-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

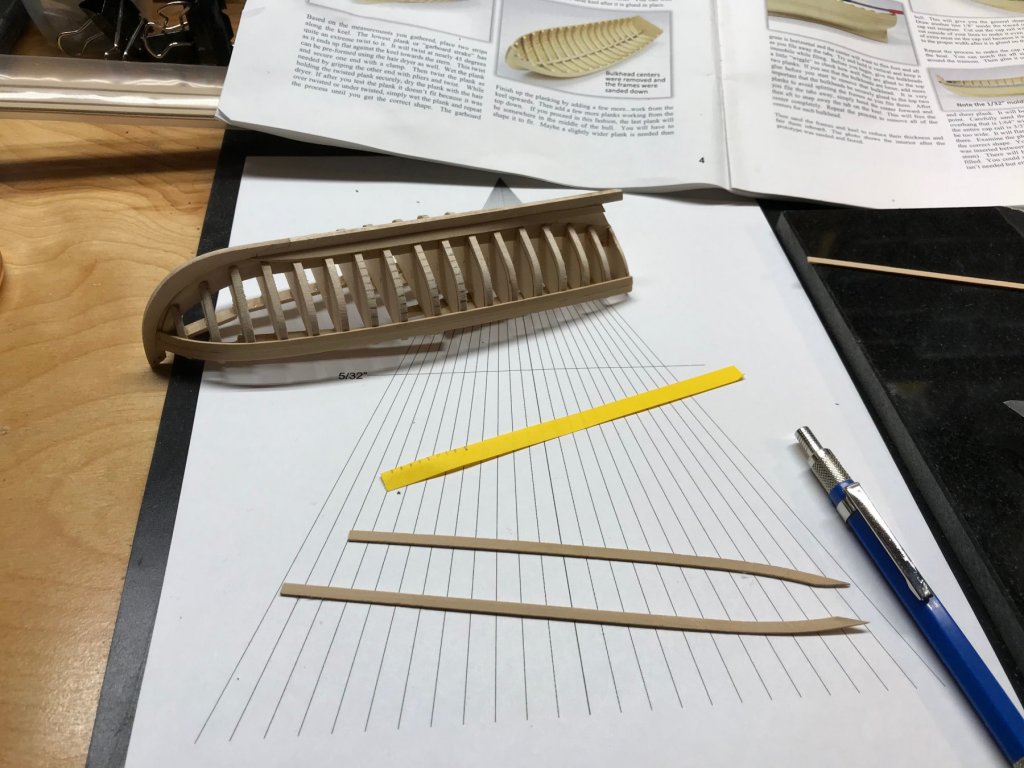

So far so good on the second try at planking this little hull. It's not perfect but is looking much better than the first try. I am edge bending and twisting the planks as much as possible before glueing them. They need much less clamping than before and seem to follow the lines better. It's going very slow though. Only 2 planks a day lately.

-

She looks darn nice my friend.

- 91 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Filler is your friend in this case but you will need to learn to spile planks for future builds. The best lesson I had was to build the hull of the Glad Tidings Pinky by Model Shipways. It has pre-spiled planks and really shows you how the planks are shaped to lay on the hull correctly. They are far from straight. Once you see how they need to be shaped you can carry it on to other models. Also, tick strips are really helpful so your planks don't get too thin at the bow. You'll get it once you see how the planks are shaped.

-

I think this fits in the Naval History section. One of my other hobbies is coin collecting and thought you all might find this interesting. They are a bit scarce but not rare. Does anybody else have any ship or Navy related coins or medals to share? I have a few others I can post if anybody has an interest.

-

Eric, Your thread is a great read. Lots of good information and something to think about. The traveler above the tiller makes perfect sense. Chuck also makes a good argument. I'll have to give it some thought and maybe do some more research on the subject. I wish the above photo was more clear but it seems to show the tiller above the traveler.

-

Thanks for the info Bob. I don't mind using the resin but may try to learn some carving. I've always admired some of the great carving work and might give it a try knowing I have the resin as backup.

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Bob, When I ordered my Halifax kit they told me they were no longer offering the laser cut stern details because they no longer have the service of the more delicate laser cutter. They now only have the resin parts. How is the quality of the resin castings? I'm sure they will be fine but I may try carving my own with the resin as a backup.

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

OK Bob, it's all your fault. I have been enjoying your Halifax build so much that I went ahead and did something really silly. I ordered the kit. I know I'm not ready for it yet but want it on the shelf for when I am. Yours has been such an inspiration.

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Not much progress but in the spirit of keeping the log up to date this is where I am. I really took my time bending and fitting the first plank. It's defenety bent in 3 dimensions and laid down with very little clamping needed. Maybe I'm getting a handle on it now but I'm sure taking my time. I'm going really slow. I hope I can get the other side to go as well.

-

HMS Naiad 1797 by albert - FINISHED - 1/48

alde replied to albert's topic in - Build logs for subjects built 1751 - 1800

That is just amazing. I really admire the quality of workmanship. -

I decided that I was not happy with the way my planks were looking so I removed them. It gave me a chance to do a better job fairing the hull while they are off too. I did learn a lot from the planks I did so it should go better this time. I plan to use the tick marks on all frames right from the beginning and using the tape method to take off the shape to edge bend the planks. I'll take pictures as I go and keep the log up to up to date. I considered cutting the planks from wider stock but decided I would continue on with the edge bending as Chuck suggests. I think it's a good way to go as long as it's done right and care is taken to put enough bend into the planks so they lay right. I think if they are bent and shaped properly they will not need much clamping and will just look better. I'll keep you posted on progress.

-

Great start. I am looking forward to tagging along on your build. Syren has been in my closet for a long time too.

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

She looks great. If mine comes out as nice I will be thrilled. Mine went backwards. I was not happy at all with the planks so I removed them and will start over. I need to improve my bending and shaping techniques.

- 91 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.