-

Posts

6,413 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

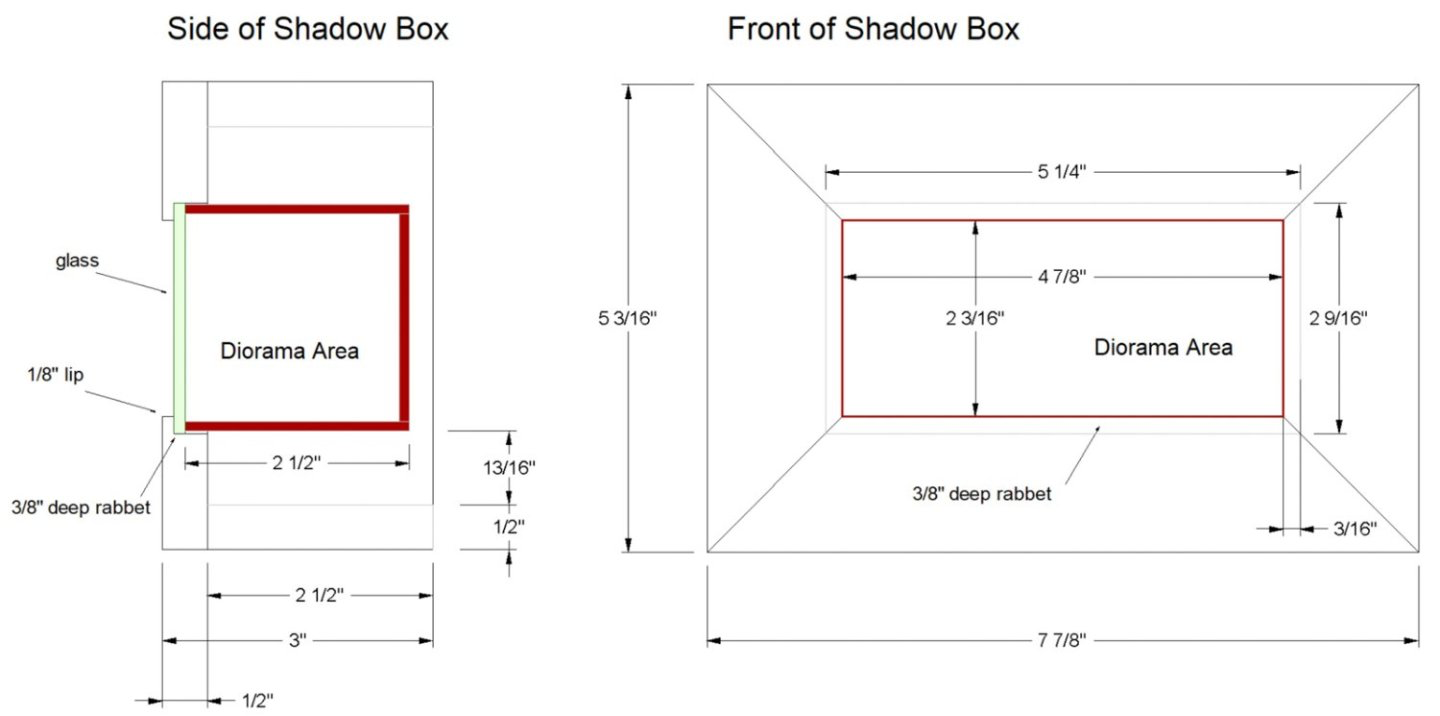

Indeed, also looking forward to your new project ! I have a conceptual question: my understanding of 'shadow boxes' or 'real' dioramas (as opposed to just a base plate with something on it) is that a frame sort of hides the left, right and top margin of the scene. However looking at your drawing below it appears that margins of the 'diorama area' are the same size as the opening of the frame. So, you don't actually get the real diorama effect. Is my interpretation correct ?

-

SMS Karlsruhe by Wreck1919 - 1/100

wefalck replied to Wreck1919's topic in - Build logs for subjects built 1901 - Present Day

Nice, crisp work indeed. Are the rail stanchions around the platform commercial pieces or did you turn/drill them yourself ? -

Looking for correctly scaled lines and rope

wefalck replied to Michael Smith's topic in Masting, rigging and sails

I am working in 1:160 scale (= railway model N-scale in Europe), so very close to your 1:155 scale. My materials of choice are fly-tying threads, e.g. the Danish Veevus and others. They are available in a variety of colours and down to 18/0 for two-ply threads. This implies that you have to make your own 'rope' from these threads, which is not really difficult. Not sure, however, whether the commercially available kits for rope-walks (e.g. the 'rope-rocket' mentioned above) would be suitable for such fine 'ropes', but I have not tried them myself, as I built my own rope-walk from bits and pieces. As Allan mentioned above, the real challenge is not so much making ropes, but rather the correct sized blocks. I know what I am talking about, as I spent considerable time on trying out different methods. However, modern technology eventually will come to our rescue in form of 3D-printed blocks. For the moment sizes below two millimetres are not commercially available yet, but I am sure they will come in the near future, if there is sufficient demand (and there should be). Incidentally, Donald McNarry didn't go too much into detail on rigging in his books, but Lloyd McCaffery does. However, he works on scales 1/300 and smaller in general and uses NiCr-wire twisted in two strands throughout. He kind of 'fakes' blocks by punching out oval paper disks (with homemade punches) and attaches them to preformed wire tackles etc. To be honest, I don't think this is results in very realistic rigging in 1:160 scale, so I dropped this idea. -

You cannot technically make ethanol at more than 96% at normal atmospheric conditions because it becomes hygroscopic and dilutes itself when left standing open. Many countries levvy a heavy tax on alcohol fit for human consumption, which is why such ethanol is expensive, though the production is very cheap. Methanol is another alcohol, but it is not fit for human consumption, it is rather detrimental to the health and can result e.g. in blindness or even death. For this reason ethanol is 'denatured' with methanol or other substances to make it unfit for human consumption and to give it an unpleasant taste and smell. It is added to a level of a few percent. This, however, does not change its technical nature and it remains a good solvent for shellac. If you live in a country without a heavy alcohol tax, it may be more pleasant to use the 96% ethanol, rather than methylated spirit. Blindness used to be an occupational hazard among 'french polishers' as cheap alcohols were used, where the distillation process was not carefully controlled to separate ethanol from methanol - the guys would take a sip from the bottle between using it to make their shellac solutions ... P.S. Jaager was a bit faster with his post ...

-

I am not sure, what you mean by 'oxidised' shellac? Schellac does not oxidise to my knowledge ... Pure (96%) alcohol is the normal solvent for shellac (flakes). You can make any mixtures you want. For instance, I keep a small quantity of shellac with a thick honey-like consistency as glue. Otherwise you can dilute it to any consistency you like/need with alcohol.

-

I made several pieces of furniture with a simplified version of French Polish, using modern materials. Traditional French Polish would consist of rubbing a mixture of very dilute shellac solution and pumice into the pores of the wood in several sessions. I replaced this with organic solvent-based sanding filler, rubbing down the surface with steel-wool. For the actual polish I used a commercial german brand of shellac solution (Clou which is equivalent to Liberon, but somewhat cheaper). The application pad ('tampon') was made from a worn-out flannel pyjama that was stuffed with cotton wool. The trick is to have the pad well-soaked in the middle, but not trickling and then to apply parallel strokes in a jet landing and take-off movement (as noted above). Do not stop, or the pad will stick to the surface and leave fibres in the coating. If this happens, let it dry and and go over it with fine steel-wool. Also, if one works too wet and stays too long with the pad on the surface, the already applied coats will soften, resulting in an uneven surface. If something goes wrong, you can always rub down the surface with steel-wool and begin again. Having said that, on models I would not use French Polish, unless it was a model of a yacht. I would rather use a commercial solvent-based sanding filler or shellac and rub the surface down with fine steel-wool. Real French Polish just gleams too much for models. I reserve this for display cases.

-

'Unpainted' wood would have been treated with line-seed oil and perhaps grease in certain places. On a model probably the most apropriate treatment would be with a wood-sealer and then to rub it down with very fine steel-wool. This closes the pores of the wood and gives it a satin surface, very much like such masts and spars would have appeared in real life.

-

It seems, indeed, that the main effect comes from the heat, rather than the soaking. However, in full-scale practice and model practice it is difficult to apply sufficient heat without burning the wood. Planks were bend over open fires in the older days and doused with water, to keep the temperature sufficiently low due to the evaporating water. Later steam-boxes where used or boiling water (particularly in model building). Today, we have steady and high capacity heat sources in form of temperature controlled hot-air guns of varying sizes. I have, for instance, an electrical hot-air soldering gun, where the temperature of the air flow can be regulated down to around 100°C. With such an implement heat could be applied locally, while the planks is progressively bent onto a former without burning the plank or formers made from e.g. wood.

-

The problem is that such measure are typically taken in isolation, not based on a systemic assessment of all the consequences and impacts. The life-cycle impact of an entirely new plate may well be higher than using some not so environmentally friendly paint (whereby the main impact comes from inadequate handling and application, rather than production). We see this over and over again in political decisions that aim to solve one problem, but then create a host of other problems down the road.

-

The apartment I grew up in for the first eight years of my life had a large tiled stove in the living- and the dining-room respectively. Both were stoked from the corridor. The other rooms had individually stoked cast-iron stoves. These stoves had a lid on top that revealed a cooker-like plate on which one could put a kettle. The tiled stoves had a heating compartment which was useful for baking apples in winter 😋 While we had moved to centrally heated apartments in the mid-1960s, the early 1900s apartment house in which my maternal grandparents lived still had stoves when they died in the early 1980s. These stoves were oil-fired and one had to get the fuel from a large tank in the cellar, from where it was hand-pumped into cans (looked liked garden watering-cans, but with closed lids) and carried upstairs. I don't remember having ever burnt myself on any of those stoves ... rather I remember cold, unheated parts of the apartments. OK these are not 'dodgy' solutions as per the title of the thread, but were standard fittings throughout the 20th century and still are in many parts of the world.

-

Picture(s) ? 'Siglo xix' is Spanish and just means 19th century ... it's not the name of the ship ...

-

Let's keep fingers crossed that this wonderful model reaches its safe haven and that it's builder also stays safe !

-

I don't know what the practice on late 1800s american fishing schooners was, but jut going round and round, as in the left example, would put all the strain onto the end-lashing. The wind would tend to push the sail towards the claw like a curtain. The method on the right example seems more probable, although one would do a kind of half-hitch at each point. This has the effect of tying the sail to the gaff very closely. In the older days individual ropes were used, but a continuous rope is more convenient. This is definitely the method used on Dutch vessels in the 19th century.

-

Interesting topic. I noticed that in other cultures people were tradtionally not in that 6-8 hours sleep and the rest wake routine, but slept in intervalls. The question seems not so much when you sleep, but how much sleep you can get in 24h. Obviously on a ship, particularly in the sailing ship days, there are periods, when the men got very little sleep. From experience, I know that at some point one dozes off, wherever one happens to be. On the other hand, being in the mast in a storm should refresh you quite well ... they used to say that sailor can sleep anywhere any time ...

-

HMS Renard 1872 by Draque - 1/24 - POF

wefalck replied to Draque's topic in - Build logs for subjects built 1851 - 1900

Lively discussion already here ... I'll keep an eye on that log for sure -

Thank you very much for the encouraging words ! Jolly-Boat continued 6 For some family-related reasons the boat-workshop had been nearly closed for a few weeks. Nevertheless, I managed to apply a few coats of white overall. Then the real painting begun. According, to a 1874 ordinance, the boats where to be painted white outside and inside, the top two strakes black, while the rubbing strake between them was left natural wood, as was the top of the wash-strake. Natural wood were also the seats and stern-sheets. The rowing-locks were bronze and were left bare. The boat still has to be kitted out with some galvanised iron-work and, of course, all the equipment such as the oars, fenders, a water-cask etc. There is conflicting information, as to whether the mast and the sails would have been stowed in the ‘ready-boat’. Somehow, I am not really satisfied with my paint-job. I didn’t get the colour of the seats etc. right, they look too reddish. I hope a wash of light ochre will correct this. I also had great difficulty to paint the rubbing-strake from a 0.2 mm wire cleanly. I tried to do it freehand, but perhaps should have masked it … With this, the workshop will close for the holiday-period. To be continued ....

-

What is the microwave-oven supposed to do? It doesn't do anything to metal swarf and won't burn away wood. There are special file brushes made from stiff brass wire, but as captainbob observed, they don't really work on the fine cuts of files, the diameter of the wires being larger than the teeth are wide. Don't even think of using acid on a file, that would be the death of it. You can soak it in (used) tea-leaves for a while to remove rust. Make sure to dry it quickly with a hair-dryer afterwards. Files shouldn't really be used on wood, this actually dulls the teeth. Rasps are for wood. Or diamond files. Of course, sometimes one has no choice, when cutting narrow slots and the likes. Remove the mass of the material with a saw and only use the file to create crisp edges. Professionals would keep different sets of files for different types of material.

-

I don't have one of those CNC-embossing machines, but thought it might be useful for exactly that purpose. Many years ago, I built an early iron tug-boat and simulated the plating in the traditional way, using a taylor's copying wheel. Then I wanted sharp positive rivet heads and did the embossing on a piece of linoleum. This surface is quite tough, but flexible. The embossing tool pulled up cone-shaped depressions, but I put the copper sheet on a harder surface and then rubbed it lightly on the back with a piece of round wooden dowel, which pushed the cones back in, leaving clean rivet heads on the other side. Want I wanted to say with that is, that it may be worthwhile experimenting with materials of different hardness/toughness under the copper being embossed in order to control or modulate the shape of the embossed marks.

-

I suppose it depends on how trusting you are in your rope and how quickly you want to strike the rigging. In ships' boats this usually has to be done fast and in perhaps rough conditions, so minimal rigging would be of advantage. On the other hand it looks, as if the set up of the forestay would not be so easy to loosen, there is a lot of friction in the deadeye and the holes in the stem. But then, it may be only necessary to lift up the mast by a couple of inches in order to get it clear of the mast-spur. Then it could be laid down.

-

Yes, but going down to the keel. Not sure how it would be made fast there at that time. Perhaps a single block and then a belaying point at the shelves?

-

Cleaning and Priming metal

wefalck replied to Cleat's topic in Metal Work, Soldering and Metal Fittings

If the flux is just citric acid, chances are that you have it already in your kitchen as de-scaler for coffee-machines and the likes. Over here in Europe we buy it in 500 g boxes in powder form in supermarkets. Just dissolve the crystals in distilled water (preferably), as the carbonate-hardness of the tap-water would consume some of the acid. -

I don't know about 18th century practices, but in my late 19th/early 20th century boat reference books such stay were taken to floor. However, the yards then were much steeper and would clear the stay and the foresail had no boom. One option is to set it flying, so that it can be cast loose, when tacking etc.

-

It indeed evokes the feeling that the crews on these little ships crossing the oceans were all on their own ...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.