-

Posts

940 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Wintergreen

-

-

Tool rants and sailing discussions aside, I said I was about to do the rudder.

Did I?

Erhm, no.

After painting the hull a couple of times it didn't appeal to me to do the rudder (too simple). Instead I've opted for somethinge inherently much harder and more complicated - the coamings for all the deck openings! Truth be told, I have never done a fish tail corner in full size and now I attempt them in 1:30.. sane? No, not really. Buth then, amongst the kids I'm not known for being sane all the time 😄

So far, so good I must say. Only about 19 or 23 more corners to do 🙂

And here is my setup with tools to accomplish to work.

Now a brake to watch some cross country skiing.

Cheers!

-

-

Thanks John, yes, it is the Admiral reading fore of the mast and the pretty little blond one is now 20 years old. Still pretty and blond, just older 😉

She's our "baby" with six older siblings (different configurations of hole, half and step siblings, it's complicated 😄 )

Cheers!

-

@Mark Pearse, yes, Sweden and the Baltic region is totally shattered with islands and skerries like no other part on the entire globe actually. It makes for quite stunning trips in the archipelago. The Admiral has a sailing friend in Florida, where they only have shallow sand beaches everywhere. To his complete horror we send him films when we sail only meters away from solid rock islands on both sides 😄

My avatar picture is of a ship that sails in the Baltic sea, owned and maintained by a Christian organization. It has been a couple of years now since I last enlisted as first mate on it, but further back I was a regular for about 7 years. Fatigue through work and cancer did its best to take the fun of it for a while. As a first mate on it I was part in everything from sailing to finding the nearest power outlet and so on.

Primarily though it is my own sailboat I commandeer. Picture below. It is called OE36 after its constructor, Olle Enderlein. He studied at Sparksman&Stephens in NY and the OE36 is very similar to the more known Swan 36. The Swan is a bit more slender around the waist compared to the OE36. 36 is the length in feet. The first OE36 is from 1969 and mine is from 1980. The Swan predates that with a handful of years if my memory is somewhat accurate.

- Keith Black, mtaylor, rlb and 6 others

-

9

9

-

10 hours ago, KeithAug said:

Lathes and mills just introduce further layers of problem solving opportunities

Which just brings us further down the rabbit hole... there is a healthy restriction to fabrication with a limited set of tools, power or not. Of course there is a monetary side to it also. It's a matter of prioritization... I will not reveal how much I've spent on my sailing vessel, but it could have with easy bought me the entire Proxxon Micromot line of tools. And I mean the Entire product catalog.

But then I wouldn't be able to go sailing, which I love...

- Keith Black, Mike Y, Nirvana and 2 others

-

5

5

-

2 hours ago, Blue Ensign said:

Anyone want some bags of rigging blocks before I bin them?

I'm good, thank you.

Getting every little detail to match in scale is hard work. I think you've made a sober decision re the dead eyes.

Keep it up BE!

- mtaylor and Blue Ensign

-

2

2

-

-

Thanks Mike!

To write it down helps the memory as well. Sometimes it feels like I'd forget my head everywhere if it wasn't attached properly to the neck 😛- Keith Black, oakheart and mtaylor

-

3

3

-

-

-

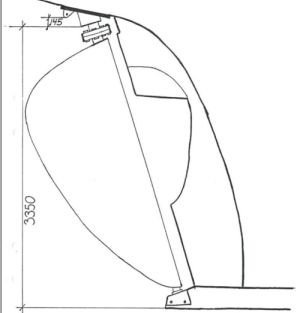

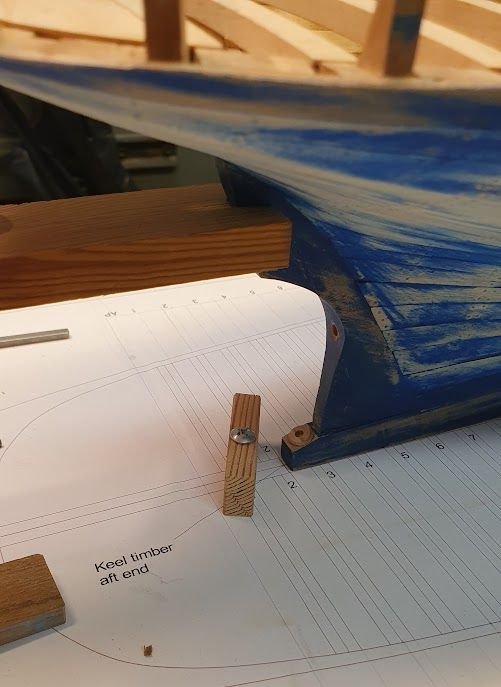

In an attempt to stay somewhat true to the original detailwise, I mused over how to fabricate the coppling between the rudder and rudderstock. Se the picture below.

What I came up with I figure is an alternative way to make trucks for gun carriages. For those of us that do not own a precision lathe, that is.

How then? Well, I used my bung drillbit, then swapped it for a regular drillbit without moving the stock. Then parted it off with the bandsaw.

Apart from the coppling I also used it as bottom support for the rudder. 🙂

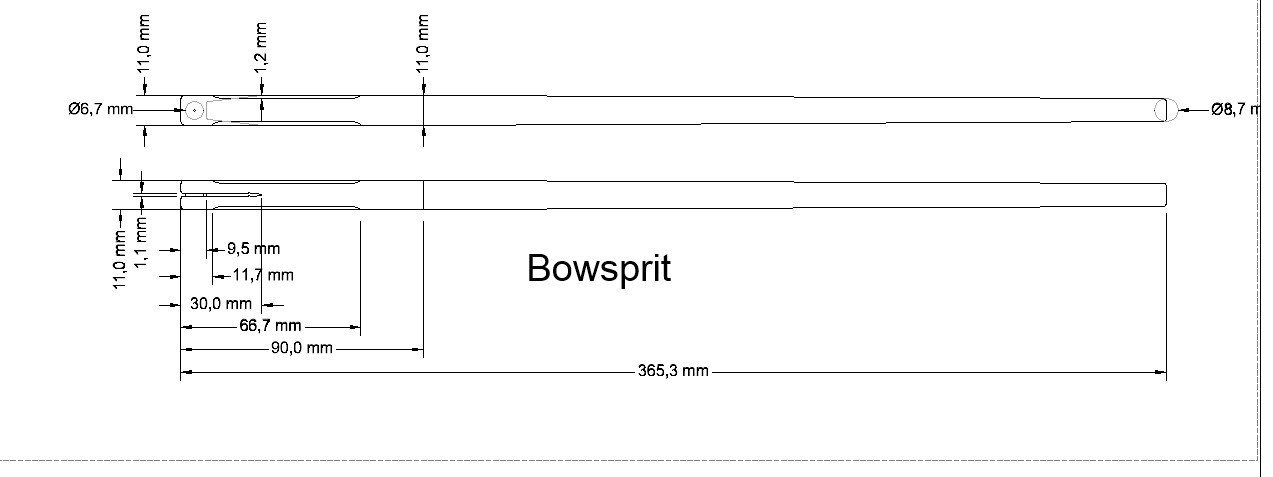

This was all for today. Now that the rudder assembly is figured out I can turn my attention to the bitts for the bowsprit. That also includes the bowsprit itself. So back to the plans and software...

Yes yes, the measurements are to scale and not real world dimensions. My reasoning behind that is so that I not necessarily need to print them out, but instead just can look at the drawing and fabricate the spar from that.

That's all for now, cheers!

-

2 hours ago, wefalck said:

Old-time well-builders with tree-trunks also use hollow augers to drill straight holes

Aha! I have marvelled over these in my shop. Spoon shaped drillbits? Really? I probably knew, back in my mind that they would work. Why else were they made?

But still, it defies rationality for the man of the 21st century.

- KeithAug, Keith Black and mtaylor

-

3

3

-

-

Looking good Tim!

About getting things square or any other intentioned angle, people here utilize jigs for almost everything. Put some time into a jig, make it to desired spec, and then build your piece. Especially if there is more than one item to do, this way is beneficial.

Keep it up!

-

I agree @wefalck, if you haven't already, look up the Tally Ho rebuild on youtube. The documentation is superb and I was especially impressed when one of the shipwrights drilled holes for the fastenings for the chainplates. All holes were at different angles and he managed to hit spot on every time.

I learned from a fellow of mine, his job is to drill in concrete, that using drill bits (or augers) with four flanges(?) makes for straighter holes. Which confirms your thesis also.- Keith Black, oakheart, FlyingFish and 3 others

-

6

6

-

7 minutes ago, KeithAug said:

The more you practice the luckier you get.

That's a quote from the Swedish alpin legendar Ingemar Stenmark, who upon the question why he always seemed to be "lucky" ie not bailing out during runs and so, replied with "I know nothing about luck. But the more I practice the more luck I seem to have". 🙂

- Rik Thistle, Keith Black and mtaylor

-

3

3

-

8 hours ago, Jim Lad said:

I bet there was a lot of double checking of the alignment before you started drilling, mate!

John

John, part lucky, part preparation and part a long true, sharp drillbit.

With the jig I got a good aim longitudinally. Elevated aim could have been better as it shows. But I am not too concerned about that.

- Mirabell61, mtaylor, Jim Lad and 1 other

-

4

4

-

Practise, we all need it 😉

Good light and magnification devices are also crucial.

But hey, do what works for you Alan.

- mort stoll and mtaylor

-

2

2

-

-

Thank you @Mark Pearse, too kind 🙂

So, drilling for the prop shaft then... or probably arboring, right?

It seemed from the plans that the shaft is parallell to the keel. That's convenient. So I dreamed up a small contraption to get hight and angle (mostly) right.

With a sharp drill bit I bore away.

It came almost at right height. Lucky me I'm not installing an engine. The surface where it surfaced is the mizzen mast step. There was a neat little cavity to step the mast in. That cavity is a fair bit bigger now, and makes for easier stepping. You have to look on the bright side of life 😉

If you think that the interior has somekind of shine to it, it is correct. I brushed on a layer of lacquer, water based. Another thing you can admire is the tight to no gaps between the planks. It seems I made something right during planking 😄

(no, I am not being humble today. This cold I got really doesnt wanna give in, so I trying my best to keep the spirits high. No @KeithAug , not THOSE spirits!)

Pax et bonum

-

Just like druxey described. Mark the width of the notch with the favourite no11, then carefully chip away. My mini chisels are 2, 3, 4 mm wide.

We are probably addressing different kind of nothces also. I'm mostly thinking of the carlings. Since it is hard to the eye if they are not i straight lines. Notches for knees and stuff are another matter. For them I guess it is not the same visual eyesore if they are slightly out of plumb (or whichever angle they are)

-

-

Thank you gents!

Keith, I am glad that you finally dropped that shady idea 😉

- Keith Black, KeithAug and mtaylor

-

3

3

-

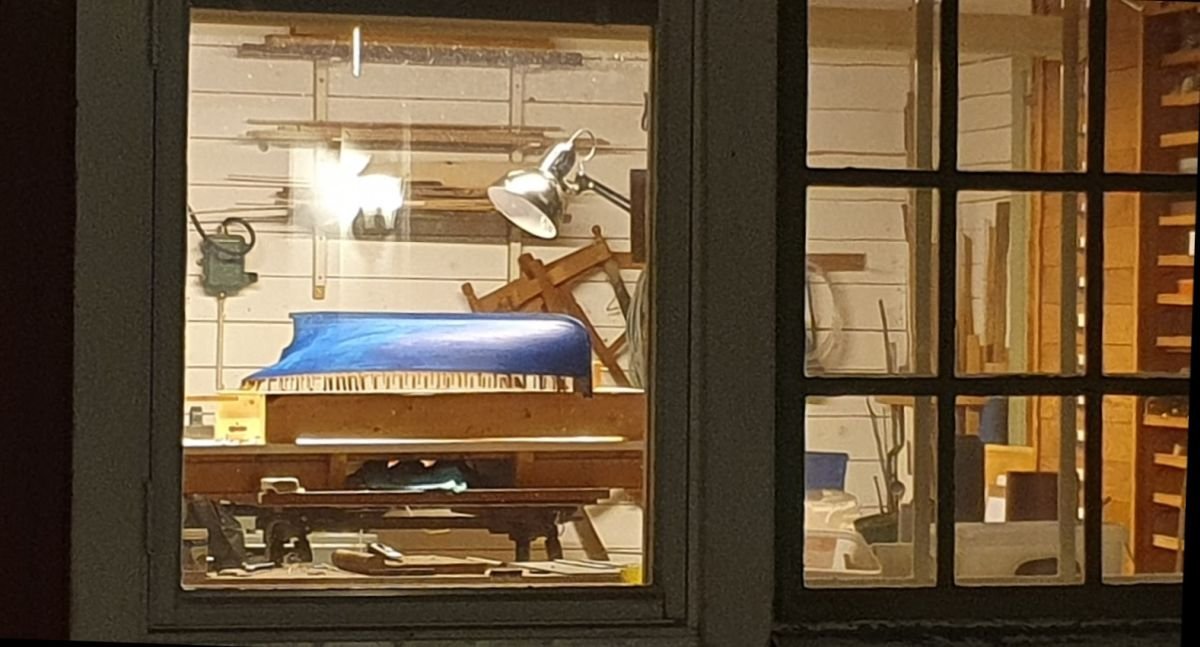

Calling in sick has its advantages on modelling time... but it does not help the revenue, so I'll go back to work tomorrow. Feeling way better today than yesterday. I even fell asleep mid-day yesterday. I normally don't do that. "What so special about that? I do that every day", I hear you say. Well, I'm not THAT old yet. 😄

Thanks for all the likes in my humble build log.

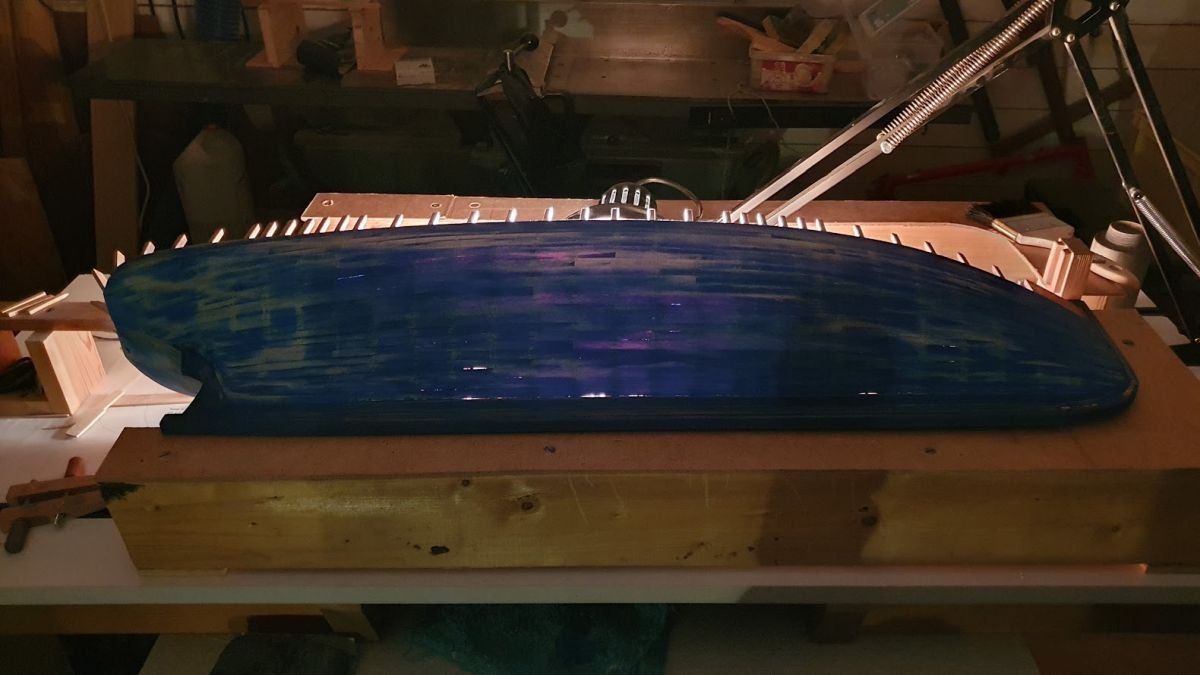

Wisky plank is in!

And all treenails are in.

Hull i sanded, painted, and sanded down through 100/120/180/240 grit. Yes, there are seams still open. Yes, you can see individual planks. Yes, it is not a museum quality piece. In fact, I will try to weather it a bit to go with the less than meticisously perfect hull.

And I thought this image looked cool:

Look @KeithAug, I did not turn it into a lamp-shade material!

Next up... hm, two things, 1. rudder shaft and rudder. Need to find the drawing and print according to scale. And 2. Drill for prop shaft. Needless to say, they will be done in reverse order...

Pax et bonum!

- berhard, rlb, GrandpaPhil and 10 others

-

13

13

Atlantica by Wintergreen – Scale 1:30 - POF - sail training ketch - a smack of English heritage

in - Build logs for subjects built 1901 - Present Day

Posted

Thanks @Jim Lad, I thought it'd be a nice Sunday challenge 😄

@KeithAug, well, I do in fact own a lathe (for wood), but how that is going to help me turning out coamings is beyond me 😛 Any tips?