-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

I hope that the 1045 is a typo since I don't think this ship is that old.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

I'm still working on the galleries... specifically at this time the finials. Tiny little things they are and I suspect that for me, the photo etch on them will be a big stretch. One is done and the other is getting there. I do see it needs a bit more shaping to match the curve of the stern. I hope these actually look like what drawings and photos show.... Feel free to critique in the comments. Gap filling and paint will come as soon as these are done and glued into position.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

M29 Weasel family 1/72 (scratch) by Backer Finished

mtaylor replied to Baker's topic in Non-ship/categorised builds

A regular assembly line you have going on there. -

Their engineering and work arounds created some problems for other countries. I forget which one it was but super fast and no one had seen one up close until the pilot defected. They were beyond surprised when they found round rivets (not flush) holding the skin on the fuselage and massively overpowered engines to make up for the drag from the rivets.

-

Phil, I see no reason for you not to scratch build parts where you think you can do better than the kit. Kit Bashing is a noble trait.

-

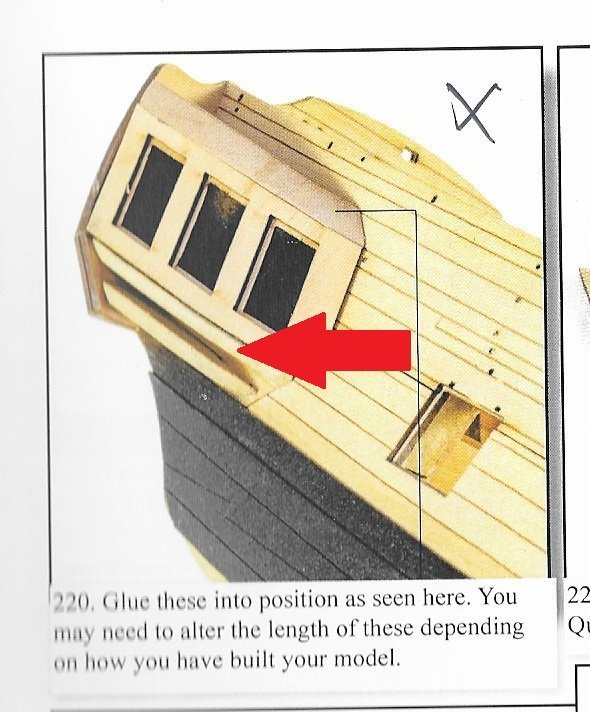

This isn't really an update but a suggestion..... I'm working on the quarter galleries and I hit instructions 218 to 220. I was trying to figure out how to install that piece and running into problems... tweezers didn't work... too thick. Finally, I took a bit of scrap wood to use as a spacer and glued it to the piece then glued it into place. As a side note, I think it was about 0.8 mm thick for the spacer but was trying different thicknesses until I found one that worked.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

I'm trying to remember where I read it but apparently turpentine was used on wounds. I'll have to find that reference and see if pine tar is mentioned. There might be an association by observing whose hands/feet became infected and whose didn't.... climbing the rigging barefoot vs shoes.

-

Drill some holes and test. Too many or too large and the insert will deflect and may even break. Do you have a shop vac attached to the saw? Those help also. I have found on my table saw and scroll saw that while the vac helps, there will still be dust after the cut. Just not as much. Your cuts on the wood look good inspite of the way the grain is running in all directions.

-

PM Tom (CAF) and ask if it's available. All CAF models are legit as I understand it.

-

Hi Rick, welcome to MSW. You've made a good choice for a first build. I hope you'll do a build log as it's a great way to get help with questions and also to meet others.

-

Well.. since you have to wait, here's some links to some reading material. Pretty general stuff but there's some good info. http://www.mini-lathe.com/Mini_mill/Main/mini-mill.htm https://www.littlemachineshop.com/Products/product_new.php (goto the "Learning Center" link at the top. There's probably more out there so check the Proxxon site and see what they have.

-

One of the proposed alternatives to the Panama Canal

mtaylor replied to bruce d's topic in Nautical/Naval History

That would have been a bit bizarre to see. I can't imagine it being expanded for the large battleships, etc. that have used it over the decades. And hopefully, no strong crosswinds..... -

Exactly, Dave. I suggest reading the tutorials/watching the videos here on MSW. (Up top....."More" and then "Planking Techniques". Some of us use very thin pins when needed (like T-pins) and pre-drill the hole slightly smaller than the pin diameter. A spot of glue over the hole while sanding hides the hole.

-

Looking great, Gary. The mech at the bench is definitely a plus. As for the engine... a bit late but you could cut off the "tail" of the transmission. Given the angle it was originally sitting at, it would look more like a manual trans and the ignition cables would be visible.. See attached photo on what I'm talking about. As an aside.. the "train your wife" photo wouldn't fly and depending on who sees the shop, you might get some backlash. LOL

-

Sandbags? Interesting. Possible I think or maybe it "tote" sacks filled with cotton, etc.? Seems discussion on historical correctness is a common topic around here. I hope you can find some more info on the colors, etc. I believe what Roger says about painting and rust. Being from the mid-west, the humidity can sometimes make you wish you had gills instead of lungs.

-

Part of our problem with ships of the age is that while we can find the evidence (Viking ships come to mind and all that follow) our knowledge is limited. Much was not recorded because it was common knowledge back then. Sadly, much of that common knowledge has been lost. Lost knowledge even hits us now...cars for example. How many 20-somethings actually know how to drive a stick shift? Change oil, spark plugs, etc. Or adjust the points in the distributor? The info is out there in books. The problem is, there are no books from the deep past. Bob, you have sea in your blood. Many of us (most?) don't. It's good that you do as you have a perspective that many of us don't have.

-

Glen, I picked up fettling from some of the builders here on MSW. Kind of fits in my mind. To me it's a mix of "fixing", "grumbling" and "multiple redo's. LOL

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks, Dave. I'm not in England for Oregon in the US. My doc and hospital have a good reputation so I feel I'm in good hands.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.