-

Posts

1,217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gahm

-

As usual you take a good kit and use your superb craftsmanship and love for historical research to get a master piece out of it. Very impressive! Thomas

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

That is a nice looking pump! And in my opinion it looks even more impressive with the handles mounted 😉. Thomas

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Your stern arrangement with all the details in place looks very nice! And you make very good picture as well 🙂! Thomas

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Outstanding! Thomas

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Will, Carl and Per, thank you for your kind comments! Will, I turned the belaying pins from tooth picks on a little Proxxon lathe. To be able to repeat the pattern reliably, I just used a little drawing with the measures/dimensions of my target pin, which I had always in front of me and which I could use for comparison (see image). That actually worked pretty well 🙂 Thomas -

The steering wheel clearly is a highlight of your deck furniture. It looks great! Well done! Thomas

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

That looks fantastic! Beautiful work! Thomas

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

Beautiful work, B.E.! I love all the details you are adding to this model! Thomas

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you, Patrick! Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you Robin and Justin for your great comments! And thanks for all the Likes! Building these little boats is a lot of fun. And as far as I know Syren had three of them. So there is still a lot to do 🙂 Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

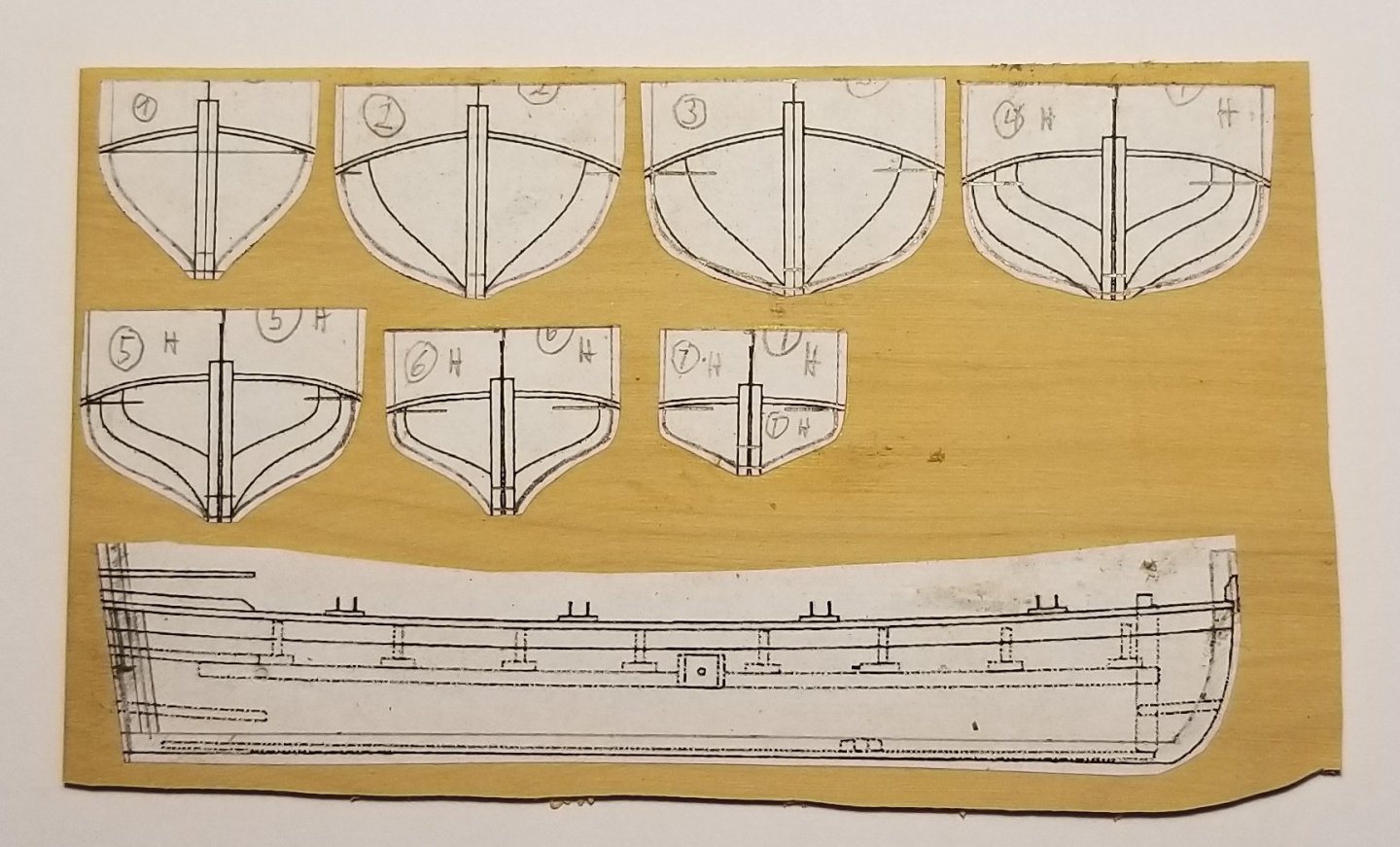

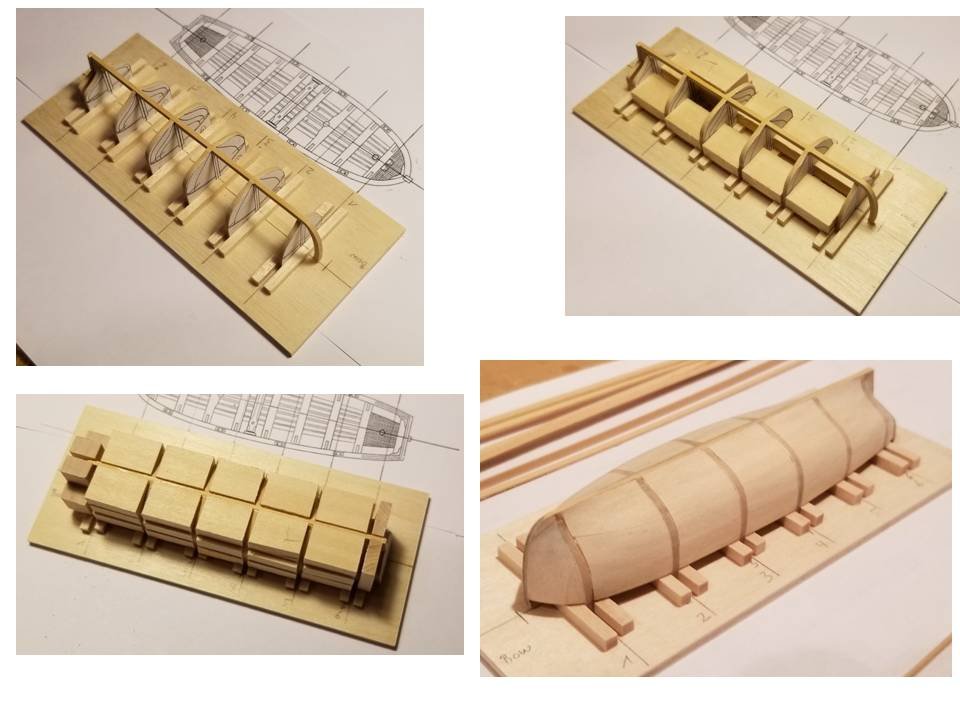

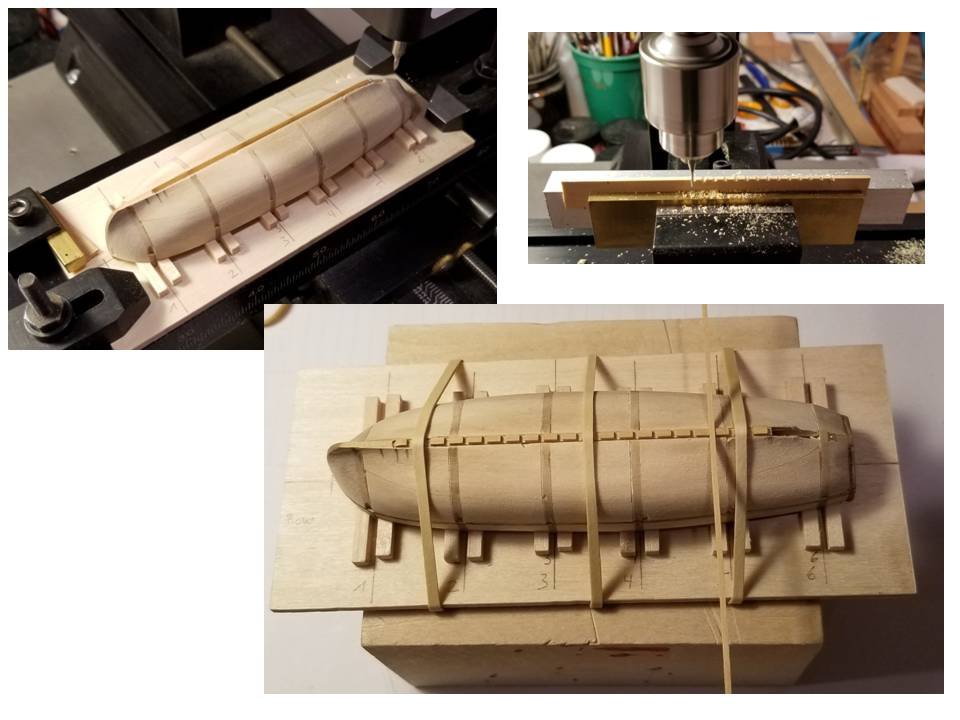

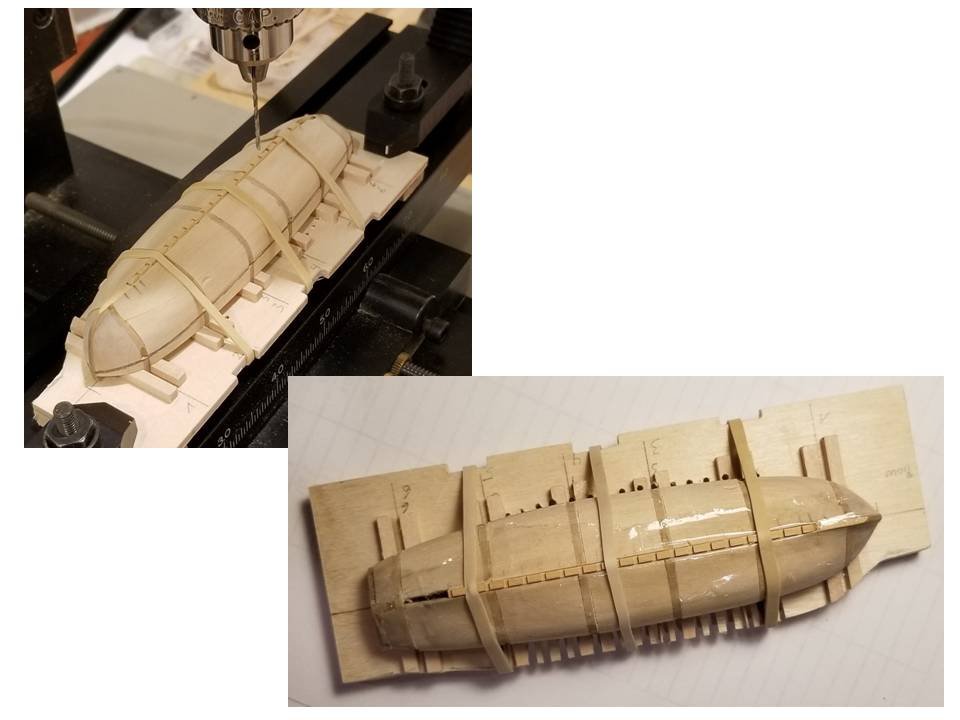

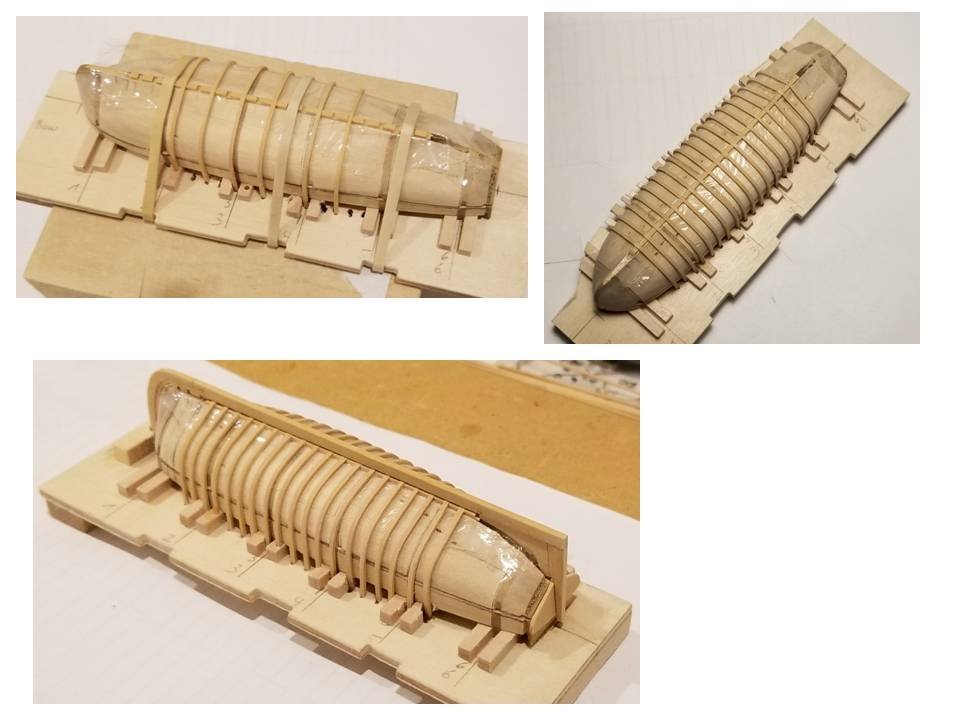

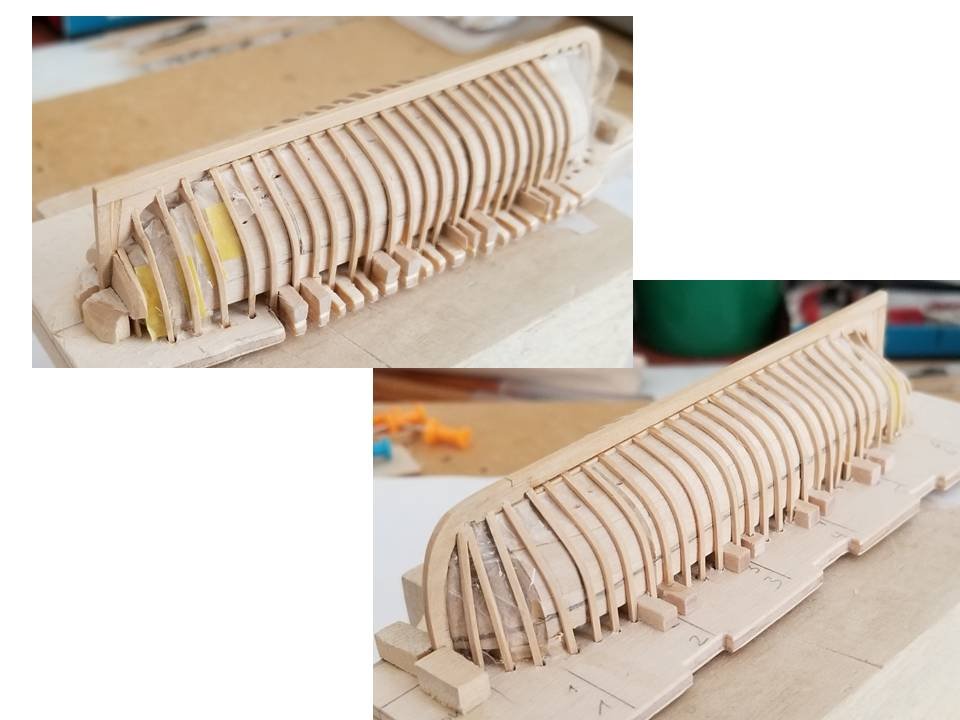

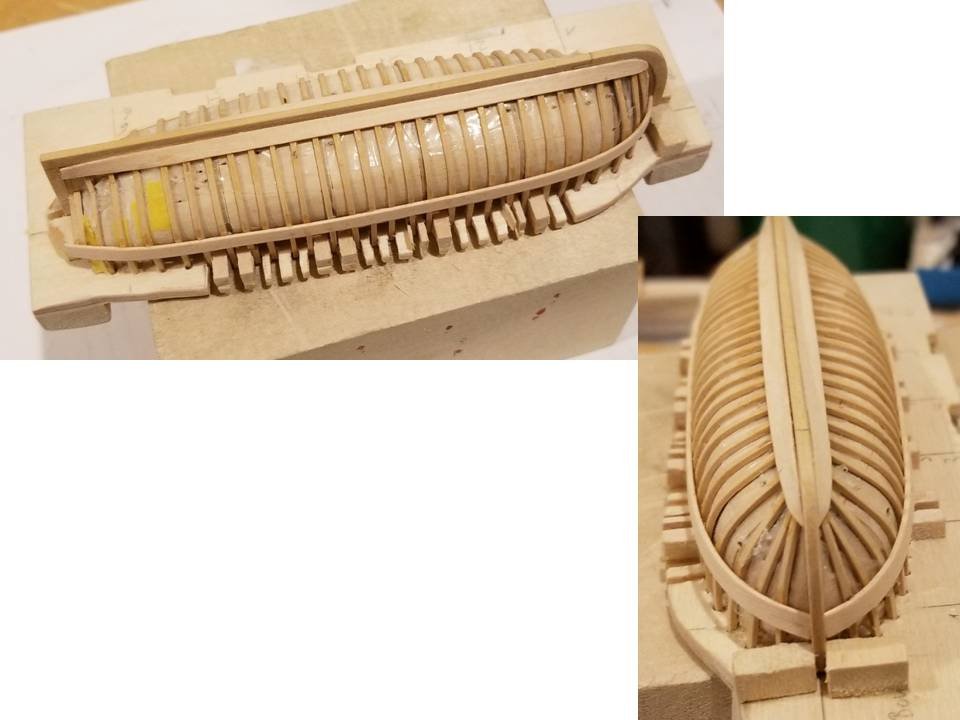

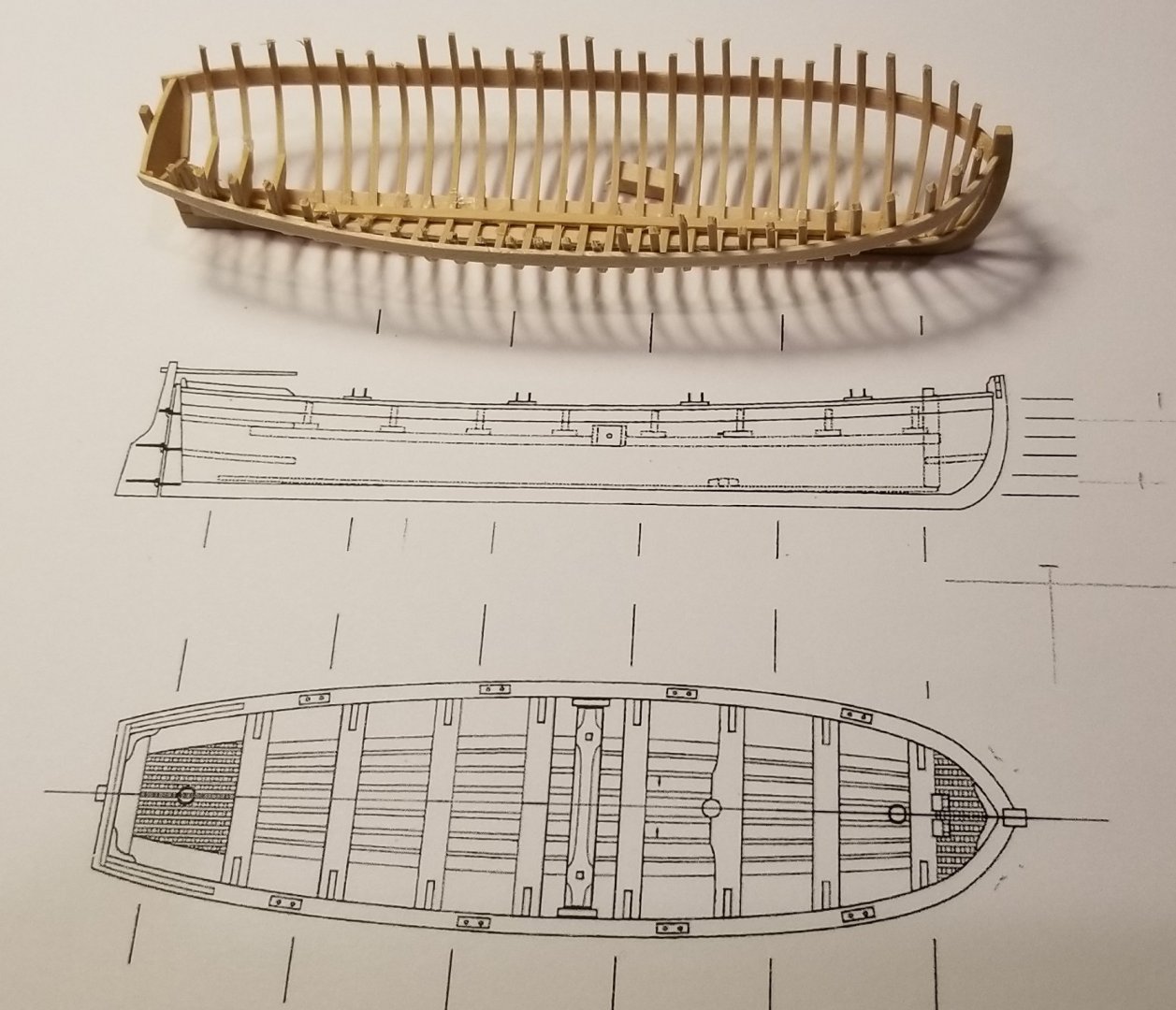

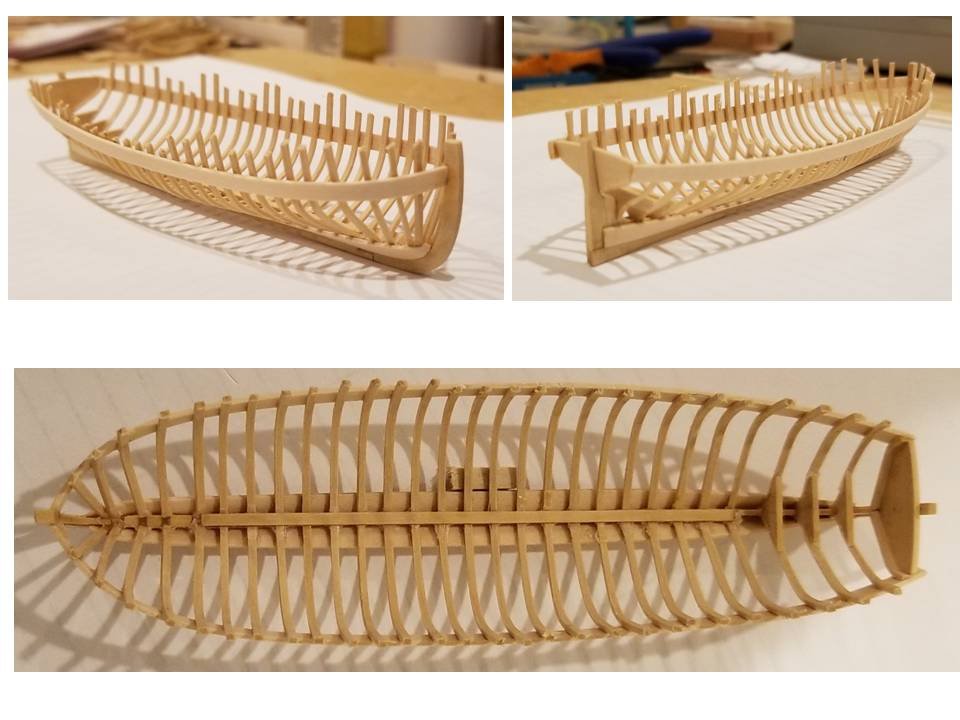

I started with the Syren longboat construction. Using Chuck’s plans provided in the Syren kit I subtracted from the frame profiles the amount caused by frame thickness (1/32’’) and planking (<1/32’’) and built a jig out of bass wood (imgs 1-2). I milled a longitudinal groove in the center of the jig for the keelson. The keelson consisted out of boxwood (width 1/16’’) with 1/32’’-wide notches cut into it at regular intervals of 5/32’’ (img 3). A thin layer of plastic foil was inserted between the keelson and the jig to insure that the longboat would not accidentally be glued to the jig during the building process. Using the mill I ‘transferred’ the keelson notches to port and starboard side of the jig to drill holes (diameter ~1/16’’) and cut slots perpendicular to the jig. Both were placed as close to the jig as possible (img 4). With these preparations finished boxwood strips of 1/32’’x1/32’’ were soaked in hot water, inserted one after the other in the holes close to the jig, bent through the corresponding keelson notches and moved through the slots on the other side to the jig. Each boxwood frame was glued into place at those three points (img 5). As a next step the keel assembly was built consisting of stem, keel, deadwood, sternpost, and transom (img 5). A rabbet was cut on both sides of the stem to facilitate planking later on. The last three rear frames were assembled out of small profile pieces and boxwood strips to accommodate the shape of the frames. Img 6 shows the front and the rear part of the finished framing. Finally to stabilize the whole construction two planks were glued to the frames on both sides (img 7). After cutting the frames above the points where they were glued to the jig the whole longboat frame assembly could be removed from the jig. This was primarily done to ensure that it would come off in one piece and that the whole construction worked 😉. The result is shown in images 8 – 10. To facilitate planking the longboat frame will be screwed to the jig again later on. Thomas Image 1 Image 2 Image 3 Image 4 Image 5 Image 6 Image 7 Image 8 Image 9 Image 10 -

Your binnacle turned out really nice! Another great detail added to a beautiful model. Thomas

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Awesome! Thomas

-

The binnacle is a very nice little project, and it is one of the more prominent deck details. Yours is coming along beautifully! Thomas

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you, Jason! -

Wonderful detail on that steam capstan! Never seen one like that before! Thomas

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.