-

Posts

706 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mark Pearse

-

The mainsail track cars are made & epoxied into place, they are basically a piece of brass flat bar with a loop & sit in a C section on the mast aft face - the C section is the track. The mainsail foot & the gaff are laced. The luff with have lacing ties from the cars to the small luff cringles on the sail. A small dot of CA glue was used at each point where the lacing thread crosses itself. Also, she now has a name.....my mother's name. The SASC A28 N is the registration number, local regs are that you can choose you own mix of letters & numbers - but it has to end in 'N'. SASC is the Sydney Amateur Sailing Club & A28 the sail number. The jib track cars are underway - 3 strips of brass flat bar, the top one is the same with as the track (so hopefully it will fit on the tracks....). The will have a U bolt with a standup block, plus a little button to replicate the thing you adjust the position with.

-

Hi Frank That's a good result. But just curious, did you try furling the jib in the actual shape using wet Silkspan? thanks

-

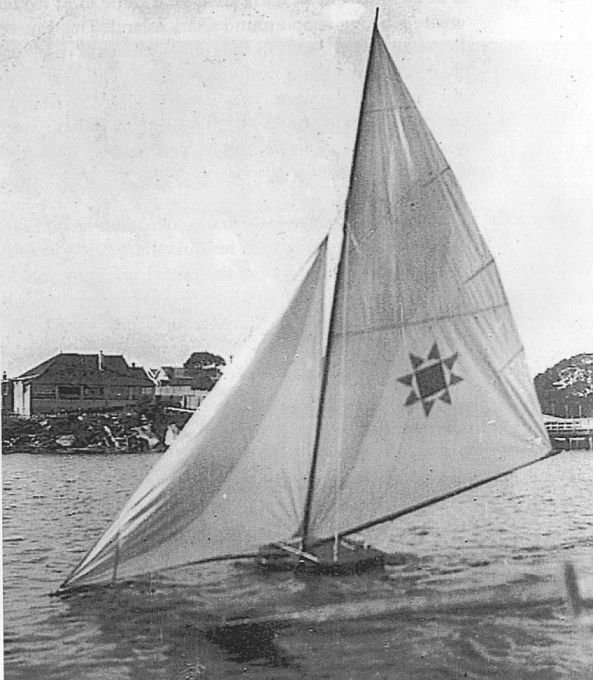

thanks everyone, Hi Keith, funny you should ask, as it happens I do have a couple of ideas... Probably it will be a half model of Karoo, a 21' Cliff Gale design from the 1920s. Karoo was an open boat with lug sloop rig. The photo below is a current boat that uses her lines, from 1988 in a fresh breeze. The model would be for the model wall at our sailing club. The other idea is a radio controlled "Balmain bug". Until the 1950s model yacht racing was popular in Sydney, the main classes 6", 1' & 2' - hull length being the only limitation. You're probably wondering how a 6" model yacht could sail in a choppy harbour, but they did & were chased by two blokes in a dinghy who would tack the boat or set the spinnaker for downwind etc. I don't think of them as scale models, really they are miniature racing skiffs. Like many of the bigger classes here, the design tried to balance as much sail area as you dared with enough ballast to keep it all up & enough hull buoyancy to keep it all afloat. Below is a 2 footer - probably not what you were expecting from a 2 foot model yacht - compare the ballast to the size of his foot & you'll get an idea of the loads. The rig of a 2 footer is large, probably an 8 or 9' mast, a 2.5' fin & the bowsprit appears to be about 6', so I'd probably try a 1 footer, & an RC motor might not cope with the 2' rig. There's a few things to work out, but it's fun to think about the possibility....

-

HI Vaddoc no problem, my assumptions about the rig this boat carries were wrong, I wasn't expecting her to be able to set a flying jib. I assumed the topsail carried both spars with it, in which case you don't have the top section of the mast above where the backstays meet the mast. You will be happily busy with that rig. Apologies if my comments were confusing.

-

HI Vaddoc, nice work, she's really coming together well. Don't forget that a gaff main has running backstays that should go to the head of the mast. Looking at your fitting they could possibly fix to the topsail halyard loop (perhaps both going to one ring on the loop?).

-

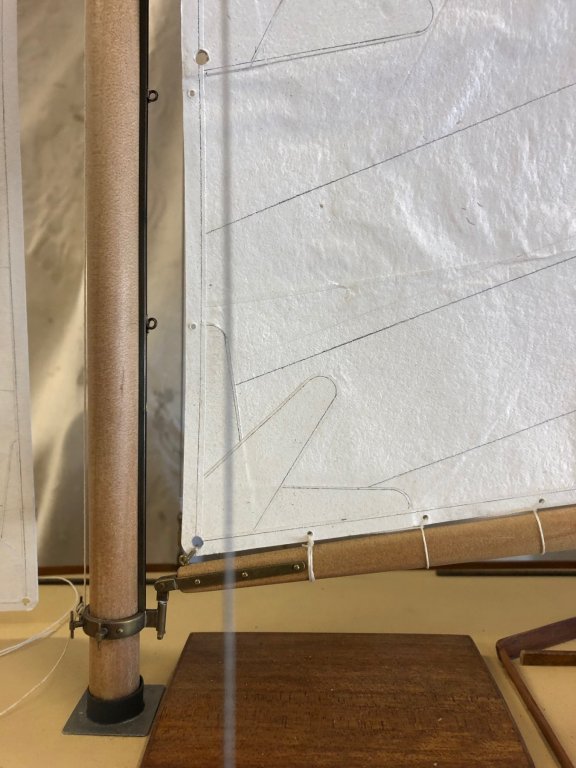

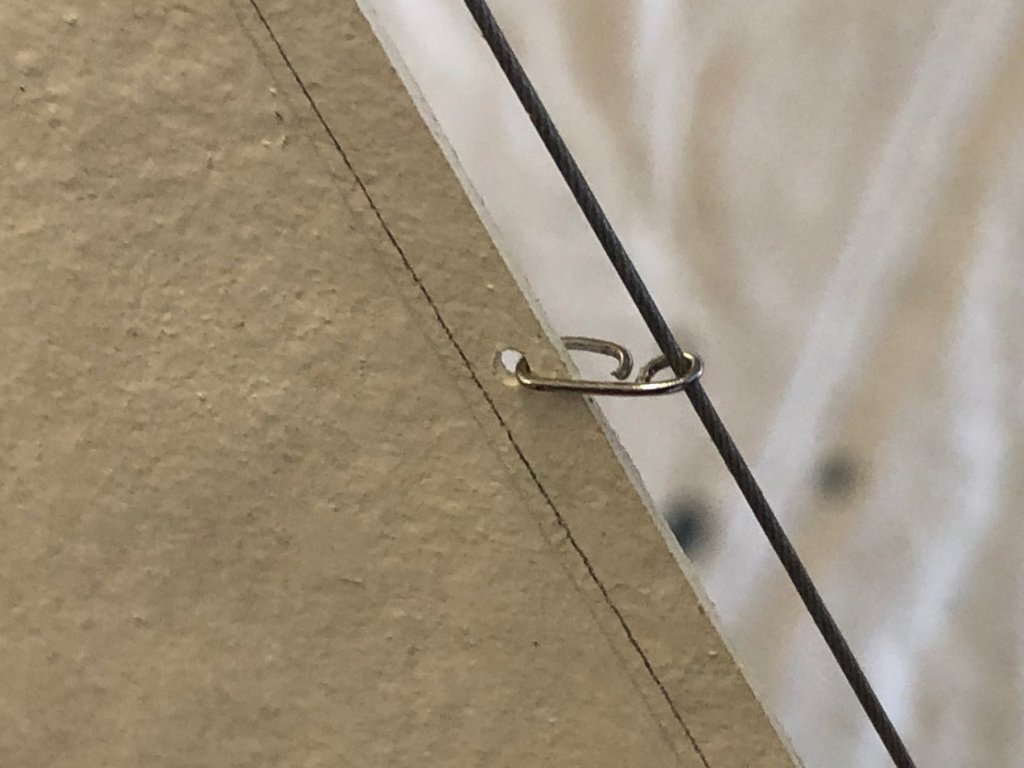

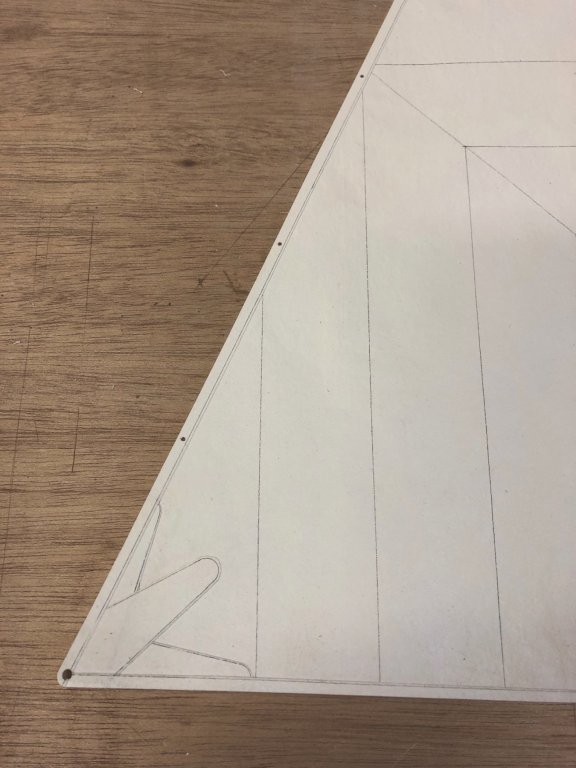

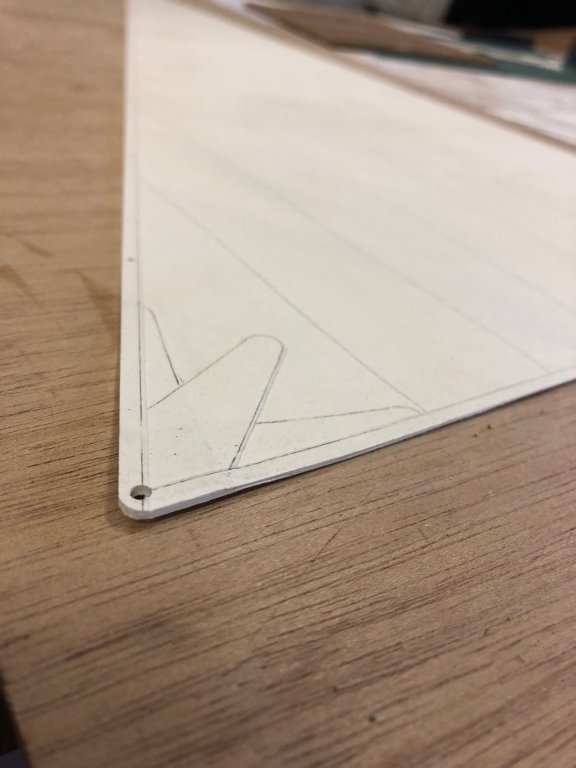

Some progress, I'm almost ready to do the final rigging of the sails. The jib is done, but without any sheet blocks or track cars to lead the sheets yet; the mainsail was test fitted, see below, & since then I've set out & drilled the luff. The luff is not laced, that's a bit old-fashioned for the 1960s, they would have likely been some simple car & track arrangement. Laced luffs are ok but can jam if it's very windy, nothing like being unable to get sails down. I've also decided against doing a loose foot on the mainsail, mainly for model making reasons. I prefer a loose foot, but it will be a greater risk for the model to have the sail loading to just the tip of the boom & the tiny block there. I think it's historically correct to do either for the time. The rig temporarily in place, the 'A' indicates the Sydney Amateur Sailing Club. The tack of the jib completed. One minor detail is that the replicated modern swage terminals - aluminium tube with the wire glued in place with CA - just aren't strong enough so I did a single squeeze on each tube with pointed (round tipped) pliers. The effect is quite good, & in fact the actual terminals do have a flat spot for putting a spanner. Jib hank: These will be the mainsail luff cars. The flat bar pieces will sit in a brass C section that's on the stern side of the mast. To be soldered, then probably glued into the track.

-

Twelve inch to the foot dinghy

Mark Pearse replied to Bedford's topic in Non-ship/categorised builds

thanks for sharing the photos, she's beautiful, & it's a good looking rig too -

A real world example is that medium & large racing yachts have adjustments to increase or reduce the mast bend. In the case of a fore & aft mainsail this would increase or decrease the fullness of the sail & give more pointing or more power etc. I'm not sure how this could translate to square sails though.

-

HI Steven you asked for comments on wedging the mast at the deck - wedges at the deck are not required if the mast & other parts are strong enough to not need the extra support, the mast can just flex it's full length & will move at the deck level. It doesn't answer your question about whether or not to do it here, but will hopefully assist.

-

Hi Steven the mast could well be salvageable. I've had good success using a heat gun & gently manual pressure to put in / take out bends in timber. If you don't have a heat gun, maybe there's some simple household alternative to warm the timber without scorching it.

-

Thanks for putting my question forwards. My gut feeling is that it's to do with the way the boats handled when working, & possibly to do with the topsails as the rake forwards affects the topsails balance the most. It could also be to do with the shrouds angle to the mast, as they don't seem to have running backstays.

- 219 replies

-

- smack

- cross-section

-

(and 2 more)

Tagged with:

-

Hi GL interesting. A couple of sail questions for you: - do you know why they raked the masts forwards? - were the topsails used regularly, or were they a 'race day' sail? Mark

- 219 replies

-

- smack

- cross-section

-

(and 2 more)

Tagged with:

-

The drawing is looking good, but some don't seem to be quite right just yet - eg number 5 looks good towards the lower part but dips in towards the top, compared to 4 & 6. Visually, it could help to see the pattern if you can temporarily 'turn off' the inner line for each rib. Are you setting up any of the horizontal hull lines at the same time?

-

What I thought I could see isn't a fairing error, just the way the hull form lifts around the aft part of the keel. I looked back at earlier photos & it doesn't seem to show, so perhaps it's just an optical illusion from the added black lines. The yacht designer Ben Lexcen often had a hollow in the same part of the hull.

-

Hi Keith yes there are some interesting things happening around the keel, just at the stern part where you filled there seems to be an intentional hollow.

-

best wishes for this Maury, she is a lovely model & I look forward to seeing the new work

-

Hi Frank, is there something to stop the mainsail halyard from getting in the way of the boom jaws (when the sail is up)? It looks like when the boom rotates, the jaws will push on the halyard -

-

Hi Keith what was the tool you used for sanding the moulds? Also, a comment: what an amazing hull, & it's one of the pleasures of a model to be able to see the whole - especially when you probably can't really see the whole on such a large yacht. Also interesting how far aft the keel is, when you include how the bowsprit will make the sailplan even further forwards.

-

Hi Keith, it is the same stuff, in medium weight. In his youtube videos, Tom Lauria who's using it as single thickness for a 1:48 model of a small cat boat, about 20 foot. The technique he shows really transforms the tissueyness of it, but I needed to beef it up even more. I decided to double the silkspan to then use that as a base material; I laid out one layer of silkspan on a flat surface &, using a 100mm sponge roller, rolled on acrylic house paint (matt finish) with about 20% standard PVA mixed in. I did this in strips across the sheet, about 150mm wide, & then quickly laid (& burnished) a second sheet of silkspan onto the wet part of the surface. Then painted another strip, etc. After the whole thing was beyond sticky I then painted one side with a good coat of the same paint/PVA mix, & when that was handleable I did the other side & then suspended it to dry for a day or two - (not worrying about it not being dead flat, photo somewhere above). This was the base material for me. The sail tack was one thickness of the above, with 3 reinforcing pieces each side (each cut from the same stuff), layered on top of each other, plus the edge tape (same stuff), overlapped at the corner. So it's the same technique as Tom's, but once I started fiddling it was clear that what would suit a 1:48 model of a small yacht wouldn't suit a 1:12 scale model of a medium sized yacht. I emailed Tom & he very generously gave some advice that helped a lot - as described above (the reinforcing pieces building up so much was my addition). So, the good news is that as a product & technique, it's quite adaptable. Unfortunately it doesn't suit my original idea of formed sails (at the scale & model size I'm doing, & with the amount of curvature I wanted in the sails). The ironing it really works well & fast, & I found that using the iron - without steam - at a 'wool/silk' setting, & the water/PVA was about 40/60 ratio. This part probably won't make sense if you haven't seen the videos. Hopefully this gives a good visual picture. At the risk of being repetitious, I'm amazed but how much it feels & bends like heavy dacron, even the sound. But if you were going to show the sails flaked, or rolled, or furled etc...my sails would possibly not work, probably a bit thick. Testing required.

-

thanks all the jib is now pretty much done. The main cringles at the tack, clew & head were drilled by pre-drilling a piece of 1.5mm styrene to the final size (3mm), then using that as a guide, & the holes through the sails stayed sharp. I experimented with replicating eyelets, by adding some black oxide to PVA glue & using a toothpick to line it on a drilled hole...but it didn't work. The tinted glue is excellent but the technique is difficult to get even, so I will just leave them plain. Better to not draw unnecessary attention to them. There's possibly an error in my setout below, but I'm not sure & will accept it as is: you can't see the point at which the setout seams meet - I set out the seams to the edge of the sails, not to the edge tape seam, which is 3mm inside the sail edge. It would look better, & possibly be correct, to have allowed for the edge tape thickness in the setout. You can see here how thick the corners are, which is fairly scale-correct.Each piece of Silkspan was doubled, & there's 11 thicknesses of that. I think that the material is quite strong & won't be at risk of tearing unless there's a major accident. The whole thing had 2 coats each side of turps based matt clear polyurethane finish, hopefully t won't yellow significantly over time. I considered treating the edges with the same, or paint, or something else - but with a clean cut edge, & the mass off silkspan/acrylic paint/PVA glue is quite well bonded into a mass, it doesn't seem to need anything.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.