-

Posts

4,234 -

Joined

-

Last visited

About Blue Ensign

- Currently Viewing Forums Index

Profile Information

-

Gender

Male

-

Location

The Green Shires of England

-

Interests

Eighteenth Century Naval History, ship modelling, wandering the Lakeland Fells, cocker spaniels, Golf, and too keen an interest in red wine.

-

BobG reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

BobG reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HM Cutter Trial 1790 by Dunnock - FINISHED - Vanguard Models - 1:64

Blue Ensign reacted to a post in a topic:

HM Cutter Trial 1790 by Dunnock - FINISHED - Vanguard Models - 1:64

-

mugje reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

mugje reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Thukydides reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Thukydides reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Jorge_Goncalves reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Jorge_Goncalves reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

AnobiumPunctatum reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

AnobiumPunctatum reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Mirabell61 reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Mirabell61 reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Thank you guys for your supportive comments and likes throughout this build, hope it will be useful to those following on. @ Nils – I have a glass case ready; it was cheaper than using acrylic, but the downside is weight. It is going to be an interesting exercise getting her into display position.🤔 B.E.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Blue Ensign reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

CiscoH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

CiscoH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Tossedman reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Tossedman reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Alexander Bulimov reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Alexander Bulimov reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

mgatrost reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

mgatrost reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

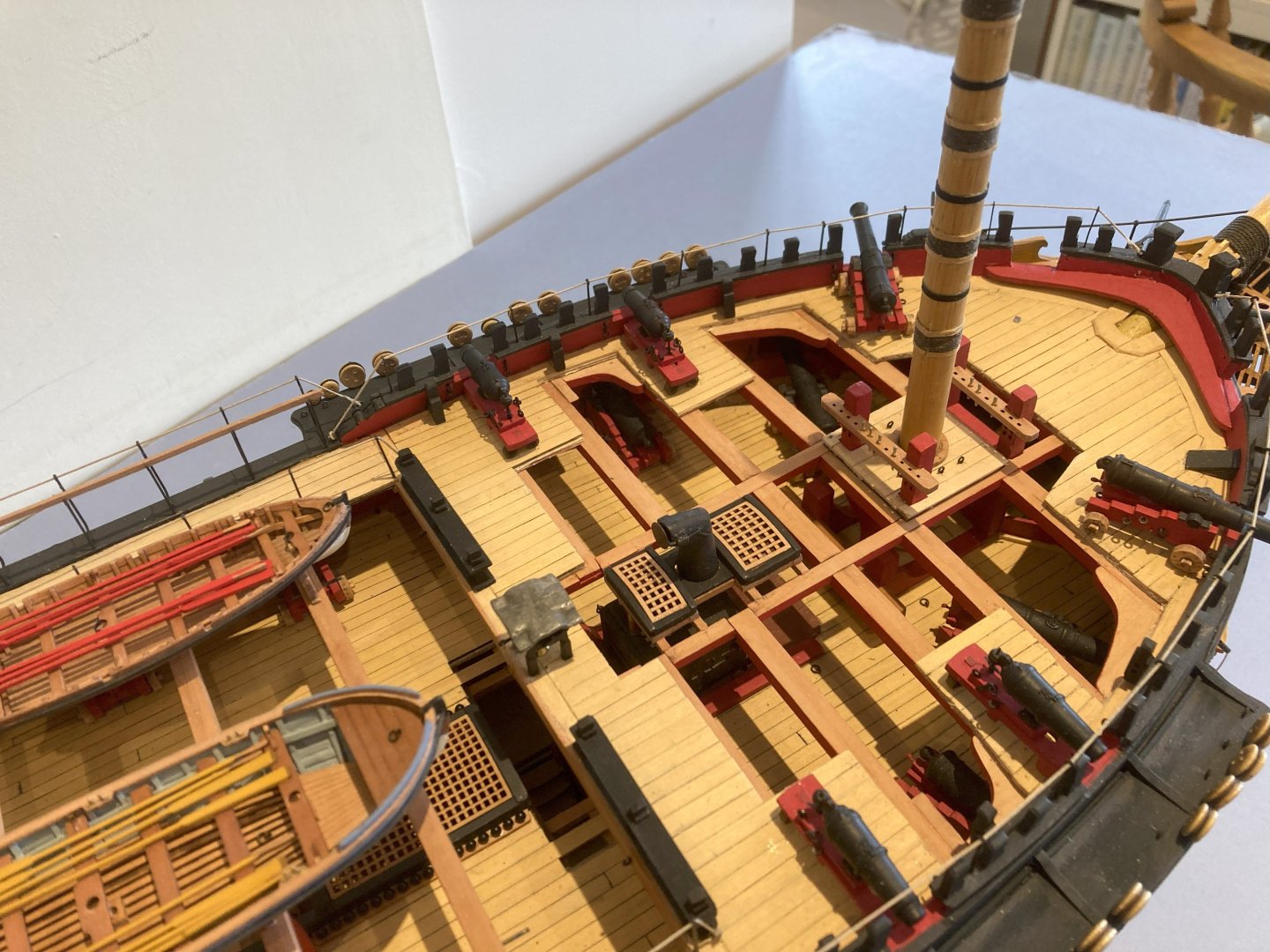

I have at last got around to taking the completion photo’s which will form part of the Photo build record book that I’m currently putting together. 4395 4361A 4392 4364 4365 4391 4390 4396 4369 4405 4395 2161A 2145a 4397 2162a 2164a 4380 4379 4388 4494a I am currently faffing around with a clinker built 18’ cutter, and ‘Indy’ is yet to be enclosed in her case, so the story has not quite ended. Then there’s the 26’ Launch, still on my mind. Cheers, B.E.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Bug, I used three each side on the Fore and Main Topmast shrouds, none on the Mizen. I used the aftermost ones for the fore and Main T’gallant yard lifts. I didn’t use the other two. Two each on the Fore and Main lower Shrouds, one on the aftermost Mizen shroud (used for the Mizen Topmast yard Lift) I recall that I used the TFFM Vol IV to decide which lines went where. TFFM indicates the fore and Main topmast shroud cleats were also used for the t’gallant clues, and the Fore topmast shroud cleats for the Main T’gallant Bowlines. I belayed a lot of lines to the rails as indicated in the TFFM. There are no belaying pins on my Pegasus. Nice work on those shroud cleats.👍 B.E.

- 312 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

Post One Hundred and Seventy Completing the Cutter. Apart from painting the bottom Ivory, and the wale Black/grey, the boat will be finished using w-o-p only. The rudder is a plain laser cut affair intended I think to simply display in the sternsheets of the boat. There are no fixings to hang the rudder either on the stern post, transom, or rudder. I chose to add these fittings including a tiller of the yoke type. 4287 Still requires a little further fining down, this is the third attempt which may still break. 4289 Trial fitting the rudder.; a few tweaks required. One consequence of changing the rowing arrangement from double to single banking is that the provided oars are too short for purpose. 4290 They are fairly easily modified but it does require using two oars to produce one. To improve the look of the oars the blades should really be thinned towards the tip. 4295 4298 4299 4311 Set -up for single banked rowing. 4302 4306 4307 I quite like the look of her on the skids and the Pinnace and Cutter don’t obscure much of the Main deck. B.E. 16/04/2024

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you Nils and Nipper. @ Nils - the figures are industrial workers which I found suitable for my Fishing boat models, but don't really fit naval figures of the early 19th century. @ Nipper - I don't really like action figures on my models, but I do like figures to demonstrate scale on a model. I agree the cook and the Pellew/Hornblower figures fit that bill perfectly. Others that would appeal to me would be a Helmsman standing by the wheel, and a Marine Sentry to post outside the Captains Quarters. I'm not holding my breath tho'😉 B.E.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One Hundred and Sixty – nine Progressing the 24’ cutter The floor of the cutter is covered by gratings at the stern, open boarded footwaling for the body, and a small close board platform at the bow. 4265 I changed the footwaling to a close boarded version as shown in the AotS book Diana which contains 1:48 scale drawings of a 24’ cutter. Before I add the ‘false’ ribs I use a copy of the kit plan to mark the positions of the thwarts. Positioning the ribs really needs to take into consideration the position of the thwarts and the related rowlocks for the oars, which are cut into the wash strake. 4268 The AotS drawings show the 24’ cutter arranged for single banked rowing. This is the arrangement I will follow, apart from any other consideration, there are less rowlocks to cut. 4270 I firstly fix only those ribs that fit aft of the thwarts before fixing the Rising, (thwart support strips) The remaining ribs can be slotted behind the Risings in the correct positions. The risings are fitted using a 4mm depth gauge but in fact follow the line of the second strake down from the top. Once fitted it is useful to check both the levels and the correct height of the thwarts above the footwaling. 4273 My 1:64 scale figures are useful for this purpose. 4275 I would like to see a sitting figure produced by Vanguard. A sitting Captain would serve well to give scale to the splendid Vanguard cabin furniture, and also the stern sheets of the boat range. 4277 I like to add small features to the boats such as here; the cap square for the Mainmast and step to take the mast heel on the Keelson. 4279 4280 4281 4280 Needs cleaning up now before finishing. B.E. 15/04/2024

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I've not seem a specific reference to Foreign Service locations, but I suspect it generally meant any location beyond home waters , particularly the tropics where repair facilities may be restricted. Clinker built boats were more difficult to repair and WE May (The boats of men of war) cites that in 1800 it was decided that the only cutters to be sent abroad should be Jolly boats. Navy board orders to Dockyards PRO adm 106/2512 no's 430 440/441. For the purposes of this build the cutter will be issued as carvel built. 9898(2) 9899(2) I do however, have a clinker built 18' cutter (Jolly Boat) ready to serve. Cheers, B.E.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One Hundred and Sixty-Eight Feeling somewhat miffed about the failure with the Launch I am moving onto one of the 24’ Cutters, if for no other reason than ‘getting back on the horse’ I have made 18’ Cutters previously, along with Yawls, and a 24’ Cutter should at least on paper be less fiddly. 4245 Before I had barely got started the tab broke off the transom piece, and once again the stern post broke part way up. This is before I even get to the delicate stem with its planking slot. I am beginning to think that use of 0.8mm Pear is just too thin for the structurally important keel part. It is pertinent that the grain on these parts is horizontal whereas any pressure tends to be lateral. It seems that any pressure, however light, gives a high risk of breaking these parts. 4243 At least with the 24’ cutter there are two sets provided, and in my case one was cannibalised to get to the keel and frames assembled. 4248 With the fairing completed this is the same point at which things went wrong with the Launch. I added further support to the stem before I began planking, and this time I resolved to use pva on the plank edges in addition to ca on the frames. 4252 The first four planks fit into the stem rabbet, or slot, happily without mishap this time. At this point the structure is much stronger, and damage risk to the stem much reduced. 4254 The garboard planks are fitted using 3mm strips. 4256 There is too little room to follow any sort of tick marking for plank shaping, so its basically done by eye. The aim is to get any less than realistic planking strakes below the round of the hull, out of sight. 4258 I achieve this by spiling the last plank. Unlike the Pinnace, removal of the central bulkheads did not result in disassembly of the planking, no doubt due to adding pva along the strake joints. 4259 There is no access to clean inside glue stains during construction so there is inevitably marring present once the bulkheads are removed. 4260 A gentle approach is necessary, I clean the insides initially by damping the excess glue with a small paint brush and gently scraping with a micro chisel. Water is used for the pva and acetone for the ca. very small amounts are used to avoid affecting the main construction. A little more fettlin’ and I can move onto the next stage. B.E. 11/04/2024

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I like the muted tones, and a good decision to dispense with any bling. I also very much liked your Diana which I can see in the background. Cheers, B.E.

- 19 replies

-

....... or not as the case may be, we will see.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you Mark, and Ron, It still rankles Ron, moving onto the 24' Cutter, we'll see how well I can mangle that one.🫤 B.E.

- 627 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.62d1d69fed1f32364417cb1f9cdeb009.jpg)