-

Posts

527 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by knightyo

-

Thanks Steven! Montaigne has made me think about adding perhaps two chests or maybe even a small side table. One with a scroll of my name/build date, but perhaps the other with a scroll with a funny/inappropriate limerick or such. That would sure be a surprise to a future viewer. It would destroy whatever thoughts they had about the builder, however. lol Decisions, decisions...... Alan

-

Those are absolutely gorgeous. I also think they look the best when matching the color of the surrounding wood, and agree that the center looks best as constructed the same as the outers. Are you going to have individual panes for each "square", or one sheet of acetate for each pane? The posting recently in which someone used a heat gun to "melt" plastic sheet around panes giving the illusion of individual windows was pretty nice. Alan

-

One of my longstanding and fairly irritating quirks is to jump into a project, get so focused upon what I’m doing, and ending up doing something exactly wrong because I’ve forgotten the big picture. That quirk has shown itself again; at some point, I’d forgotten that the drawer in the binnacle is actually what the compass itself sits within; it’s not a separate stand-alone drawer for maps, etc. The below photo from “The ships of Christopher Columbus” shows how that drawer is supposed to be used, which I’d completely forgotten about once I started to cut wood. That shouldn’t be impossible to fix however, and it will actually allow me to create a little more elaborate compass than I’d originally intended. I think I’ll cut a piece of brass round-stock to shape, insert a small printed compass image within, with perhaps a coating of something over the top replicating glass. I’ll unfortunately have to get rid of the scroll/map in the drawer with my name/build date, which is disappointing. I guess the scroll/map turned out to be slightly oversized anyway.

-

I have Reed's books as well and have always been very tempted to build the exact ship he did in the exact manner. I know I'll never get around to doing it however, at the slow rate of speed of my other projects. One thing I'd point out to anyone considering a small scale is that once you are used to working under magnification, it's not really any more difficult to build at a small scale than it is large, especially once you get used to "bracing" your hands/work. I've grown very attached to a pretty low-quality, inexpensive magnifier I use to work on my Nina. I tried the optivisors, but to me, they were almost more of an irritation than a help. It's much easier to work under a "desk lamp-arm style" magnifier. The only drawback to working in a small scale is your audience. If you build a ship that is a couple of feet long, your viewers will probably be far more impressed than they'd be by a tiny ship, which may have taken you just as much time to build. They may also be more likely to label you as weird. However, since we are really supposed to be enjoying this hobby for ourselves alone, neither factor should matter. Alan

-

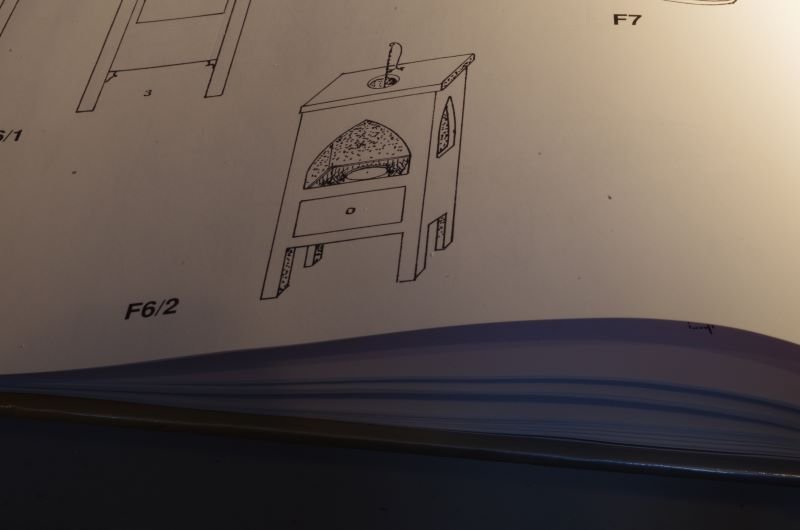

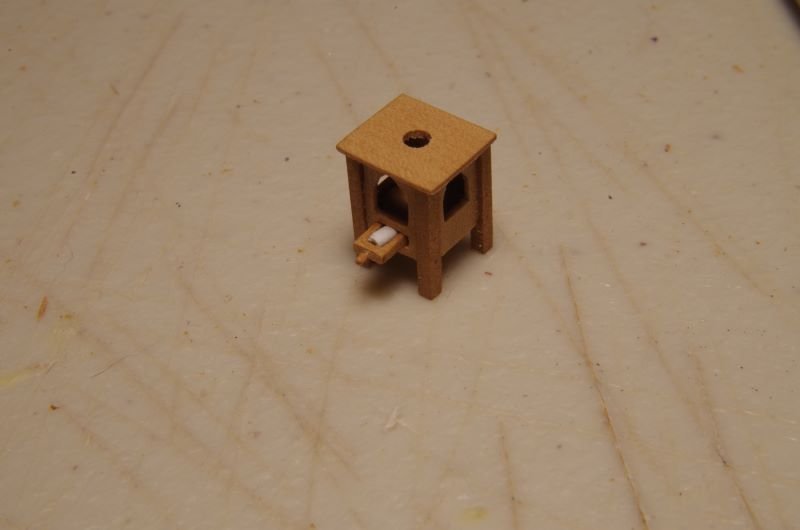

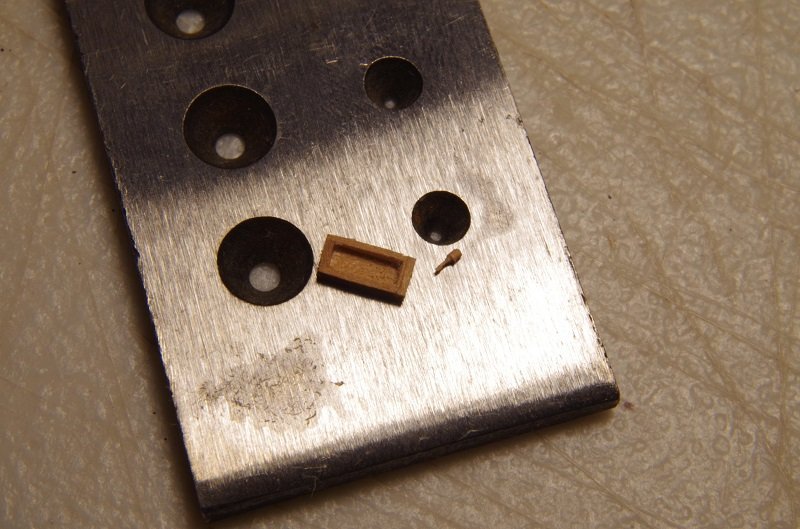

Ok, still plugging away on this one. The below parts have been burnished a bit to see what the final look might approximate. They are still a bit thick however, so will be thinned out a bit, and the recessed areas near the tops will also be thinned down more. Then they'll receive trennails along with the adjacent knees. I'm still building up the back quarterdeck area, so not really affixing anything to the deck yet which could be knocked away. Binnacle! I've been building up the binnacle, which I'll be able to install after the masts have been installed, and the quarterdeck complete. Below is the drawer, and a little knob which was almost impossible for me to make. They are resting on my drawplate next to the smallest hole. I couldn't see what I was doing with these pieces unless working on them under magnification, but I'm happy with them now that they are done. Below is the main body of the binnacle with the drawer hanging out. If my printer will do it, I'm going to print a scroll with my name and build date, and will then place in the binnacle drawer which I'll leave slightly ajar. The "pegs" sticking out of the sides will be clipped off and sanded down; they are just trennails which have just been glued in and are drying. There will actually be 4 more attached lower on the legs. Once that's done, I'm going to be cutting a circle in the top of the binnacle for a light to hang down into it, which will illuminate a very small compass, providing my printer can print it small enough. Since the backside of this binnacle will be resting against a mast, I'm thinking of installing a very small led up through the deck and between the binnacle/mast, and into the back of the binnacle, which can then provide light. Hard to explain, but I'll post pics.

-

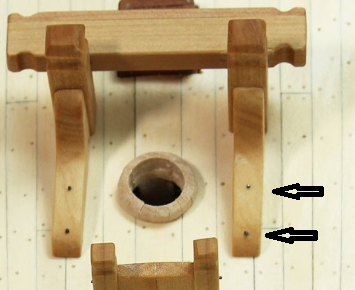

Thank you Allan, that was exceptionally helpful, and explains why there were only bolts shown on the bottom parts of the standards on tlevine's work. I might do two bolts on the bottoms of the standards, and trennels on the tops. Below is what I'm approximating, (working replica of Pinta), but it's hard to tell how they were constructed there. I don't see any bolt protrusions, but for this working replica, they might not have been trying to replicate the original to that degree. Or, they were, and trennals are just the way to go all around. Decisions.. Alan

-

This might be a fairly obscure question, but regarding a photo from tlevine's Swallow log below... Are "fasteners" to be inserted ONLY on the bottom portion (see arrows) of the standards? I'm close to attaching similar components on my 1492 caravel (bottom photo), and am not sure of how I should reflect the fasteners; for that matter, I'm not sure if they should be trennails, or raised nails. Any guidance on this would really be appreciated. I do know that the standards are currently too thick, so will be adjusting that, but I'm really wondering about the fasteners. Initially, I was thinking that I'd apply fasteners to the upper sections as well, but now I'm assuming that tlevine's fastener's are correct, and that I'd I'd install two of them, both on the bottom section of the standards, but wanted to pick the collective brain of MSW on this one. - Alan

-

My palms became sweaty while reading this thread. I never would have made it in the navy. Ironic, as building models ships is my passion. lol Alan

-

Ok, so working at my usual pace, but incremental progress is better than none, I suppose. The entirety of the hull inside and out is now planked with pear. It's dusty in this photo, but compressed air and brushes should remedy that before any finishes are applied. I'm considering applying tung oil and/or shellac, and will be experimenting quite a bit with both. The replica Pinta had a unique looking capstan which caught my eye, and which I wished to replicate on the Nina. Who is to say that the original Nina didn't have this type capstan as well? Below is a start, but will need to be "skinnier" to match the replica; especially the center "X" sections. Not pictured are a few more brass parts I've cobbled together which will need to be blackened. Time to start working on these little guys. Making these at this scale is quite a challenge, and I'm having to make these under magnification. It's still a satisfying exercise, however.

-

Thank you both! I will start performing some fairly vigorous experimentation with both shellac & renaissance wax. Ironically, scraping is indeed how I started out finishing the rails; however, I was clumsy and ended up with numbers of fine "cut" lines that I ended up sanding out with a very high grit wet/dry paper. What I'm left with is burnished large surfaces and unburnished small pieces, recessed pieces, etc. Alan

-

As I've been toiling over my small Nina project, I've ended up basically burnishing the wood in numerous sections. The rails for instance, are swiss pear, and in a "burnished" state really have a nice look. Are there any recommendations regarding what to apply over burnished wood? My Google searches have made it pretty clear that standard finishes are out as the pores of the wood are effectively sealed when the wood is burnished, which makes sense. Has anyone experimented with applying any type of finish over burnished wood? Alan

-

RGL, you should know that you are responsible for about 5 of my model purchases. Oh they'll never be finished, but this thread inspired me to buy them. lol Alan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.