-

Posts

940 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Wintergreen

-

-

26 minutes ago, Mirabell61 said:

excellent planking job Wintergreen

Thank you Nils!

I've done my best so far 🙂

- Mirabell61 and mtaylor

-

2

2

-

Thanks for likes and comments 🙂

2 hours ago, wefalck said:If the interior of the ship cannot be seen, you could have used 'fake' butts by putting a small piece of wood behind the strake, where there is no frame to land on.

Wefalck, that is of course a fair advice. Thank you.

I did not think of that when I started and now it is too late anyway. I guess it is one of those thousand small tips that one collects over time and when gaining experience.

Andy, yes, this ice age is soon over thankfully.

Keith, better you prepare your socks and long johns then?

- Mirabell61, Keith Black and druxey

-

3

3

-

20 hours ago, KLarsen said:

I'm finding it really hard

Well, you are not alone with that feeling 😉 It's easy to feel inferior when looking at some of the builds here on MSW. Then we have to remember that with any performing art there are thousands, and even tenth of thousand hours behind in training to perfection (or as close as you can come).

You are doing good from what it seems!

Keep it up!

-

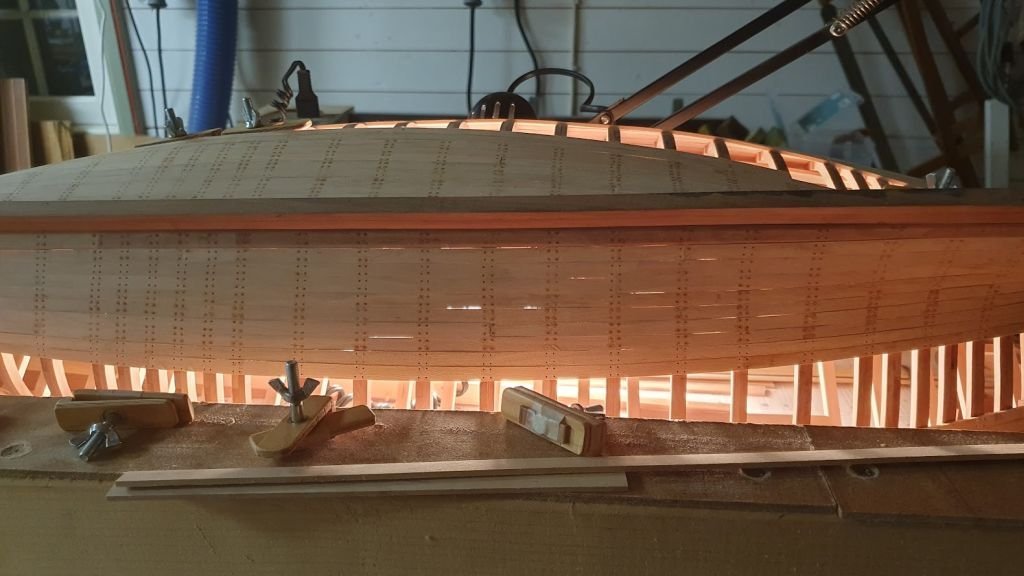

Soo, the plan to have the planking done by tonight failed.

Why? Because a couple of reasons. One - yesterday and the day before we had arctic temperatures here at -22 C/-7,6 F and my shop is of course insulated, but not to cope with such temperatures. Hence no boatbuilding done yesterday. Although I have an air heater at 9kW I couldn't be bothered spending all that electricity it would take to raise the indoor temp to a reasonalbe level.

Today it was "only" -10 C/14 F, so I cranked the air heater on. But sadly, everything out there is cold and I also have lost my mojo temporarily. It is what it is.

Here is the current state though. Three strakes left to do on each side.

For the next time I plank a hull I will be more pre-planning. Both in regards to the run of the planks. You know, divide each side in sections and make sure all sections have a fair run. And secondly about the butt shifts. This current build it is not exactly up to specs. The specs being three strakes in between for butts on same frame and 5 feet apart butts on adjacent strakes and 4 feet apart with a strake in between. Since I left out every second frame I only have the 4 feet option for large parts of the hull. As I didn't pre-plan, now when things come together I can't follow the specs either if I want to have reasonable length for the planks.

The plank length is another topic that I haven't research a great deal. I reckon a manageable length is somewhere in the ballpark of 18-27 foot. Can anyone confirm that?

- FlyingFish, mtaylor, KeithAug and 11 others

-

14

14

-

Looks good!

I am looking forward to the ships boat build. When I build my Regina I opted out for the boat since I didn't had the skill at the time. Maybe I can muster some confidence I try it some time.

Sails and rigging also looks up to par (golf term). I hope you can share a closeup of the crowded area around the mastheads later when all is nice and tight.

Keep it up!

- Keith Black and bolin

-

2

2

-

-

12 hours ago, KeithAug said:

but if you are dissatisfied you can always convert it into a lamp shade😃.

Thank you Keith, that made me chuckle 😄

No, I don't think I'll convert it to a lamp shade 😋

12 hours ago, Jim Lad said:Don't be too hard on yourself over those light glimmers through the planking - they'll be totally invisible once the deck is on.

Yes, I know John, I know. Thanks for the appreciation.

Also, I will paint the hull and that will take care of all the small crevises I think.

Cheers!

- Keith Black and Jim Lad

-

2

2

-

Had peace of mind to browse through some build logs here and re-discover your Meteor build. I'm glad to see that you're finally allowed back to a "normal" state.

It strikes me that the Meteor hull without bowsprit and what not is very similar to Endeavour (or any East India man for that matter) although almost a century younger.

Ship design did not evovle quickly back then. Mostly because lack of science I guess and that the marine environment (socially) were reluctant to changes.

Anyho, glad to read an update here John!

-

On 11/18/2023 at 7:35 PM, KeithAug said:

What a pity, but there is always next year.

Speaking of which...2023 soon in the books.

After my last update in early November I had a thought that I would wait with next update til the hull was all planked.

But then I thought that if you were to wait that long you'd probably would be thinking that I'd abandon ship.

So, here is an update on the planking progress. My new plan is to have the hull planking finished when I venture back to work in a litttle over a week from now. Will see how that goes...

And a rough cut stern.

The planking looks decent from a distance (remember, it is more than 30 years since I last planked a hull...), however, like Jake states in Blues Brothers: "I can see the light!" 😄

But, oatevva, thatts what caulking is for innit?

I bid you all a (select all that applies, multiple selections are possible):

- peaceful

- merry

- wild

ending to 2023 and a prosperous new 2024!

- Mark Pearse, Keith Black, berhard and 7 others

-

10

10

-

That's excellent Alan, well done!

I give you an A for effort but not only that, you also receive an A for execution. 😉Step back, dim the ligths and admire your wheel, because it is worth it.

Keep it up!

- AON, mtaylor and mort stoll

-

2

2

-

1

1

-

-

-

Thank you Brinkman, Vaddoc, Keith!

Yeah, carvel built boats are very different compared to the klinker type.

And yes, I appreciate birch a lot. It takes steam and bends easily. It is a bit on the soft side, but as long as you have that in mind it works out relly well.

Keith, yes the summer was cut short due to c**p weather and engine troubles.

- Keith Black and mtaylor

-

2

2

-

-

That's a simple and accurate way of controlling the angles. Very clever Siggi 🙂

- druxey, Siggi52, Hubac's Historian and 2 others

-

5

5

-

Thank you Mark, you are absolutely correct in you assumption!

There are several ways to skin a cat, sorry, to plank a hull.

Planking with the hull upright wasn't working practically.

Why not upside down then. Well, I couldn't fit the hull on the building board in a secure and safe way. Would need a second board. Also, access to the inside, handling clamps and such is not possible hull upside down. In all fairness it must be said that I bugged up a bit in laying the deck structure, but I can still reach in and fiddle with clamp despite the deck beams when on its side.

So basically I just dreamed up a jig that would hold the hull somewhat secure laying on its side. The jig looks sturdy but flexes at the stem part. No worries though since I planked the beam shelf inside. The hull is rigid.

Why two? Well, I cut the planks in pairs and it seemed efficient to do the planking switching sides. Also, the room for creeping errors is less when you constantly can check that the plank ends meet at opposite side of stem and stern. Now I plank two strakes on one side, one going down and the other going up the hull, then flip the hull over and repeat.The planks has some shape to them and cutting two blanks at the same time saves time and brain cells.

-

Nice black smithing! Very neat hardware.

Maybe you want to shave off the lower edge of the rudder a fraction. The reason being to prevent the rudder from un-shipping if the boat is grounding. Again, just a minor detail.I also think you are correct in giving the rudder a shaped cross section, even shipwrights of old must have had an eye for that I presume.

Keep it up!

- Brinkman, Mark Pearse and mtaylor

-

2

2

-

1

1

-

Thank you Andy, Per and John. 🙂

Progress is actually quite good given available time. I'm happy.

- Nirvana, Keith Black and mtaylor

-

3

3

-

- davyboy, James G, JacquesCousteau and 11 others

-

14

14

-

Guess a lot of us have...

How about addressing something other than the issue that keeps you from the build? Plan for rigging, do some other small tasks.

Usually, practise makes perfect, and if we always stop at the same step, we will never succeed.

I know my planking on my current build is not perfect. There are gaps and other ugliness, but I've decided that I'm fine with that. My goal is to finish the build and at the same time practise some lost skills.Hopefully my next hull will be fairer.

Kind'a - just do it!

That said, if you can pinpoint what the trouyble is there are a lot of members here that will help you sort it out.

- Ryland Craze, Canute and mtaylor

-

3

3

-

What Steven said. Very nice progress 🙂

One little thought about the stringer. While it does look good on the model I think it would probably not been let into the frame tops. Mostly for the additional exposed endgrain from the notches. Yes yes, the stringer itself blocks some water intrusion, but I think it would eventually open up and let water in since it is subject to some forces.

Instead, pragmatically bolted to the frames without any notches.

Keep it up!

-

1 hour ago, wefalck said:

Interestingly, different countries seem to prefer different types of tools. For instance nos. 6 and 7 in the first picture I have only seen in France, while no. 3 in the second picture is an US American tool.

I guess that comes down to how the various trades has evolved in different countries. Like how dentists work in one countr vs another, watchmakers, jewellers and so on. I too have marvelled over this where one tool that is prevalent locally can not be found elsewhere or overseas, and vice versa.

- Canute, Roger Pellett and mtaylor

-

3

3

-

Hi @Mark Pearse, the design is influenced from one of the master builders here on MSW. Initially I had four excenters opposing each other, but I quickly removed one side and glued a steady support to one that side instead.

There is not enough friction for the pieces to stay in place without additional force. So the strip holder is a two hand job, one hand to apply pressure with the help from one or both the excenters and the other hand to operate sanding block or low angle block plane. I am left handed which is why the right hand is left to do the simple task of applying pressure.

I have yet to figure out how to sand/plane convex shapes in an efficient way. Adding small pieces for support is one way, but probably not the best.

- Keith Black, FlyingFish, Nirvana and 3 others

-

6

6

-

Very nice and well fabricated windlass Erik!

I really like the hull form in the picture above in your previous post. You can quite easy see the resemblance with the Swedish cog that I built a couple of years ago.

Keep it up!

- mtaylor and Knocklouder

-

2

2

Atlantica by Wintergreen – Scale 1:30 - POF - sail training ketch - a smack of English heritage

in - Build logs for subjects built 1901 - Present Day

Posted

Absolutely John 😄 If it continues to raise like this I'll bring out the shorts in no time. ha ha.

Re plank lengths, yes, my mind was playing with such scenarios also.