-

Posts

1,490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Maury S

-

Here is the link to my cutter. Clinker planking was new for me. David's suggestion was to plank without frames on the plug and add them later. Maury http://modelshipworld.com/index.php/topic/7678-18-cutter-by-maurys-scale-148-small/?hl=%2Bcutter+%2Bmaury

-

Danny, I started the cutter, and get back to it when ever I come to a stopping point on the Echo Section. It's small, so when I'm in the mountains I can take it with me. Not power tools necessary. I'm sure you'll have yours completed by the time I turn around. That will help me a great deal when it comes time to get the frames in. Maury

-

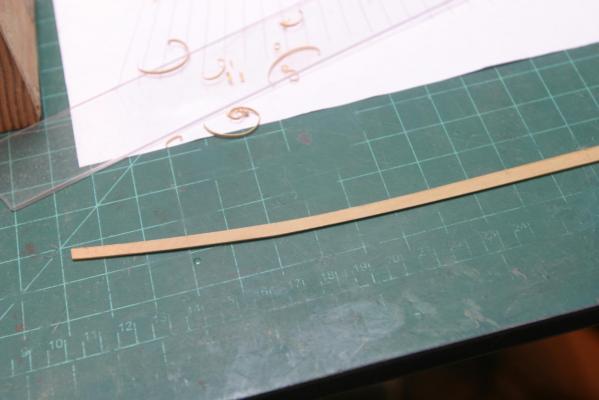

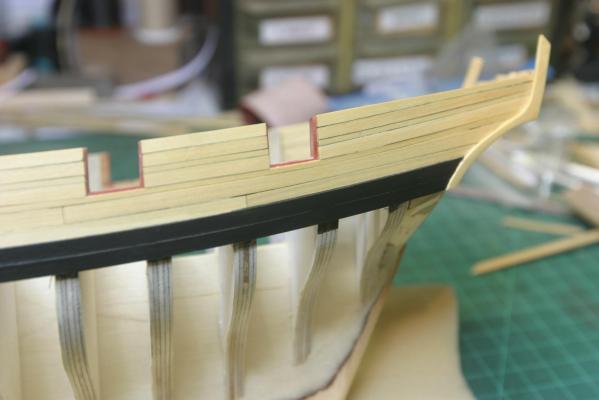

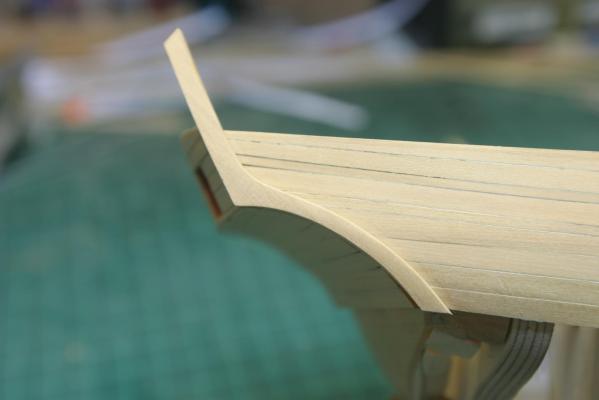

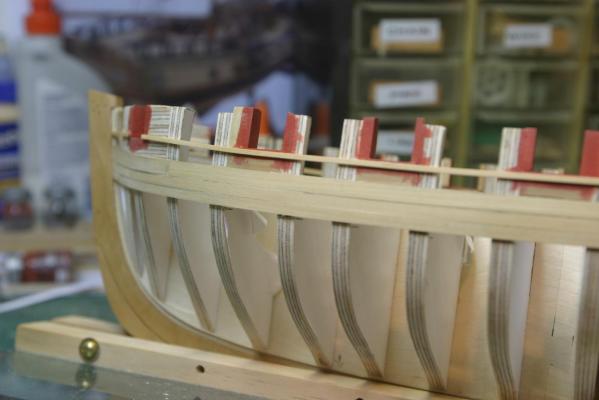

Laying out the planks below the wales. I used tick strips every other bulkhead starting from deadflat and ran a batten at the mid points (10 planks down) from stem to where the square tuck joins the stern. That seems the most critical alignment of the planks. Since it was fair, I marked all the bulkheads with a dark line. Same exercise on the other side. Maury

-

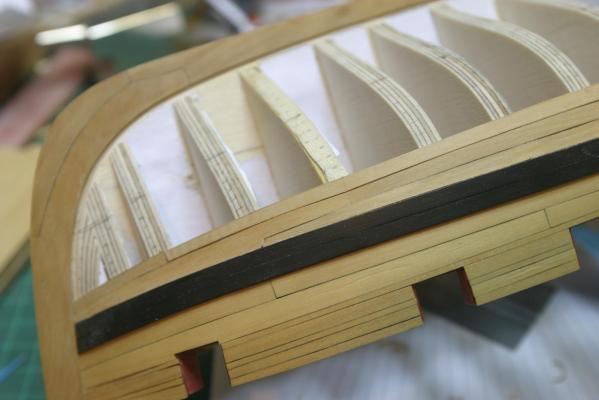

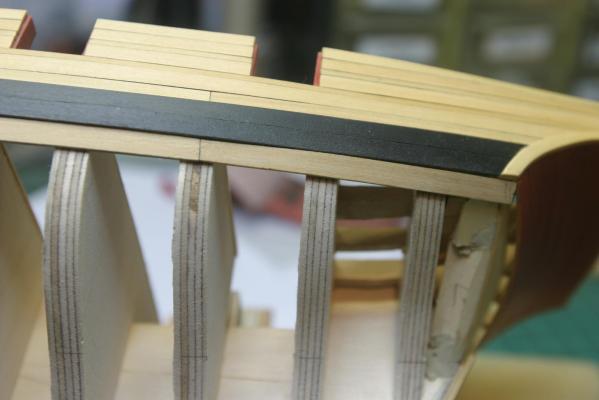

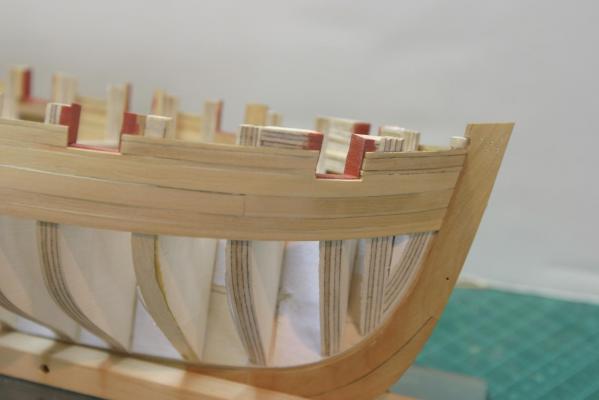

The wales have been installed on the starboard side. The pieces were cut to size, tapered at the bow and cut to fit the shape of the fashion piece at the stern. These went on much easier than the original planks. A little sanding, then I'll put a coat of sanding sealer and start painting them. Maury

-

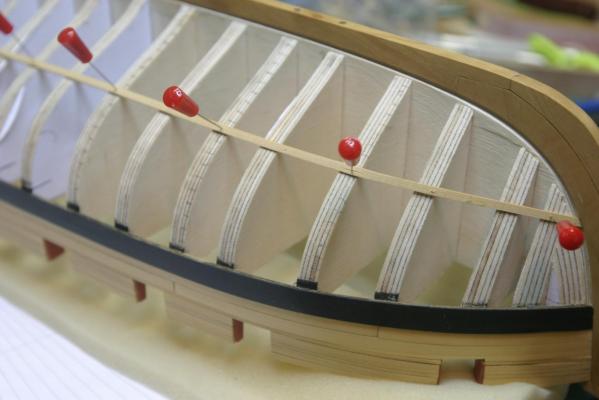

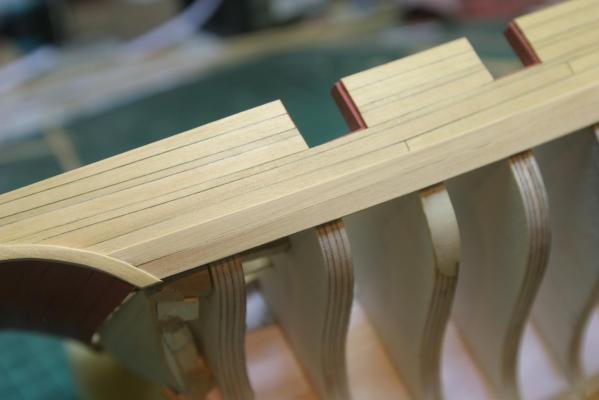

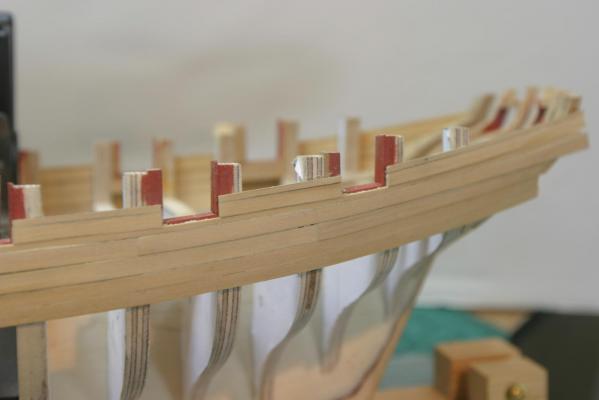

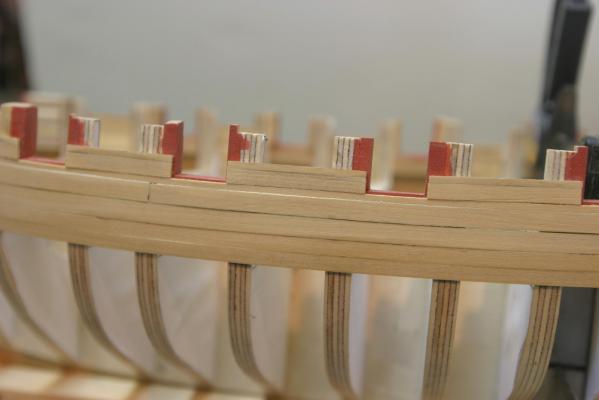

Using Chuck's bulkhead kit keeps everything lined up nicely. I had quite a few adjustments to make by cutting them myself...particularly at the stern. Looking good. Maury

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Echo by Maury S - FINISHED - Cross-Section

Maury S replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

In real life, the spaces between the frames would have been filled-in. Those pieces are not included in the plans provided. Maury- 324 replies

-

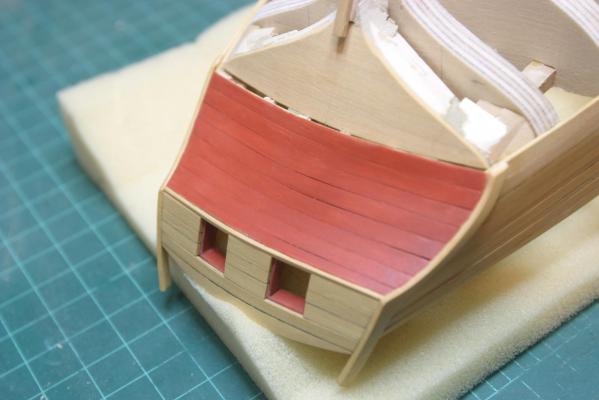

The counter took some edge bending as well as the gentle bend of the stern and came out well. Edge bending is still something I'm getting comfortable with...the inside of a bend seems to bend a bit sharply in the center rather than a gentle sweeping curve. I even place two clamps in the middle of the plank to widen the curve. Trial and error. The transom edge bending is less severe and went on well. I did the lower strake pieces first, then moved to the solid plank above the gun ports and then filled-in the rest. Next up are the fashion pieces covering the edges of the counter and transom. Question for Chuck...The planking over the square tuck is vertical on the plans and in your build log, but seems horizontal in the pictures with the instructions. I seem to recall more discussion about the vertical planking and the surround on the build log at the time, but that does not appear now. Maury

-

What a great range of knowledge we have available! Maury

- 15 replies

-

- Cutter

- Sherbourne

-

(and 2 more)

Tagged with:

-

Ed, I can hardly wait for the book, but this hobby has forced me to understand "Patience". Maury

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

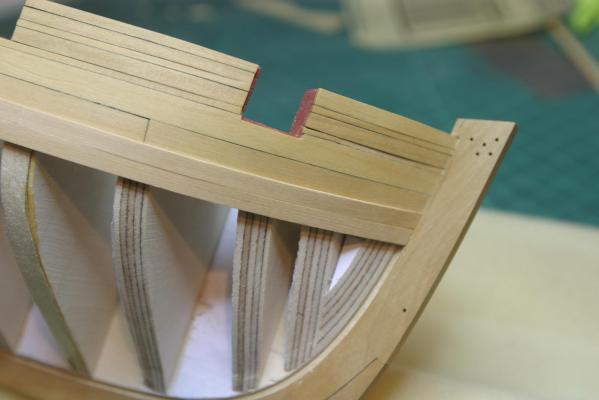

More planking. I started using CA on the planking and things went much faster. The next step is to make sure the tops of the frames are fair and match from side to side. Tops of gun port verticals need to be sanded off. Square tops of the frames get faired. This will give me a place to measure the width of the next two planks up to the shear. Maury

-

I bent the stbd side piece and over did it a bit. Easy to correct. Just learning to make those little adjustments that only come with experience. Chuck, the strake above the molding is broken up by the gun ports. Do you bend a full-length piece to a fair run before you cut it in small segments or bend the pieces separately? I'm not there yet, just asking. Maury

-

Completion of the first strake above the wale on the port side. This involved edge-bending the long center plank so I tried Chuck's clamping and heating method. It did not hold much of the bend after 5 minutes with the blow dryer on high. I repeated and let it set for an hour...not much difference, but enough that I did not have to force it too much. I clamped it both against each bulkhead, and also against the wale. The aft-end part of the strake is too short to do much bending so I mark the width and used a ships curve to to get a mild curve to match the run of the wale. It fit perfectly. By the way, after marking the width at each bulkhead and drawing a fair line, I clamp it in the vise and use a very sharp 1" chisel to cut close to the line and finish it off with 100 grit and 150 grit sanding sticks. Maury

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.