-

Posts

736 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by ChrisLBren

-

-

Hi Group,

I am considering making an investment here soon. Currently I use a Proxxon MF70 which is a great little machine - however I am now building in 1/36th plank on frame for the foreseeable future. I picked up an Emco Unimat 3 a couple years ago from a member of this site which I will set up as my lathe and want a bigger dedicated mill.

It seems the models that are most mentioned here are Sherline series or the Proxxon FF230. I need the ability of a tilting table and or vise for either choice. Most swear by Sherline - would love thoughts as to model and accessories needed for my specific needs of larger scale/complicated assemblies. Sorry if my question here is redundant or been addressed.

Black Friday is approaching - so I am curious if either would potentially go on sale based on past history.

Thanks

-

-

-

Incredible work at this scale - amazing !!!

- MICHELE PADOAN and mtaylor

-

2

2

-

-

Thanks for the tips everyone. As a matter of fact just finished reducing some pear 1mm for more frames (32 completed and counting). I used a combination of the Proxxon Planer and Brynes thickness sander for the final .5mm. Cutting the boards in half to 12 inch lengths helped as well as being conscious of the feed rate and applying constant pressure to the board on the feed table. It worked great - my sander has course paper on one side which I used to get the billet to almost final dimension and finished with the other fine side.

-

I have been folllowing your buiild logs on the ANCRE site for years. Welcome to MSW - your art is truly maginificient and inspiring.

- MICHELE PADOAN, Keith Black, mtaylor and 1 other

-

4

4

-

Hi Group,

I would appreciate some operational tips here. I am sure this is my fault not the tools - sometimes I am experiencing dips inthe 2 inch wide by 24 inch long plank I am dimensioning (probably from the drum of the sander). Usually they only about a 1/8 of an inch wide or so accross the plank so I cut around my parts around it which wastes wood.

Is this a feed issue or am I trying to take off too much wood in one swipe ?

I am reducing boards approx 6.75 mm thick to 5.6 mm final dimension.

Thanks much,

Chris

-

-

-

-

Greetings Group,

I restarted this build in earnest beginning of August and have completed 20 frames (roughly 1/3rd of the total frames). The frames have not been sanded or bias added, simply assembled (each frame is 12 parts and stacked) with some extra "fat along the bold line of the frame patterns.

I carve out early a couple hours early 430 AM - 630AM before the kids go to school and my day starts - has been working really well so far !

-

-

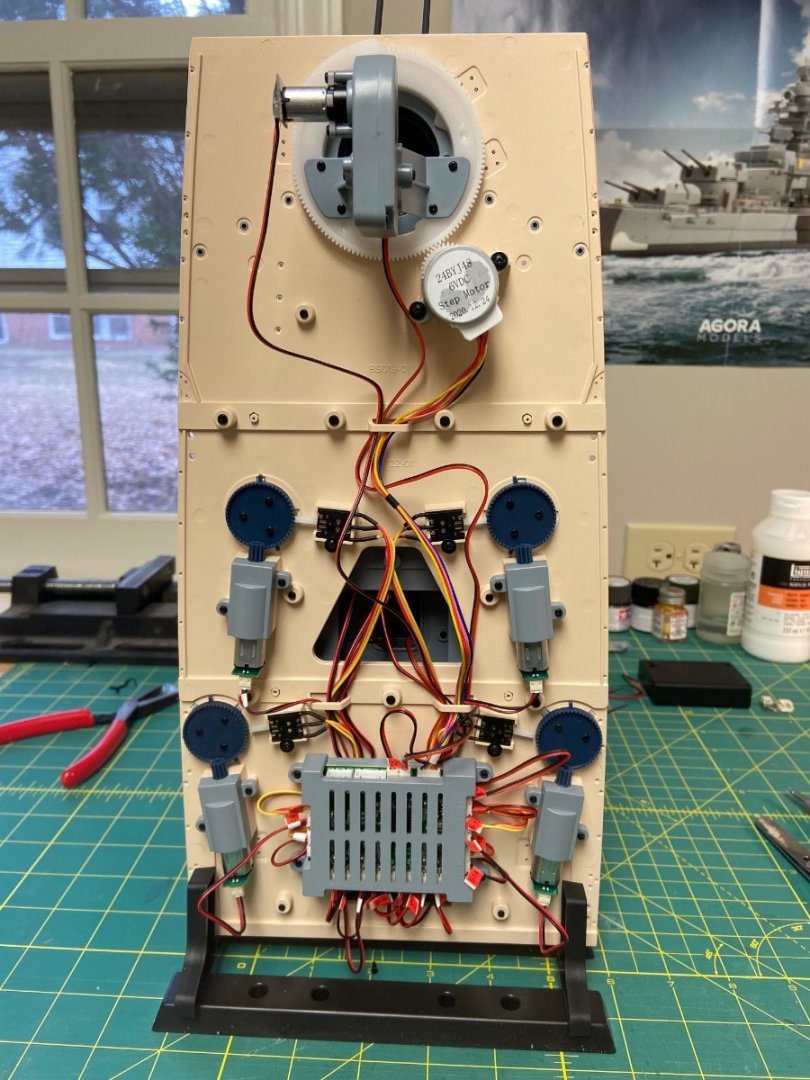

Bismarck is completed. All of the electronics work (turrets rotate, elevate, and make firing noise), as well as props, lights and anchors. My kids think its the greatest ship ever - so its going in their room !

It was a fun build but a bit dissapointing considering its price - as you can see - massive fail plastic fail on the main mast while rigging. I used EZ line - not much tension and it buckled. This part should have been made out of metal vs plastic that bends.

I am anxious to get back to working with wood on an Ancre build after this year long project. The best thing about this one is it got me out of the modeling doldrums - I am now carving out 2 hours a day early morning in the shop before I start my work day.

-

-

Hi Group,

I purchased 2 modules of this kit and have glanced at the plans and parts - both the plans and wood sheets are still wrapped in plastic. Its a high quality kit, perfect for someone who wants to build a POF model without the necessary power tools to cut out all of the parts from sheets.

With the Bismarck almost complete I am motivated to get back to one of my ANCRE Builds so I am parting with this one. I will include a copy of the Anatomy of the Ship Series HMS Granado with both boxes of module one and two - which include the consturction jig and most of the hull timbers. Module 3 was just released recently by Tom at CAF.

Together these two modules list new at 654.00 without shipping from China which is very expensive. Please only serious offers.

Thanks feel free if interested to PM.

- thibaultron, Ronald-V and mtaylor

-

3

3

-

-

-

-

Thanks HOF - the deck is plastic. The design nature of this kit makes it necessary as you can see all of the wiring, motors and servos involved you need to screw in to the bottom of the deck.

I have seen some terrific examples of this model weathered - which I may or may not do - I dont have much experience with this technique

https://community.agoramodels.com/topic/340-bismarck-photos/page/2/#comments

-

- Ian_Grant, GrandpaPhil, rvchima and 8 others

-

11

11

-

-

-

.jpg.c8fc21a22394a76e62d4ab4cc1ff6727.jpg)

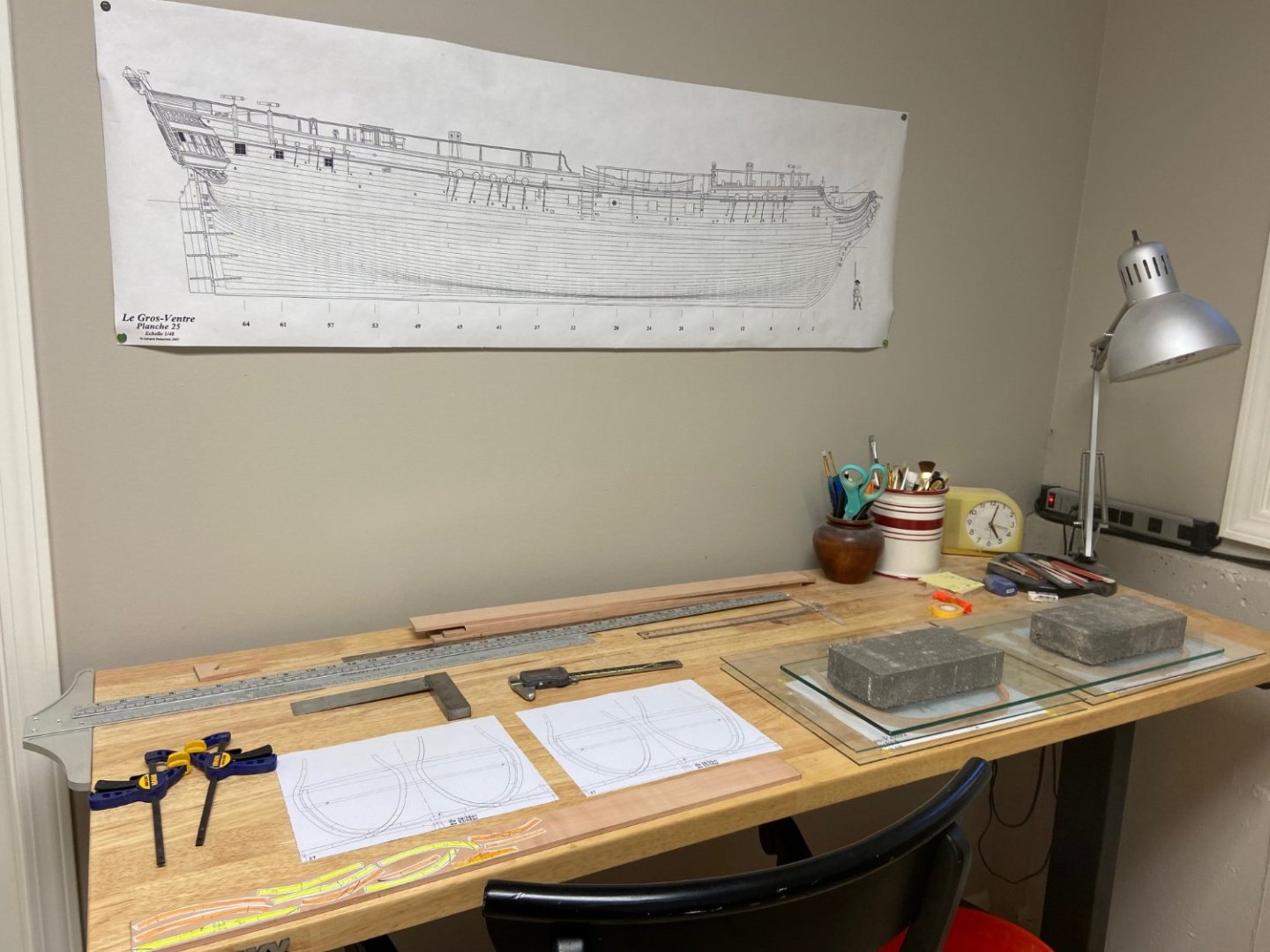

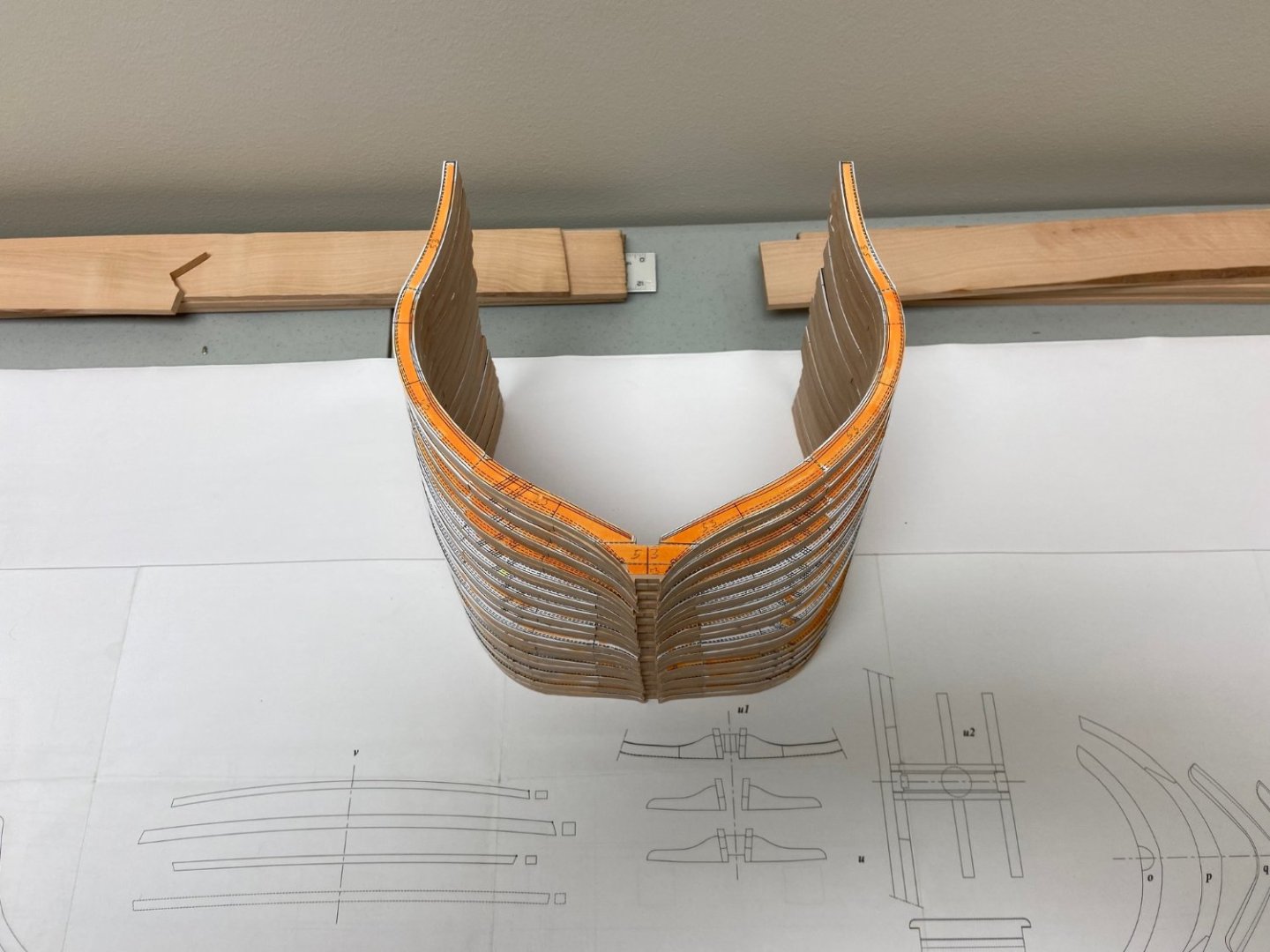

Le Gros Ventre by ChrisLBren - 1/36

in - Build logs for subjects built 1751 - 1800

Posted · Edited by ChrisLBren

After 2 months of consistent work - 63 frames are cut and assembled and ready for sanding/bevels. One partial stern frame remains to be assembled later. I need to tweak both the stern keel parts to make sure everything fits snug and re do bow parts part h and i. Then to cut the rabbet. Thanks for stopping by.