-

Posts

13,130 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

50-gun ship by newbee - 1/72 scale

druxey replied to newbee's topic in - Build logs for subjects built 1751 - 1800

There are 5 sheets in the plan set, apparently. The how to model this subject was described in a series of 1953 Model Engineer articles by R.J. Collins. I believe that the plan set is still available (search on-line) and old copies of Model Engineer can be found on e-Bay. Happy hunting! -

Renshape for scratch builders

druxey replied to rshousha's topic in Modeling tools and Workshop Equipment

High density foams have been around for a while. I've used them in theatrical set construction in the past. They work very well for carving in detail but, as mentioned, are very expensive and only available in large chunks. My only reservation would be the longevity of the material, but for most folk this probably isn't a big consideration.- 11 replies

-

- scratch building

- parts

- (and 8 more)

-

Superb work, Ed - but now you've made me run out of superlatives!

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Interesting thread. I recall visiting an English country church in my childhood. There was an ossuary in the undercroft with stacks of both femurs and skulls. I presume these had been disinterred from the churchyard to make room for newer arrivals (think of the graveyard scene in Hamlet).

-

Pete is correct: in the 18th century the copper strakes started at the keel and were laid parallel to it. This results in the highest strakes running out at an angle fore and aft at the waterline. On way the sharp ends were dealt with was with a wood batten nailed along the waterline overlapping the edges of the copper. Another, probably later, way was to run the top two strakes of copper along the waterline. See the photos of a coppered model of Bellona on the National Maritime Museum's 'Collections' site that shows the earlier method.

-

I like your pin-holes idea for maintaining position of the square on the building board. Good move!

- 889 replies

-

Card, ply; it doesn't matter which material the square is made from. The important thing is that it's not made of metal, so that if it falls over on the model it won't damage it.

- 889 replies

-

I don't think anyone gets this right the first - or even second - time around. Eventually you will nail it, Ben. I find that a heavy card square set up on the board aligned with the layout helps a lot.

- 889 replies

-

"What will they think?" That's a pretty powerful motivator, Ed, especially when you've set our expectations so high! But you've never disappointed us yet.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

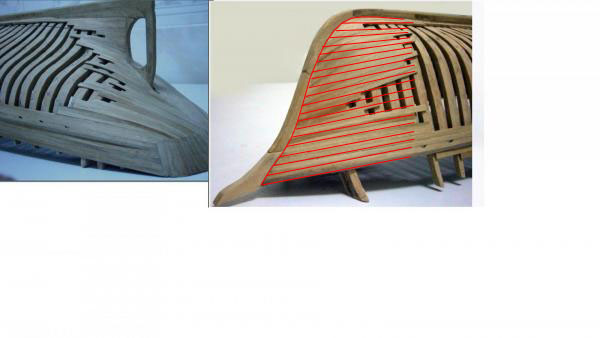

Sorry, folks, but I respectfully beg to differ. The planking runs at the bow don't look right to my eye. The garboard strake runs too far up the bow, causing crowding further up the bow (if it were the right way up!). See my sketch for what I think would be closer to the way it was done. Others have already commented on the plank butt scheme, which seems random to me. However, ultimately the result has to please the builder.

-

That last photo, with the height of the keelson, gives one a real appreciation of both the original ship's structure and your re-creation of it, Ed.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

From contemporary models, the wash cants appear to be composed of planks laid diagonally, as Dan has shown.

-

what is the ideal modelling table?

druxey replied to AON's topic in Modeling tools and Workshop Equipment

Better smuggle your new stuff in using plain brown bags, Alan! -

That is probably one of the most tricky strakes in the whole build. Your scratch molding cutter worked very well.

- 1,449 replies

-

No apology required. Curve - I mean curse - spell-check!

- 889 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.