-

Posts

2,877 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by thibaultron

-

-

-

Part 003

I received the Boesheild rust converter/protector/blade cleaning kit recommended in the site I talked about earlier, and worked on cleaning up the sheet metal parts of the saw.

The protectant and the resin cleaners are both recommended for wood working tools and are stated not to effect the finishing of the wood.

Here are three shots of the sheet metal assembly, before I treated it. In the first shot I had already tested the rust converter on the inside of the center area.

I disassembled the main and end pieces, so I could get to the area between them.

I started with the smaller piece, spraying the converter on and using a green kitchen scrubby to work the solution into the pits, and loosen the flakes of rust.

I then repeated the process for the rest of the assembly. The write-up I mentioned said to use a brass brush, but I could not find mine. Looking at the photos, the scrubby did not get down into all the pits, so I would recommend using the brush.

In the last picture, you can see that the converter also darkened the galvanizing slightly.

After rinsing the parts with water, I sprayed on the protectant. It seems to be similar to WD-40 in application. I set the parts to dry, as in the instructions on the can, and will check them out tomorrow.

-

PART 14

A quick update. I sanded the faceplate to expose the original plastic color of the part, and it worked. I wish now that I had painted it with a lighter color, to make the contrast better, but you can clearly read the name. Here is a shot of the nameplate. I only had 320 grit sandpaper available, so you can see some scratches in the close-up, but not from viewing distance. I touched up the areas around the edges that also caught the sanding, and will go with this look.

- cog and GrandpaPhil

-

2

2

-

My condolences!

- druxey, Canute, Ryland Craze and 2 others

-

5

5

-

-

-

PART 13

Well, after a long delay, I’ve finally made some progress on the model!

I painted the interior Vallejo “Light Blue”. This color is the closest I have to the Humbrol blue provided in the kit. As you can see in the photo , below, some of the blue got on the side of the white rail, but that is the best I can do. It is almost invisible from more than a few inches away. I will probably have to replace the plastic traveler ring, that I broke when painting the hull (in the left of the picture). I’ve tried gluing it a couple times, and have had it not hold. I’m not sure that the ring would hold up under the stress of rigging, even if it was intact.

After looking at this photo, I noticed that the white primer was showing through the blue, so I gave it another coat.

I painted the name plate the same color as the base and masts.

I then tried a couple of different ways of highlighting the name. The first was to paint some gold onto a glass sheet and carefully press the name plate onto it, so that only the letters would get coated. This failed as the letters are too shallow, and/or the paint too thick. The paint got on the nameplate surface every time I tried it. I had similar results trying to paint just the letters. Finally I painted the whole front and sides gold, and in a day or two, I will try carefully sanding the letters to expose the brown paint or raw plastic.

This “simple” build to give me a break from longer builds, has turned into an equally long one.

My next major task is the sails. Do I use the vacuum-formed ones in the kit, or try to make some silkspan ones. The plastic sails would look OK, but both the larger “Square” sails are formed billowing, which is wrong for this type of boat. In the real boats each sail is set on opposite sides of their mast from how the other sail is hoisted. One sail is hoisted on the port, and the other starboard. Thus as the boat sails, one sail is always pressed up against its mast, causing it to crease where it touches the mast. This is quite unique, and I would like the model to show this. I can’t find my silkspan, however, and I’ve never made sails of any type before.

This is shown on the cover of a different release of the Heller kit (circled in red). As a side note, this cover also shows that no one is minding the tiller!

I once owned a 17 foot sailboat, and obtained an ad for it on the Web. The boats “spacious” cockpit was shown with 4 or 5 people occupying it! On closer inspection all the people were young children. I love ad companies!

- GrandpaPhil, hexnut, cog and 1 other

-

4

4

-

A model to be proud of indeed!

- Canute, Old Collingwood, mtaylor and 1 other

-

4

4

-

Yes and no on the maintenance issues. Toward the end of steam, they had progressed mechanically with roller bearings and better counterballancing to where they did not require much more maintenance than the diesels, but the die was already cast. Yes they did dent the track over time, but the diesels did, and still do, wear the track just about as much, but in a different way, the drive wheels slip more and burn the rails.

- mtaylor, popeye the sailor, Canute and 2 others

-

5

5

-

I'll be following along too. I've read his book a couple times, and have the kit also. If you have questions, just ask the forum, they love to help.

-

-

-

-

-

Part 002

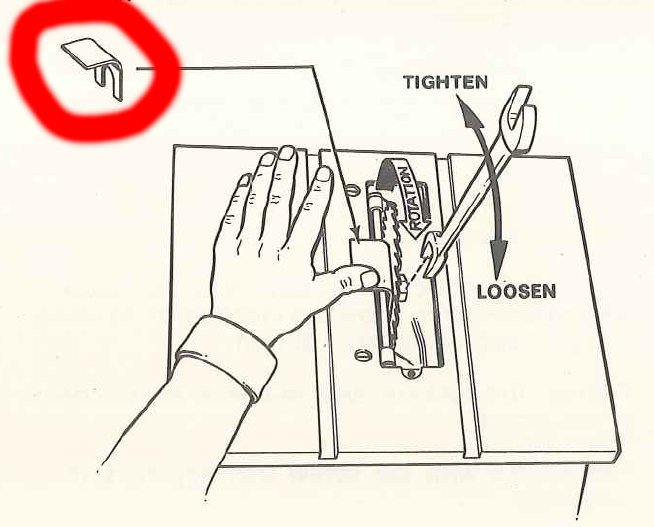

I started working on the saw today. The first task (after I disassembled it), was to make a wrench for the blade shaft. The shaft has two flats on it to hold the shaft steady while you remove the blade nut. When new, the saw was supplied with a little wrench made out of sheet steel, shown circled in the picture below.

The photo below shows the area the wrench has to fit in, with the flats circled.

The space for this is too thin for a regular wrench to fit, and the Dremel part is long gone. So I made one from a piece of an old carpenters square. It is not fancy, but it works. I cut out a ¾ inch wide slot in one end with a Dremel tool with a cutoff disk, then I chamfered the other end to remove the sharp corners.

The next task is to firm up the assembly that tilts with the blade and motor, to make angled cuts. The whole assembly rotates on hinges mounted on a sheet metal plate. The motor and blade assembly then slide on this plate to raise and lower the blade. The picture below shows the plate. The hinge for the assembly is one the right, and the slot that allows the motor/blade assembly to slide up and down is on the left.

This shot shows the two bolts, circled in red.

The saw has bolts for mounting the motor/blade assembly. The instructions say to tighten them, then loosen slightly to allow movement. This allows some slop. My idea is to put a nylon washer under the regular washers, and tighten the bolts so that there is no slop, but the assembly can still slide freely on the slippery nylon. I did not know the size of the bolts, so I bought washers for #6 and #8 screws. The store was out of the #10s. Well guess what, the bolts are #10s, naturally. I’ll stop at a different store and get some #10s. I need to buy a nut for the one screw, the factory supplied one is missing. The housing is taped and the nuts are used as lock nuts, once the bolts are adjusted.

The hinge/plate assembly is tight, so there is no slop in it, though there is some flex. There is another area that allows some slop, and once I correct this, I’ll see if I have to further work on this problem.

I also need to clean up the rust and add a protective coating to the steel parts. I’m a little short on funds, so that will have to wait until next payday.

-

On the stripe of oil on the wall behind the lathe. I bought a large piece of formica and leaned it behind my lathe, resting the bottom inside the chip pan. This kept the residue from the wall. Eventually a little got on the ceiling but that was over a few years.

I use cutting oil for all my machining. There are various types for different metals, but the regular ones for steel work, if that is all you have. I never turned copper, so I do not know if there is s specific one for it.

-

Looks great! Wish I could get one of mine to look half as good!

- Canute, popeye the sailor, mtaylor and 2 others

-

5

5

-

The above link is for the model 580-2 (The second version), here is a link to the revised 580-2 model parts list.

http://vintagemachinery.org/pubs/1798/1665.pdf

Here is a link to the original model manual, circa 1978

-

Here is a link to the manual. Note that this is for the second version, circa 1990. The saws only had slight differences. You can tell a 580-2 from the first model, as it has a black background on the front panel decal. The first version had a red background.

-

-

Thanks for all the input! For now I just need to rip planking for some dioramas and decks. I will not be doing a lot of scratch building, for now. I just need the saw for upgrading some of the woods supplied with the kits I have, and a couple of small scratch built boats I want to do.

Mark, I will test the supplied blade carefully before doing any major work with it, safety first! Thanks for the link to the saw blades.

At some point, if I find that I need a table saw more frequently, I will get the Byrnes saw.

-

Part 001

I looked at my available options for a modeling table saw. The contenders are:

1. The Harbor Freight type 4” table saw (many similar types of this basic type of saw).

2. The Proxxon table saws, the cheapest is in my price range, the others cost enough that they are almost as expensive as the Gold Standard Byrnes table saw (see below).

3. The old Dremel 4” table saw.

4. The Byrnes table saw. The best and the Gold Standard, but well over my present funding level at about $500 with shipping. I hope to get one of these in the future, but that is at least a year or more away.

The Harbor Freight type table saws are poorly built, and the blade height adjustment is by raising the table, on I’m sure poorly fitting leg/slides. It also does not have a fence. The saw blade slot is cast integrally with the table. This prevents you from cutting thin pieces, as they will tend to be pulled down into the slot. On a regular table saw the blade comes up through the table in a removable insert. If you are cutting thin pieces you replace the insert with one with a thinner slot. In many cases you put a solid plate in and run the blade up through the insert, giving you a zero clearance fit. Of course you need a carbide blade if it is a metal insert, but you can make a thin wood insert from hobby plywood for a regular steel blade. I can’t imagine the Harbor Freight type having good enough tolerances on the table slides for this, even if you can attach something to span the slot. Prices on these range from about $40 to over a $100.

The cheaper Proxxon saw has a fixed blade height, also no insert, and only a 2” diameter blade. It does however come with a small plastic fence that does not span the full depth of the table. Prices range about $125 to $200.

The Byrnes saw is built more like a machine tool, rather than a saw, and has a large array of available accessories, but it comes with a matching price tag. If you have the money get this.

The Dremel saw is no longer made, but is available used for about $125 to $225,with shipping on Ebay. It has a blade that can be raised from under the table, as in a standard large table saw, and the blade can be angled also as in a standard saw. The blade is belt driven and the motor is more powerful than the Proxxon and HF type saws. It does come with a fence that spans the whole depth of the table, and a miter gauge. It has a removable insert. The base is a thick plastic, but durable. There are some accessories available in the aftermarket, but the sources are drying up. The blades and belt are still readily available, though.

I chose this route as it falls within my price range, and has more standard table saw features, including a blade insert. My saw did not come with a blade protector, some of the later models did.

The blade raising/tilting mechanism is not as sturdy as I would like, the miter gauge is a bit loose in the slots, and the fence is not the most robust, however. I will attempt to remedy some of these faults as this build log continues. The saw is eminently usable, though.

This log will not be a regularly updated one, but I will relate all my experiences with both using and upgrading it as time goes on.

Here are pictures of the saw as I got it.

The first shot is the top. I noticed when I was editing the photos, that I had a visitor. I’ll have to fog the shop, this week.

This is the front with the blade raising and tilting controls. These are the same types as a standard table saw. The power switch is on the lower right corner. If you look closely you will see that both front mounting lugs are broken off. The seller did not pack the saw well, and I guess the box got dropped at some point! Both lugs were in the box, though. I assume that they were still attached when it was packed, otherwise I’m sure they would have disappeared before the unit was sold. I’ll glue them back on with epoxy. I am not sure what type of plastic the base is molded of, so using a plastic cement may not work. If I had to guess, I would say ABS plastic.

Here is the “guts of the saw from underneath. This is also similar to how a standard table saw is built. Notice though that there is no back to the saw. At one point there was an aftermarket back available, with a vacuum outlet, but they are no longer sold. I will make my own back for mine. Note that the rust is not atypical, the metal parts were not painted when built. It does not affect the operation of the saw.

The saw ran well when I plugged it in, with the belt running smoothly.

To start with I will disassemble and clean the saw mechanism, using the tips on this site.

https://karincorbin.blogspot.com/2009/07/ye-olde-dremel-table-saw.html

I will also need to come up with a support for the back of the blade mechanism when making fine cuts. This support may have to be removed to tilt the blade. I have to think more on this idea.

Until the next part, thank you for reading my thread.

-

Frank, wonderful model, and thank you for bringing us on the journey of her construction!

-

Carriage Gun Rigging

in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Posted

In model railroading, you can find a prototype for just about anything. One of the hard and fast rules, though, is never put a window in a chimney. However, when I lived in Pittsburgh, there was a house with just such a window in the middle of the chimney! A couple of years ago I found the house on Google Maps, and the street view shows that the chimney and window are still in place!