-

Posts

5,447 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Jack12477

-

-

Ah yes ! "garde a l’eau!” (“watch out for the water!”) or In England, “gardy-loo!”

-

-

See New York Steam Engine Association . Canandaigua is in the heart of the Finger Lakes region of New York State

- popeye the sailor, mtaylor, Canute and 3 others

-

6

6

-

If you visit the Cloisters in

RiversideFort Tryon Park, Manhattan, just north of the George Washington Bridge, you will see similar examples of exquisite woodcarving.- Mark P, hollowneck, Keith Black and 2 others

-

5

5

-

Several years ago a replica Viking Longboat sailed across the Atlantic and made several Ports of Call alone the Coast including one to the Hudson River Maritime Museum in Kingston NY. Had a beautiful pair of carved figurehead on bow and stern. See photos below.

Eric, your model looks great. Well done!

-

Diorama is coming out nice, Alan.

- Old Collingwood, lmagna, Canute and 1 other

-

4

4

-

1 minute ago, king derelict said:

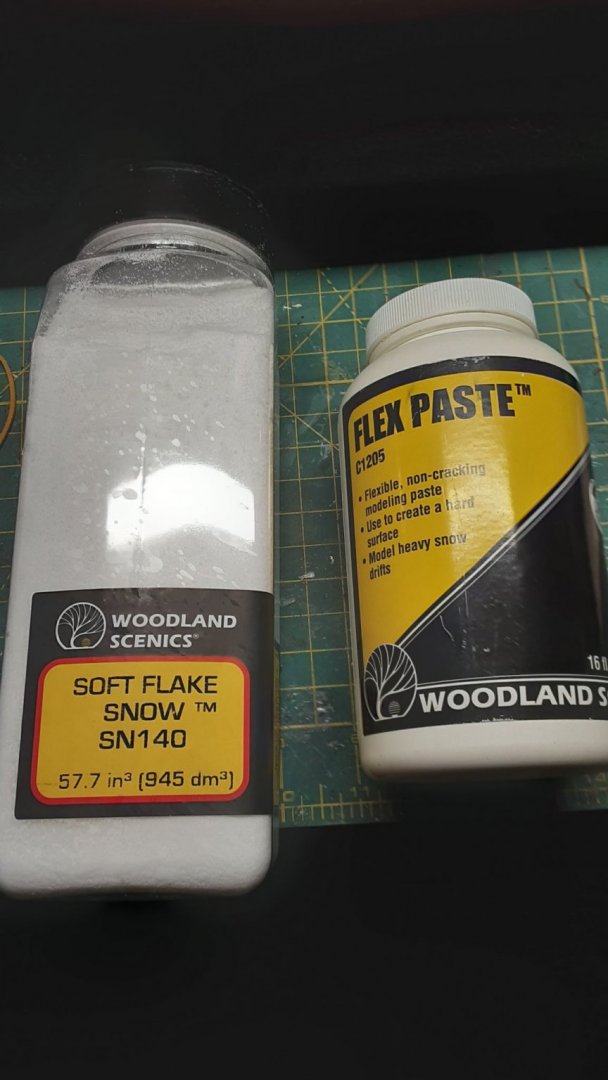

Woodland Scenics look like a great resource for diorama building.

It is ! Their pre-made trees are very good, as are their cast white metal trees. The ground foam works well also. And yes there are some good videos on YouTube .

- Old Collingwood, Canute and mtaylor

-

3

3

-

- mtaylor, Old Collingwood, CDW and 2 others

-

5

5

-

6 minutes ago, CDW said:

Very thankful we were spared yet again.

Yes ! Good news!

The latest track shows the outer most cone passing roughly 50-75 miles southeast of me later in week.

- Canute, CDW, popeye the sailor and 3 others

-

6

6

-

-

Just an FYI, Alan, Woodland Scenics makes some really good reusable rubber molds for all types of cliff faces, etc. I've used them on several dioramas. See my Sherman tank build log around post #158 for an example..

Nice job !

-

Very nicely done! 👍👍

-

Very nice figure & diorama, Wefalck.

-

If it was me, I would try to salvage the side pieces, first soak in water until wet, careful not too long or the ply might delaminate, then using a hair dryer try to flatten out the curvature, one piece at a time, go SLOW. Once flat clamp between 2 pieces of 1/2 inch or thicker hardwood, cherry, oak, maple. Let sit overnight. Unclamp and see how it looks. If necessary, reclamp and let sit for another 24 hours.

It doesn't have to be perfectly flat since it will conform to hull curvature anyway.

-

-

Bottom 2 photos look like Caverns of Luray, Top photos Shenandoah. Been there, outstanding pics

- Edwardkenway, Chuck, FrankWouts and 1 other

-

4

4

-

Sorry to hear that news Michael, but better to get it corrected now before it gets any worse. Best wishes for a successful surgery and speedy recovery.

- Keith Black, FriedClams, druxey and 1 other

-

4

4

-

Here it is guys ! Dig in !

-

welcome back !

- Steve 12345, mtaylor and Ryland Craze

-

2

2

-

1

1

-

5 hours ago, Don Case said:

That's not the minimum length I'm looking for. If a ship is 110' long and the contract calls for minimum 25" what do they do when they get to the end and have a 10' gap to fill?

If the minimum plank length is 25 ft and the ship is 110 ft, then two 40 ft long planks plus a 30 ft plank would meet the minimum length specified in the contract (40+40+30=110 or 30+30+25+25=110). Minimum does not preclude using longer length boards, but it does preclude using shorter lengths, as in your example, 10 ft, 15 ft or 20 ft.

-

Ryland, it is under Account Settings in your profile

- Ryland Craze and mtaylor

-

2

2

-

Beautiful ! Nicely done ! Enjoy!

- Keith Black, Edwardkenway, Egilman and 7 others

-

10

10

-

It also makes using the J-stroke to keep the canoe on track easier to execute, especially if solo.

-

Hmmmm ! I always knelt in the bottom a canoe with my tush resting against a thwart. Never sat in the bottom of a canoe. Wonder what paddling from that position is like.

Anyway, beautiful looking canoe, Chris. Great job building her.

HMS Penelope by King Derelict - FINISHED - Flyhawk - 1/700 - PLASTIC

in - Kit build logs for subjects built from 1901 - Present Day

Posted

👍👍👍👍