-

Posts

734 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by ChrisLBren

-

-

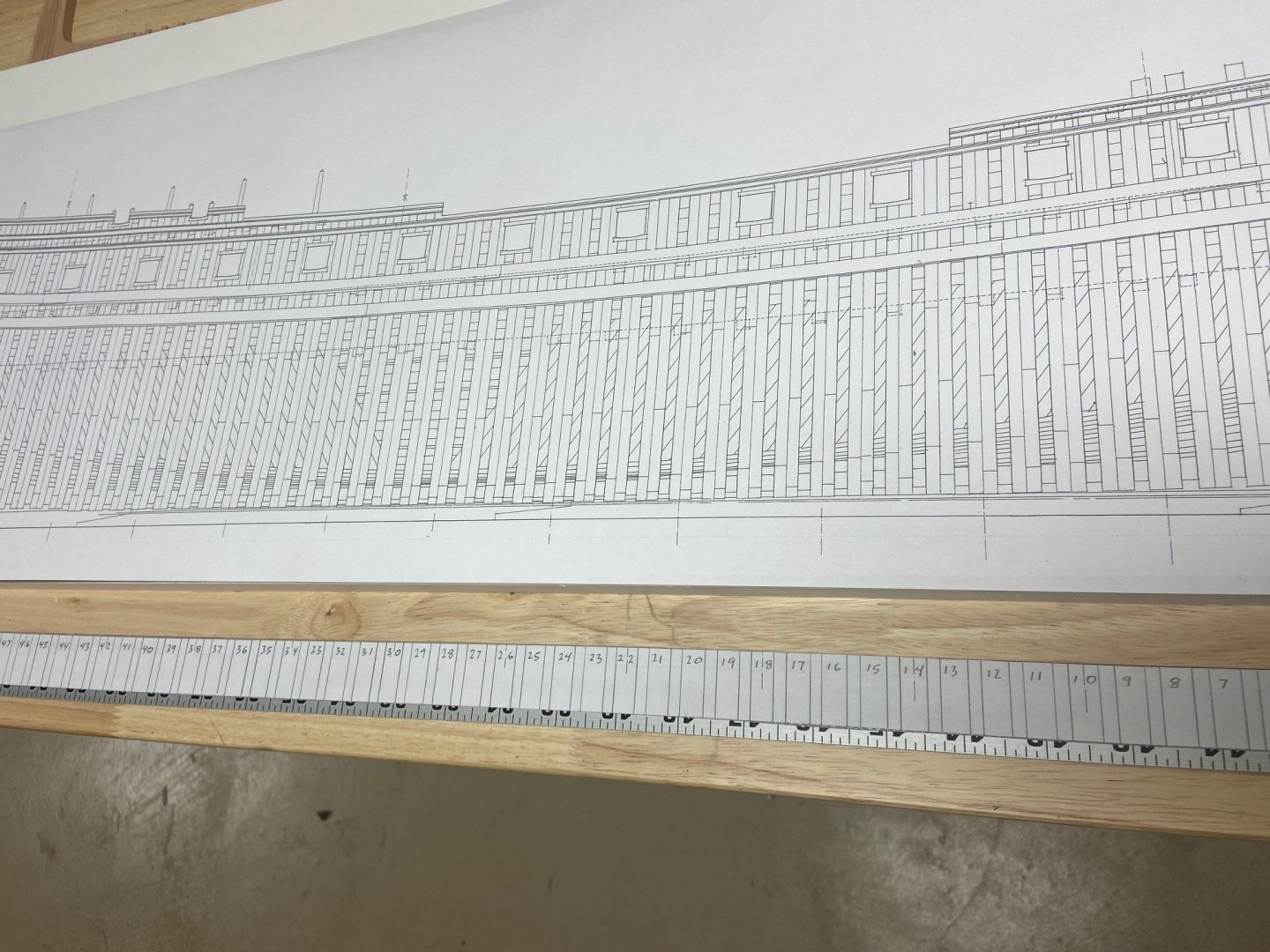

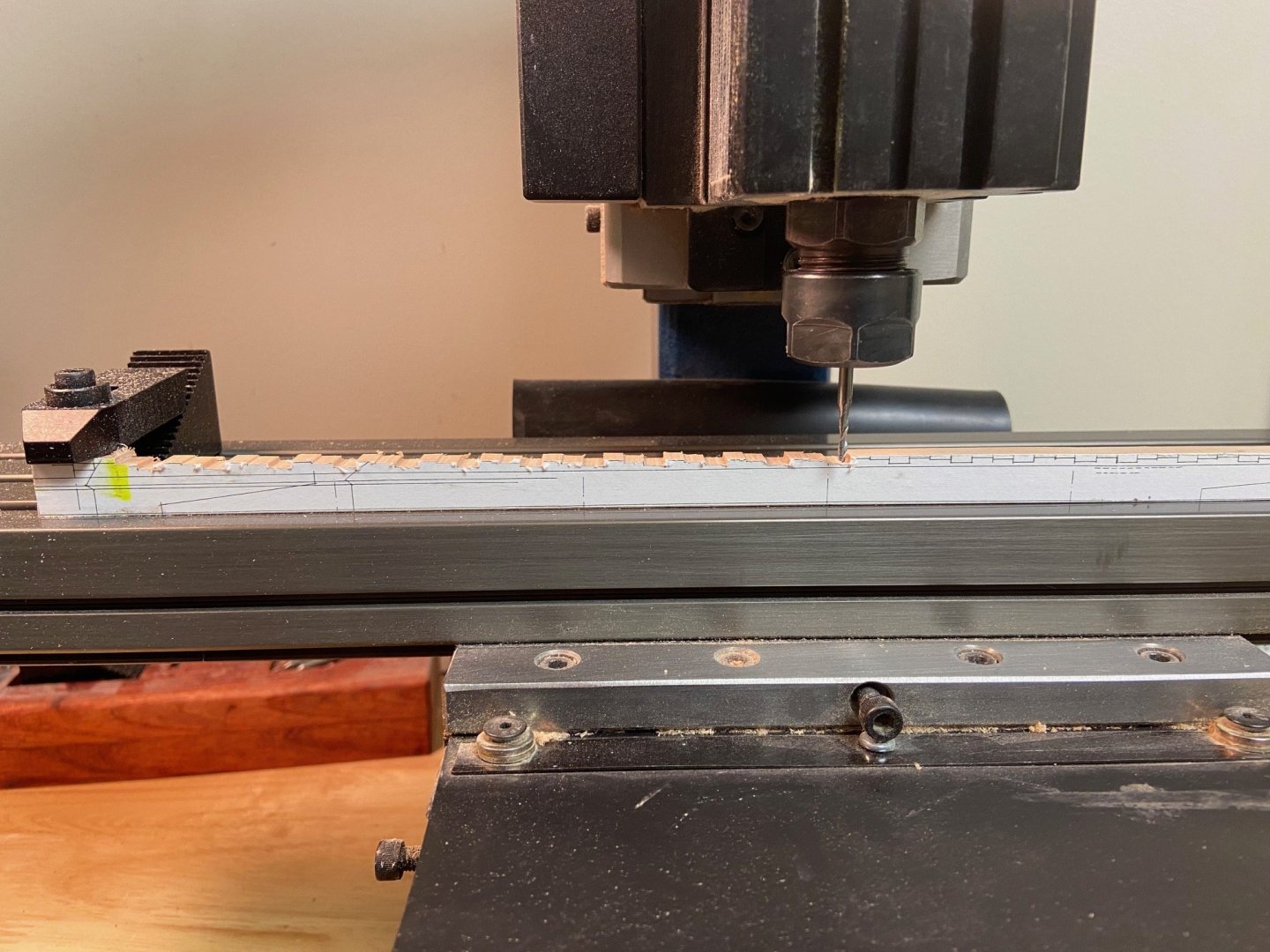

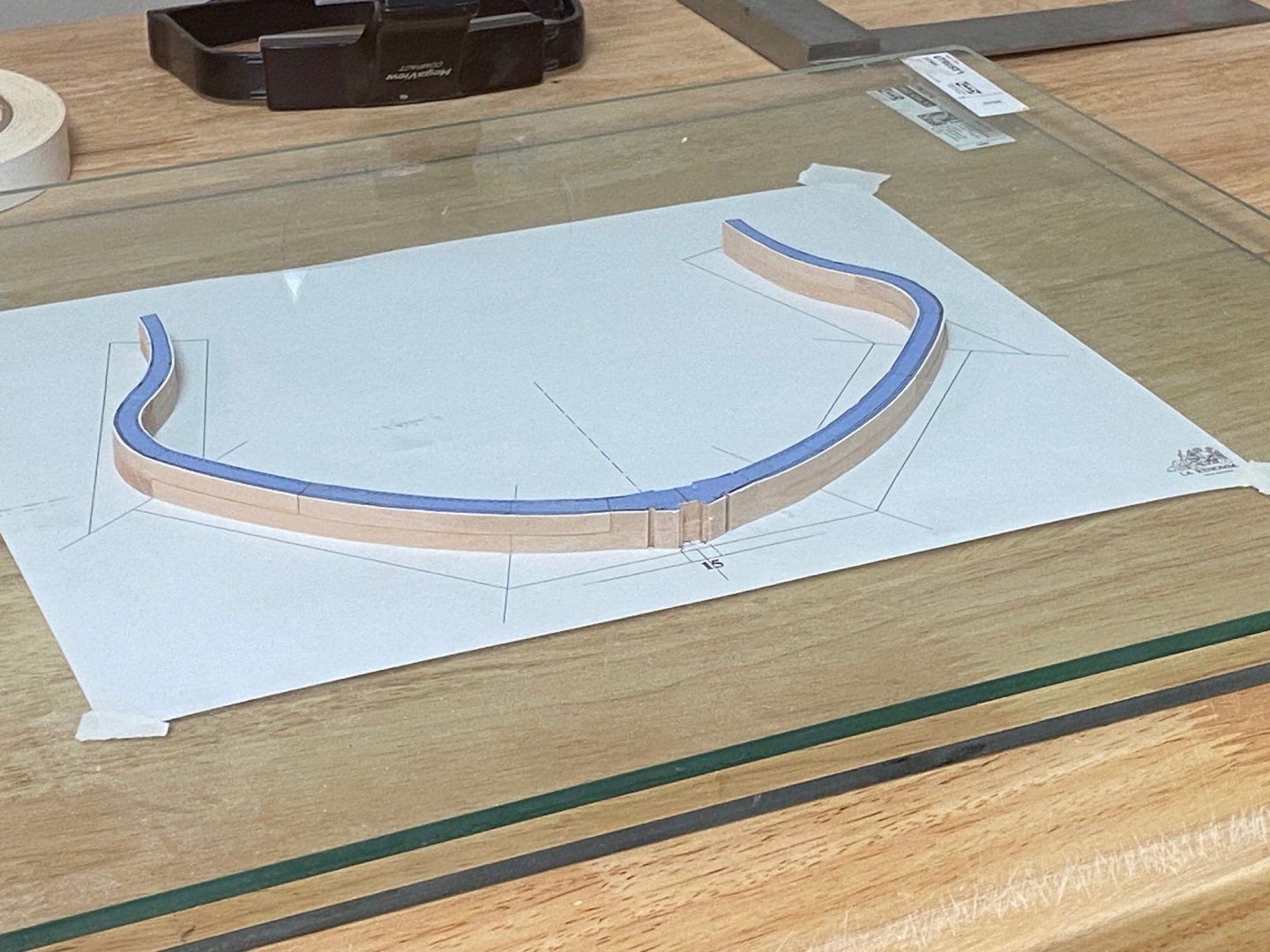

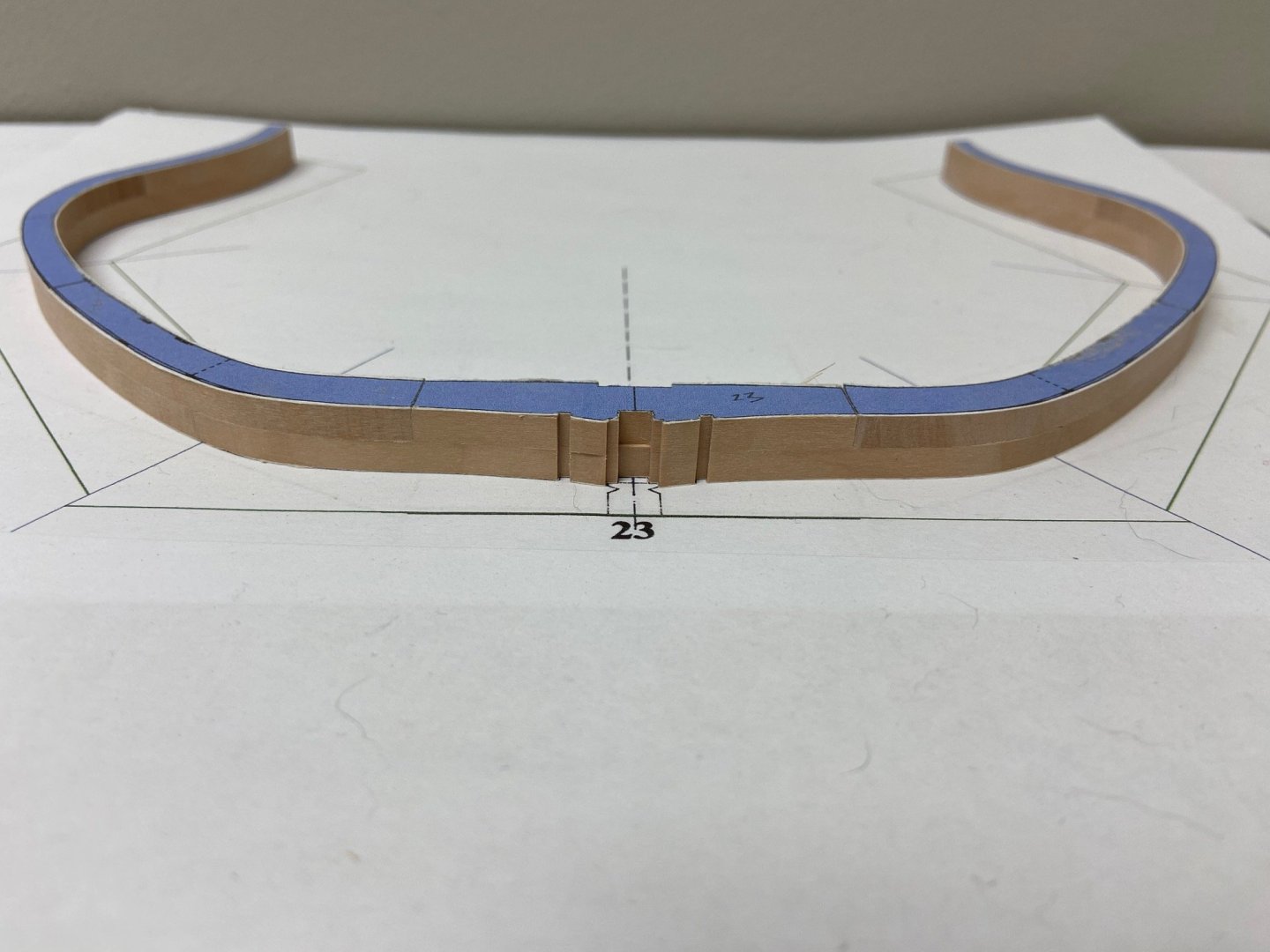

Here's a simple yet brilliant idea - a frame calibrated ruler. The applications including the creation of a construction site are many. Take the lines off the frame profile plan and apply it to a yard stick using double sided tape. I borrowed this one off a French site I have been referencing for my build.

- Maxthebuilder, Archi and druxey

-

3

3

-

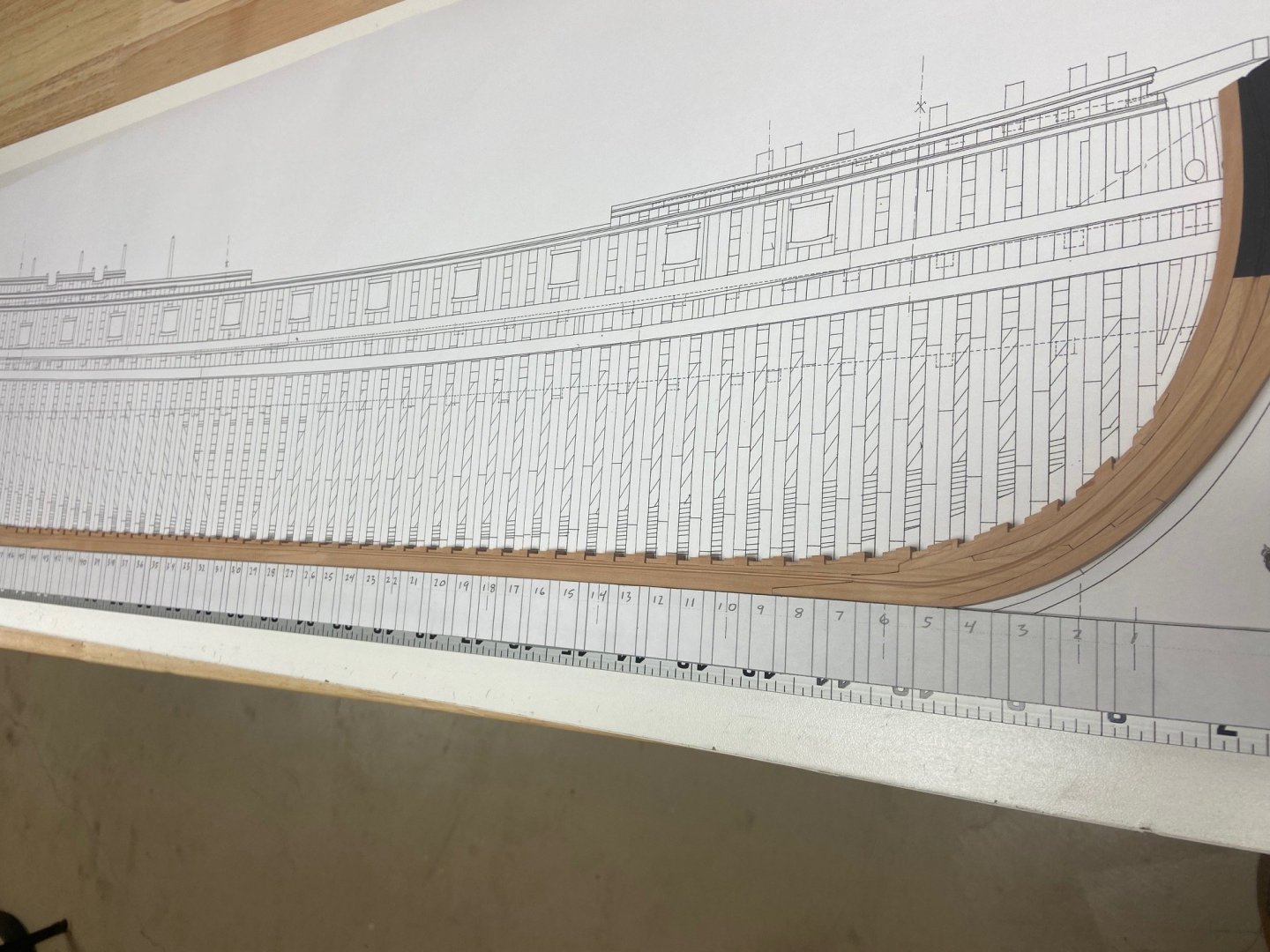

Thanks gentlemen ! Thats a really nice reference Greg. I really took my time with these assemblies so I am hoping for a nicely faired hull. I am about to proceed with the construction site and make sure its exact to give myself the best chance of success here.

-

Thanks Druxey - this keel assembly was not easy so I appreciate your compliment here !

- druxey and AnobiumPunctatum

-

2

2

-

-

-

It does - thank you V !!!!

-

-

-

Thanks friends - still quite a bit of work to go on the keel before its ready for frames !

-

- GrandpaPhil, G. Delacroix, scrubbyj427 and 7 others

-

9

9

-

1

1

-

-

Nice recovery Mark ! Have a great time in Crete

- No Idea and Keith Black

-

1

1

-

1

1

-

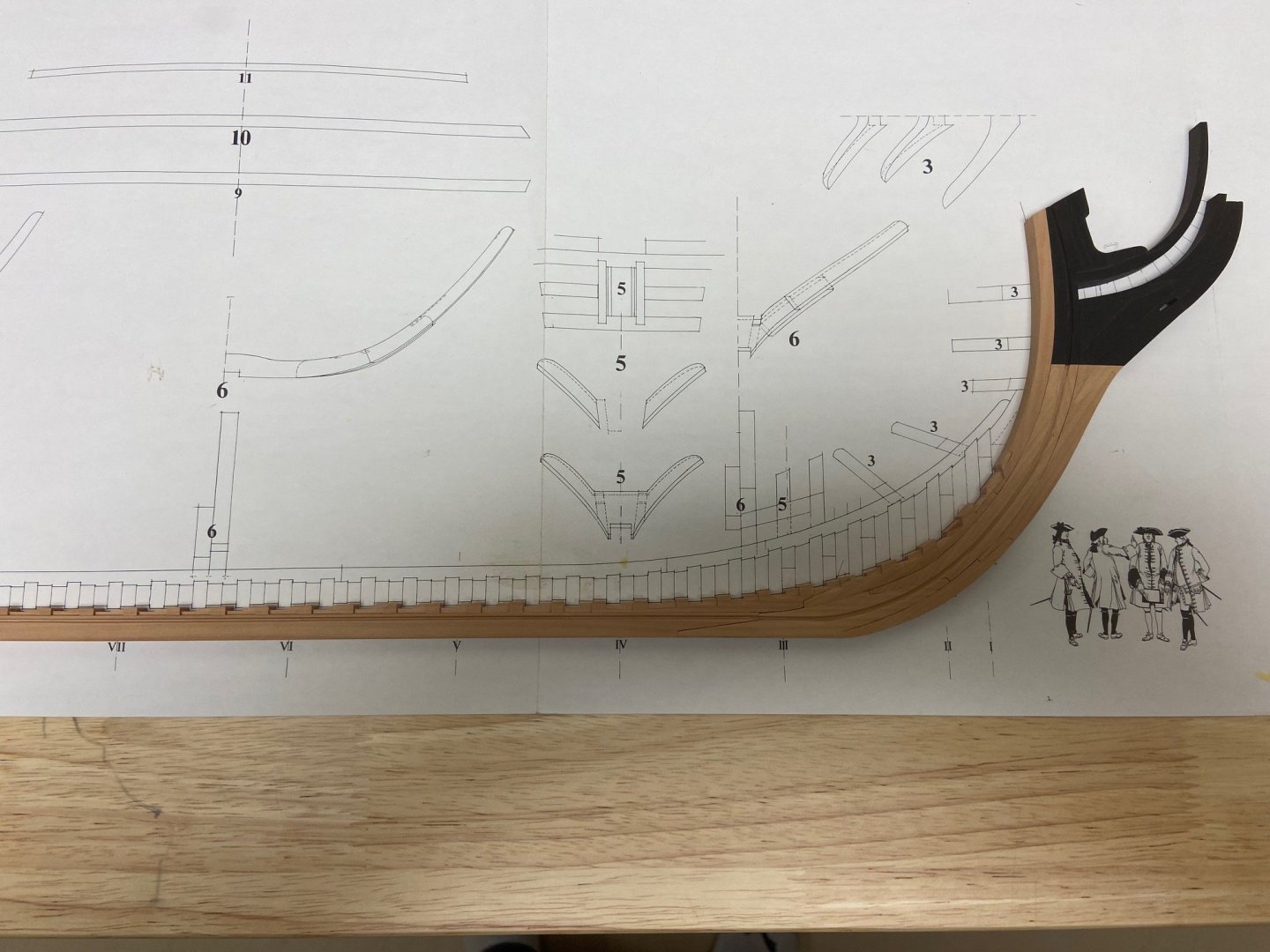

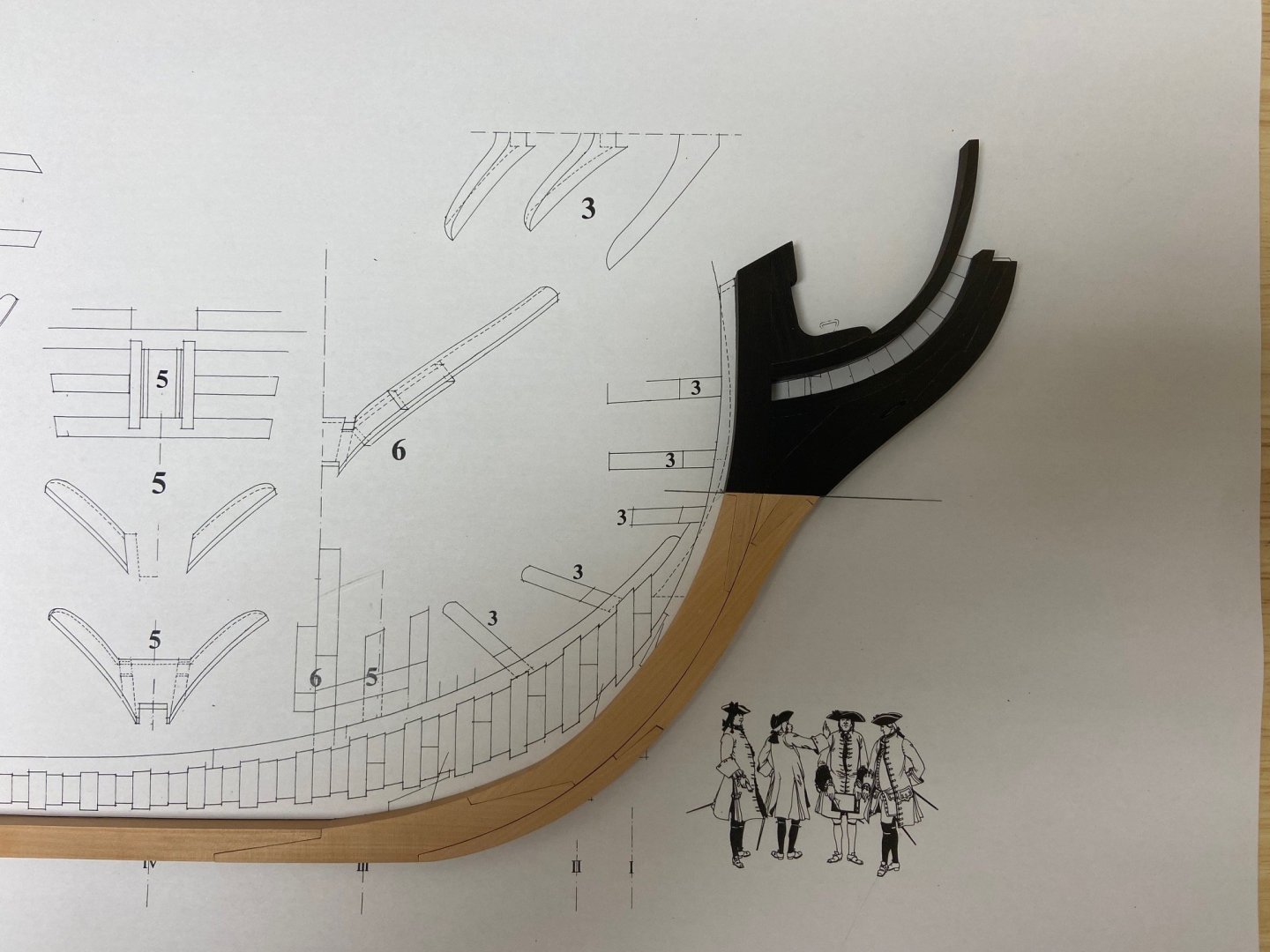

Thanks guys - I like the Hornbeam a lot so far. It cuts easily and glues well. Also it carves nicely - harder edge to it than Pear or Box. Many of the Eastern European modelers swear by it as a replacement for ebony. As far as bending with heat - I will let you know once I get to the wales. That's probably months away - so far I've broken down and rebuilt more assemblies than I care to admit !

That stem was probably version three. My mill went astray this AM while cutting the rabbet. So I took it apart with my friend Iso Alcohol and will reassemble it tomorrow with a new forefoot. I am very happy the upper part of the stem consisting of black hornbeam was not yet glued to the lower half.

- druxey and scrubbyj427

-

2

2

-

-

Looks like an interesting product. Tell us more about its workability !

Best of luck with the renovations - can't recommend Vahur enough for terrific products and service to the group for wood purchases.

- Wahka_est, Ryland Craze and hollowneck

-

3

3

-

This is the scroll saw you want - and buy the optional stand.

Having a good scroll saw for scratch building is vital. The other tools I use the most are Jim Byrnes Thickness Sander/Disc Sander, Oscillating Spindle Sander and TAIG Mill

-

-

- scrubbyj427, TJM, Dan DSilva and 11 others

-

14

14

-

Thanks for the tip Mike - your frames look great ! I know many use monofilament successfully. I really want to simulate the square bolts that were used on French ships of the period - so square wire either copper or brass is my preference.

- AnobiumPunctatum, Mike Y, Ondras71 and 1 other

-

4

4

-

Thanks for your comments ! Tobias - I haven't received Vahur's delivery of Black Hornbeam - it should arrive any day. I won't be using it for another month or so as I want to finish all the frames before beginning the keels parts where it will be needed.

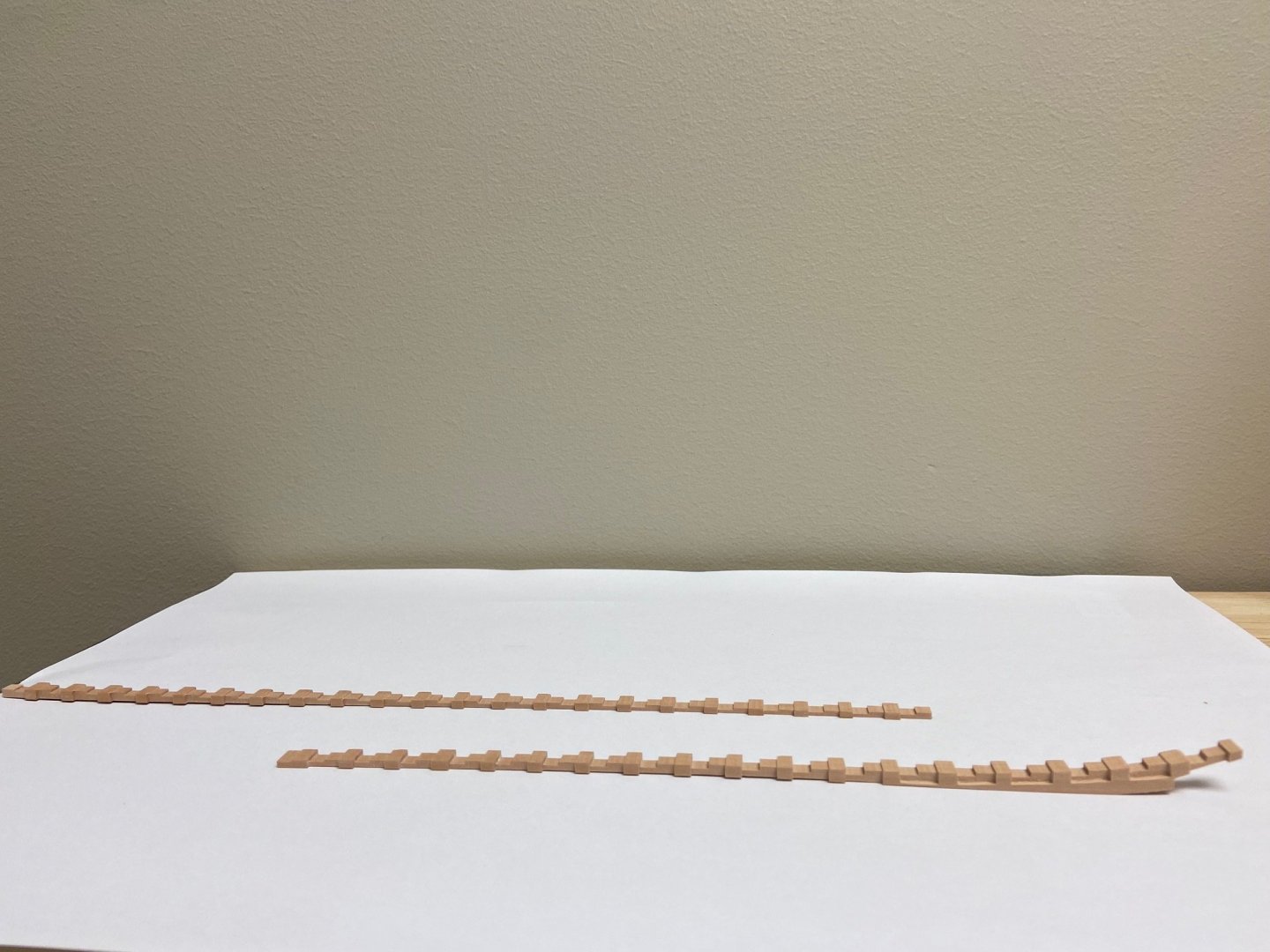

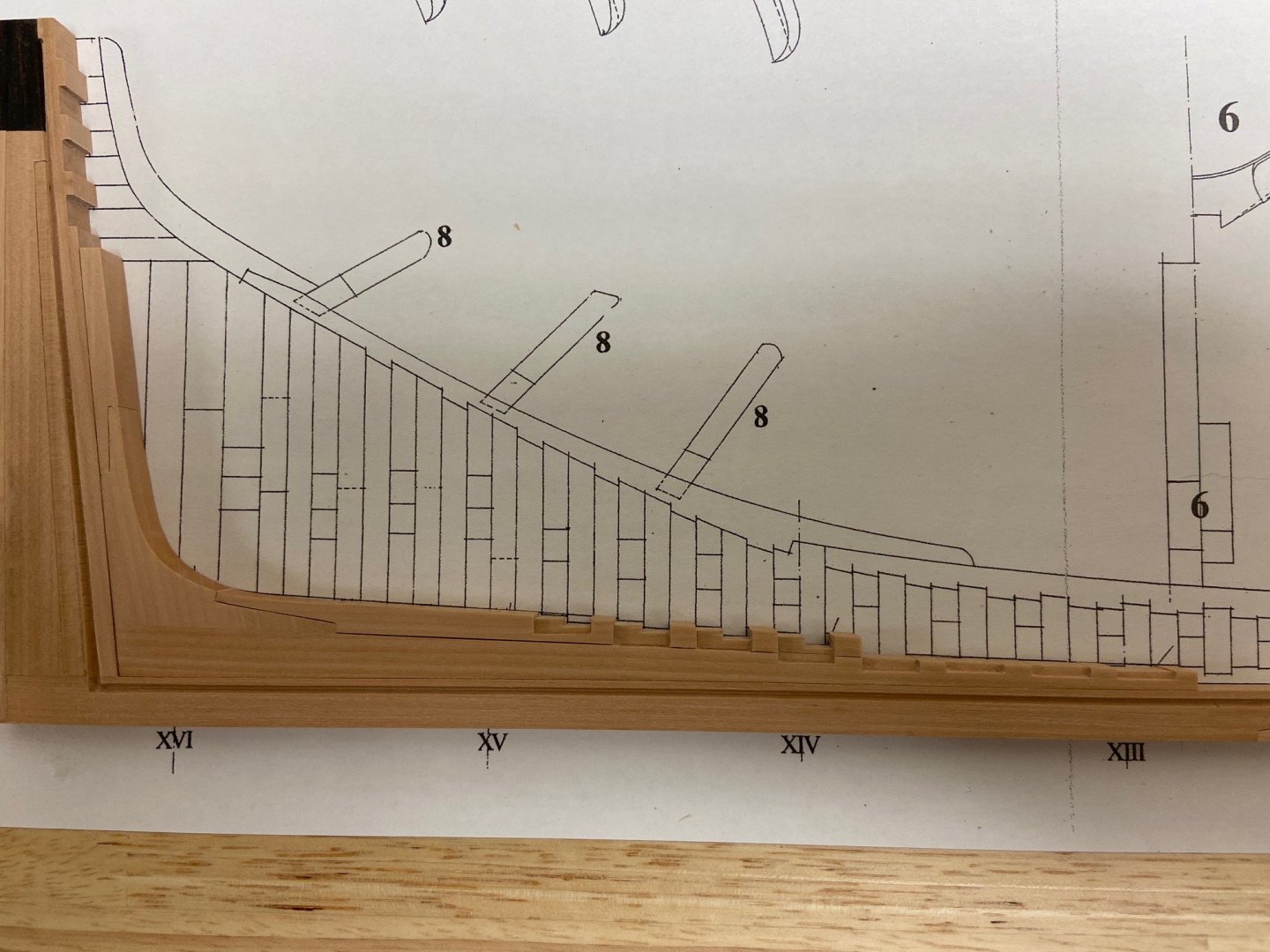

Update - the first 29 frames of 58 total are assembled and roughly finished. I will be installing bolts once they are faired and ready for final install into the jig. I have seen either copper square wire or brass square wire as the material to simulate them, copper has the advantage of blackening it in situation without bleed into the surrounding wood. I am curious if using brass do most simply just install the brass square wire and let nature burnish it over time or blacken it. My understanding is you will need to seal the wood first before attempting to blacken brass in situation to avoid the bleed.

-

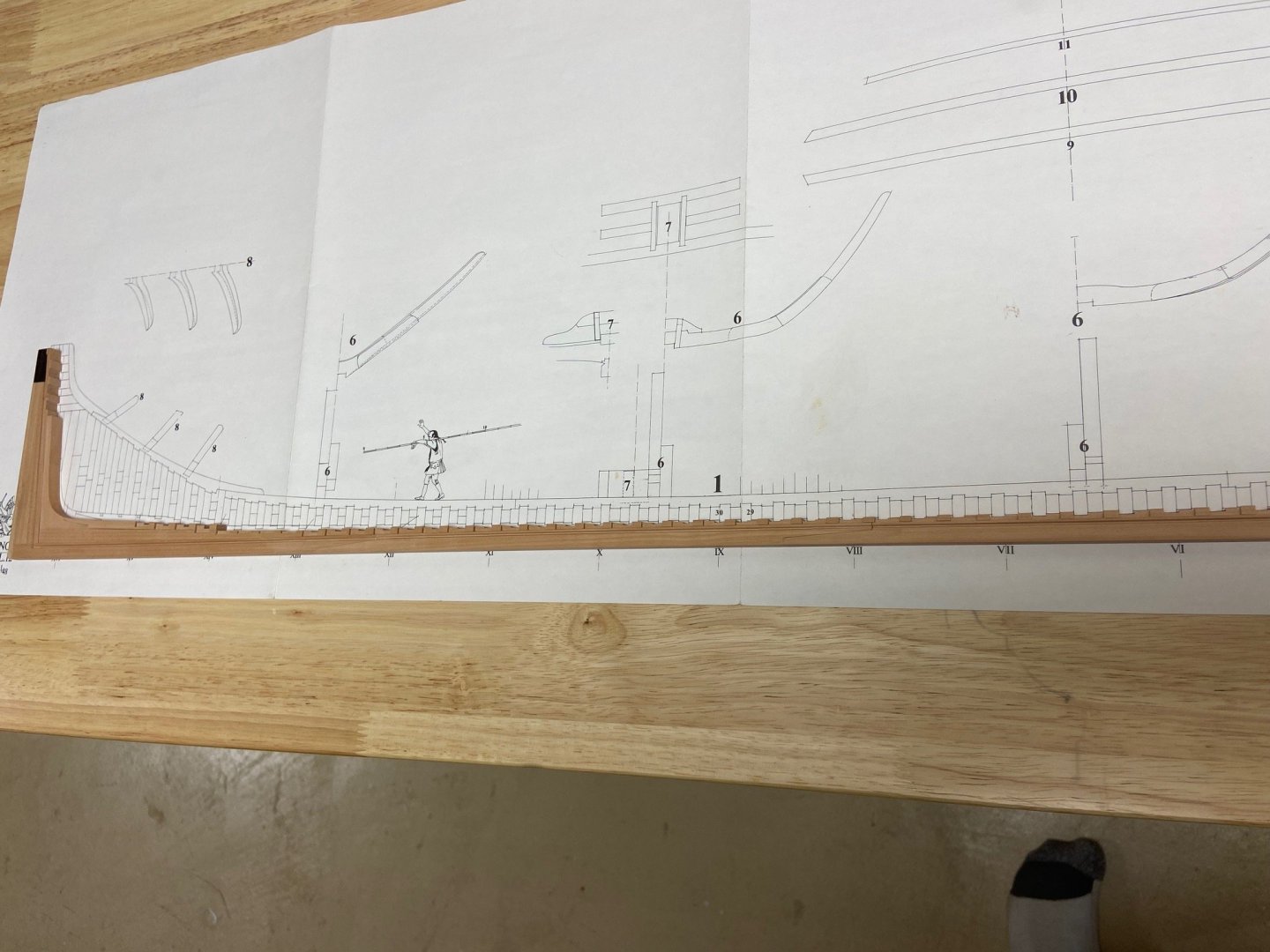

Thanks everyone for your comments. This week was negative progress...

I was up to 20 frames and decided to test fit all of the notches with scrap wood - 4.5mm for the inner slot and 7mm for the outer. I should have done this during construction. Some of the first frames were off by almost .5mm which is a big gap in this sort of construction. So 10 frames ended up in the trash can and 10 remain.

Moving forward not only am I using an optivisor while milling, I am doing my best to cut halfway into the lines. The good news is I have plenty of Pear wood and I am in no hurry to complete this one. I really want to take my time to get this right rather than use any flawed part and pay for it later in construction.

Huge tip I figured out - always use a backing piece of plywood while milling parts. Im getting perfect cuts with no tear out.

-

Thanks Pavel !

The modelers on the French site swear by 1/36th scale Greg as Im sure you're aware ! This frigate in 1/48 will still be over 36 inches in length unrigged so by no means "small"

-

Greetings Group,

Back in 2017 shortly after finishing Confederacy, I attempted my first Ancre scratch build, La Renommee. I have always been in love with this Frigate and her unique lines. I, however did not possess the skills yet to do her justice, nor a mastery of my recently purchased tools (chisels, Byrnes Machines, Sanders, and my first mill). Raising small children and establishing a new business also provided problematic to achieving my goal of building this ship.

I worked on a few other projects including Le Gros Ventre in 1/36 scale which did increase my skills with the scroll saw, sharpening and working with chisels and scrapers, the Proxxon MF70, reading plans, building a build site and milling wood. However after a 2 year break and revisiting my progress I noticed, being new to creating frames, they were too large and would require a heck of a lot of sanding to get to spec. Also the Proxxon MF70 while not a bad tool, is not nearly as accurate as my recently acquired TAIG mill. I really wanted to give all the keel parts another go with this tool. The question became do I re do Le Gros Ventre, or work on one of the other Mongraphs I own in both 1/36 and 1/48 scale (Egyptienne, Renommee Amarante, Requin to name a few)

A friend has shared the frame drawings of La Renommee 1/48 fully laid out (in the Monograph Boudriot only drafts half frames) and easy to print on my home computer. These are a god send vs running to the local UPS store to make copies over and over again (my experience with Le Gros Ventres frames). After running some tests I found I do like the smaller scale of 1/48 (at least so far) as it gives me the option to rig later. So Ive sharpened all the tools, cleaned up the workshop and La Renommee was started again two weeks ago.

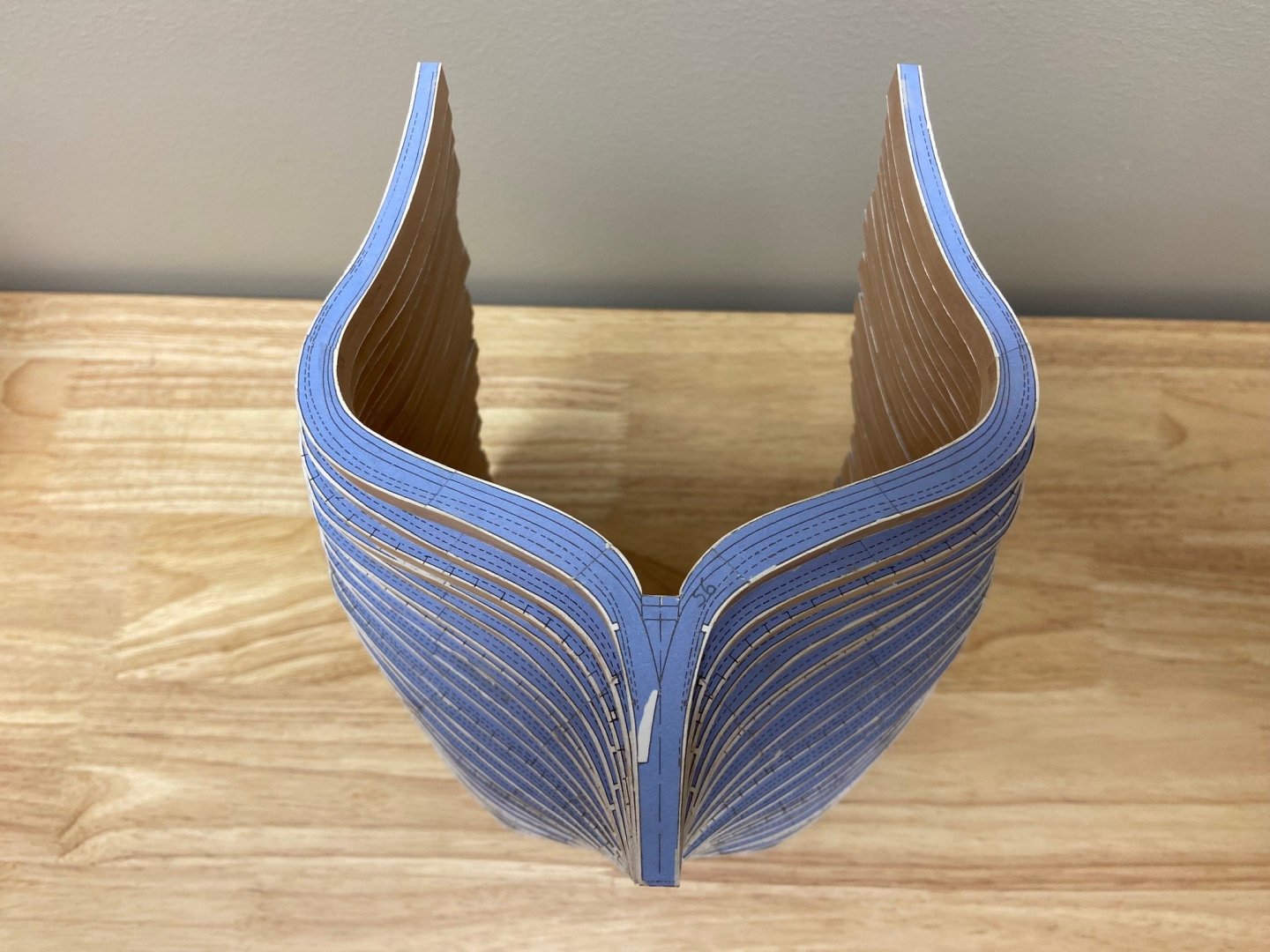

So far I have completed 14 frames that are very accurate with only about .5mm of fat. As you can see the notches on the frames are a bit complicated. I can not image this build without having a good mill. I have some black hornbeam on the way from Hobbymill in Europe to use instead of ebony for the black parts and plenty of Pear I've collected over the years. I will need to learn metal work in the not too distant future and carving in the really distant future, however I am confident with some good coaching I'll get there.

-

Looks great ! I love the shellac finish - did you mix it yourself with flakes ? If so what ratio did you use - I may be applying the finish on my build.

Chris

- mtaylor, Keith Black and No Idea

-

2

2

-

1

1

La Renommee 1744 by ChrisLBren - 1/48 - 2025

in - Build logs for subjects built 1501 - 1750

Posted

Thanks Brad - I am following your build as well - love the Salamandre !!!