-

Posts

360 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Alex M

-

-

-

Very good planking, Lee!

I find a clinker hull easier to plank than a carvel one....How many clinked hulls you have build? Can you show us fotos?

Alex

-

Perfect mast partner, very fine work, Remco!

Alex

-

Hi druxey,

I assume, that those technical drawings show the actual shipyard practice.

Alex

-

I'm sorry if this make you less happy, but the whole is more complicate, as far as I know...

The garboard plank was beveled in mostly cases to match the rabbet. As clearly shown in those drawings:

The garboard plank was beveled in mostly cases to match the rabbet. As clearly shown in those drawings:http://collections.rmg.co.uk/collections/objects/85449.html

http://collections.rmg.co.uk/collections/objects/80965.html

http://collections.rmg.co.uk/collections/objects/80745.html

here the later practice:

http://collections.rmg.co.uk/collections/objects/80704.html

and here a couple of frame drawings that show tre rabbet and garboard planks:

http://collections.rmg.co.uk/collections.html#!csearch;searchTerm=Telavera_1818;start=10

-

-

-

Hello,

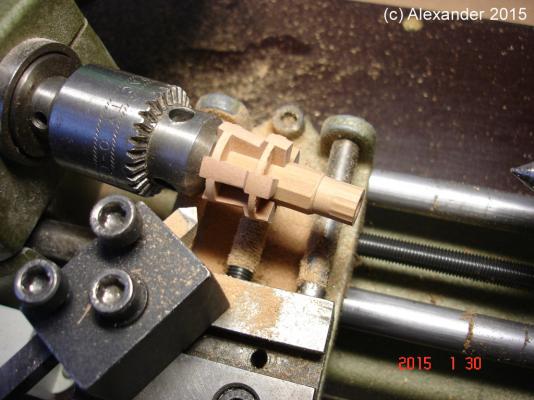

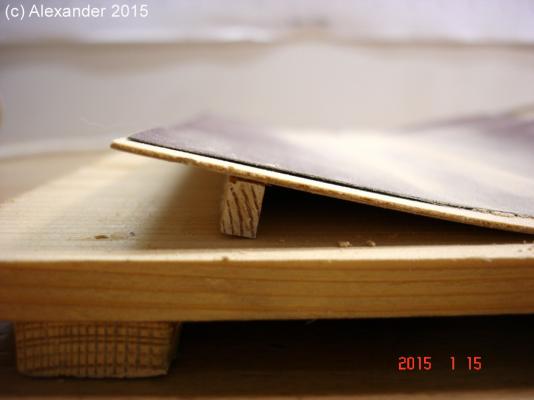

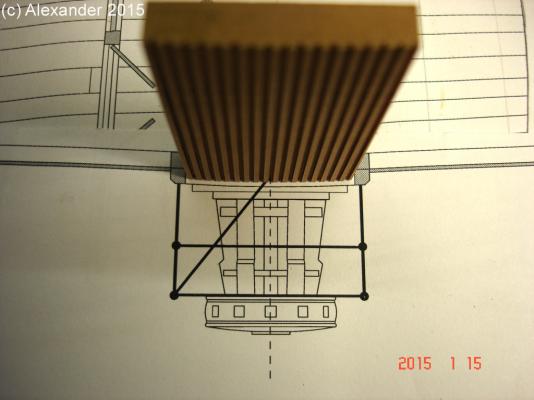

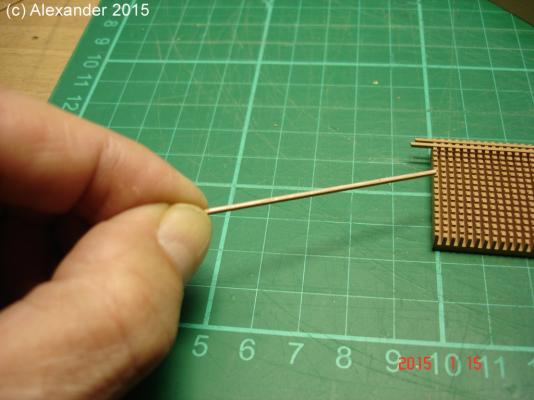

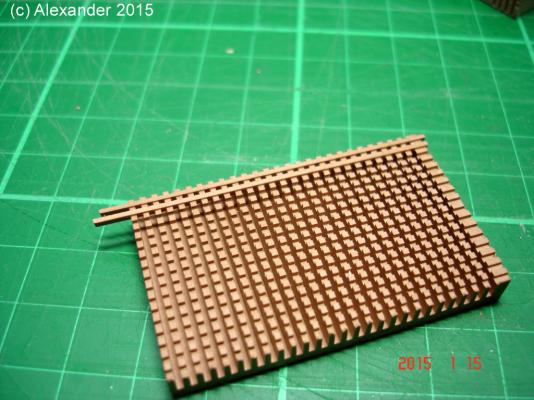

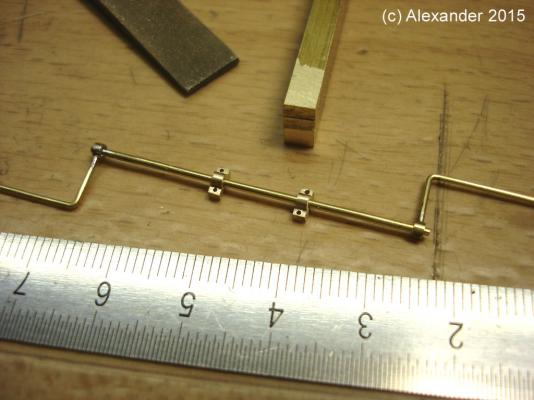

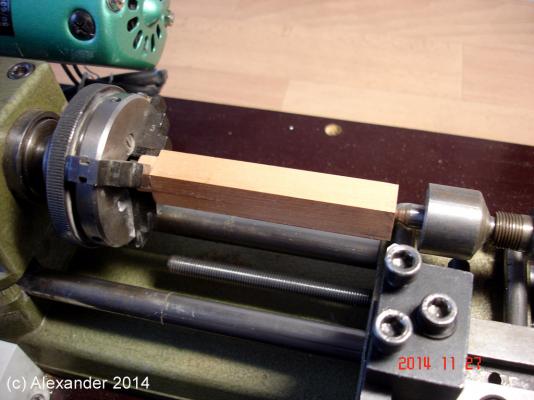

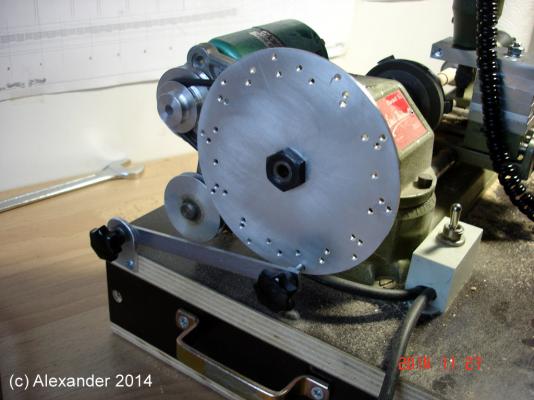

the work continues with the gratings and coamings of the quarter deck, and ladder way to gun deck. In this case the gratings should look like "real" and have proper thickness and shape. Follow images show the process. First the upper edge of the block was shaped on this jig:

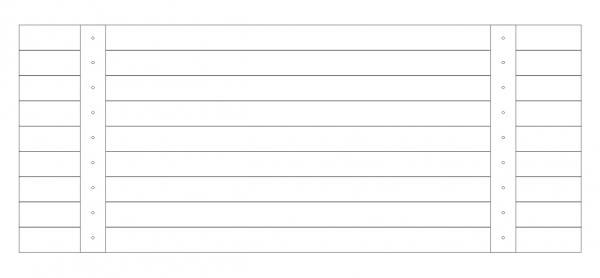

then cuts are done on tablesaw:

then strips are glued and the whole was sanded again in the jig:

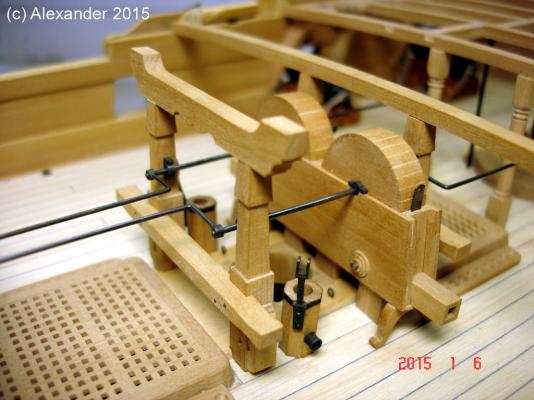

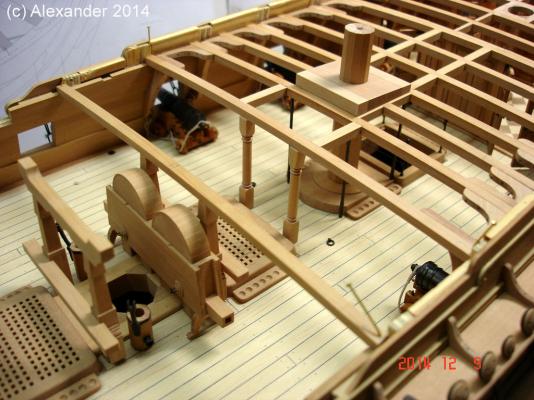

Coamings are build around gratings, ladder way and coaming added:

All is dry fitted now.

Alex

-

-

Hi Lextin,

I would screw two or three 2x2 inch boards of hard wood (oak as example) to the underside of table. You can also glue them all together before them. Important: bound boards tight all together with ratchet straps before screwing. I have one very similar to yours in my basement as workbench, is very solid and stable.

Alex

- edmay, GLakie, qwerty2008 and 2 others

-

5

5

-

Hi Lee,

looks very good! It's a lovely little and fine model!

According to beams: I would highly recommend to cut them instead of bending. It's not soo much more work. Otherwise this can end with bad surprises later... Now it's a state where you can avoid some problems.Alex

- mtaylor and Jaekon Lee

-

2

2

-

-

Hi Johann,

great work on breeshing rope! very nise details, and nice battery of carronades!

Alex

-

Hello Tom, thanks for warm words about my plans!

Alex maybe I should stop right now. I know that I can't achieve the level of finish that you produceI have folowed your build of Vinal Haven and should say, that you model looks very realistic. So please do'nt stop!

I will follow your build!

Alex

-

Hello TBlack, nice start! looks like my Sphynx at beginning

Alex

-

-

- thomaslambo, dvm27, dafi and 38 others

-

41

41

-

Hi Mark,

I know what you mean, it looks really odd and unusual. But doing this to show two ways of planking the wale, is probably an idea, if also a little odd

Alex

-

That is a very fine drawings, Mark! A warm welcome and have fun

:D

:D  :D

:Dthe buts of two plank rows of main wale aft of main mast - shift the lower one further aft...

Alex

-

-

Hi Greg and thanks!

Alex

-

Hi Chuck, excellent planking job! Very clear and smooth!

Christian, I'm not Chuck, sorry, but if you look at the image with red painted counter in Chuck's previous post, you will notice a small step between them and tuck. The tuck will be planked later, and all will follow the plan. Very smart solution, Chuck!

Alex

-

-

HMS Vulture 1776 by Dan Vadas - FINISHED - 1:48 scale - 16-gun Swan-class sloop from TFFM plans

in - Build logs for subjects built 1751 - 1800

Posted

Incredible rigging, and traveler too, Dan! Lovely work!

Alex