-

Posts

13,374 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

This gets more interesting! Thanks for the replies on the fore ports.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Not an entirely satisfying answer, Chuck, but thanks for trying! If the windlass and bitts were moved 2' 0" aft, I could see that it might just be possible on the starboard side. The bowsprit would still intrude on the port side, though....

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Often 're-makes' give fewer headaches down the road than 'fix-ups'. Those station lines are good reference points for other structures, but if you shift some of the frames and not others, you'll end up confusing yourself. If I may advise, the re-make route is the better one.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Looking great, Chuck. One thing that's puzzled me for years is why there were large ports placed right up in the bows. There's no space to move, much less work, a cannon or carronade of any sort. Do you have any idea of the purpose of those ports?

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Real progress visually now, Frank. That is looking great!

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Try seeing how 6' 0" above deck looks for a starting point.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Nice simple method for ensuring the partners are on the centreline, Frank.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

One can never have too much line! I think you will be happy with Syren's cordage.

- 24 replies

-

- three sisters

- schooner

-

(and 1 more)

Tagged with:

-

Your choice, of course; but in the lower picture the boat hull looks a bit naked without its garboard strake!

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If you are working with rigging thread, you might wish to consider the line that the Syren Ship Model Company produces. (Scroll down and click the link on the right side of the cover page of this site for the Syren web site) It is produced in many diameters and is probably the best commercial line available. And you are right: patience is the word for any model work!

- 24 replies

-

- three sisters

- schooner

-

(and 1 more)

Tagged with:

-

Check the SeaWatchBooks site. I'm not sure of publication date, but it should be out sometime in the next three months, all other things being equal. Thanks for your interest!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Steamboats and other rivercraft - general discussion

druxey replied to Cathead's topic in Nautical/Naval History

My mistake: I'm remembering this from nearly 40 years ago, Gerhard! Thanks for the correction. However, looking at the photos you've linked, this was a much older Edeltraud that I recall.- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

Aaaand... you are out of the starting gate!

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Yes, Landrotten, that's one of many techniques that will be included. Slainte!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Postscript: Since the last posting there have been revisions! The sweeps were discovered to be sized for a single-banked boat not, as in this case, for a double-banked one. So, a new set of 12 sweeps have been made, 15' 0" as opposed to 19' 0". I also took this opportunity to paint the dolphins on one side the correct way up! Now, at the risk of incurring the wrath of the moderators, I'd like to mention that the full story, along with various techniques of making small open boats will appear in a full-color book shortly. Stay tuned! Again, my thanks to all who contributed to this log. You helped to make a better model.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Brilliant - as usual! Love the tooling as well as the final product.

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

Oops. my apologies, Frank. (Excuse: I was always poor at remembering people's names!) I agree: wood.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Coming along beautifully, Albert. The knees (standards, if they are that way up!) look right. I doubt if anything would be stowed along the midline anyway.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

See the pics I posted on your model log, MK.

-

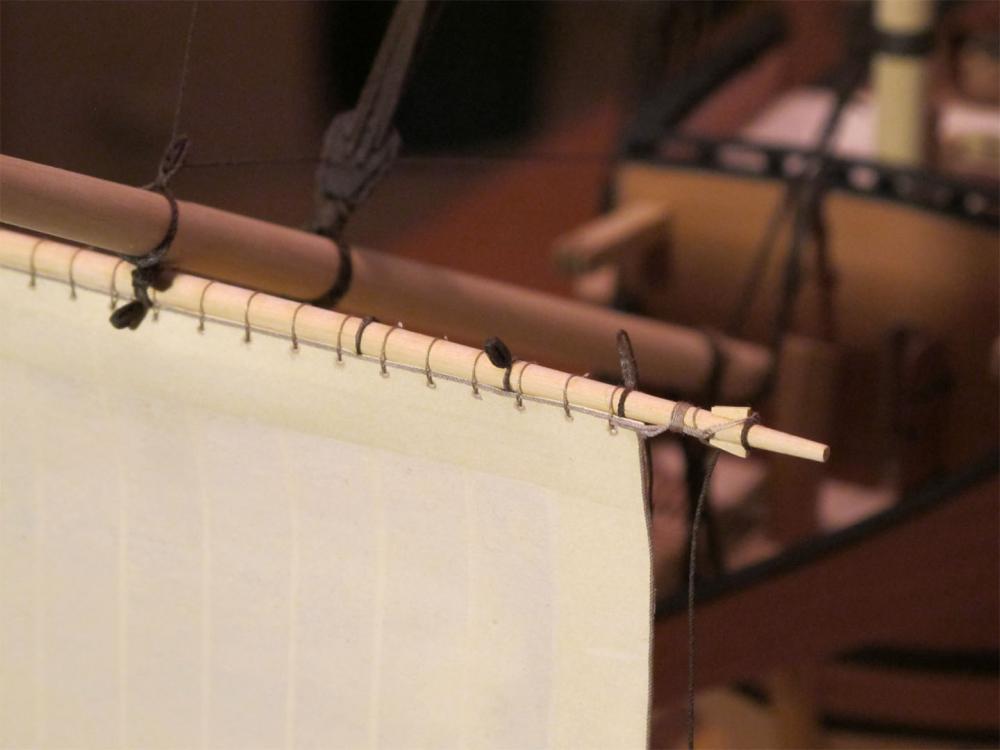

Don't try to sew at that small scale, MK. Take a look at paint on SilkSpan and glued bolt ropes, etc. in the photos and see what you think.

- 29 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.