-

Posts

978 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mugje

-

-

-

-

Yeah you can always take it a bit further when laying the first foundation of planks. The flow of the planks will reveal the spots that aren't faired enough. Especially the bow and stern were for me a point that I needed to correct. But like I said...that isn't to difficult to do it then.

- Mr Whippy, KurtH and CaptnBirdseye

-

2

2

-

1

1

-

-

-

-

-

Will be interesting to see how much difference there will be between the standard supplied blocks and the pear wood set.

I have the idea that the items are so small...that I wouldn't really see the difference, but who knows

-

-

Thanks for the likes and compliments!

Just a small clamping tip regarding the gunport linings. Especially the lower cill was frustrating to properly clamp or push down until the glue would set, but clothespins help with pushing down the cill until it's dry. Just reverse them so they push against the upper and lower side. The side cills could be hold in place with larger tweezer clamps, but the clothespins can be used also for this.

- CiscoH, DonSangria, Mr Whippy and 19 others

-

22

22

-

-

Little update here:

I didn't had a lot of time to work on the Sphinx because I was renovating my garden these last few weeks, season is beginning and needed to do quite some work.

But these last few days I could do here and there some work on the ship

.

.

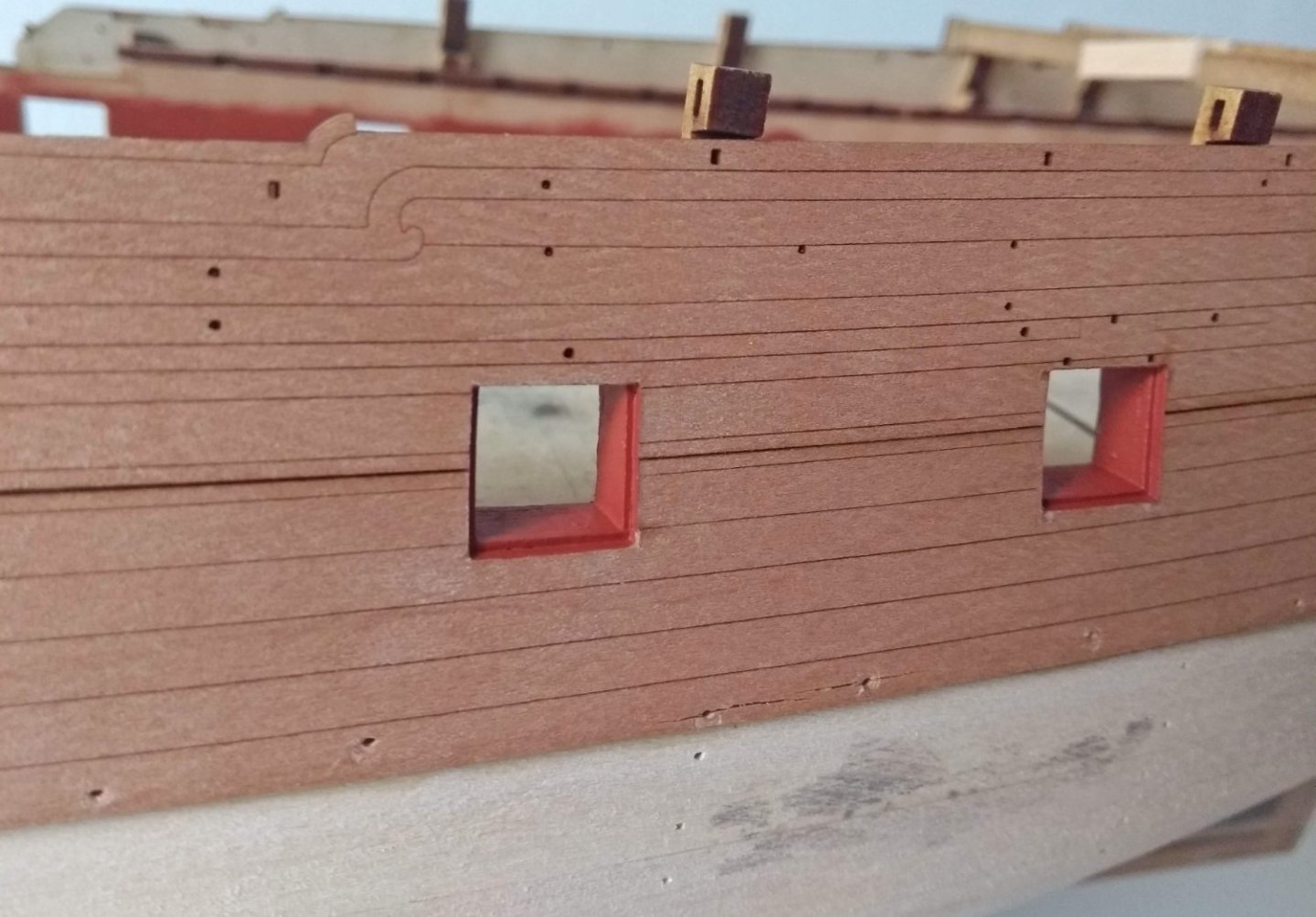

I have glued the large pear sidepanels onto the hull. Not super difficult, but some concentration is needed to get a good fit. Especcially the lower front pieces I found the most challenging. I do have a small gap here and there between the upper and lower parts, but overall i'm happy with the fit. Those seams are going to be covered anyway so it's not really a problem. The most important thing for me was that I got all the right curves of the hull and the pieces were glued firm against the underlying patterns.

I advise to have a sound clamping plan before you begin

it takes away a bit of the stress when you apply the diluted pva and the pattern begins to curl a bit.

it takes away a bit of the stress when you apply the diluted pva and the pattern begins to curl a bit.

So dry-fitting first helps with this.

After that I sanded all the gunports flush with the inner MDF frames and began a test fit with the gunport linings. Used 0.5 pear for this and are quite happy with the first results. They are not too much in your face but distinctive enough to notice. Also the 3 ports with the lids need some extra work, because the underlying pattern didn't lay flush with the MDF inner frames. So I need to fill up or sand down here and there. It's a bit different for each gunport, a little bit of extra work...but that's part of the fun

2 done....18 more to go!

- chris watton, BenD, Javelin and 15 others

-

18

18

-

Great to hear your plans! What do you considering "medium size"? The Flirts and DoK or also Sphinx size? Just wondering

- AJohnson, thibaultron, Canute and 2 others

-

5

5

-

She looks fantastic! And so massive! Then you can appreciate when fittings etc are designed in the right scale, and not a gross blob of wood/metal. The fine details really gives the ship a massive appearance.

- mtaylor, Blue Ensign and hollowneck

-

2

2

-

1

1

-

11 hours ago, rvchima said:

Hey Mugje,

I just ran into a problem where my rudder with the tiller arm wouldn't fit into the opening in the hull. I had to remove about 6mm of the rudder post to make it fit. I recommend removing the main rudder piece from the 3 mm sheet now to see if it fits. It will be easier to fix now than later.

Thank you for the warning! I did have checked it when I dry fitted the lower counter. So I think i'm good there. But will check it again, because i'm a bit in doubt now haha. Double check wouldn't hurt 👍

-

-

Greetings from Friesland

I wish you all the best with this build. It's a beautiful ship when it's finished!

I wish you all the best with this build. It's a beautiful ship when it's finished!

-

-

-

-

-

-

7 hours ago, allanyed said:

Based on contemporary models this is what appears to have been the common method. I have only seen one that may have a stop on the bottom of the upper sill that forms the top of the gun ports, in this case on the lower gun deck. This may be original or may have been a modern repair, not sure. Regardless they were only about 1 1/2" thick (0.6mm at 1:64) for a vessel the size of Sphinx (20) 1775

Allan

Thanks Allen for clarification...yeah there were a few examples in the topic that I posted, on contempary models but also for example the HMS Victory. But I do think i'm going now for only the bottom and sides of the gunports. It does look good and it's also a bit less work.

I need to see if I have some 0.6 material laying around, otherwise I settle at 0.5 pear that I have in stock. That tenth of a mm...I can handle that difference

-

30 minutes ago, Cjames said:

Hi Mugje. Re your question about gunport linings, I installed them on the bottom and sides of all the open ports. I used material a little less than 1/32 in and cut each individual lining from a pre-painted strip about 5/16 in wide. See below.

I would complete the finish planking around the ports before installing the linings. You may have to sand the inner surfaces of the ports somewhat to match the exterior planking, and if you install the linings before doing that you'll have problems. I installed the linings the same way Blue Ensign did; bottoms first, then the sides. As he notes, the bottoms are easy, the sides not so much. Each side piece is angled top and bottom, and there are slight varIations in the angles for each piece. Do the best you can and plan on filling some gaps. Also one note. On my build the guns sit fairly low in the ports and with the linings installed the cannon barrels barely clear the bottom port sills. I would mock up one of the guns and test it with the material you plan to use for the linings before proceeding.

Best regards.

Cjames

Thanks Cjames! That's a helpful post

. At first I wanted to do all 4 sides of the gunport, but looking at your close-up...3 sides do look good also, so maybe going for that too. 1/32 is about 0.8mm so you used the same material as the outer planking? My thoughts were to use 0.5mm thick linings (not sure how much inch that is

. At first I wanted to do all 4 sides of the gunport, but looking at your close-up...3 sides do look good also, so maybe going for that too. 1/32 is about 0.8mm so you used the same material as the outer planking? My thoughts were to use 0.5mm thick linings (not sure how much inch that is  ). Will experiment a bit with different sizes, and what looks best.

). Will experiment a bit with different sizes, and what looks best.

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Exciting! I'm almost there also...just need to finish the gunport cills...taking forever with those