-

Posts

4,669 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by augie

-

Come to think of it, those deadeyes kind of look like donuts You'll get used to standing up while you work. Or do what I do....have a second workbench that's only 0.6m high off the floor.

-

Guys.....I'm telling you....epoxy is so easy to clean off with 91% alcohol before it sets that it's almost a joke. When I break it out I have a 'rule'..... three bottles---resin, hardener and alcohol. Never lets me down.

-

Way to go! When all else fails we simply will the piece into submission. My kinda guy

- 1,148 replies

-

Thanks Andy, Frank, Thomas, Dirk, Kevin and Dr. Hamilton. As John (Jim Lad) says.......time to put the spiders back to work

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I don't think so Adeline. Looks like the bowsprit is slightly off center to port. Let's see what John says......I hadn't noticed that before.

-

Sometimes a good nites' sleep makes things work better. Good luck!

- 1,148 replies

-

Thanks Mark and Daniel. Hey Daniel ---- batten the hatches! It just started up here as a combo of gale force wind, rain and ice.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks for that point Dan. I haven't run a lathe since high school back in the 50's.

- 1,148 replies

-

Well, BE, when I can come up with something that can hold it's own with that last photo you posted of your newly masted Pegasus, I shall be a happy man. Be that as it may, I am smiling just a bit. Thank you.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Darn----even a file! I'm astonished. But never worked with cherry. Oh....do it by hand. If you buy a lathe, the next thing is I'll lose you to the dark side and your thread will trun into a tool review

- 1,148 replies

-

True but what a sight to see two top notch builds with cutter rigs as high as the sky and long as the horizon!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Welcome back to the shipyard mate. I've used the old drill to taper round sticks but never to try rounding off a square one. Might work if you flattened those edges to an octagon first?

- 1,148 replies

-

Thanks, Popeye John- Glad you approve. As for the strange weather, yes.....this has been quite a Spring. But not unusual for up here. We have a saying --- 'if you don't like the weather, wait 10 minutes'. By the way......did you see Chuck's latest project that's taking shape...... a 1/4" scale cutter? Love to see she and your 'Stag' side by side one day!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Robert --- you can keep whacking the horse Garwood- The beige line is what was supplied with the kit. It's a nylon twist. For the standing rigging I used Morope. All lines have been stretched and dressed with beeswax. And thanks also to Ben and Ken!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Wayne, JP, Sjors, Buck and Tex. Really nice to see the '3rd dimension' in play. But Garwood has hit it on the head ----- long way to go yet until she's done and in her home. So I'm not feeling melancholy about losing an old friend! Bob- my work has gotten better since the beginning because of the legacy set down by you and the other Syren builders.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

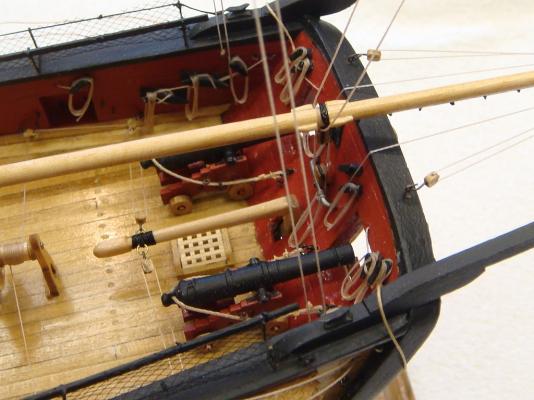

OK, time for a proper (Sjors approved) update. As reported, the main and fore lower yards are now in place. I've added the brace pendants, trusses and lanyards between the thimbles . Here's what's really fun about this kit (thanks to Chuck). When you put in a thimble, block or sheave way back on page 6 [without any concept of why you're doing it], when you get to page 116 and go looking for that item, it's already there!!!!!! Really folks, these plans/instructions are the greatest thing since sliced bread. In addition, the inboard main couse sheets and braces have been fixed to the bulwarks with about a mile of line waiting to be attached later (see above). We've just hit 1300 hours into the build, adhering to my motto 'I may not be any good, but I am slow'. Will be finishing up jeers, lifts, leech/buntlines before moving on to the topsail yards. Between shoveling snow, planting tomatoes (unusual, but this is Colorado) and an upcoming family visit we may be somewhat becalmed here. But there's always time to do something. All stay well.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Don't sell epoxy short. It's very strong.....really stronger then we need for most ship applications. What I like about it is that it comes in a variety of 'set' times from 5 minutes up to several hours. Also, the viscosity can be easily adjusted with isopropyl alcohol (70 or 91% 'rubbing alcohol') and of all the glues it is the easiest to clean away excess. Just use that same alcohol and it will be gone from surrounding areas----completely. Yes, the fact that you need to mix it does generate some waste. But you can mix very small quantities on a piece of wax paper with a toothpick and you're all set. One other thing. If you leave the component parts of the epoxy in their original containers after opening they last a very long time. If they thicken while sitting on the shelf you can return them to their original viscosity by heating for a few seconds in the microwave (be sure and take the top off). Like most of us, I use PVA and CA's 90% of the time. But the last time I counted I have about 9 different adhesives in the shop that can come in handy like JB Weld for metal-to-metal and RC 56, a clear drying glue that is very slow setting and excellent for glazing applications where other adhesives tend to fog acetate 'glass'. Ya never know what's going to come up . Some of the railroad guys are masters with glue!

-

Just delightful. She brings a whole new meaning to the term 'pocket battleship'. And one day, those guns may come in handy!

- 52 replies

-

- steelgolem

- missouri

-

(and 1 more)

Tagged with:

-

Have a safe and memorable trip Gil. Your netting looks great. And if you can get a blue background for the model picture of the bowsprit, you'll fool me!

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.