-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FrankWouts

-

Looking very good so far Glenn! Frank.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

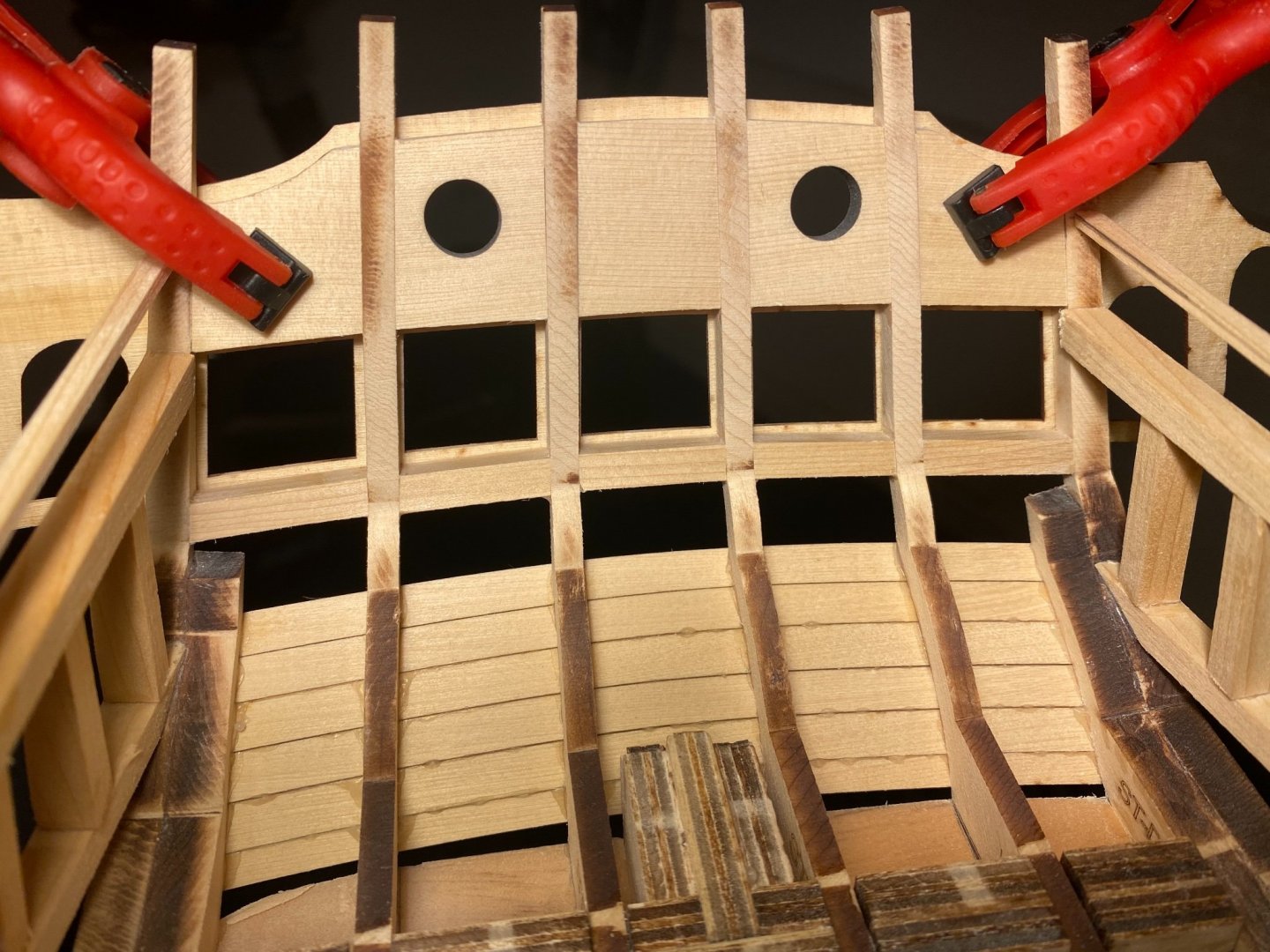

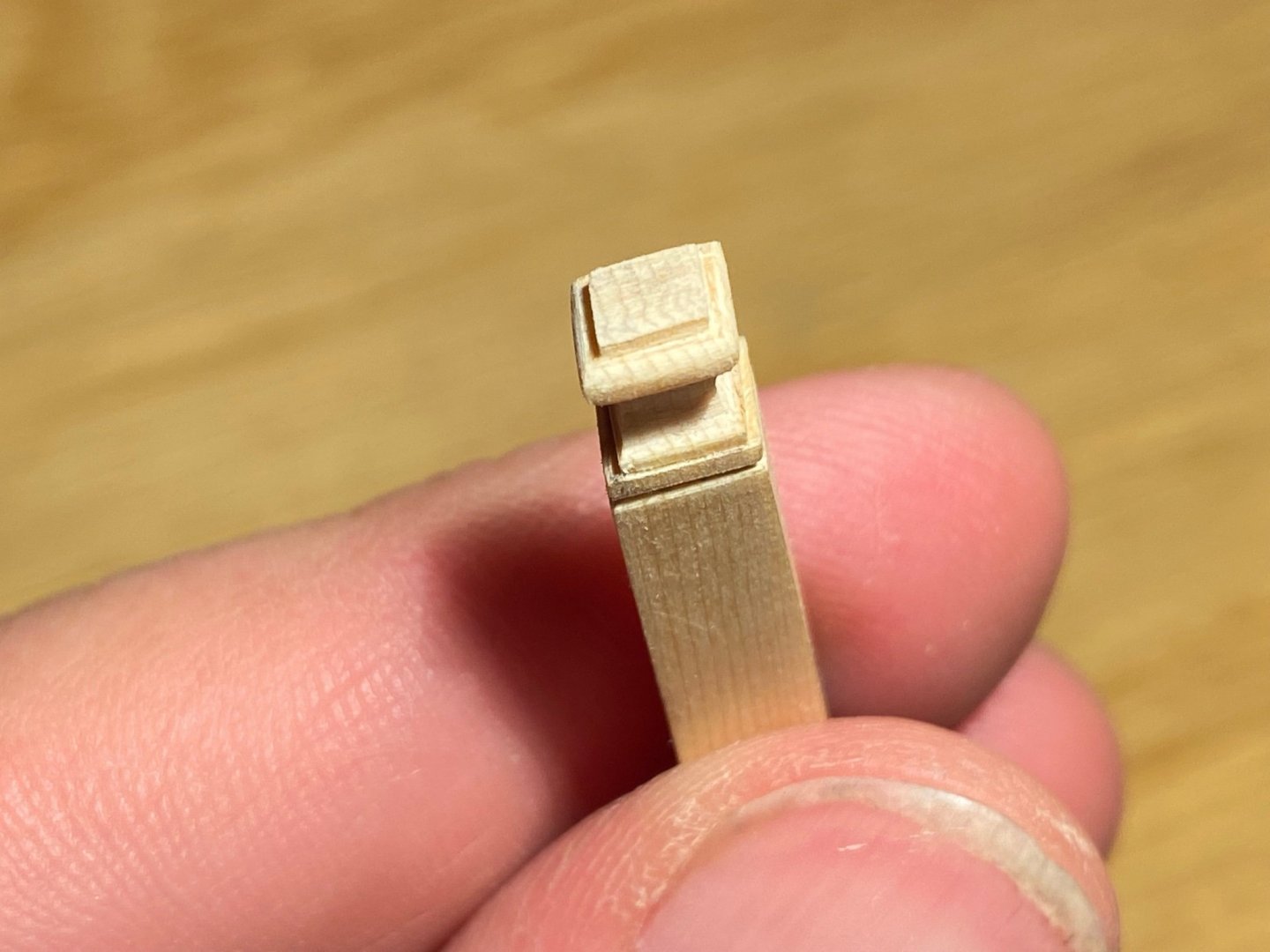

Corrected the upper sides of the transom filler pieces I forgot to sand before glueing them in. Checked with the transom piece if I’m still within reasonable boundaries, symmetrical and even. When the bowsprit hole in the bollards piece and in place, I now finally will finish chapter 1 this weekend.

-

Looking good Steve! You earn 100 points extra from me when scroll sawing your own keel and bulkheads…I cowardly bought the laser cutted stuff from Chuck and it is spot on, I couldn’t beat that in a thousand years with my sawing talents…But then ofcourse now I again miss some practice. So I’m already thinking of after this first one in Alaskan Yellow Cedar, build a Cherry version, both wood colors are so beautiful! Perhaps you can correct that very small bend in your keel when gluing the bulkheads? Or are you afraid risking good precise made bulkheads on the bent keel? Anyway, very warm welcome and I’ll be following your build log as well! Frank.

-

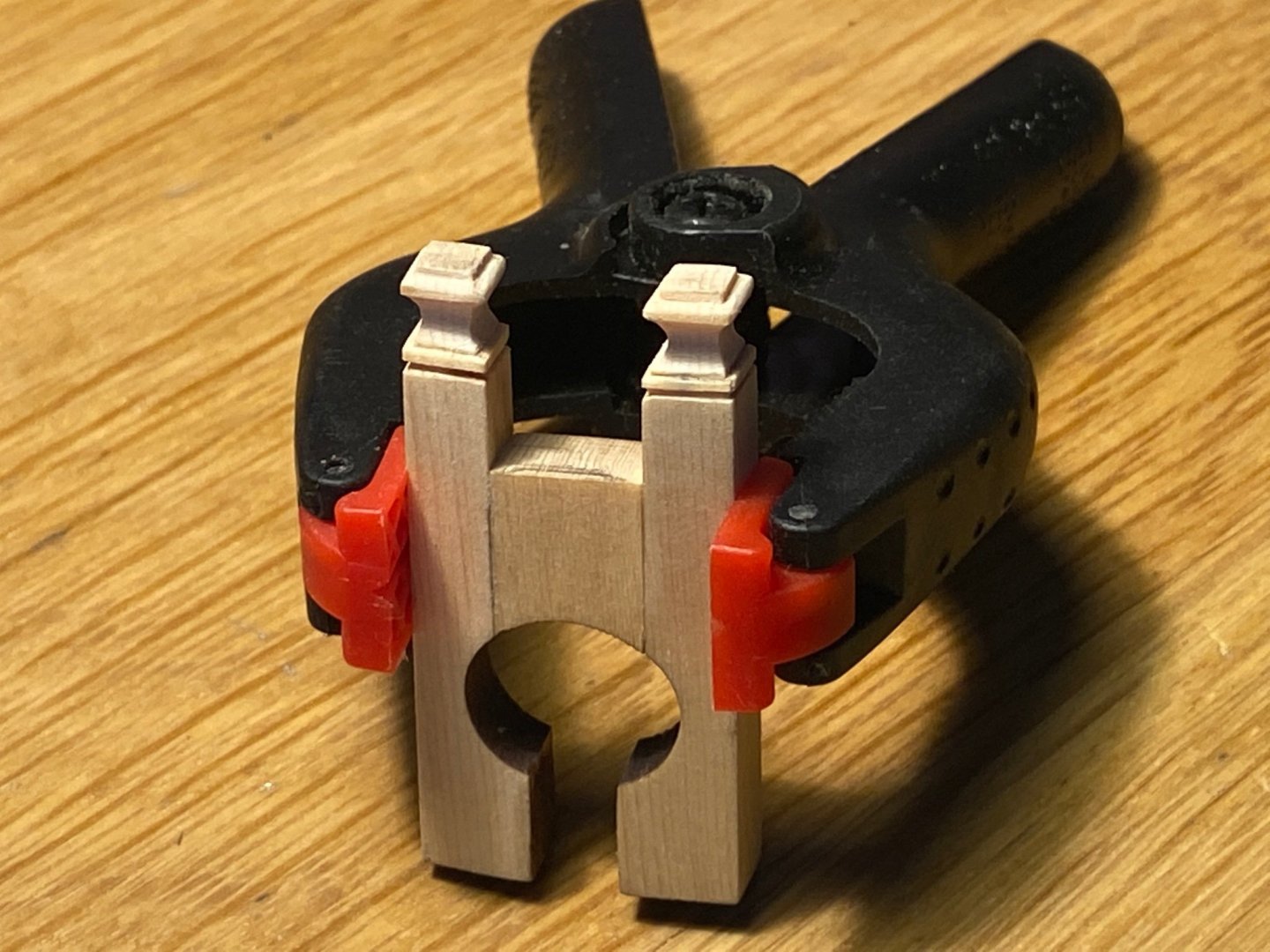

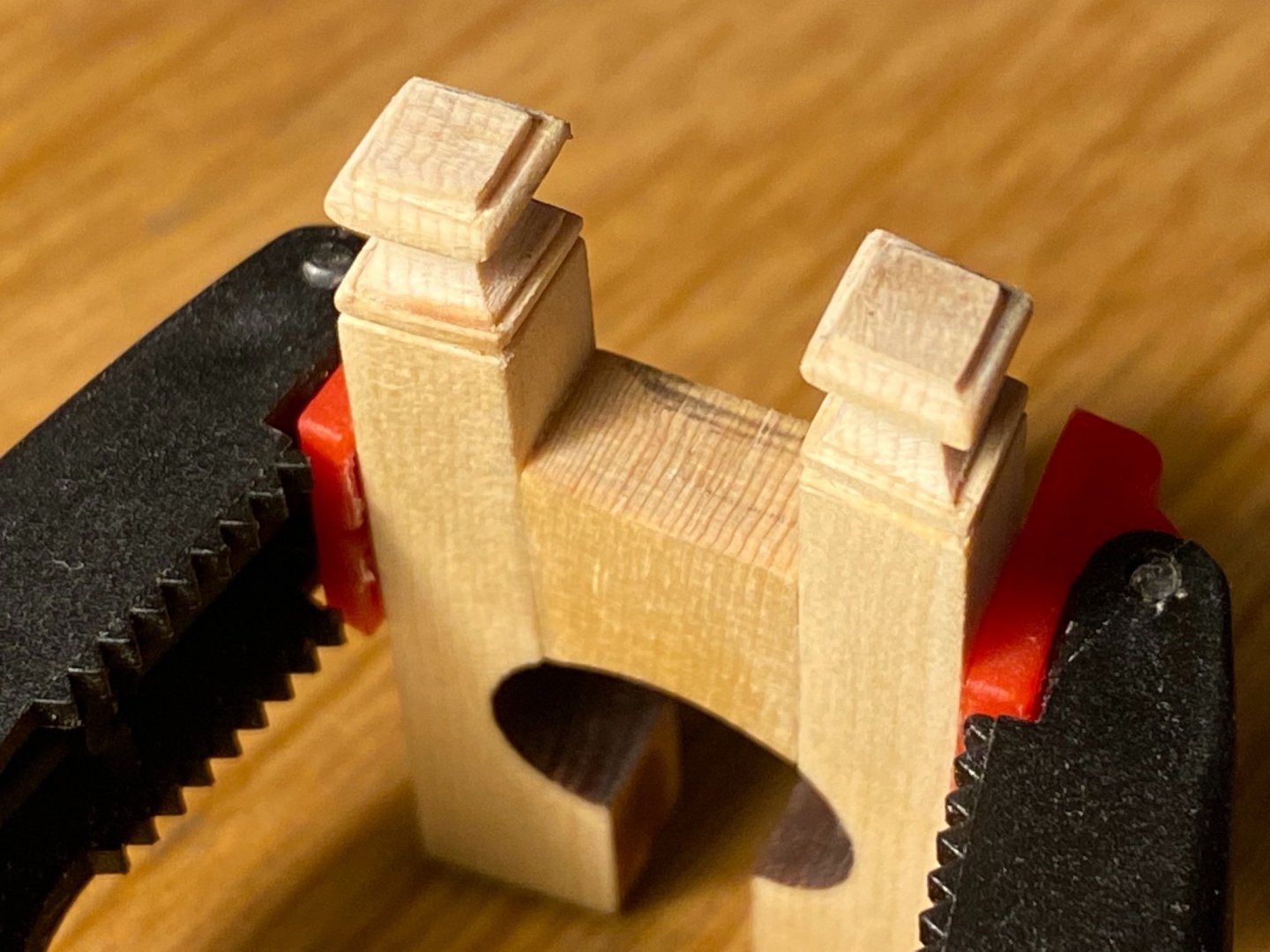

Me neither, I wish I was, as this is so beautiful! But I'm still taking my time cutting the bollards. Also cut my finger last week cutting making the second version of the pair of them. Will update soon, the version without blood on the parts ofcourse...

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'm glad to read you're starting another build Glenn. I admired your HMS Vanguard and was sorry to read that your seventh build would be your last' and that you 'were done'... Luckily Chuck succeeded tempting you to build another one! I'm following your build and will check your updates. P.S. that's a very nice, clean and light workspace you have there!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hahaha Matt, first the sneeze wood, then giving your old ugly kit(s) away to someone you don’t like, then the carving and headreail porn and now the green bananas. I feel we must go to the pub sometime together and have some large pints! And your latest updates look awesome and very beautifully build Bob! It’s a piece of art already and if it were to stay the way it looks now, I would definitely display it in my living room! I like reading these Winnie build logs for ever more reasons day by day! Frank.

-

No idea yet how I’d tackle all this headrail and carving beauty, but I have eight or nine chapters to think and contemplate on it and cowardly watch you guys all donit before me I guess. I will sure take all the time it needs like I’m doing right now with the bollards . But I agree with the apparent consensus : no compromises to detail nor quality, let’s take the hard road!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Le Soleil Royal by Nek0 - 1/72 - Marc Yeu

FrankWouts replied to Nek0's topic in - Build logs for subjects built 1501 - 1750

Très, très belle, formidable et superb! Any chance you might want to share some early drawings with us Marc? Just name your price!- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

I always make sure I hold my iPhone 11 horizontally, with the camera push button at my right thumb, both pictures and movies are upright and can be watched on a computer screen or tv upright and full screen, that is, no small vertical phone recordings. Even uploading to this site can be done without problems.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ok thanks Chuck. Yes, I'm glad too to be working on her again and defenitely determined to finish her! I understand, but the plank that will end exactly in the corner cannot touch the filler piece this way and will not be in line with the rabbit strip, but beyond it as the red line is more towards us that the green one: the green one lines up with the back of the filler piece, the reds one is 1,5mm 'loose' from the filler piece.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.