-

Posts

690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hornet

-

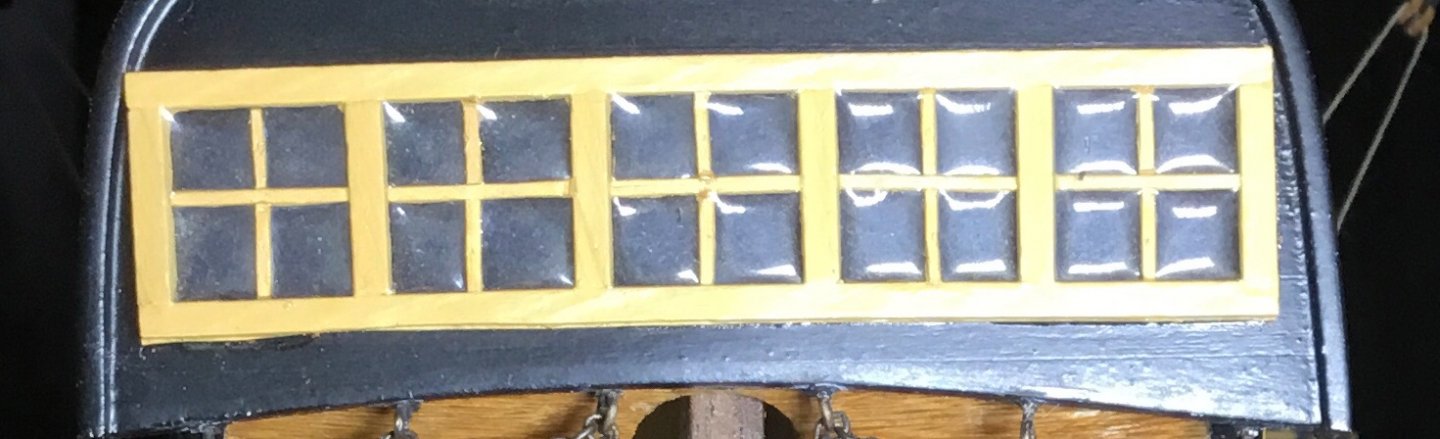

I’m currently building the Caldercraft version and it is on the brass etch sheet. It may be that yours is the same. I replaced mine with ones I made from timber.

-

Holding small parts for soldering

hornet replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

-

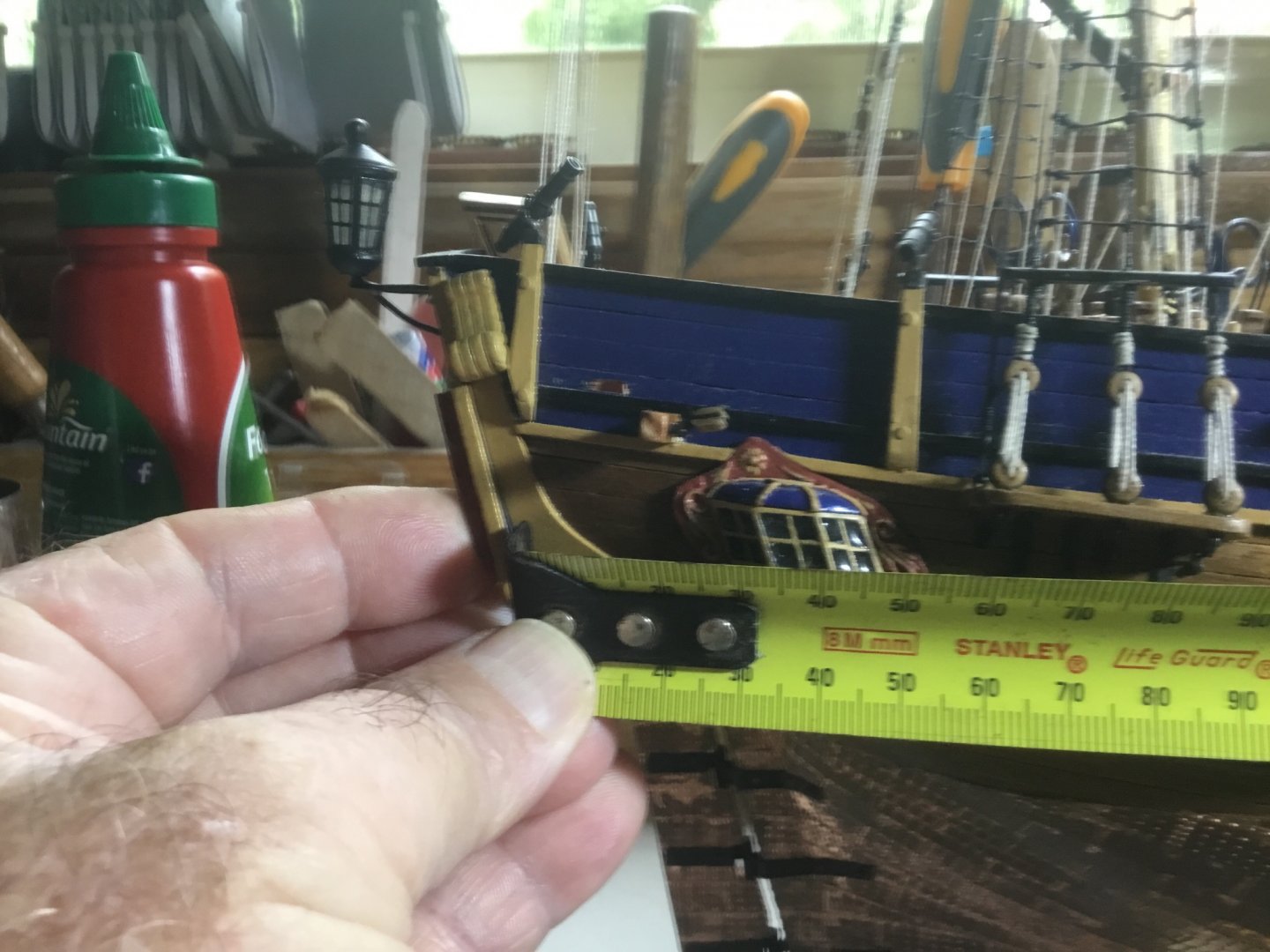

This is mine. May give you some ideas.

-

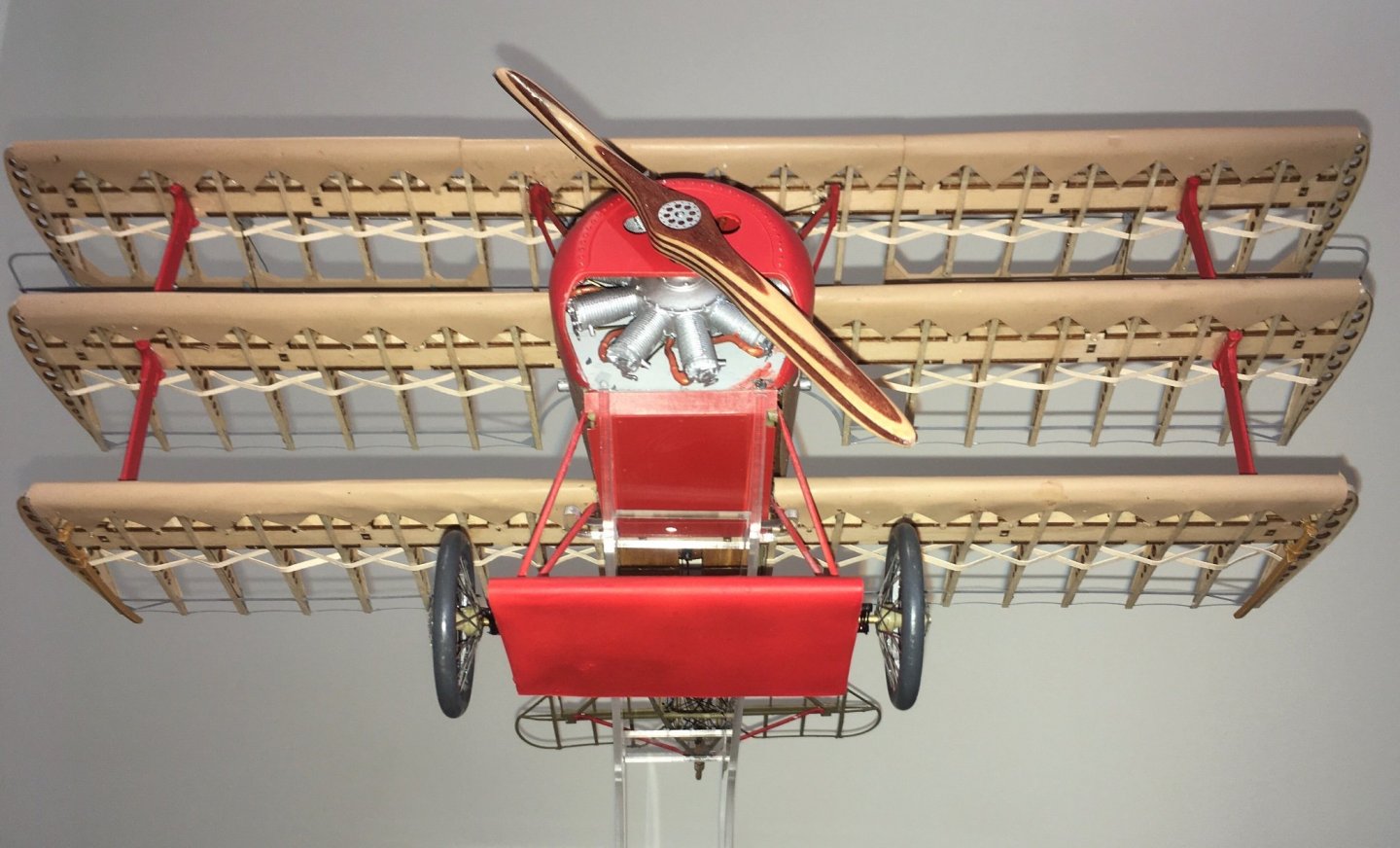

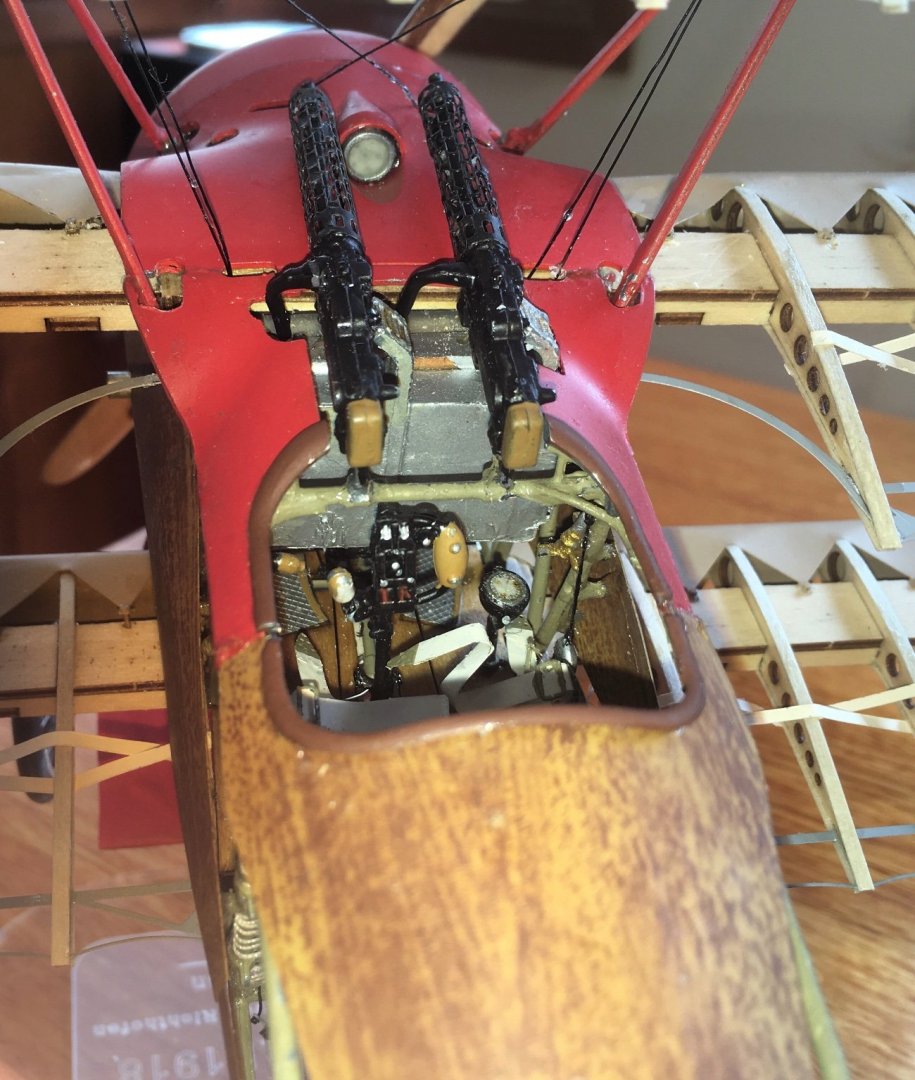

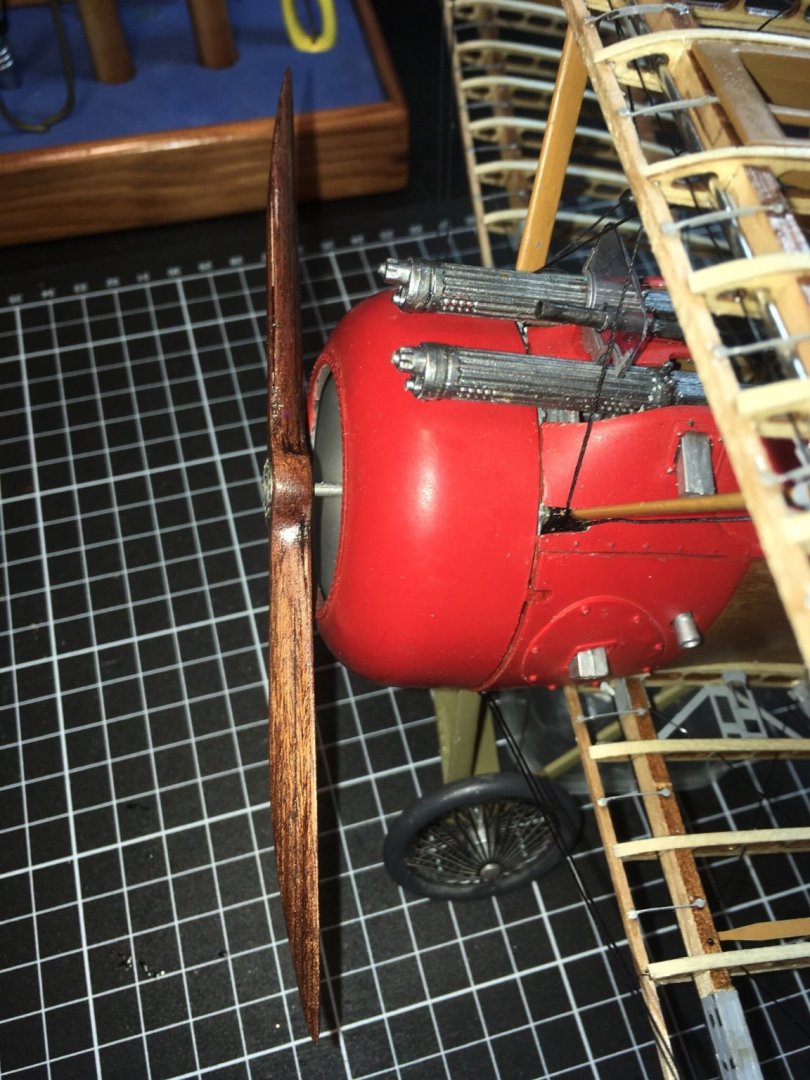

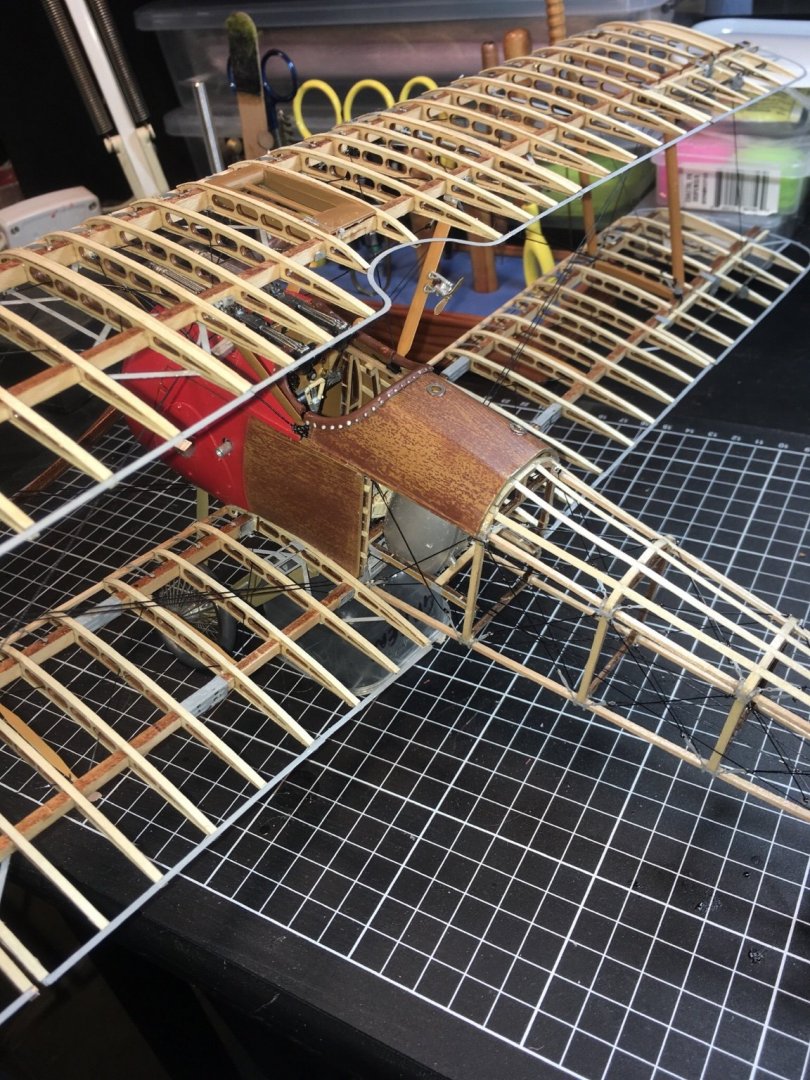

Fokker Dr.I by hornet - Artesania Latina - 1/16 scale

hornet replied to hornet's topic in Completed non-ship models

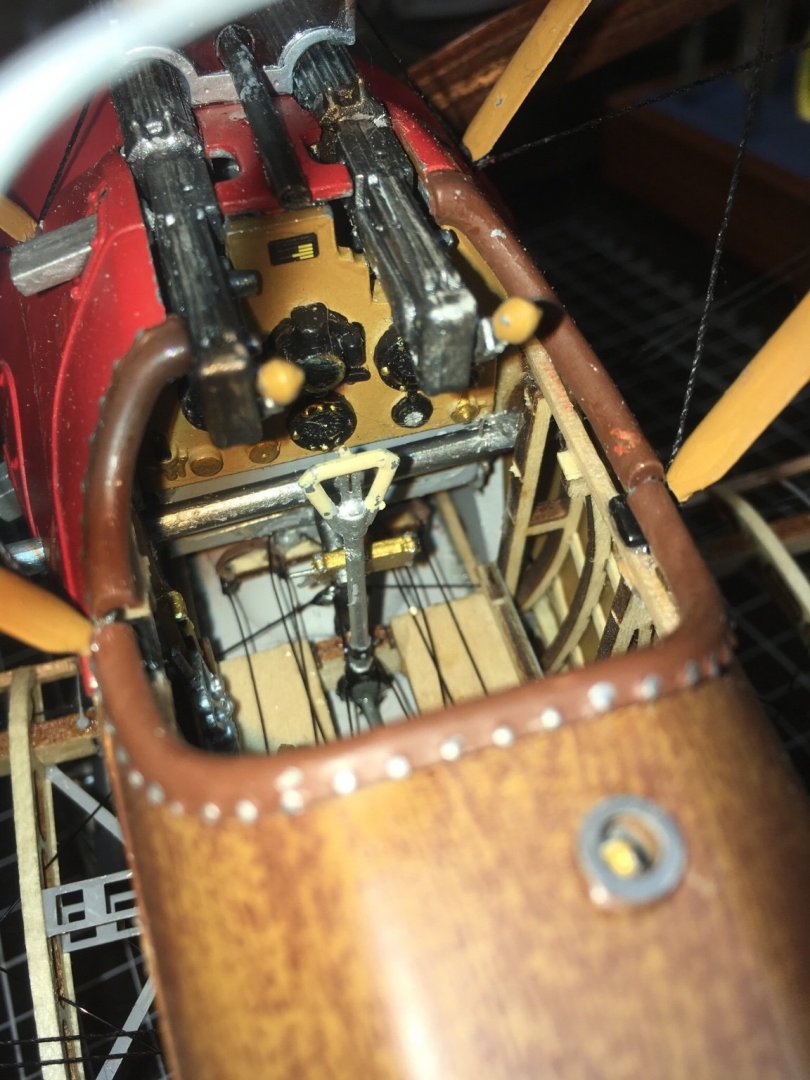

Cast pieces on the Artesania Latina kits are quite well done. My biggest issue was that gluing was done with cyanoacrylate glue which I am allergic to. I used 5 minute epoxy which was awkward at times. -

Sopwith Camel by hornet - Artesania Latina

hornet replied to hornet's topic in Completed non-ship models

Was quite an enjoyable kit to build. Instructions on CD not printed but you could print them off if so desired. Great detail in kit. Gave me a chance to practise my airbrushing skills too😀 -

Short break - something different - before beginning the HMB Endeavour. Am also going to build the Fokker Triplanes by the same manufacturer.

-

I find that holding very small items like blocks in an inexpensive fly tying vice is very helpful. There are many cheap vices for sale on eBay. I have found that my fly tying vice is one of my most useful tools in model making.

-

I’ve built two Caldercraft models and am on my third. They are quite good quality for the money and have a good range of models for different skill levels.

-

Rope-where to go since Syren is no longer making it?

hornet replied to bear's topic in Masting, rigging and sails

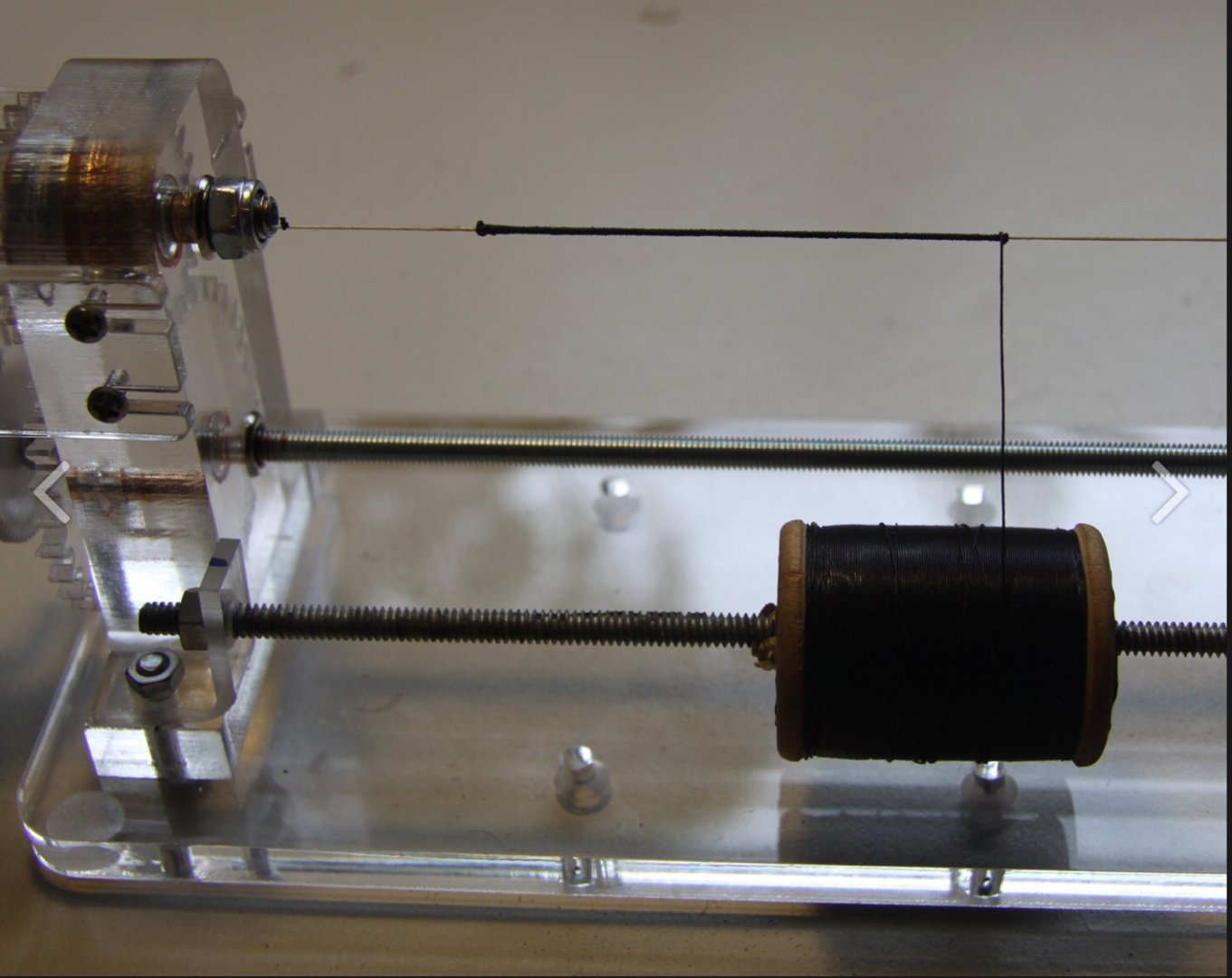

I use my own home made rope walker. I scour antique stores for cotton and linen thread. Apparently old cotton reels are collectable. I’ve found that old thread is often better quality than modern thread. -

If making your own rope, haunting antique and collectable shops is worthwhile. Apparently the old cotton reels are now collectable. I’ve managed to gather quite a collection of linen and cotton threads in a range of colours and diameters that are much better quality than modern thread.

-

HMS bounty colour?

hornet replied to Rich12ace's topic in Painting, finishing and weathering products and techniques

I used Admiralty paints on my Bounty. Excellent. - French Blue - Red Ochre - Yellow Ochre http://www.jotika-ltd.com/Pages/1024768/PSA_Paint.htm -

Domanoff Rope serving machine SM4 question

hornet replied to modeller_masa's topic in Modeling tools and Workshop Equipment

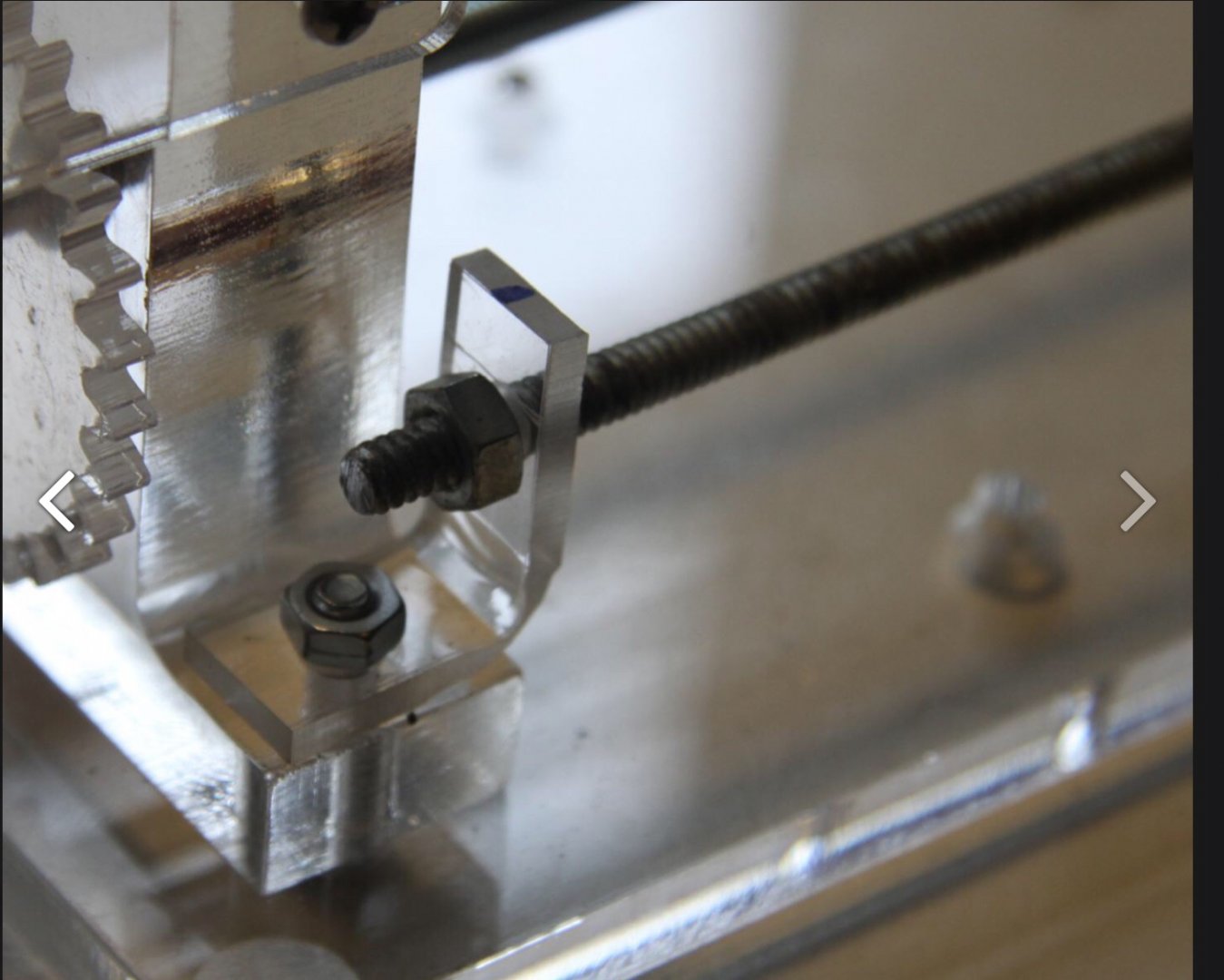

I have an older model of this machine. I improved it by adding another length of threaded rod to the front to hold a reel of thread. It makes the job a lot easier. I simply drilled and bent up two right angled brackets in Perspex then drilled a hole in the front (base) of each of the legs on the serving machine. I bolted on the the brackets then threaded the rod through holes drilled in the top of the brackets. I can change thread reels simply but undoing one of the nuts on the threaded rod and changing reels. -

Frosting Acetate

hornet replied to traumadoc's topic in Painting, finishing and weathering products and techniques

I use 2 part epoxy designed for coating fishing rod guides. Mix together then add very small amount of enamel paint. Place oven bake paper under window frame and apply mix. When dry, peel off oven bake paper and you will get realistic looking glass - concave or convex shapes can be achieved depending on how you apply mix. I usually use a toothpick. -

I wouldn’t be without my cheap fly tying vice. Excellent for many jobs where a third hand is essential.

-

Making and using a draw plate

hornet replied to Don Case's topic in Modeling tools and Workshop Equipment

If you do a google image search for the Byrnes draw plate you can see the step down between hole sizes used. This drawplate is brilliant. As to cutting bamboo cleanly, I use a pair of cutters with very, very sharp, fine jaws. -

this is my ropewalk. Works a treat. https://modelshipworld.com/topic/14464-inexpensive-powered-rope-walker/?tab=comments#comment-449106

-

I have spent quite a lot of time haunting antique shops. I have collected a lot of old cotton and linen thread - people actually collect cotton reels - which is (in my opinion) often better quality that the tread produced now. I calculate diameter then make up appropriate diameter ropes using various numbers of threads on my home made rope walker. It is now one of my favourite model related pastimes.

-

Question on ropewalks

hornet replied to DispleasedOwl's topic in Rope Making/Ropewalks's Rope Materials and parts resources

Gday Mate, the rope walker in your pic is the one I built quite a while ago. I have made many great looking ropes with it since and it is now one of my favourite aspects of the hobby. In answer to your question, I didn’t put a motor at the other end of the Walker, but after I make a length of rope on the walker, I have found that attaching a cheap battery powered screwdriver on a low speed setting to the rear of the bolt on the trolly to which my rope strands are tied and giving it 50 - 100 rotations tightens up the rope even more. The rope still needs to be under pressure i.e the lead weight is still attached to the trolly. After removing the rope from the Walker I always run it backwards and forwards over a curved , hard surface to ‘harden’ it. The pic attached is my trolly with the screwdriver sitting on the bolt which goes through a bearing to a ring onto which I tie my threads - it is not set up to make any rope - just a demo pic so you can see what I mean. Hope this helps. Steve (hornet) -

-

Inexpensive powered rope walker

hornet replied to hornet's topic in Modeling tools and Workshop Equipment

Larry Leno cogs are marked z24. Diameter 25mm. Wheels (pulleys) on trolly are marked 1-05. 30mm diameter. -

I hold this size block in a fly tying vice, ream the hole out slightly with a very fine drill bit then use a doubled over very fine piece of copper wire taken from the core of a piece of electrical wire. BTW an upturned glass jar (with concave base) makes a good receptacle for a few drops of CA glue.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.