-

Posts

13,268 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

HMS Leopard by gobi71 - 1/300 scale

druxey replied to gobi71's topic in - Build logs for subjects built 1751 - 1800

Bulkheads and sides were most likely whitewashed below the gun deck. The deck furniture, such as bitts were red and the hatch coamings black. -

I suspect the real ship had wavy top timbers as well! Beautiful, nevertheless, Gaetan.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

I think your problem is trying to drill round stock. It's all too easy for the bit to skid off the copper wire. Might I suggest starting with square stock, drilling it, then turning it to round?

-

A further note on gesso: treat it as a sealer and surface filler. When fully dry it may be fine sanded.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Frieze background colors vary. Blue is common, but I've seen black as well as red. The painting by Marshall in 1775 of King Fisher (sic) shows quite a vivid blue! (Science Museum collection, Kensington.) Your choice, Ms. shipwright.

- 1,449 replies

-

Looks pretty good to my eye, Remco. Well done.

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Clear Shellac Sanding Sealer

druxey replied to grsjax's topic in Painting, finishing and weathering products and techniques

Shellac - aka french polish - will whiten if you get a spot of water on it, won't it? -

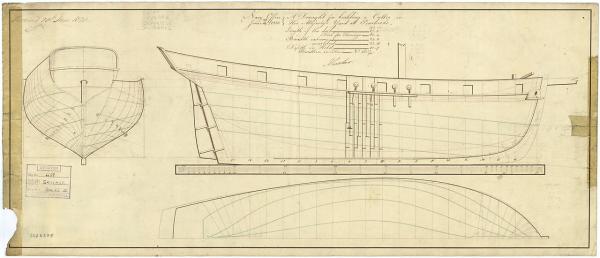

There it is! The black lines are external planking and the red the internal. It's hard to sort them out at such a small size, but much easier to distinguish at 1:48 scale. This drawing was actually done in the shipyard as the ship was being built!

- 1,449 replies

-

I think the widest marks were placed with the letters tight against each other, as the example from the NMM. These were from the wreck of the Royal George, sunk in 1782.

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

That is great news that the Hornet planking scheme is once more available! It is truly authentic.

- 1,449 replies

-

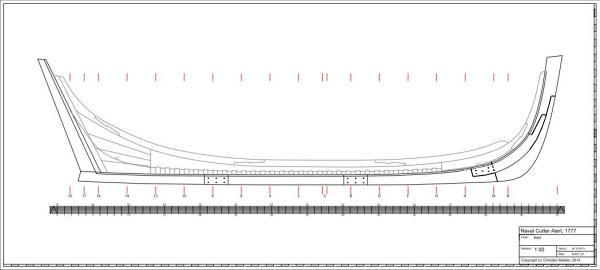

That Cheerful draught is unusual: if it was drawn that way, it must have been done like that. However, I'd say that was most unusual. The strength of the joints would be compromised and more bolts would need removing to replace the forefoot or gripe piece. The attached image is rather small, but demonstrates my point. (If you click on it, it will enlarge.) Note the keel joint at around station 6, aft.

-

Some ships' draught marks were made of sheet lead: some have been recovered from wrecks.

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Agreed, Chuck: that would be my conclusion as well!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well, the Holman painting certainly muddies the waters! However, I think there is another clue on contemporary plans. If there is only a rail above the port opening, there is no 'meat' to fix port hooks. Therefore no lids. However, if there is at least one strake of plank above the port, then that would provide material for the hooks and hinges. Look at the Holman painting again: one strake of plank over the ports with lids. Cheerful/Surly fall into the first category. Conclusion: no port lids. I rest my case, m'lud.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Admiralty Models is running sailmaking workshops shortly.

-

I suspect bucklers were the thing if freeboard were low, making her a 'wet' ship. Otherwise, port coverings on an open deck make no sense.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You should be able to cut and fit hanging knees in your sleep by now, Ed! She's looking beautiful.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Lovely draught marks, Remco! Are you putting them on the stern post as well?

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.