-

Posts

343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pete Jaquith

-

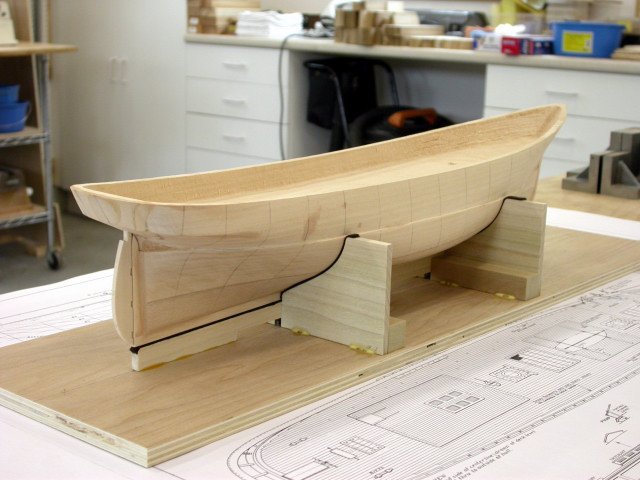

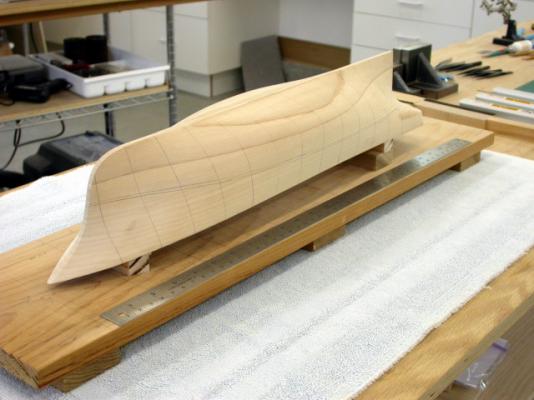

Steve, I use laminated basswood for my scratch built POS hulls. Pilot Schooner "Katy" and Brigantine "Newsboy" were machine carved kit hulls using laminated basswood (or similar). I have had no problem with cracking or delamination despite moving from New Hampshire (hot/cold and humid) to San Diego (hot and dry). I use dark Tilebond glue in gluing up the laminated hull blocks.

-

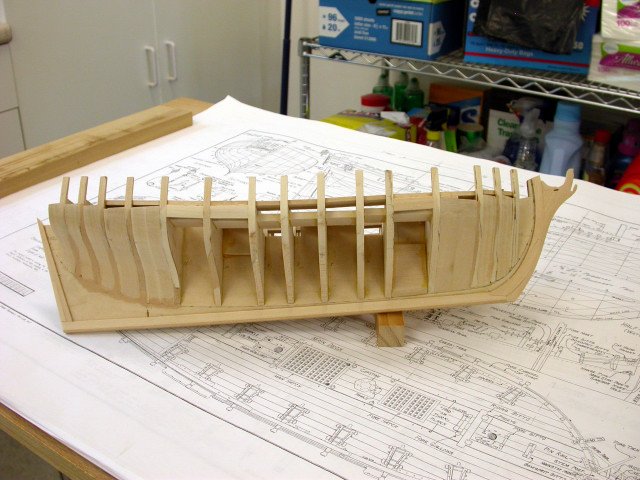

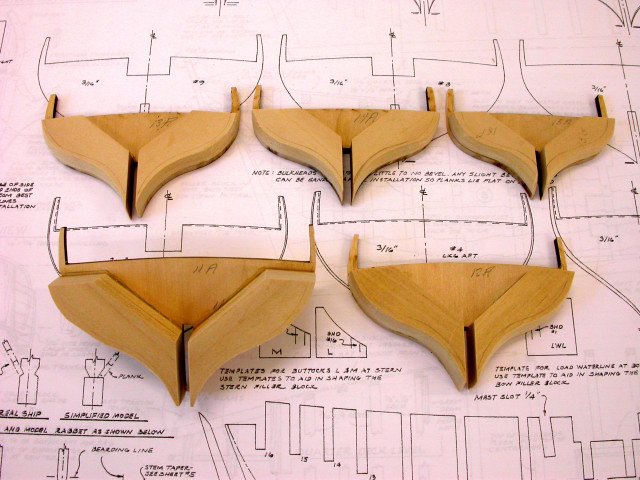

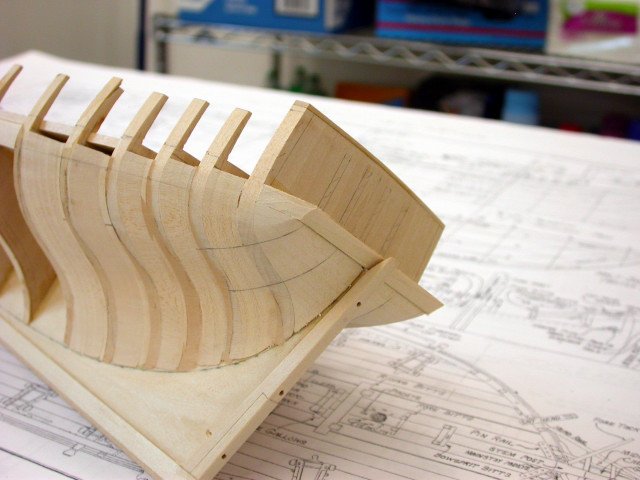

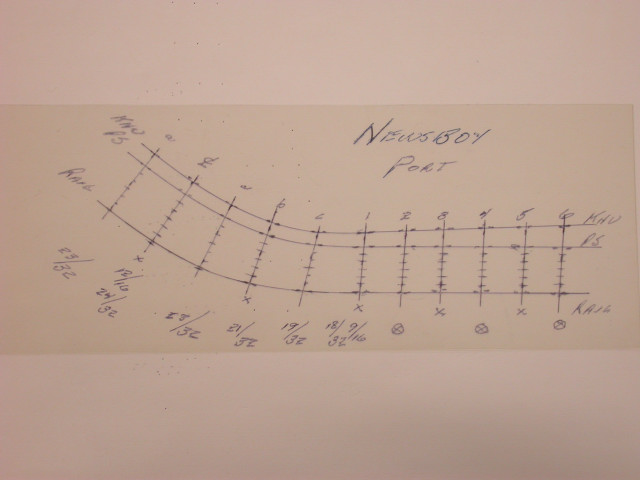

Steve, My Topsail Schooner "Eagle" 1847 1:64 scale build was scratch built using plank on solid (POS) construction while my Brigantine "Newsboy" 1854 1:64 scale build was POS construction using a machine carved hull. As these hulls were coppered, I recessed the upper hull 3/64" to accommodate hull planking. On both hulls I used 1/32" bulwark planking and 3/64" hull planking. I prefer a wood fiber filler by Carpenters vs softer spackling fillers. Pictures below illustrate "Eagle" and "Newsboy" construction respectively:

-

Elia, Nice looking spars and rigging ironwork. I look forward to seeing your work on silkspan sails as I plan to go that way for future builds. Regards, Pete

-

All, We have relocated from Hancock, NH to our home in San Diego, CA. I have also kept busy with my full size 1:1 scale shipbuilding projects. I am now setting up my shop and hoping to return to modeling in the near future. First project will be to rig the Brigantine Newsboy 1854 and complete the 14 Gun Brig Fair American circa 1780. Regards, Pete

-

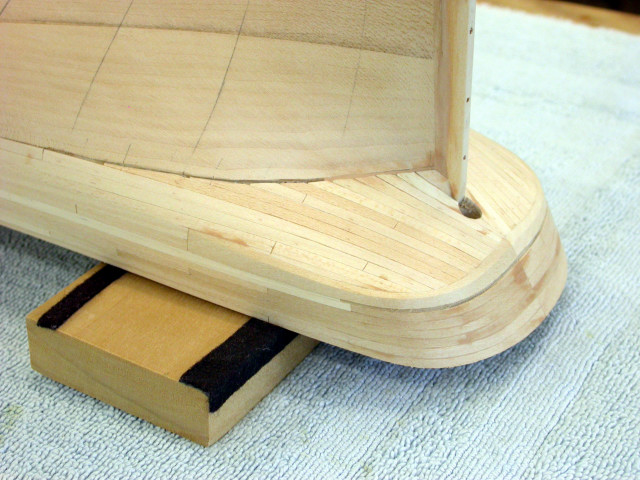

Hi Chuck, I would suggest the use of sharp gouge and chisels finished off with flexible sanding sticks. If the deck is low or lacks camber, you can build it up as shown below. You will find more pictures on carving and working with solid hulls in my Brigantine Newsboy of 1854 build log here at MSW. Regards, Pete

-

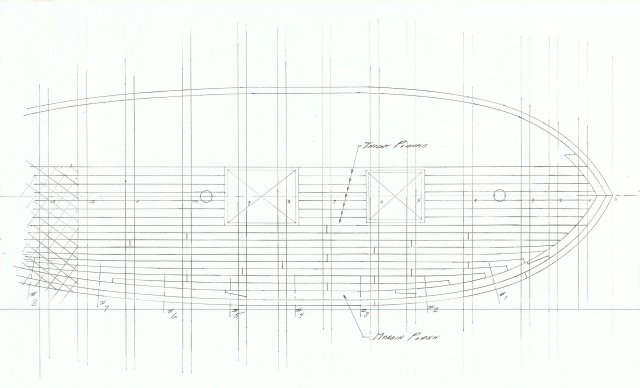

I would suggest basswood or pine for filler blocks. Easy to shape but providing more support than balsa wood. See attached picture of my "Fair American" build. Regards, Pete

-

Phil, The following pictures illustrate copper sheathing applied on my Brigantine "Newsboy" 1854 in 3/16" (1:64) scale. Copper sheathing was applied using Bluejacket self adhesive copper tape cut into individual 1/4" x 3/4" plates using a simple card cutter. I did not emboss a nail pattern due to the scale. Blue masking tape strips were used as an application guide. Regards, Pete

-

Hi Michael, In my 14 Gun Brig "Fair American" build (here on MSW) I choose to use filler blocks to assist in hull fairing as well as providing improved support for planking. Filler blocks were bass wood glued to the bulkheads prior to hull assembly. Fairing was accomplished using 60 grit sandpaper wrapped around hardwood dowels. This approach was successful in providing a well faired hull from an inaccurate set of kit furnished bulkheads. I wood recommend bass wood or pine for filler blocks as its easy to work with but strong enough to support planking. Regards, Pete

-

jct, I look forward to following your build. My Brigantine Newsboy build log here on MSW illustrates my approach to carving and finishing a solid hull. Note that I found a digital caliper useful in thinning the bulwarks. Regards, Pete

- 258 replies

-

- harriet lane

- model shipways

-

(and 1 more)

Tagged with:

-

Hi John, Very nice model of a beautiful/interesting mid 1850's American sailing ship. Your model gives a real feel of these small working vessels. Regards, Pete

- 159 replies

-

Rob, Coppering of Brigantine "Newsboy" in 3/16 scale using individual plates without imbosing. Regards, Pete

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Chuck, If there was sufficient interest there, I would like to see a series of quality mid 1800's American merchant sail. This is an interesting period of marine history and it played an inportant role in developing the United States economy. Additionally, the brigs, brigantines, packards, and clipper ships were beautiful ships. Key attributes for these kits would include: quality plans, quality instructions, quality fittings, and prime wood. Hull construction could be POB or POS. Fabrication of deck furniture, masts, spars could be left to the modeler. Regards, Pete

-

Tim, With respect to plating your 1:192 scale liberty ship model the following points might be considered: Depending in the shipyard some liberties were fully welded, some had welded hull plating with riveted frames, and some had rivited hull plating with riveted frames At 1:192 scale 1" shell plating (.75" might be more typical) would be .0052" in scale, so I would suggest keeping the plating sutle Regards, Pete Shipbuilder

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

Vossy, My notes on coppering here at MSW can be found at the following link: http://modelshipworld.com/index.php/topic/6783-coppering-the-ship-model-hull/ Pete

-

Ed, Very impressive work. Nice crisp deck details. William Webb would appreciate your work. Pete

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

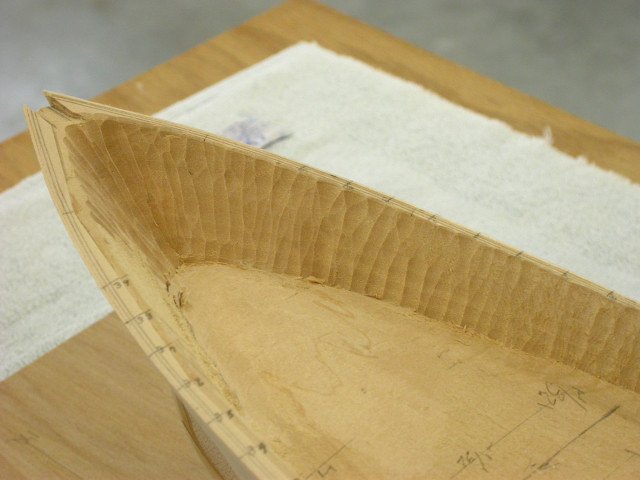

Edward, Some pictures of carving the bulwarks on my Newsboy 1853 build. Vertical cuts with a sharp gouge, then vertical cuts with a flat chisel, followed with flexible sanding sticks from the beauty salon finished it up nicely. Digital calapers helped to check the thickness. Regards, Pete

- 32 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

You may wish to delay coppering until completion of all exterior hull outfit. My Newsboy build log here at MSW will show this approach. Regards, Pete

- 32 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Edward, Good luck with your Phantom build. I am building the brigantine "Newsboy" also by Dennison J. Lawlor of Chelsea, MA. For shaping your hull, #60 grit sandpaper around a large hardwood dowel will will do it quickly. Regards, Pete Shipbuilder

- 32 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.