-

Posts

13,369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Bandsaws are fine for straight and some curved cuts but, as Blue Ensign points out, cannot cut tight curved or intricate and thin pieces. Also, it's much easier and cheaper to replace a scroll saw blade!

-

The model making business is a continuous learning curve, Mark. She's looking much better. I don't know whether it's the photos, but check the spacing and angles of the counter timbers. They don't look quite equally spaced: particularly on the port side. If they are not, it will come back to bite you later when making the lights.

-

Yes, Ed, I think it's 'rebranding'. I suspect the title The National Maritime Museum will be dropped after an interim period. Thanks for all the recent comments and 'likes'.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

The Radetzky March? No-one ever seems to know whether to clap on the beat or off, in my experience! (Generally, people hedge their bets and clap in between.) The extensions of the cranes would probably bend to conform with the hull inside. They would not pierce the hull.

-

It's always worth re-doing - you'll be happy once the struggle is over and won. Sometimes it takes several runs to get things right. Go for it!

-

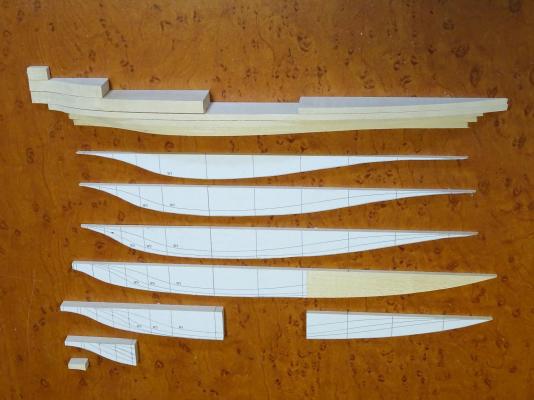

This is where I wish I were building at a larger scale! First the central spine elements were cut from 3" thick stock, with the exception of the stern post. This was cut from 4½" wood. The keel is very light at only 3" square and has a 1" rabbet cut into it. To prevent total insanity, I cut a scratch moulding contour into a piece of hacksaw blade. By rubber cementing the blank to some scrap board, this held it firmly. I cut the rabbet in for most of its length. To prevent an uneven rabbet, I cut the steel profile so that it bottomed out on the board at the correct depth. The stern post was tapered from its full thickness at the top to 3" at the foot. All the various scarph joints were then fitted using - believe it or not - a ½" chisel. When I was satisfied with them, I glued up stem, keel, stern post and stern standard or deadwood. The rest of the rabbet was carefully cut using a scalpel blade and very well-honed chisels. The bow was especially challenging at this scale, as the planks come in almost parallel to the stem. There may be a hiatus before the next instalment as I now have restoration work in the studio, and that has to take precedence.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

Well, practice varied between English and Continental shipbuilding. Generally British practice was to drop planks just under the wale as necessary. -

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

Chris: see my post #6 for the shape of a plank on a bow similar to Endeavour's. The shape is not what you'd anticipate. -

Michael: I'm planning on using Castello boxwood for all the elements. Usually I plank in holly, but the scantlings are so light on this craft that I need all the mechanical integrity I can get. The keel is only 3" square - 1/16" actual before cutting in the rabbet. (This instalment coming soon to an MSW site near you!)

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

Chris: in real life these planks would have been cut from narrower, naturally curved wood. -

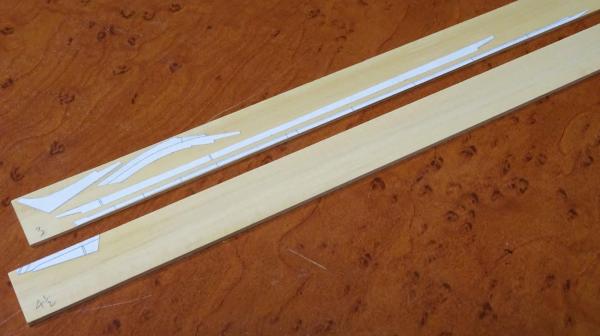

Well, some progress. The first photo looks confusing, but what i've done is rubber cement on the offcuts to the assembled lifts in order to be able to scroll-saw the profile of the boat. The second photo shows the profile cut into the starboard half-hull. The third shows both half-hulls cut and ready to shape. The last photo shows the central spine elements laid out for cutting. (The elements of this were not delineated on the original draught, so I had to be my own master shipwright.) More anon. Thanks for the 'likes' and comments.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

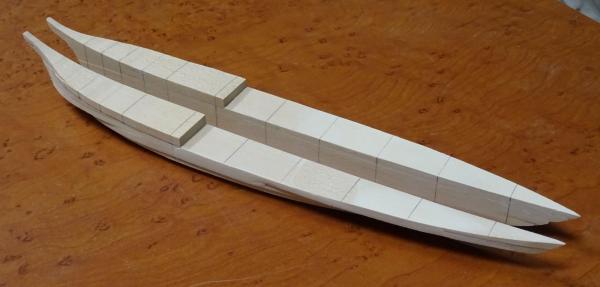

Thanks, folks. Yes, Joel, there will be cushioned seats and drapes, as well as a certain amount of giltwork. No unicorns, alas. Mark: the two hull halves are so that a central spacer can be inserted. The remaining slot will hold the keel, stem and stern in place while planking up. All will be revealed in time! Certainly making the plug in two halves helps maintain symmetry as well.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

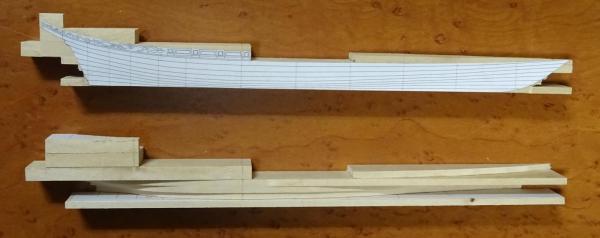

Thanks for the comments and 'likes', everyone. The next step was to cut out the various lifts. Copies of the half breadth were rubber-cemented on to the prepared blanks. The blanks were also paired together with rubber cement and cut on the scroll saw. The photo shows one half of the plug dry-assembled with the other half laid out. The overall length of this hull is a little under 10".

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

I'm now completely hooked on your Saturday updates, so please keep them coming, Glenn! I like that you decided to include the repaired cam frame, but don't yet see the iron wedge. Planning on including this?

-

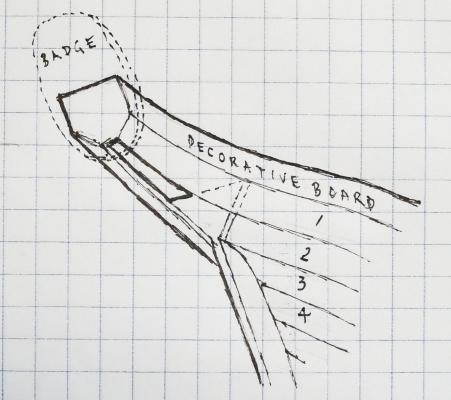

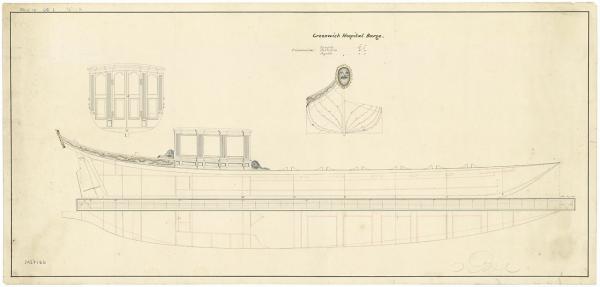

Now for something a little different: the Greenwich Hospital ceremonial barge of 1832. There is a draught in the RMG, formerly NMM, collection of this lovely sleek barge that makes an attractive subject. (Image allowable use by RMG.) Normally such small craft are modelled at a larger scale, but as I've been building at 1:48 scale for decades, why stop now? This is a part-time 'fun' project between other professional work, so this log may be rather sporadic. The first task was to develop a workable set of lines from the rather sparse draught. There were relatively few body sections (somewhat fanciful, as it turned out!) and no waterlines. One item that tripped me up for a while was what appeared to be the line of a 'knuckle' on the half breadth. While it more or less fitted the fore body, I could not get this to reconcile aft. Eventually I saw two very faint lines on the body plan: it was, in fact, a proof diagonal. Duh! Once I'd figured that out, everything fell into place and a fair hull form resulted. The clinker planked hull will be built on a plug, so basswood was prepared to exact thickness for the two half-hulls, less the thickness of the keel, stem and stern posts. One interesting complication is the pink-style extension of the stern (see sketch). Next up: cutting out the various lifts and assembling them.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Hegner (Swiss, I believe) are the Rolls-Royce of scroll saws, and commensurately expensive. Frolick is a fortunate fellow to own one. Almost as good, but much less expensive, is the DeWalt 778. I've used this saw for 15 years. It works beautifully and vibration-free.

-

Interesting solution to your dilemma, Ed. Seems like a very reasonable one, too!

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed, I once successfully sanded a wale after masking off the planking above and below with tape for safety. Hopefully any polymerized oil has not penetrated too far into a dense, close-grained hardwood.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

druxey replied to rafine's topic in - Build logs for subjects built 1801 - 1850

My smile for the morning, Bob. Very nice progress.- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.