-

Posts

2,239 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

ty for the comments and likes everyone- blue ensign- yes i like the research side of things and the other keith (keiths) has been a great help along with matthew betts build log- long live the little terrors😁. Geowolf- that is why i have replaced the kit supplied very thin splintery veneer with 0.5 mm x 4mm walnut strip which will allow a bit of sanding back. Keith

-

Thank you Keith- i have a natural distrust of ca glue for plank work - even though you can get a tight joint the wood can actually splinter away with bits of the parent surface still attached🤪. don't know if you can get it over in Canada but i use evo-stick interior wood adhesive which has a fairly fast "grab" time and is set in about 6 hours which is a lot faster than P.V.A. but you do have to be fairly quick in forming the bond (couple of minutes). As an aside has anybody else noticed spell checkers arn't familiar with nautical terms for ships furniture- been teaching my samsung galaxy phoneand think it's getting to grips😁 Keith

-

you could add a skin of veneer planking after sanding back. Keith

- 106 replies

-

work slowly progressing on the 2nd walnut planking- using white wood glue as opposed to contact adhesive thus only a few planks at a time and the dressmakers pins😁. also fitted the garboard plank. take care all keith

-

back in the shipyard due to bad weather again- got the clewlines and lifts belayed for the fore topyard then can start on the fore t'gallant. take care all- just hope the rain remembers to stop - cumbria is the wettest area in england- suppose thats why its called the lake district and not the dried up riverbed district! Keith

-

HMS Victory by Helli - Caldercraft

clearway replied to Helli's topic in - Kit build logs for subjects built from 1751 - 1800

looking good - tearing off the old shrouds must have hurt a little, but replacements look a lot better. i nearly bought the caldercraft victory but the price was wayyyyyyyy too much despite the excellent detail😁 Keith -

for weathering the lifeboat try a couple of washes of diluted grey paint to tone down the effect? Keith

-

Thanks for the views and likes everyone. Thankyou geowolf and your english is very good. Back in the shipyard and continued with the second planking. The counter was planked with walnut and will be sanded back when rest of planking finished on the "tuck" still trying to work out best way to tackle the run onto the sternpost🤔. Take care all Keith

-

due to continued showers through the day had a little time in the shipyard and got some of the walnut planking added below the shroud protector- getting a feel how the finish will look. take care all. Keith

-

thinking about strengthening the bulwarks- how about using thick card without the corrugations glued to the frames ?

-

😁good idea about reducing the hole size- them new belaying pins look a lot more realistic, and as we know from the wreck shot the belaying pins are a brass alloy - still freaks me out because they look like they have only been underwater a week or so! Keith

- 206 replies

-

No problem Keith- we are experiencing massive delays with the u.k. postal system because they can't cram the staff into the sorting office due to "social distancing/ safe space rules" at the moment so are having to work with 30% of the staff doing 100% of the work. except for the mizzen build the masts as occre describe but with the squared tops to the masts and i will most likely scratch new tops as the ones in the kit are too small due to having 2mm wide rim added- i will make them to the different shape and add a finer rim on top so deadeyes are at the edge- will do the mizzen as fore and main but with just the crosstrees and trestle trees. i will also be scratching the trees for the top mast as i dont like using ply for them (same with mizzen) probably out of walnut or basswood as they will be painted white. Keith

- 206 replies

-

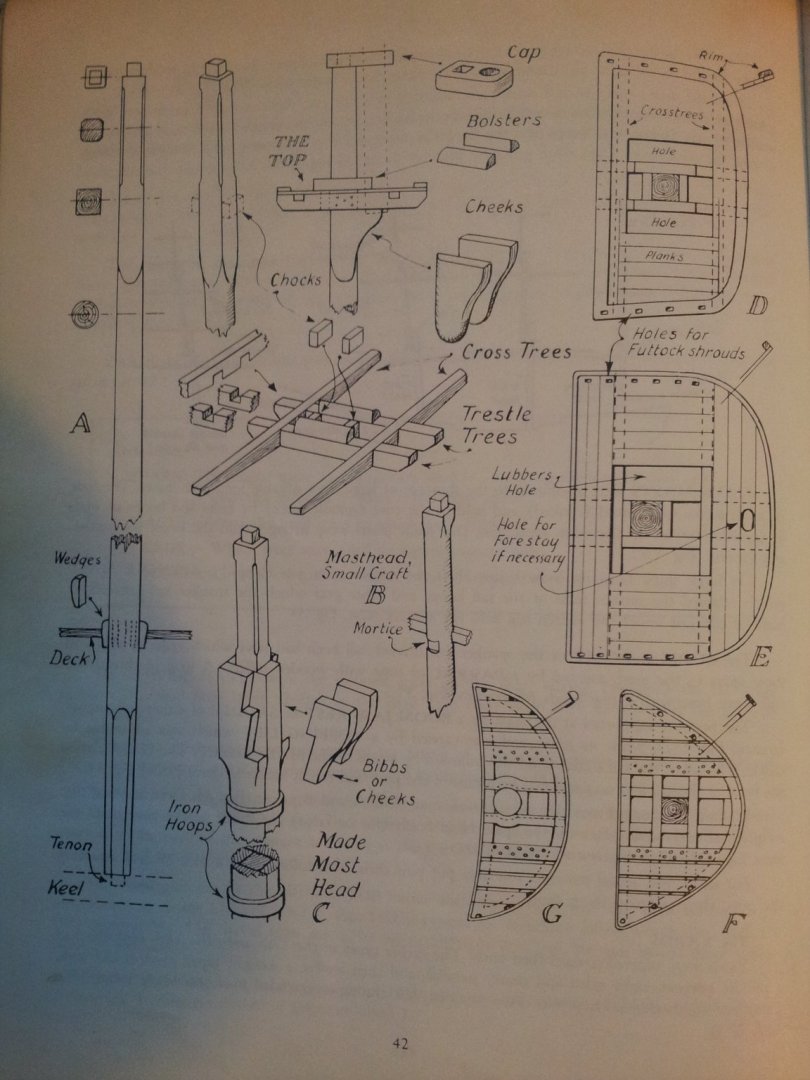

all sailing ships had the tops of the masts squared at the tops where they doubled- i make the top including crosstrees and trestletrees then trim the top of the mast , first with a knife then fine tune till the top is a nice fit- you will need to carry the flat down the sides for the cheeks and the two pieces of flat timber that run so far down each side- it shows some of what i did earlier in my victory log- also see below which shows varios styles of top through the ages. i think terrors will be like the top one fig D Keith

- 206 replies

-

yep spider band looks a lot better keith- i think occre have the heights of the masts about right but dont fasten anything to them until you have squared the tops and added the bands etc. Keith

- 206 replies

-

good to hear Keith , your soul sounded in a dark place there for a while. Not a bad little boat and nice seeing a sailboat gaff rigged as opposed to the run of the mill triangular sails you see . Keith

- 206 replies

-

Hi Keith- sorry to hear about the lost book- if you need any info in the future just ask(when i get to it there is a standard ratio they used for lengths of masts/ yards- a little "modellers licence" is allowed though😉. Taking a break from her is a good idea if it is doing your nut in- there's gaps of 6-12 months where i havn't touched victory, and i still have to finish a scratch built dredger i started in 1998! Out of curiosity what type of craft are you building as i grew up around boats being the son of a fisherman and was hopping over bulwarks and anchor chains about as soon as i could walk. take care Keith

- 206 replies

-

i install the masts then rig the shrouds starting with mizzen and sequence forward - basically there is a step by step guide on my billings victory log- then i install the driver boom and gaff then the yards working from mizzen forwards- on ships from terrors era the futtock stays rig to cains around the mast as opposed to the shrouds on earlier ships.😉 beware occre havn't got the rigging 100% correct. Keith

-

not much happening in the shipyard due to D.I.Y. projects (getting my winter messy job lair organised with spray benches, stove and lift up shelter on veranda - admiral says i look like kiosk keith!) did manage to get the walnut planking on the outside of the bulwarks which gives an idea how the hull will look colour wise- should be dark enough though walnut can mellow in colour when it is exposed to air long enough. the access ports etc still need trimmed to size on bulwarks. take care all Keith

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.