-

Posts

1,197 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stuntflyer

-

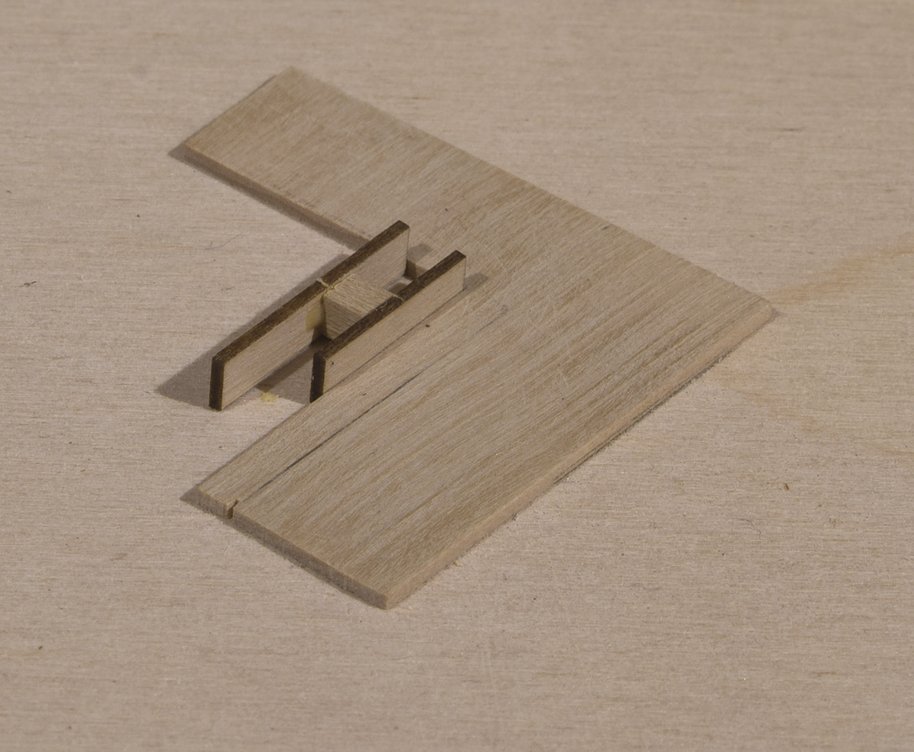

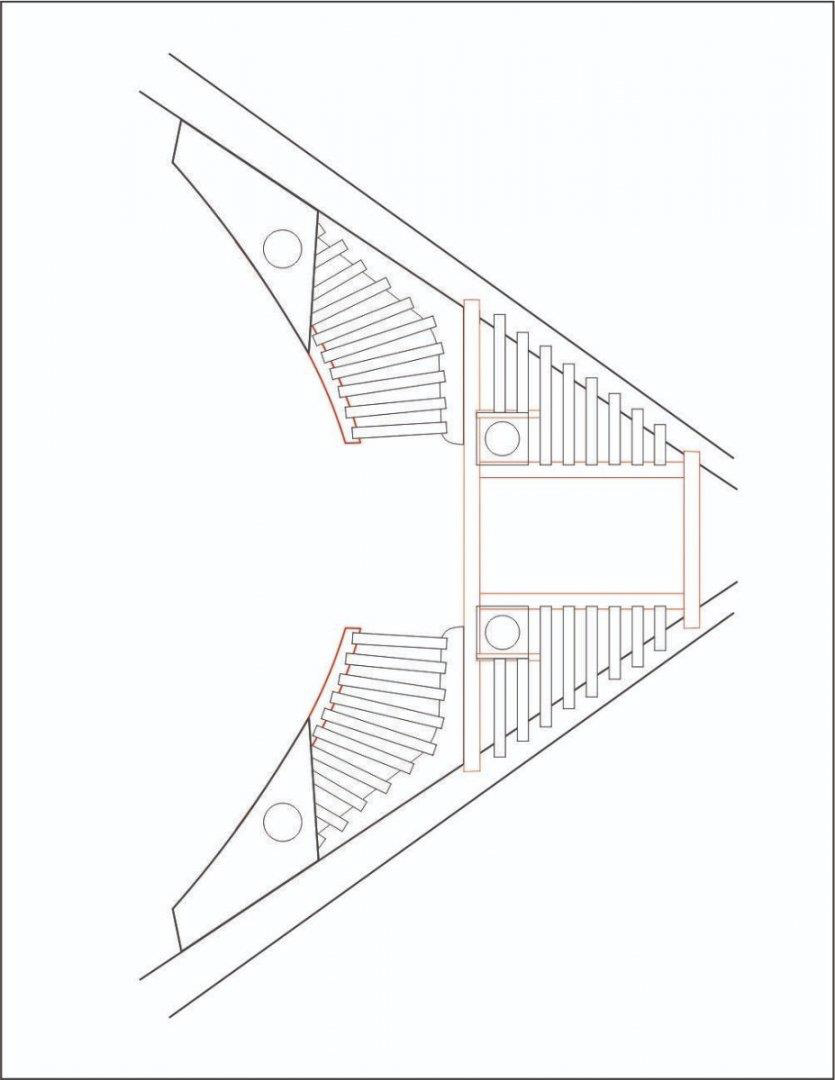

Moving along. . An easy way to align the first two sides of the poop scoops is to use a jig similar to what was used to round up the coamings. The poop scoops are completed. The alignment being that they are parallel to each other vertically and the tops are flat across the top. I found that the best way to do that was to set one first, before moving onto the other one. The three battens on the outside really help to hold them firmly in place. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

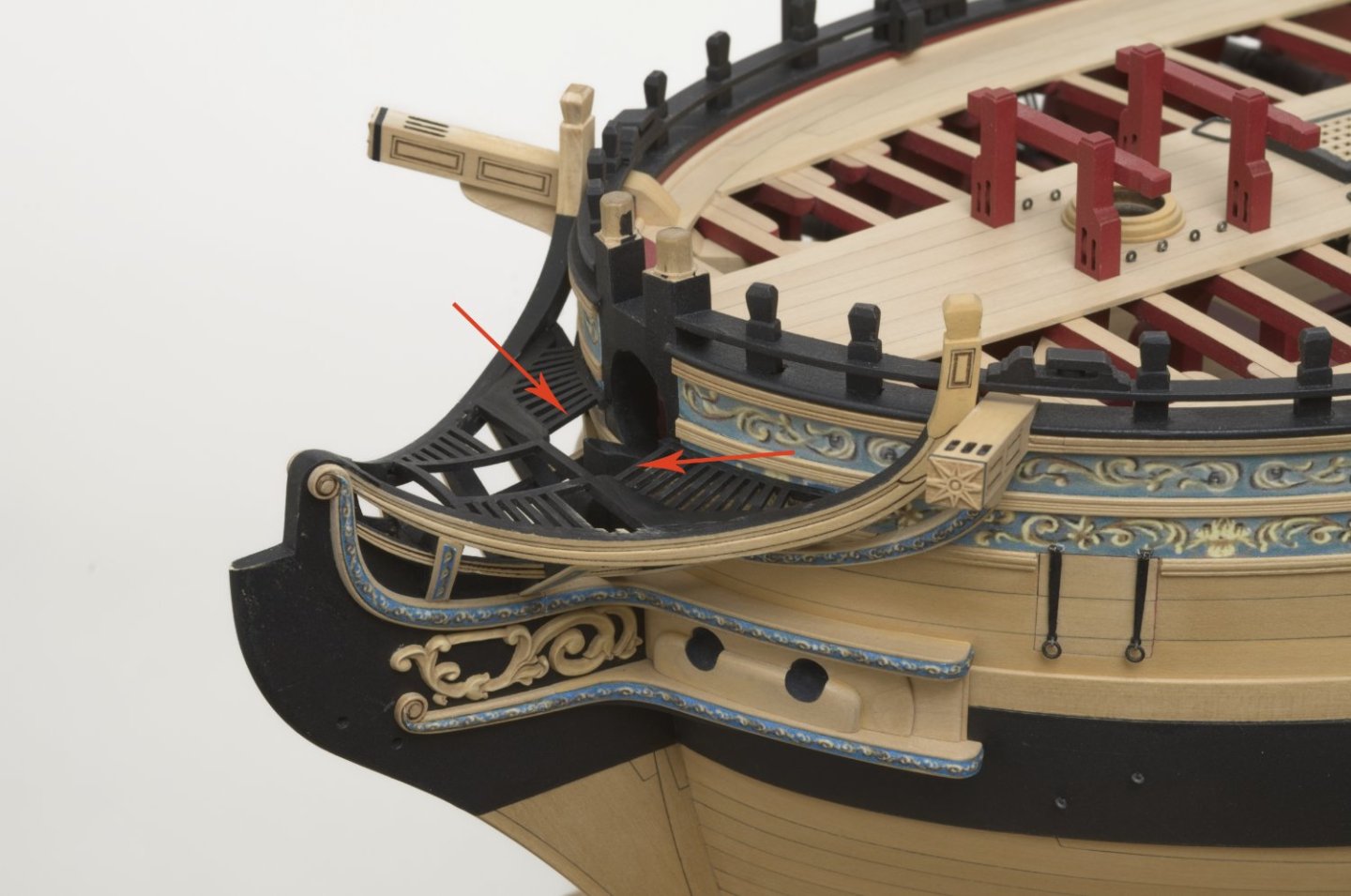

One thing I almost forgot to mention. . I think that It's very important to keep the two inner battens parallel or at least at the same angle relative to the center line of the hull. It's quite noticeable if one batten is at a different angle than the other. Just something to be aware of when you get to this stage of the build. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

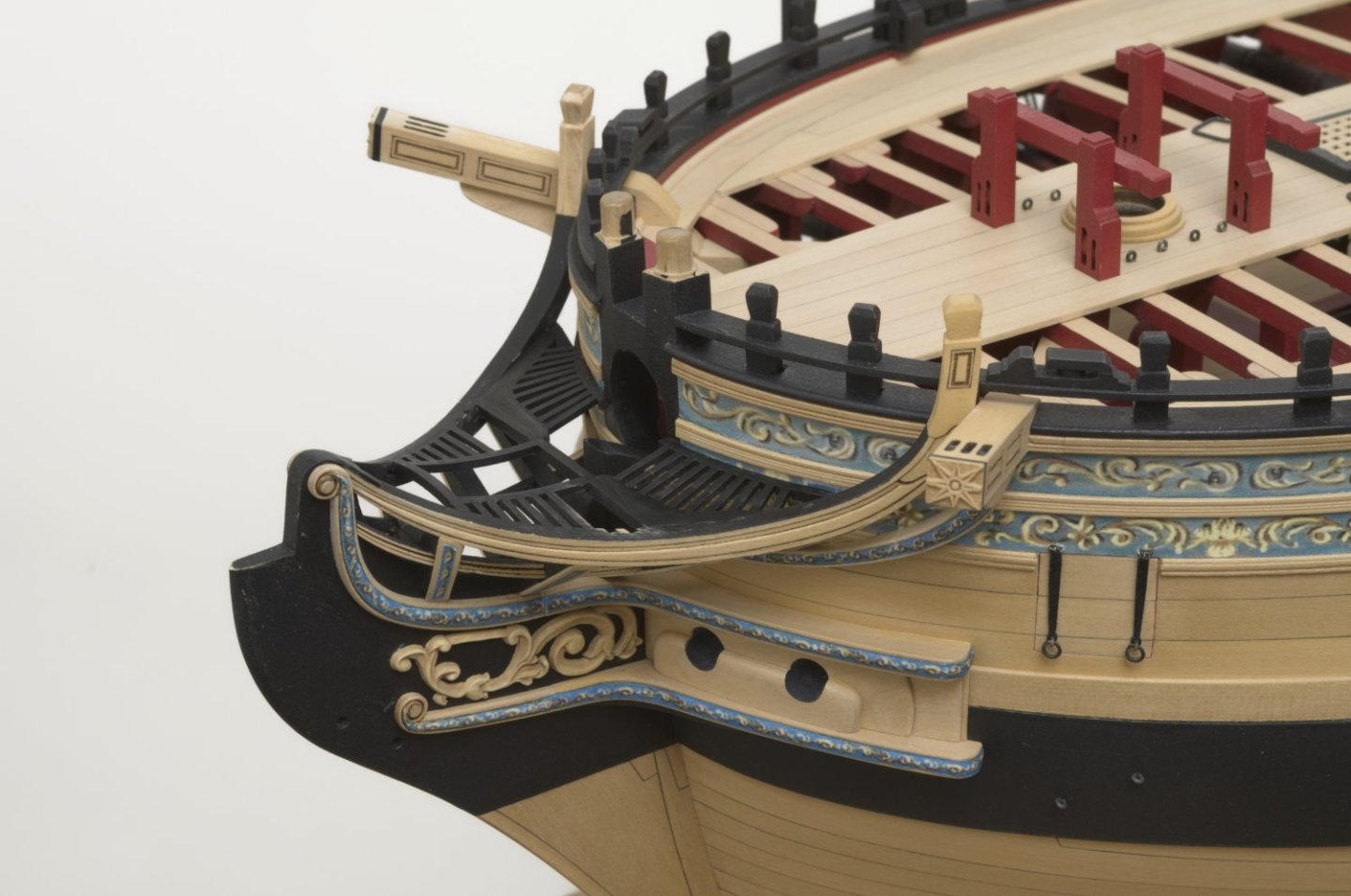

More grating work completed this week. As you can see I have not spent a lot of time on paint work. It's just too easy for things to get scratched while working in this area. I lowered the notched batten at the hull around 3/64" since the angle appeared just a bit too steep. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've started on the head gratings. A few of these battens are quite small, yet none of them managed to fly off into nowhere land. All of the joints needed a bit of wood filler before painting. I added the first coat of black paint of which more are sure to come. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck, Regarding the head gratings, specifically the two inner battens that run from the knees to the hull. The drawing shows them skewed slightly. Should I ignore that and stay parallel to the center line of the hull? Mike

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Moving right along. .Did you have fun making the port lids? They look quite nice.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

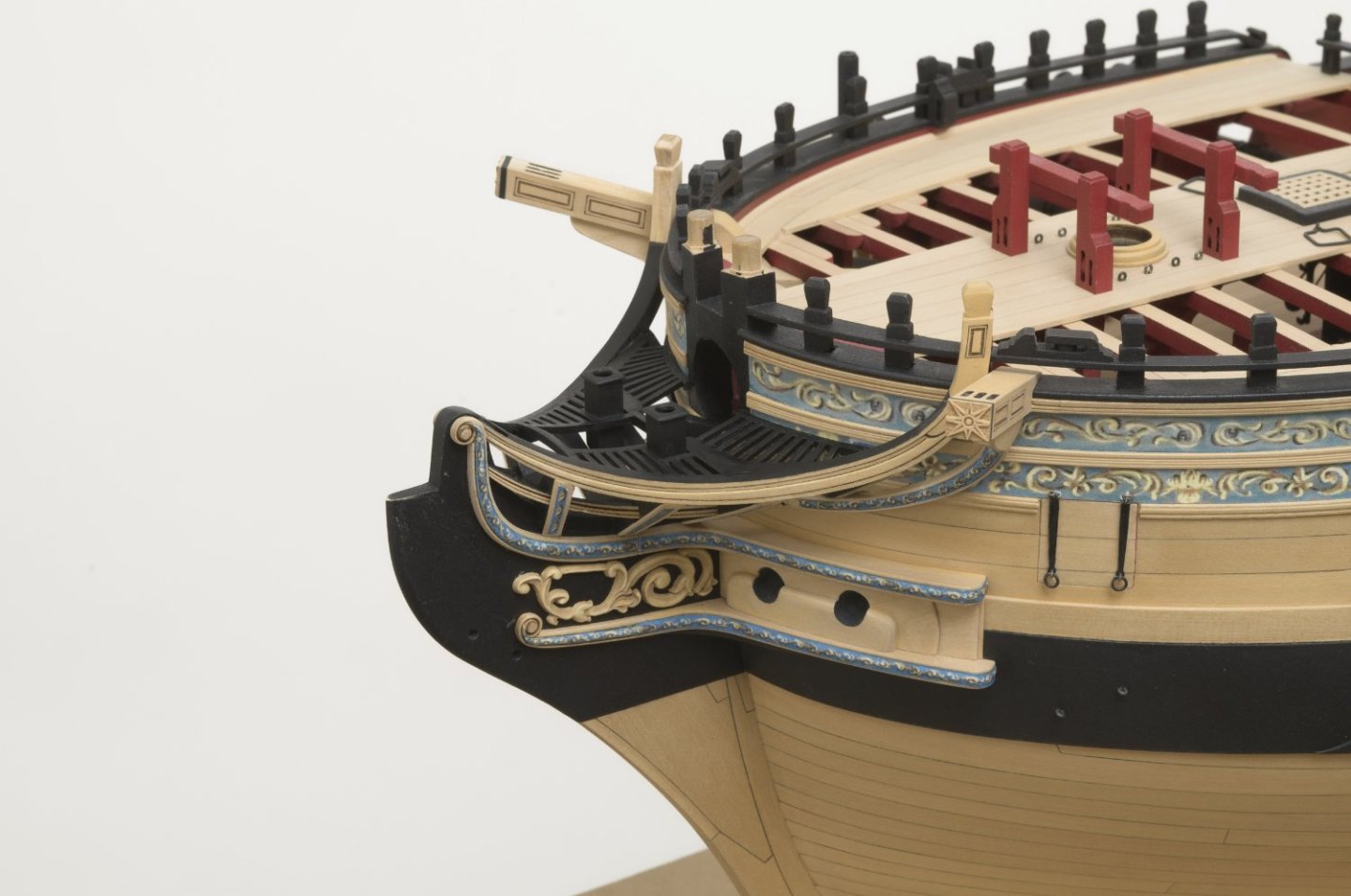

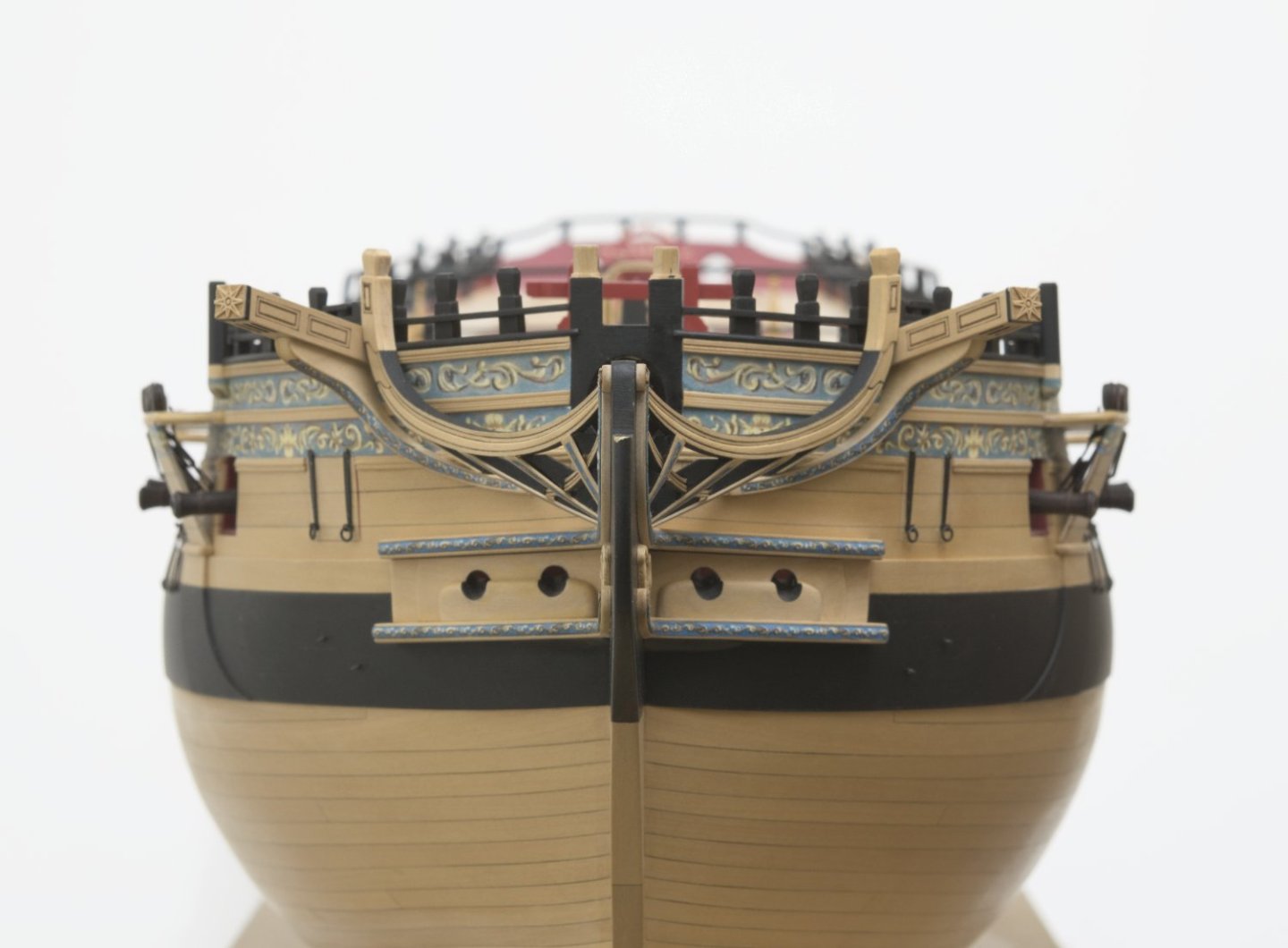

Well, I'm not sure if I would call it a milestone, but it does feel good to have finally finished the head timber work. It's challenging and sometimes tedious work. The secret to any kind of success is to just slow down and think things through as much as possible. The head gratings are next. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking very nice! You'll see her really start to come together when you do chapter 11.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you all for the kind words and for all the like's! Chuck, I still have to complete the two aft head timbers. I did remove the lower moulding which should make things easier. It's a tight area to work in. Stay tuned. .

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

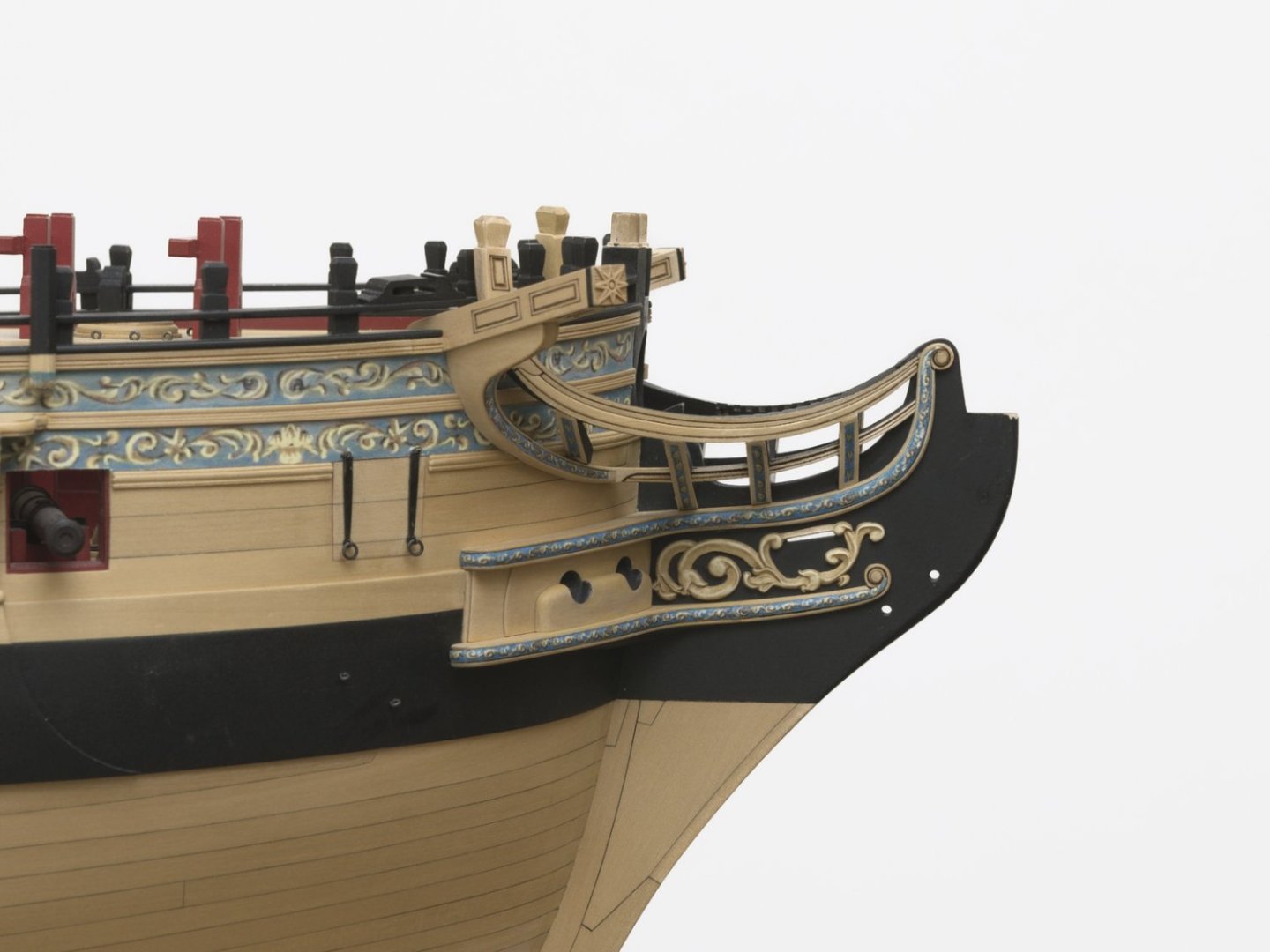

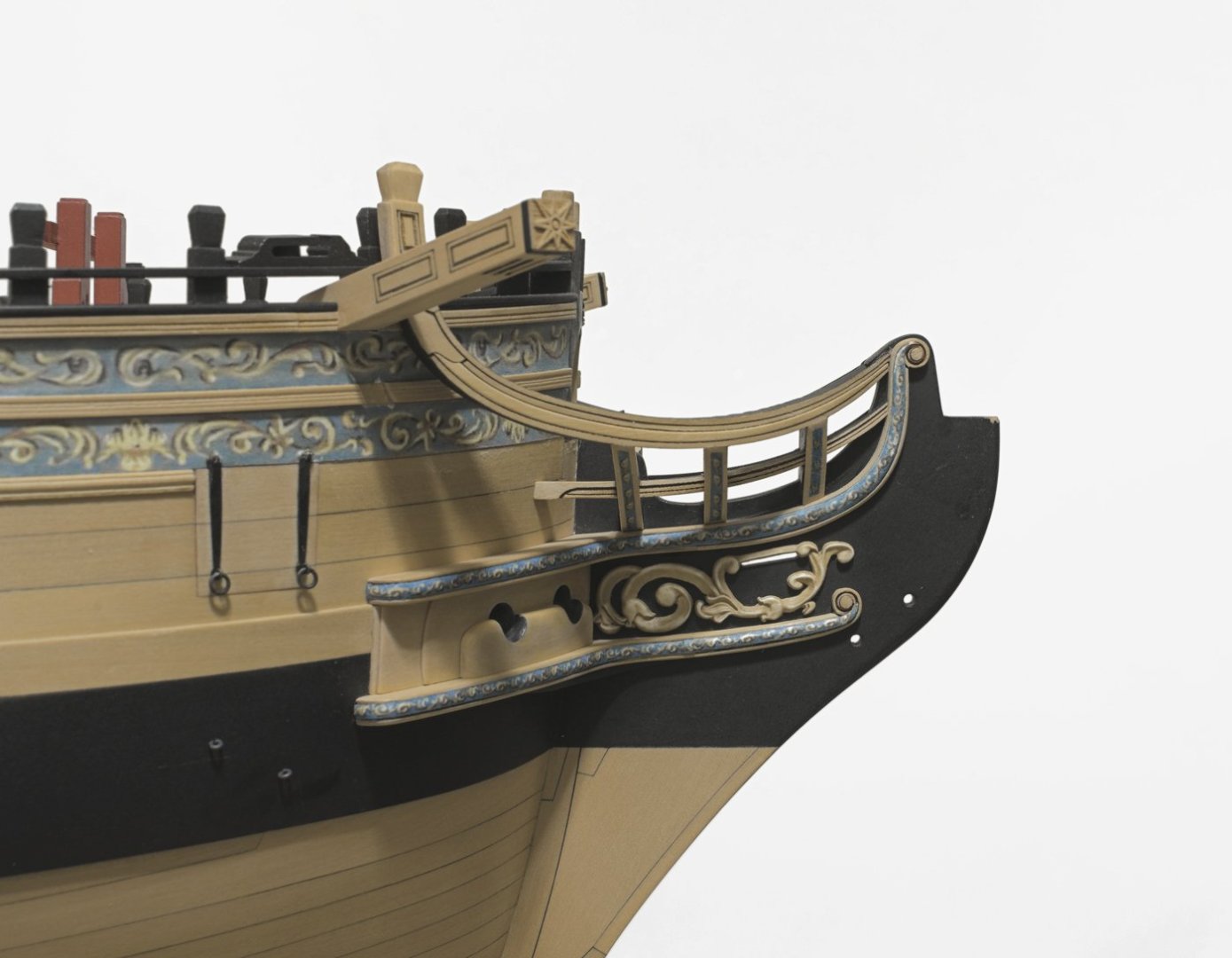

Work continues with the completion of the cathead rail. A ton of fitting, tweaking and re-fitting in order to get something that I liked. It would be great if one could add the thin outside layers in one piece instead of a splice. Of course that would be more difficult to do since both halves of the rail would have to be glued together first, while matching the shape of the hull at the same time. Anyway, here you go. . Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've been looking forward to getting the cover boards completed, not necessarily doing them. I had to file down a few of the head timbers or change the angle slightly before I could glue the boards in. I recommend using slow drying CA and not PVA. I also removed some of the moulding under the frieze to make things easier when it's time to fit the lower rail. Anyway, now that they are done I am feeling pretty good about how they turned out. Now its onto the lower rail. Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well Greg, you have built a beautiful ship and seven years of your work certainly has paid off in spades. Even at 1/4 inch scale, Speedwell is a small ship and you have shown all of us what a master builder can do. Mike

-

They are not that difficult to make. . Wet the wood and bend them together or separately while clamped around a curved shape similar to that of the hull. A large can or plastic container works fine. I sometimes use a round table edge like the scroll saw table. The bend always allows for some spring back. Hot heat dry with a hair dryer for a few minutes, and then let everything cool completely. I always make these pieces longer than needed to allow for clamping. Once the spring back is reduced substantially it should be easy enough to shape and clamp them to the hull. Anyway, that's how I made mine on the Winnie. Mike

-

FWIW, I agree with David and Greg, Maybe your idea of lowering the profile of the letters would be enough.

- 889 replies

-

I buy these from https://www.harveytool.com/ These are end mills for plastics. They are not cheap, but seem to work quite well on boxwood. They are long reach too. The end mill I mentioned is # 938931. https://www.harveytool.com/products/tool-details-938931 They will send you their catalog. I usually call them and they direct me to a local distributor to place the order. Harvey tool: 800 645 5609 Mike

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.