboard side as well, I will have to clean the plates to remove glue drops and fingerprints.

-

Hi Hamilton Very fine work. About those capstan bars. I wouldn't stow them in this form loose on deck where they would come adrift. So they are probably really footholds.?? Anyway I will leave them off. Cheers peter

-

Hi Glenn Thanks very much. Your America looks fine. I like the keel with the false keel included. Is it the Constructo model? I'm looking forward to the start of your build log. It helps a lot if you get the -always kind - feedback to your very own struggle. Cheers peter

-

Congratulations on an excellent Model. I especially also like that stand. And now the mother of all questions: What's next? cheers peter

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

The second planking is now finished. It took some time because of the fine weather. Also my immune system resented somewhat the use of CA glue and I had to make some breaks as well as use a mask. I did stick to a nose-friendly glue but this did not fully prevent some cheerful sneezing. The form of the hull was a bit of a challenge to follow with regular planking. In the lower part I used a lot of - rather simply formed - stealers to allow the plank a natural run. This will be covered by copper plates anyhow. The keel was also planked with 5 x 0,5 mm strips to bring it up to its full strength of 5mm before coppering the whole lower hull. some more sanding is needed before starting painting and coppering.

-

Wonderful coppering, Hamilton. I especially like the third picture - with a sea cucumber's point of view. Cheers peter

-

Hi Martin Between HMS Victory and Pickle were about 50 years. About the same age difference as between Pickle and America. While the first two follow approximately the same construction principles, the second two show a huge step forward in understanding hydrodynamics and hull forms. Fascinating. But America is still a schooner with that relatively simple rig which asks for full sails to be set. The build has already started - just follow the link on the bottom of my post. And I will most probably travel back in time again after America. Cheers peter

- 293 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Gentlemen, While checking that log I found several unanswered posts. Sorry. Thank you all for the compliments. Pickle really came out quite fine. She now has a fine berth in a book case in our bedroom - with the full support of the admiralty! I'm already struggling with my next project - Mamoli's America. This is on a quite different quality level but fun nevertheless. Cheers peter

- 293 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

second planking The second planking was started on the stern. Then the wales and the rail were glued on. While continuing below the wales I noted that some tapering was necessary already for the lower part of the wales and the first plank. I think that trying to use straight planks as far down as possible is one mistake occasionally seen here and I try hard to overcome my laziness and continually form the planks in a way that they may follow a reasonable 'natural' run.

-

The first planking is now finished and the sanding done. The definite form of the hull was given by eye and a few hours of filling and sanding. For the stern I decided to have a convex, roughly triangular counter from the rudder up to the taffrail. It will have horizontal planking similar to traditional counters of the early 19th century. The decision came after looking at several of the different America's stern pictures in the web. The form of the stern as a rough sketch on the first planking

-

Hi Martin Those hatchways don't look that bad to me. I wonder if sanding all flush and giving the top a convex finish (parallel to the cross section of the deck) and perhaps slimming the frames by sanding on the outsides would make the whole arrangement more acceptable to you. Please, give my regards to that gun-toting old lady in Boston and don't forget to visit the museum-shop - I found some useful books there. Enjoy the trip! peter

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Hi Bob That's a very fine Granado in the making. The kit itself is excellent and your work improves it further. Do you plan to make openings for the quarter lights? (I did but am not sure if it's noticeable at all.) peter

-

Metric vs English

flyer replied to jdiven's topic in Building, Framing, Planking and plating a ships hull and deck

Although I live the metric system I still find it difficult to think of flight altitude and -speed other than in feet and knots. The only finicky thing is to transmit speed in my head from knots into mph (have to work via kmh). It all depends what you are used to. However, it doesn't need different measurement systems to screw things up. Some 10 years ago they built a bridge across the Rhine river with one end in Germany and the other one in Switzerland. About to meet in the middle they found a difference in deck height of 54cm (21 1/4 ")! After some hard head scratching and deep recalculating they found that Germany and Switzerland indeed use different reference levels - Germany using sea level based on the North Sea and Switzerland on the Mediterranean. Now the good thing was that somebody realised in the planning stage that this difference exists and is exactly 27cm (10 3/4"). Unfortunately the correction was added on the wrong side... Cheers peter

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.