-

Posts

2,239 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

Ty Emmet and welcome back, just double checked the plans and the top of the galley stove should be on the same level as the top of the bell so will drill down through the deck as well as the hatch and adjust to height. before i move on much further though i am going to have to tackle the chainplates which i am still figuring out but no surprise will look nothing like occres instructions😉 Keith

-

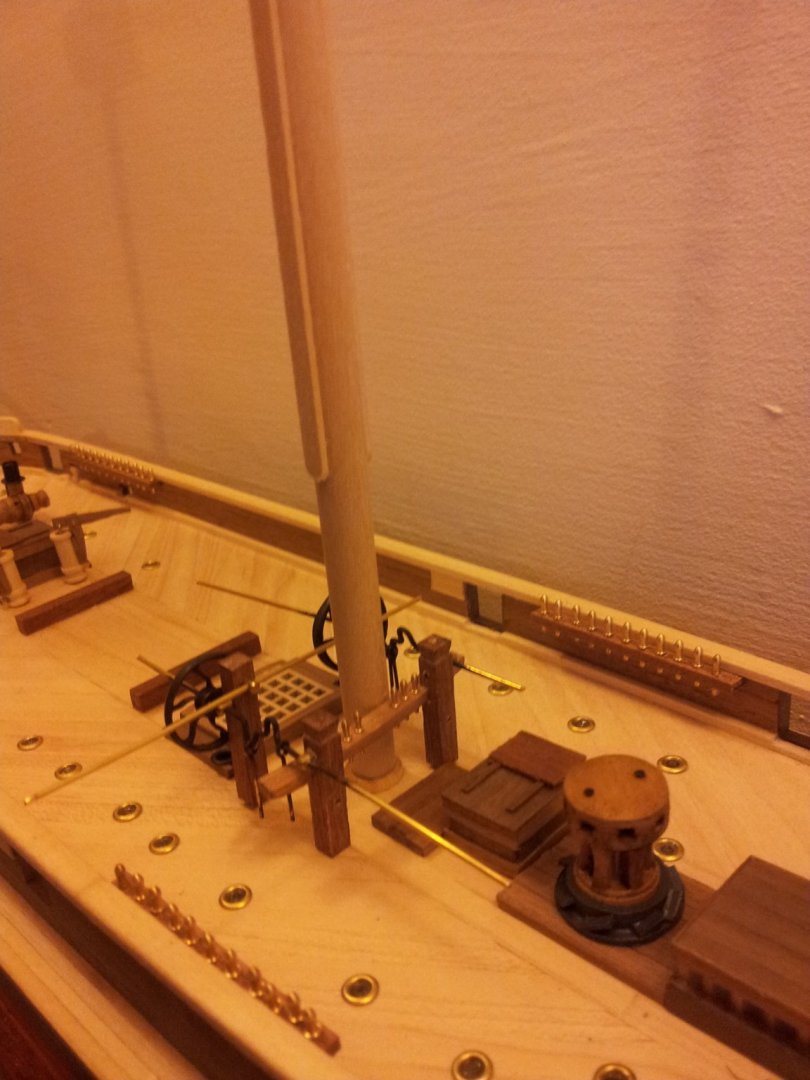

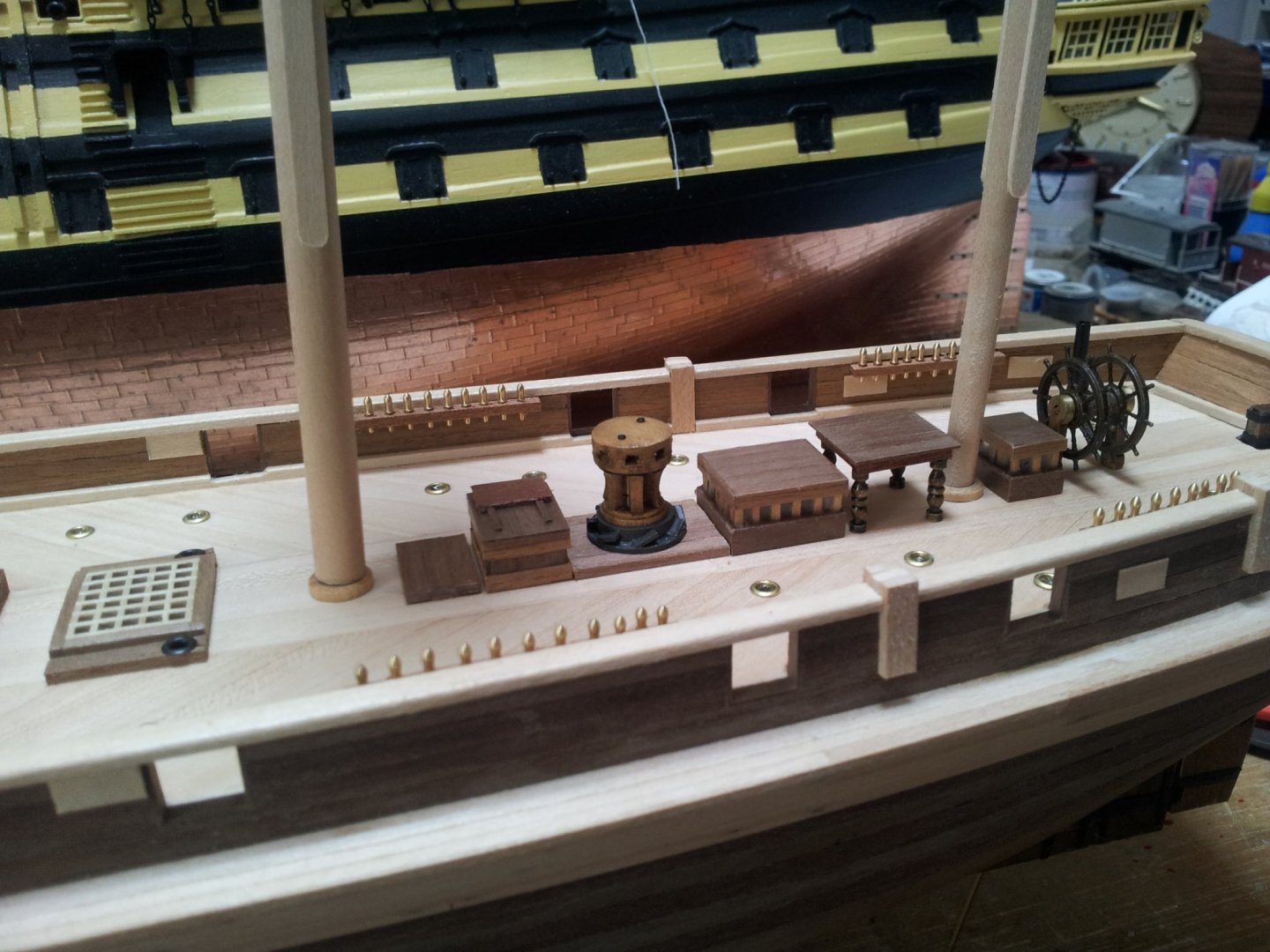

Ty for the comments, likes and views as always everyone (glad you like it geowolf😁). Today the belaying pins were fitted along with the ships bell, i suspect the bracket should be more square but i like the curved top. The bell is actually a billing boats one out of my bits box (never throw anything away). also replaced the galley chimney with one made from brass tubing with a more accurate screen on top (on the plans i have seen there are not any ridges on this and it looks a lot taller than occres). Also finally got the windlass fastened in place and the accomodation hatches and galley grating glued in place, starting to look nice and busy around the foremast area🙂. The elm tree pumps are amati fittings but not really right style so might have to scratch build a couple, but they do look nice🤔. OMG actually back into work tomorrow albeit part time for now after 5 months! take care all. Keith

-

seeing that takes me back to when i first started building billings kits, basically all they done was mark the wood out for you, I was going to buy the billings l'etoile years ago but didn't bother, however did buy the dusek le belle poule which after checking the contents looks like a fantastic kit and will be a lot easier than your beastie😁 Keith

-

<<<<<pops head round door takes one look, shakes head and books you in for some serious therapy🤣

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

Ty keith, it's the way i have always done them for the reason you suggest about being a stronger fit (can be a bit nerve racking drilling down to your nicely planked deck and going for it with a square file though). for a first time build yours is pretty outstanding to be honest and you have done good to spot the mistakes you have. Keith

-

ty to anyone who has looked in, back to remedying the works of fiction that are occres pumps/ fife rail assemblies🤨. the fore fife rail and pawl posts are glued together, but only dry fitted to the square holes drilled/filed in the deck also got the holes in place for the main fife rail/ winch/ pump posts, the timber was curved by soaking and then bending while using a clothes iron to steam it to shape (don't let the admiral know😱)! take care all Keith

-

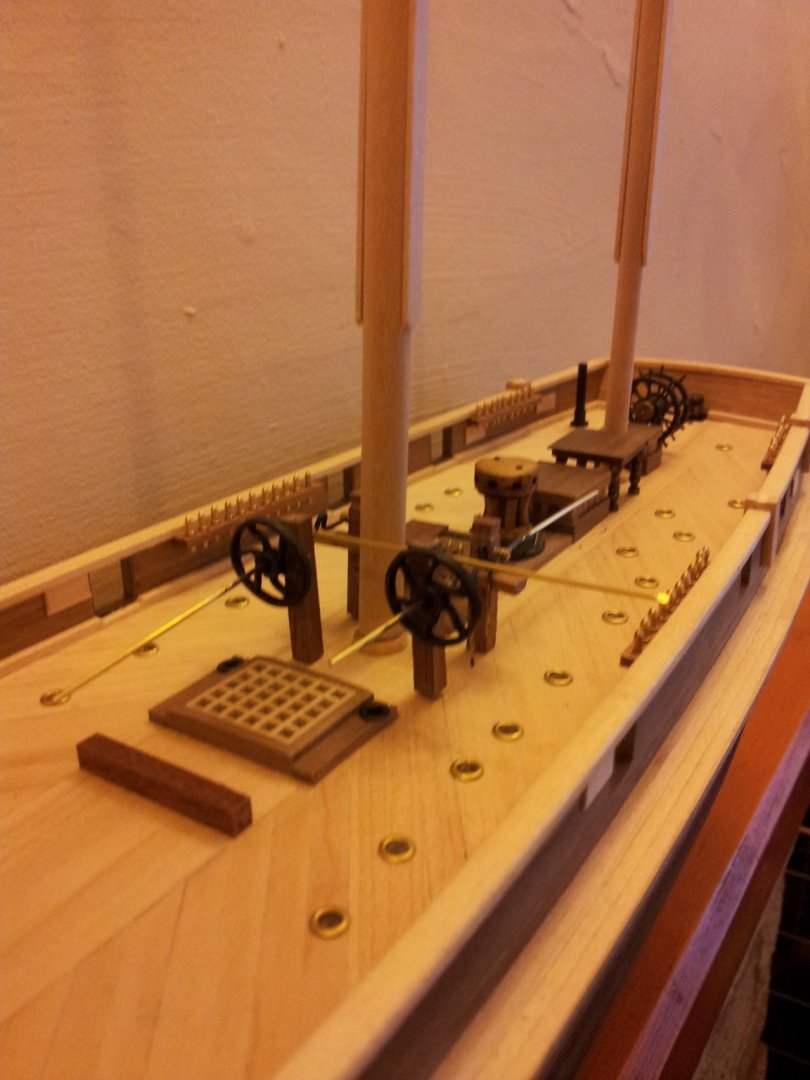

thanks for looking in everyone, been working on model railway stuff last few days as a rest from shipping, but started on the mainmast fiferail and massey pump assembly/ brail winchfor main jeers. everything just test fitted at the mo with no glue. the posts will be morticed into the decks. take care all Keith

-

Holystoning was used to smooth the decks to rid it of splinters as the crews on earlier vessels were actually barefoot so it was a safety practice to avoid splinters. However we are talking royal navy here so "swabbing the decks" would most likely have been carried out until they were in the icefields i would have thought so a little light weathering maybe but don't go over the top. As an aside i am not sure if the royal navy did this but a lot of wooden fishing vessels used to use linseed oil on the decks to preserve the wood which was done every year until costs curtailed the practice in the 1970's (in the west cumbrian fishing fleet anyways) Keith

-

oh how we forget the basic nightmares we were faced with years ago when you had to cut everything out because laser cutting didn't exist😱. nice fix though kev. i have two open fires so my used/ scrap wood is cremated- however need to make sure you have really finished with it! Keith

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

at which point did you say what have i done to myself🤔😉, should be a great build though. Keith

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

yes i agree the supplied planking is very thin, that is why i used some 0.5mm walnut to 2nd plank mine. sometimes eureks moments happen when you spend time away😉 Keith

-

welcome back dominic looks good, in a moment of madness i bought the trumpeter 1/200 and its hugeeeee🤔, wont start it til i finish my victory though. Keith

-

if in doubt follow the destructions😉, looks nice and weathered. Keith

- 106 replies

-

you might be able to tidy it up when the capping rail is added, you can always cut out planking and replace it. Keith

-

Thanks for the likes everyone. sounds like you have a bit to keep you occupied emmet! on the good news front boss has decided to try and reboot the company so i will be back in work from next week under the partial furlough scheme🙂. on the shipyard front a lot has happened on terror in the comps absence! bow plating added and painted (used self adhesive copper strip in the end), pin rails added to bulwarks, rudder and prop in place and skylights finished + added some brass eyes to the anchor hawsepipes in the bow. take care all Keith

-

Thanks for likes and views folks -sorry for delay in answering Emmet- comp on blink again!! it's hard in hot weather to find the get up and go to chop firewood! Hopefully will be able to wrestle this laptop off the son later and post some update pics. keith

-

thanks for looking in everyone, back in the shipyard and now have the strengthening straps and gudgeons on the sternpost, also got the glazing in the larger skylight and painted the brass bollards on the windlass. the rudder is just resting in place, i have put a pulley wheel for lifting it but still need to add the pintles. take care all Keith

-

ouch Emmet at least it missed the buildings! you will have a nice supply of firewood though😉 Keith

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.