-

Posts

4,669 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by augie

-

I knew Sjors couldn't avoid the call of Aggie. I picture him like our Abe Lincoln, studying his plans by candle light and waiting for the sunrise to count the ratlines . If he has another week off he had better start coming up with something better then sandwiches for dinner

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Not sure why they may have been lighter below decks Keith. Either the elements or perhaps by design to lighten things up? I use Minwax stain products. I use the pre-stain, stain, WOP sequence on everything even though I went to it for basswood which is soft and prone to blotches from the stain itself. Even used it on the oak case and I'm not disappointed. The WOP comes in a variety of 'glosses' from High to None. I generally use the low gloss version as, even though it's considered 'heresy', I like just the hint of shine on my natural surfaces. The gloss disappears with time.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you Chuck for the black paint idea. That's the kind of thing I usually think of when I'm rigging the backstays. You're a Godsend. It's now 'on the list'. Darn it, folks.......he's GOOD!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

OK on cut, sand, trial , pencil. But then I glue them on and sand lightly again. I'm using PVA here so I'm not worried about CA getting all over. Then I pre-stain...........this is basswood and it minimizes blotches. Finally WOP. I use the same sequence on deck. Hull planking is different. There I use a thick CA which does not make a mess or penetrate the wood and then go right into sanding and finishing.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

I didn't know you were modeling the Nantucket Light ship

- 116 replies

-

- finished

- Lackawanna

-

(and 1 more)

Tagged with:

-

I think the eye roll is Anja knowing that, as soon as they got home, she has to start the laundry and begin preparing a 5 course dinner while Sjors opens the box to drool over his new plans.

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

And now back to our regular programming She has 3 platforms to construct which represent the lower (sub-gun deck) deck. They will be barely visible through some hatch openings. Here is the completed first platform. It is made of 23 planks of basswood, stained with a natural finish and given a coat of WOP. The edges of the planks have simulated caulking using a #2 pencil on one edge only (I don't like the caulking too heavy). I chose not to simulate the treenails on these lower decks. Chuck states in the practicum that the lower decks were generally lighter in color then the main deck. I intend to maintain that concept but we'll need to wait a while to see that effect (like about a year). The planks for the remaining 2 platforms have been cut and will go in very shortly.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

I'm lying sideways on my desk to get a full appreciation. Offhand, I'd say you have a better eye for nautical stuff and should bag the idea of being a window treatment consultant

-

Ah, the wonder of plastic mitre boxes. Time to upgrade I'm finishing my lower decks just as you are. Are they visible? Barely. But we'll know they are there

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

No, that's not it. It's the fact that she is handling the luggage, passports, cameras and other various items essential for international travel while Sjors focuses all his energy and attention on carrying (and protecting) his latest project.

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Getting the shop organized and making spaghetti sauce.....now that's a weekend. Congrats! Now here's more good news. The sun, which has been nailed in the sky for a month, has slipped behind some clouds and it looks like some cooler weather is on the way. Should get to you by tomorrow . Be well!

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Looking good. Hope you're liking working with wood!

- 188 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

Nice work Jim. The details are really bringing her together :)

- 116 replies

-

- finished

- Lackawanna

-

(and 1 more)

Tagged with:

-

No Popeye. The bulkheads were fit, squared up and glued, then the fillers put in. Your idea sounds logical......except if you set in one bulkhead and filler and it were to be a little 'off', I think the error would compound as you move along.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hamilton- no, she will be strictly the Admiralty version. I have no room for her fully rigged. Maybe the next one John - I was never a big fan of minimal engineering. She's not destined to fly so weight is no object. Chuck - thanks for stopping by. The BF was arrow straight to begin with and the fillers were applied while she was firmly clamped straight. At the moment she looks to be straight from stern, bow and overhead. John - I will probably use the method Chuck suggested in the practicum.....temporary 3/16" braces running from port to starboard at the tops of the 'antlers'. However, Bob (Rafine) has just planted an idea in my mind that he's going to use on his Essex. Will let you know.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Fantastic opportunity. Give Sjors something to eat. Poor guy looks like he just survived pneumonia :D

-

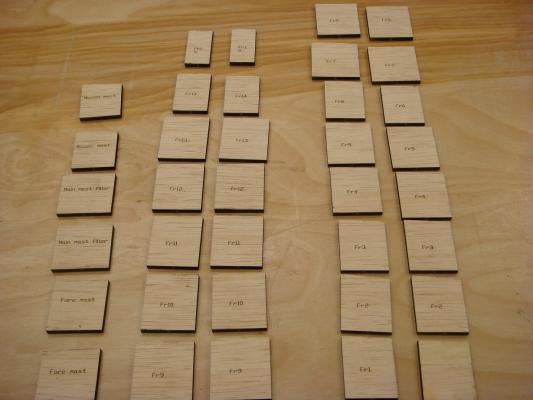

Update time. A series of laser cut 'fillers' is supplied. Here are the bulkhead fillers which bolster the bulkhead former between the bulkheads: If you look at the column on the left, these are 'extra' fillers that were supplied and labeled as mast fillers. They are not in the practicum or depicted on the plans. In discussing this with Ben (Trussben), I decided to install these at the appropriate locations. I believe that they would be essential for a model that was to be fully rigged. Additional fillers are supplied for the bow and stern: Here, the bulkhead fillers (including the mast fillers) have been installed. They were very accurately sized and needed only light sanding to remove laser burn: Here's a closeup of the mast fillers which were installed at Fr 2, 7 and 13 Now for the stern and bow fillers: Finally, just an overview: There will be additional fillers added at the stern later on. I don't believe the bow will require more. The overall frame now is pretty stiff ---- and straight. The bulkhead uprights are quite high and fragile. I may brace these before continuing. Next, we will be building three sub-gun deck platforms from basswood planks before we break out the sanding blocks for the ever popular hull fairing. So far, so good

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Yes Larry and Borge, it would be nice if upgrades were offered. But kit manufacturers have so many kits it would be tough to cover them. It really requires a personal touch and interest. Not to diverge too far off course, in the airplane model world you can buy a set of plans and there are actually outfits that, for the more popular aircraft, will laser cut the bulkheads, formers and parts that lend themselves to sheet cutting. You then supply your own sheetwood and sticks/dowels, etc. And there are other outfits that supply molded/cast parts and photoetch. It's a GREAT way to build --- you are 'making' your own custom kit. Expensive? Yes, a little. Perhaps one day that will be possible in the model ship world for those who choose not to get too involved in scratch building. It's all in the economics and demand.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Nice work .... glad to hear ME came through. Pretty long 'horns' on the quarterdeck bulkheads. I know you'll work carefully.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Ok, hope they respond. I apologize as in focusing on the photo I never realized you didn't have the stem on yet. You'll have room to play with it once you're ready to fair it. I'm sure when that's completed you won't want any piece of the buklhead out there on the stem.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Keith- I've always been afraid someone would ask that question . The old log was about 50 pages when it went down --- but in those days there were only 10 posts/page. I don't really care about the # of pages although I know it annoys some people. I post as many photos as I can without being silly. With Syren it was about 135 photos. Confed will be more as I've learned what folks might like to see. My logs are open to everyone and I welcome active participation. Those who don't care for our 'family' environment can choose not to follow. As Andy said earlier, all chances of this being a 'highbrow' log went out the window with the appearance of the first moose. Of course I'm part of the problem as I tend to care as much about the folks on here as I do about reporting that I glued stick 'A' into slot 'B'. More pics in a day or so.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Do your plans include drawings of the bulkheads themselves? Many plans do so you have something to check against. If not, can you check the specified height on the plans using a side view of the hull? Are all of the other bulkheads ok? (an obvious question but I had to ask). Does the manufacturer have a contact number listed anywhere? They may be aware of the problem and offer a solution. You can, of course, make it shorter......but is it actually too high at the top or too low at the bottom? The vertical slots may give you a clue. Are they in line with the slots on the other bulkheads? Keep in mind that changing the height, from either top or bottom, may alter the lines of the hull. You should be able to check that by running a horizontal plank up and down the hull and see what it does ---- sort of the same process you'll use to 'fair' the hull. Beyond that, I'm stuck. Let us know what you find.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks for re-posting that John. I think all will appreciate seeing it if they hadn't before.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.