-

Posts

698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mark Pearse

-

-

Hi Scott

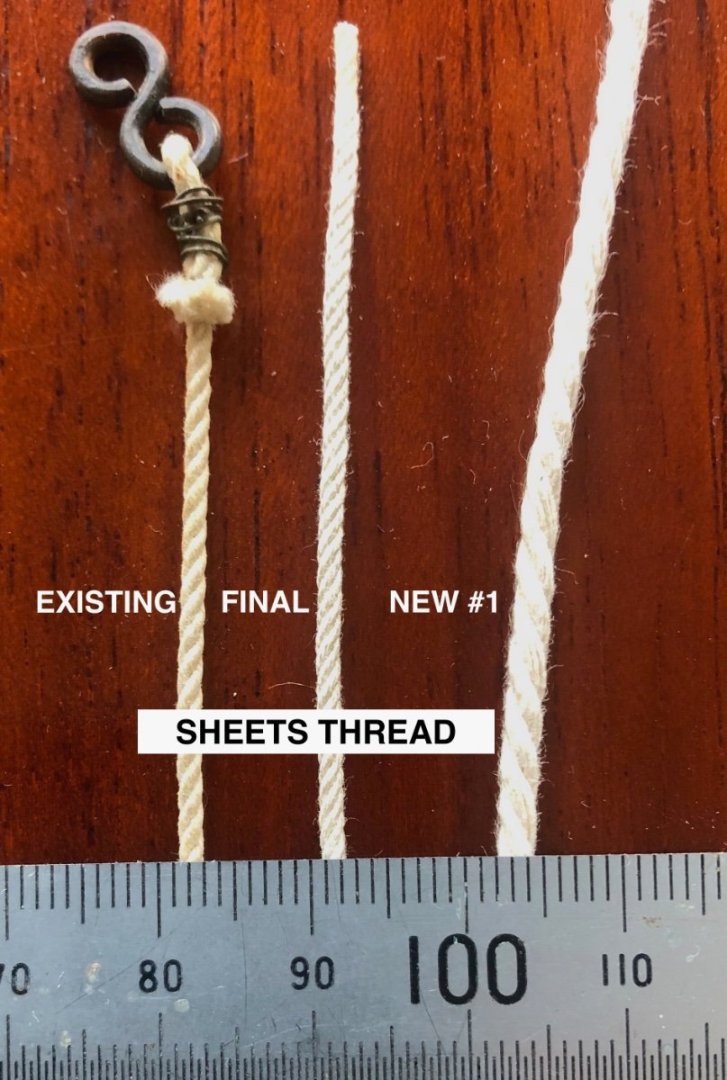

Thanks, some of those strings would have been perfect. I did end up getting just the thing via the internet, 2nd time lucky.....see below, the New #1 was the first (& unsuccessful) string order, & the Final was deemed good enough.

I see that this is your first post, are you interested in or working on any model yachts?

Posting this, I realised that I never really finished this blog off, so I'll add finished photos below & give a short overview of the completed model repair.

Overall photos, in the house of the owners. The model is large, as you can see here.

And a gorgeous hull shape. I am guessing it's 1880-1910 in age, probably pre-1900, as the hull shape is typical of the 'lead-mine' hulls of the 19C.

Bowsprit repair at the stem. I re-wrapped the bowsprit with brass wire, where it had been done to cover/strengthen a previous repair.

Sail repairs, the cotton was weak, so I painted the tacks, leeches & heads with diluted PVA, then new stitched rigging using whipping twine. In this photo, I extended further down the sail in white so it's not so obvious, but adds some badly needed strength.

Tip of the bowsprit, some of the hooks were missing & were copied. The repairs did not try to o'improve' on previous work that wasn't perfect, I made the decision to leave the model with it's quirks & eccentricities (below the whipping in wire...)

Foredeck, also showing how the headsail sheets were lead. This model would not have been raced, I'm sure of that. Swapping the sheets for th opposite tack would have been slow. She was owned & sailed for the pleasure.

As a final note, I believe she was built in Tasmania, as the bowsprit, I believe, was King Billy Pine. For those that know the timber, it's a lovely light-weight timber with an even grain. The hull & deck is Australian Red Cedar, which was shipped to Tassie, & I am guessing that King Billy Pine was much less available in other states than RC was available elsewhere.

thanks,

- paul ron, Roger Pellett, mtaylor and 1 other

-

4

4

-

Hi Steven, I enjoy the way your models come together. It might seem haphazard to you, but it seems thoughtful to us. And the mosaic in your last post is a very fine work of art, did the mosaics as art works inspire the interest in these boats?

- mtaylor and Glen McGuire

-

2

2

-

-

-

-

-

Expanded polystyrene is an underrated material aesthetically, however I was wondering if you were going to do a stand, & what sort of design?

- vaddoc, mtaylor and FriedClams

-

1

1

-

2

2

-

Hi Brinkman

From a practical boat building point of view, if floors are fixed to the hull there should be some side gap, even if small. I haven't looked it up, but my guess timber will expand across the grain around 2% - so 3mm for a 150mm board. Floors can also be fixed into panels that are loose, not fixed to the hull - in that scenario they could be done without gaps. For a working boat, there's a lot of advantages to loose floors. Is there evidence in the example you cited, that the floors were fixed to the hull?

PS The dark colour is beautiful

-

Congratulations Vaddoc,

A gorgeous model & one that must have been a very demanding build. You really had to build the whole boat & it's a beautiful result.

- FriedClams, mtaylor, AJohnson and 1 other

-

4

4

-

-

-

Hi John

That's a beautiful model,

- Keith Black, mtaylor and FriedClams

-

3

3

-

Hi John, Steve

Thanks for the offer Steve, I have used quite a lot of epoxy. I built a small open gaff sailing boat some years ago (strip planked), helped my wife build a lovely plywood kayak, & myriad repairs on our boat Cherub. I'm using Araldite Super Strength for the model. Per ml it's expensive, but the tubes make it easy to proportion a serving, & the quantities will be small. Also, it is far tougher than it used to be. I have tried West System, Bote Cote, Norglass, Epiglue, Aradite & the SS Aradite is almost the equal of Epiglue. The 5-minute is good for some uses, but that doesn't include planking this model.

For a model, I would only consider an epoxy that was pre-mixed with fibres, that is a 1:1 ratio, & available in a convenient form in small quantities - other ratios wouldn't be practical for the quantities we typically mix. So that cuts out most of the above, & I'm not a fan of Norglass epoxy. Lastly, it is widely available.

Previous models I mainly used PVA, especially Titebond.

Do you use epoxy for models?

- Jim Lad, Scottish Guy and Jack12477

-

3

3

-

Since my lost post I have been preparing for planking & adding a keel.

I have made the front inner part of the stem; put solid blocking between the moulds (mainly to give the keel something solid to be fixed to); some solid blocking around the propellor cutaway (the final shape is best made from solid timber, so again the blocking gives something good to fix to); plus some timber next to the transom, just so the glueing surface is greater.

I did some fairing of the moulds, it's not yet 100% completed but the lower parts of the hull, towards the gunwales, are pretty accurate now. The hull is a raised decker, so the topmost full length plank is from the top of the transom, which is lower than the main deck line. I decided to do this plank first then plank up & down from it. The process was influenced by the fact that it won't be traditionally planked, because this actual yacht was built strip planked (ie: wood epoxy composite). I've realised it does give more flexibility on planking. Anyway, the do the first plank without pinholes in it, I pinned a temporary plank on each side, but 2 planks distant....2 planks so that I didn't glue the pinned plank to the moulds. Subsequent planks can be clamped to the ones already installed.

You can see it below, the glued plank is not pinned. Spacers offset so they didn't glue to the hull.

First plank done, some slight imperfections, but within 0.5mm sanding depth. Planks are 2mm thick, replicating the actual strip planks of 25 x 50mm approx.

I used epoxy for these two planks. I hoping that I can use it for all the planking, including the edges (ie: plank/plank). I'm hoping that it will give a more monocoque hull so the planking lines won't be visible. Strip planks don't run in the natural way, so seeing the trace of them will be off-putting, & given the hull colour is black detail issues will probably be more visible.

all the best

- Scottish Guy, druxey, Jack12477 and 3 others

-

6

6

-

Hi there Håkån

That's an interesting way to plank it - it looks like you have two mirror-image jigs. You do a bit of planking one side then flip the model into the other cradle, clamp the keel & do some planking on the other side...? I like the way it means you can clamp the keel straight each time.

I haven't seen that before, could you explain why you are doing it this way?

- mtaylor and Keith Black

-

2

2

-

On 10/20/2023 at 3:30 PM, silverman834 said:

Maybe I should make them slimmer?

Hi Silverman, as you raised the question, I looked & I do think that you are right - the lower part of the two centre knees are a bit heavy. Remembering that their job isn't to support or strengthen the beam itself, but to brace & strengthen their connection to other members. The part of the knees sitting on the top of the central beam probably need to be more slender than the beam. Perhaps also the aft knees a bit as well.

best wishes, looking superb

-

That thing to hold narrow timber for planing is great. Do the wooden cams stay in place when tight?

- Nirvana, Keith Black and mtaylor

-

3

3

-

Hi there,

Nice to see this lovely model back on the bench.

I think you should go with your instinct regarding the bowsprit. The posts don't make as much sense for a number of reasons, but your solution is simpler & just looks right.

- hollowneck, Brinkman and mtaylor

-

3

3

-

On 9/9/2023 at 9:07 AM, Louie da fly said:

The isopropanol makes the glue go gooey so you can adjust the joint a bit

Hi Steven

What glue does this work on?

Mark

- Glen McGuire and mtaylor

-

2

2

-

Lovely.

You got the deep & squarish forefoot of the bow, apparently it's so the boats can drift well. If the forefoot is too rounded they don't hold a drift abeam to the wind, the bow blows faster than the stern.

- Louie da fly and mtaylor

-

1

1

-

1

1

-

Hi Steven,

A subject close to my heart, they are wonderful boats & I race against them quite a lot. For once I have a bit of knowledge - the fish they went after is Barracouta, & not related to Barracuda. The bowsprit question I had to look up in the wonderful book "First Home, The Couta Boat & Victoria's Couta Coast". I had assumed it was to get a larger jib, as sailing performance was important - the first boat home got the best prices for their catch. This is partly correct...on the curved bowsprit (on Coutas called the jibboom) the book says "The early boats ... had little or not bend in the jib boom. Later, the larger boats ... had higher bows & more sheer. Extra bend was put in the jib boom to get more length in the jib & to improve the appearance of the boat."

The book has a lot of details, if you want anything you could post or PM me. The model is looking lovely, & I shall follow with great interest.

-

Hi Keith

The lines drawings show very careful & patient work, they are a credit to you. It's a fascinating hull. Like a sailing boat, but not a sailing boat.

- KeithAug, mtaylor, FlyingFish and 1 other

-

4

4

-

Hello Håkan

Greetings, this is a very special build of a remarkable yacht. I haven't been following the forum closely recently, & this shows what I've been missing. I hope that you got some good sailing in during your summer. Best wishes & I look forwards to updates.

- Keith Black, Wintergreen and mtaylor

-

3

3

-

Hi Steven

Have you come across the photos of Alan Villiers? In the 1930s he spent some time on lateen rigged dhows. No doubt many differences, however it's just possible some the the technical questions might be helped by some details that are visible. His photos, if you haven't seen them, are very good quality images.

- mtaylor and Glen McGuire

-

2

2

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

in - Subjects built Up to and including 1500 AD

Posted

Your post raised an issue of modelling accuracy - not accuracy to history but how close to square, how consistent in size & shape, etc. My boating experience is with smaller traditionally built yachts, & even boats that were built by recognised boat builders of the day have many inaccuracies. It's clear many things were set out by eye, & quickly at that. Hatches well out of square, portholes not aligning on each side of the hull..... I suppose I'm pointing out that what you described is probably more true than a high level of accuracy & consistency.