-

Posts

13,368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Echo by Maury S - FINISHED - Cross-Section

druxey replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Further to yesterday's post, here is a photo of a baseboard that was veneered and banded using Titebond. The other advantage is that you can spot-tack the pieces in place: they don't 'grab' like contact cement. A little heat will reverse the bond so that you can reposition a piece if you need to.- 324 replies

-

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

It's nice not to have to fight and wrestle planks, isn't it? -

Echo by Maury S - FINISHED - Cross-Section

druxey replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Titebond is good if used the right way! Coat both the veneer and the substrate with glue. Allow to dry. Then iron the veneer to the substrate. (Careful not to have the iron too hot. A layer of paper will act as a bit of insurance.) Works a treat, and no contact cement fumes or strings! You could try ironing your wavy veneer down, Maury. Rubber cement is not permanent, BTW/- 324 replies

-

Nice detail, Toni! It's amazing the number of bolts of various sorts that went into a vessel this size.

- 1,449 replies

-

If one needs to paint, sanding lightly first before any solvent use would be good. Too much solvent may affect the glue in the model.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Part of your issue may be the thickness of the material you are using. Some modelmakers get better results using SilkSpan (model aircraft supplies).

-

Wayne: part of my issue is that Steel does not, in his glossary, define either 'stop' or 'lining' (other than 'lining out' - a completely different subject!). Thanks for the Fincham extract, as I do not have that volume. So, if I understand rightly, Fincham calls the inner layer of the port lid the lining, the pieces around the port opening the back stop or port stop. Is this definitive?

-

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

I haven't experimented with off-model edge-bending, Nigel. I've seen Chuck's results and they do look very good. I wonder if there will be a tendency for them to 'spring' later on, after a year or two? Similarly, how easy would it be to edge-bend a complex 'S' shaped wale plank accurately, such as shown here? -

To spile or not to spile...

druxey replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

With all due respect, Nigel, while one can edge-bend a plank to a degree, the ideal is as Joel states; "The plank should set onto the hull with no stress, totally relaxed". It imparts a good deal of stress to edge set a plank more than a few degrees. Heat and moisture can help, for sure, but I wouldn't want to attempt edge-setting planks around a bluff bow. I tried that on an early model of mine and, after a few days, the result looked like clinker planking, except it was supposed to be carvel! -

I've generally not had problems with Fiebings, except on one lot of wood where the dye uptake was blotchy and I had to paint.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

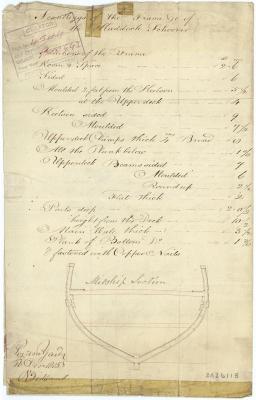

Coming into this discussion a bit late, but the rise in deckhead aft for the cabin overhead was not uncommon in smaller vessels. The step-up in Ballahoo/Haddock is a bit more unusual, but solves the same problem of restricted clearance. I note a gun port in line with this raised deck, so would not be workable. Speaking of gun ports, their sides appear to be parallel to the sheer rather than the keel - most unusual. George, were you aware of the nice section with scantlings for Haddock (ZAZ 6118) in the RMG collection?

-

Bee-utiful, Glenn! I'm getting addicted to your weekly progress postings. Might be fun to show the kludged spare cam frame....

-

Soldering dangerously close to the hull

druxey replied to popeye2sea's topic in Metal Work, Soldering and Metal Fittings

Another possible heat sink is to use a chunk of apple or potato (depending on your taste!). -

Frégate d'18 par Sané , la Cornélie

druxey replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

Bien fait, Monsieur! Je vous remercie pour les sabords flottants! Thanks for the 'extra' floating ports. -

Just catching up with your work, Clare. What delightful vessel! I'm sure other builders will appreciate your comments and helpful tips. Well done!

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

I've had a whole container turn to a solid gel, Mike.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thanks, Ed. I guess to get in to either the locker or the head, one would need to crouch over like Igor. "Walk this way."

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.