-

Posts

198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bobstrake

-

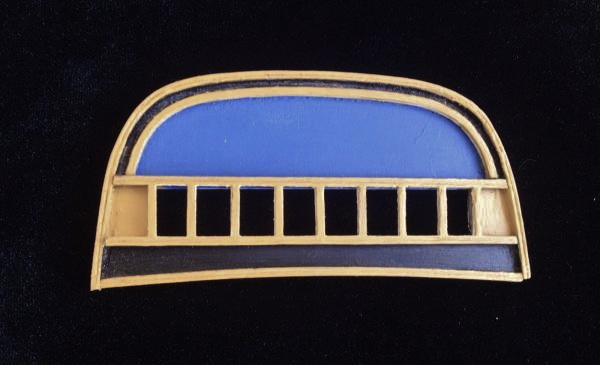

I just can't leave it alone. Worked on the colors, put the correct number of window panes this time, and test fitted the cast pieces. Getting closer... I'll try try fitting each of the 8 windows with clear styrene squares, and maybe won't get glue spots on the panes this time. Oh yeah, and I made the window panes with thread that was reinforced with super thin cyano.

-

Nick, It's good to hear from you. I look forward to your posts. I'm very pleased to see that the cast parts are so much better than those depicted on the kit's packaging. I removed the windows and fiddled with the gallery. I didn't want it to be garish, but it looks like it is. Now back to planking and making windows

-

My progress is slow, but stimulating. The strakes are added at an impercepable rate. I am experimenting at putting windows in the gallery, and tried using thread to maximize viewing the interior. I am dissatisfied with the final quality control, so will tear this out and try again. Good practice. Brian (GuntherMT) kindly chided me for not completing the Carmen yet, and I have one excuse, lack of will power. I love working with wood, but I haven't even been able to make friends with the needle and thread. I can stand only an hour at a time cursing, I mean, sewing the sails.

-

Really bad news, indeed. Best wishes to you, and hope you can beat the big C.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Brian, That's some serious workshop! It mirrors some serious ship building.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

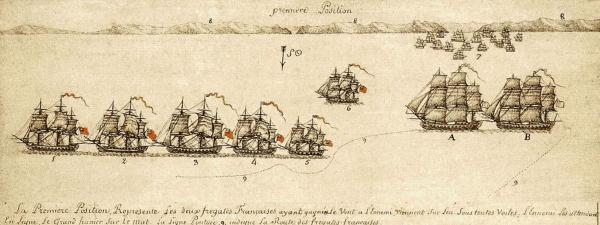

Jparsely, I'm sorry I took so long to answer your insightful question about coppering the bottom. I just read the The Battle off Spanish River, on July 21, 1781. The site: awaitsea.com, gives the British and French versions of the battle. The French ships, L'Hermione and L'Estree, were described as coppered and uncommonly fast. L'Hermione is labeled as B, but sped right past A, L'Estree. I didn't plan on coppering the bottom of L'Hermione. I wanted to show off the beautiful wood planks. But I am NOW toying with the idea of showing the waterline with weathered copper, hmmmm.

-

That's one fun and imaginative windlass at any size. I'm amazed at your detailing at this size!

-

Model paint data base

Bobstrake replied to jbelwood's topic in Painting, finishing and weathering products and techniques

Thar be GOLD here! Thanks fer sharin' th' booty. -

Okay, I've finally completed the darning. Well, "gosh darning" would be more correct. I would say this has been an eighty "gosh darn it" job so far, with several other expletives thrown in as well. Nobody wants to be near me when I'm sewing. Now that the hems are complete, I will have a go at the seams.

- 47 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Looks like a great kit and a serious shipwright. Great pix. Thanks for sharing.

- 133 replies

-

It's always a joy to watch you and the boys at work. I can hardly wait to see your next work of art.

-

HOF, I was only able to cut a bearding line at the bottom of the stem and stern. I'm not sure how this is going to work out. Since the bluff bow butts up against the break water, and the false keel ends right at the bottom of the bulkheads, there is no space for a bearding line here. I was reluctant to cut into the keel. This is quite a thoughtful learning process. I am savoring the experience. I visited your spectacular Cutty Sark build and hope to one day approach your skill. It is the kind of model that you want to revisit often. I will.

-

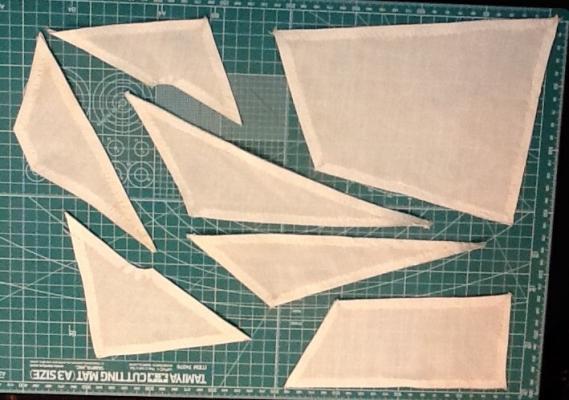

Jparsley, I appreciate your interest. I got a good deal on a Mamoli Connie, but was sobered up by the size of it when it arrived, over 6 feet long! I spend hours on each strake, narrowing the stem, spiling the edge of the plank to fit tightly against the adjoining plank, bending and twisting to pre- fit the hull, then gluing. I have to psych up for each strake. Here's a poor photo of my last strake before gluing. It cut off the twist for the stern. One more strake since the last post. I am experimenting with a removable cover below the captain's cabin. I'm hoping to attach it with magnets. We'll see.

-

It's a joy to watch your build, and fine attention to detail.

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Jeff, I'm late to see your build. I'm sweating out the gun ports on my AL build, but will use your build as inspiration. Your detailing is more than I plan on my build, and adds a lot. Can you show another long shot of your build? It is such a beauty, and I would like to see it with the new detailing.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.