-

Posts

2,238 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

niceeeeeeeeeeeee😁- on the fishing vessels i have been on they led from the wires going from yard to yard to a couple of insulators to either the wheelhouse roof or radiocabin depending on size. Keith

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

i know how you feel- always the same when leaving the instructions well behind- do i go this way or that way🤔- and terror would most likely have had a jackstay on top of the yards for the square sails with the sail attached to it- not hanging from the bottom of the yards which was earlier practice🤨. Keith

- 206 replies

-

the link on matthews victory log is for a demo on this site but looks cool either way- on the MSW link he actually reduces the sail area to make life easier- mines going to be full sail methinks after watching that😁 Keith

- 206 replies

-

thanks for the views and comments everyone- back in the shipyard and we have the rest of the keels, the sternpost assembly and the bulwarks planked- still need trimmed around openings though😁. also bought these 1/72 ships boats from quaycraft which are 85mm long- i have a 100mm boat and some stud link anchor chain on order with cornwall model boats- by the time i have finished will have spent more on upgrades than cost of kit 🤪 take care all Keith

-

nope don't think so he is using a different technique which looks better. Keith

- 206 replies

-

hello keith if you go to matthew kassebaum's hms victory log there is a link posted by mtaylor regarding making furled sails.😉 Keith

- 206 replies

-

looks like hms revenge i built years ago by airfix

- 165 replies

-

- english galleon

- revell

-

(and 2 more)

Tagged with:

-

nice deck shot keith- note the sheaves in the bits on the fife rails at the base of the mast- the rope you see leading through one of them then tied off is for the jeers holding the lower yard up. i am going to plank them as i will most likely go for a varnished hull with just the "ice bumper" and lower masts bowsprit , mast doubling , tops and crosstrees painted white. Keith

-

cheers Jeff and thanks for likes and views as always everyone. giving the prow plenty of time to dry before fitting forefoot and keel /sternpost so started fitting the waterway. next up will line the bulwarks with the ceiling planks- dont know why occre didn't bother with any? Keith

-

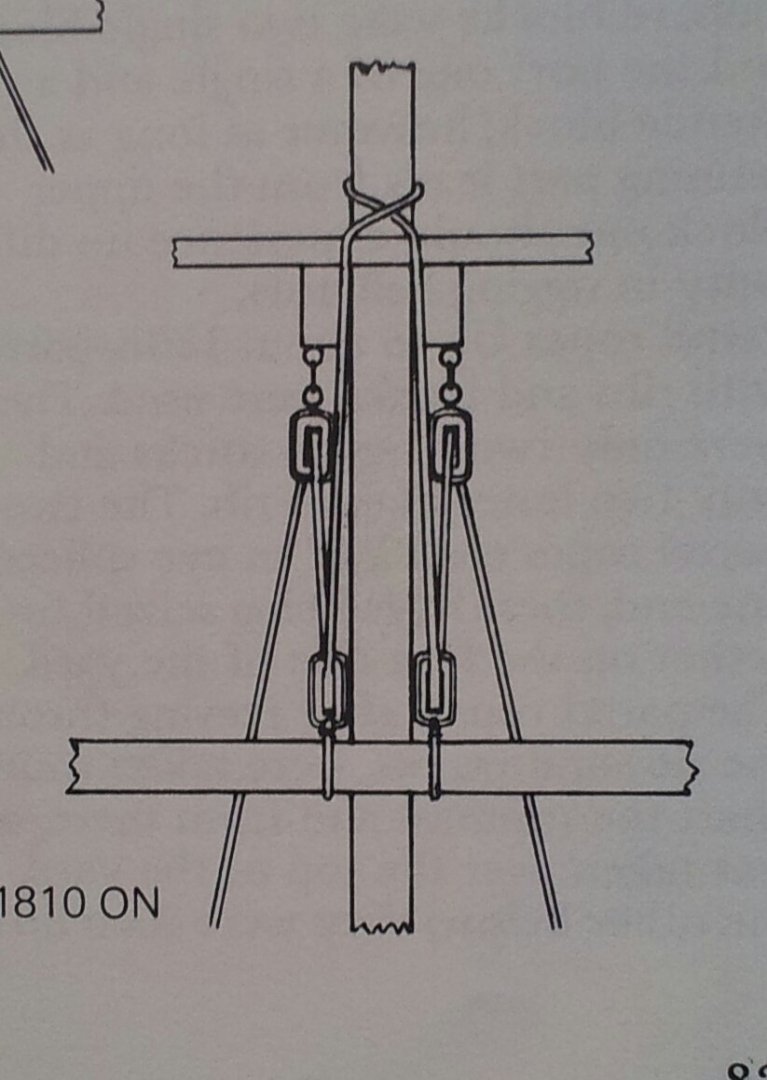

pic below shows set up for topsail yard halliard post 1810 -the topgallant yard halliard goes through a sheave in the topgallant mast.

-

the rigging will hold the masts in place- occre do include a block in the middle of the yard for the jeers so this will hold the yard up then the lifts from the end of the yards to the masts will keep them trim- i have never glued a yard to a mast- you need the play because you will catch them by accident (wish i had a fiver for everytime i have knocked victory's yards so far! Keith

-

lol keith we best not take over this guys log lol but yes you are right with the furled sails. Keith

-

that is correct keith- unless modelling as a museum ship (victory and constitution to name two where they are "hoisted " but without sails like my victory build. Keith

-

in reality it was a lot more complicated than what occre have shown! the truss which holds the yard to the mast is in two interlocking runs which lead to blocks at base of mast- the yard being held aloft by the jeer blocks and sling.- see my hms victory log which shows earlier style but terror would have had later style which run the trusses slightly differently😁- hope i havn't scared you too much😱 Keith

-

thanks for the views likes and comments everyone- the deck planking is now in and shaped and filed a filler piece for the bulwark at the bows using a piece of scrap ply from another build, and glued the stem piece in place. take care all Keith

-

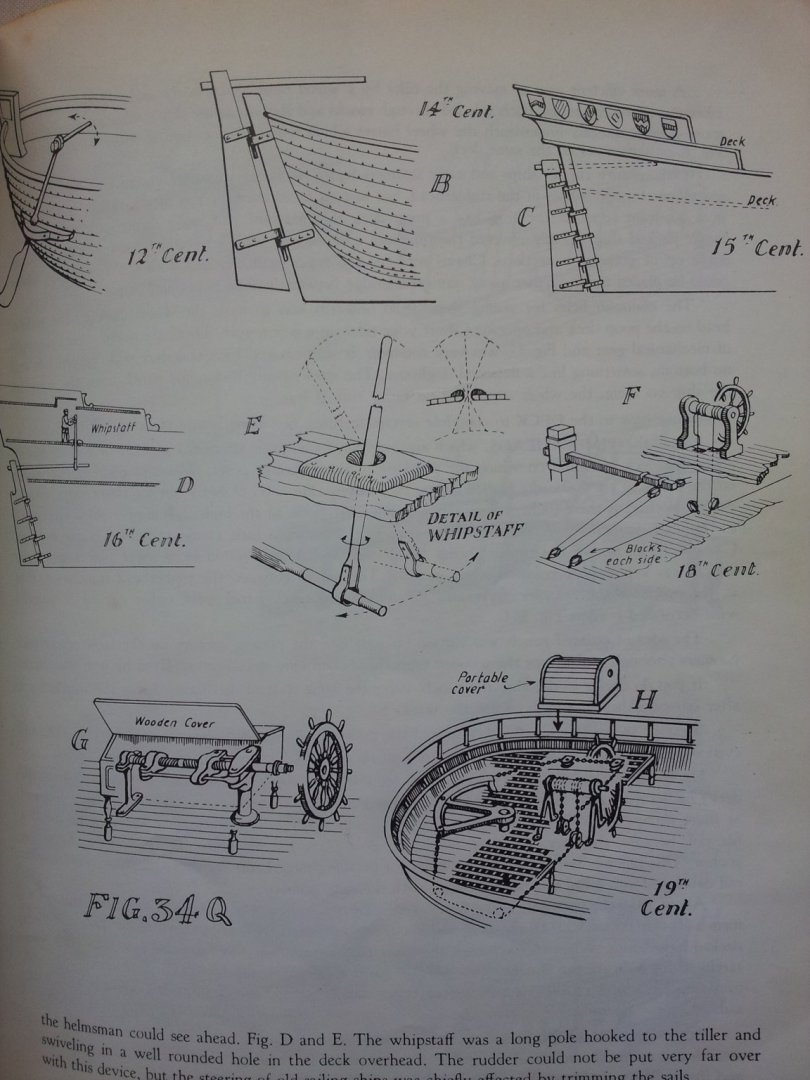

looks about right Keith as people had to get past them- below is a shot from an old book on ship modelling showing various steering set ups across the ages:- ships at the time of terror were sort of a cross between diagram F and H Keith

- 206 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.