-

Posts

13,405 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

L'Amarante by marsalv - 1:36 - POF

druxey replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Sweet! -

Good questions. I think you need to do your own research. Look online in the RMG site. Check not only the plans, but contemporary model photos as well. An example: https://www.rmg.co.uk/collections/objects/rmgc-object-66464 Blow up this image. Although lo-res, you can see that the fore face of the bollard timber projects forward of the hawse timbers, above the line of planking - in this case.

-

My method is to use a long length of wire, and bend one end into a short 'V'. Then thread on the ring. The next step involves holding the two end of the V (inverted so gravity moves the ring out of the way) )in a parallel plier and squeezing the V together using a needle-nose pliers. I then release the ringbolt and, with fine wire cutters, cut the short end at an angle and then the longer end to make a stem. As observed by Gregory, the bolt is partially sunk into the wood. After drilling a suitable hole, I open it up using a miniature jewelers' screwdriver tip held at about a 35 degree angle. This forms a sort of countersink for the ringbolt.

-

Early carronade mounts are a subject in themselves. This was something I delved into some years ago for a 1782 fireship. From the evidence I could uncover in Caruana and elsewhere, the early carronades were mounted on the 'outside principle' and had no muzzle extension to limit blast spread. Also, there were no wheeled trucks on the inboard end of the slide. I'm about to read your pdf and may have some additional comments later.

-

While the use of wax or modeling clay (Plasticene) is very helpful to work out the problems of a carving in 3D, the process is quite different. In the case of carving, the process is subtractive, while modeling using a plastic material is additive. Sure, one can carve wax and clay, but if a mistake is made , one simply adds more material. Try to do that with stone or wood!

-

Welcome here ! Nice job on the pram. The puzzle under it looks challenging as well!

-

Fascinating. The 17th century English fashion paice was set is a similar way and, by the end of the 1600's, the two radius stem was also used, although sometimes in a slightly different way. Usually the lower radius ran smoothly to the keel. In other examples there was an angle at the forefoot as your example.

- 49 replies

-

- Wildmanden

- Turesen

-

(and 1 more)

Tagged with:

-

Sail feedback request, Mondfeld method

druxey replied to travis's topic in Masting, rigging and sails

Curious. I've never known real Silkspan to tear like that. It is, in fact, very strong. Are you sure that this was, in fact, SilkSpan? -

Sail feedback request, Mondfeld method

druxey replied to travis's topic in Masting, rigging and sails

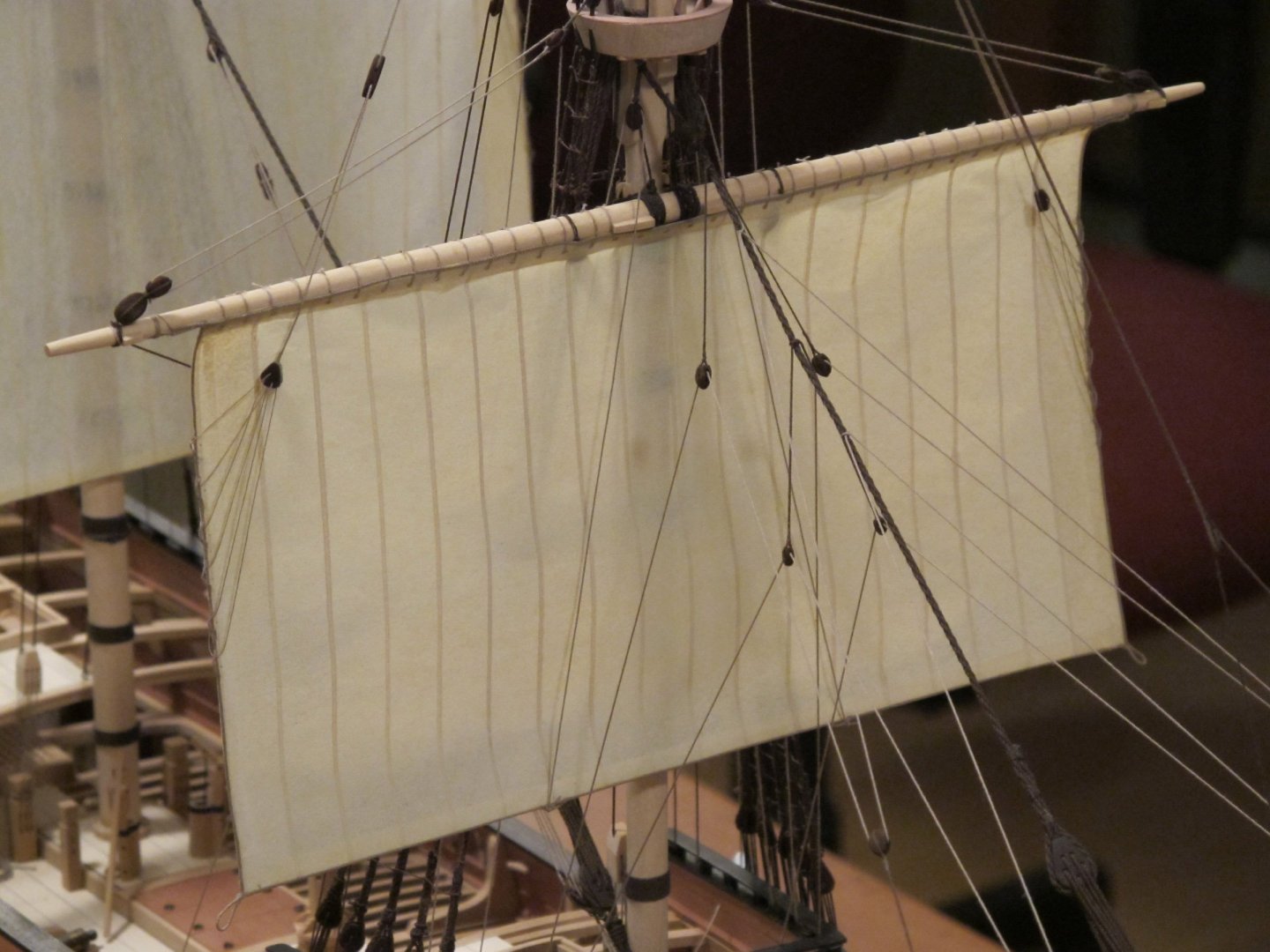

You've done a very neat job, but there is basic problem of scale. You mention 1:60, and one can never stitch that finely to be even close to scale, as well as the material is over scale thickness. What youa re doing is also very labor-intensive. Now, if that's the way you want to do it, read no further! A better way, IMHO, is to uses the material called SilkSpan. It is essentially a thin but strong paper product. The overlaps can be easily simulated with acrylic paint applied using a bow pen. The reinforcing edges are glued and rope also applied using white glue or matte acrylic varnish. An example is pictured below at 1:48 scale. Instructions of how to make sails using this technique are available through SeaWatchBooks: https://seawatchbooks.com/products/swan-iv-sail-making-supplement-from-the-revised-and-expanded-edition-by-david-antscherl

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.