-

Posts

10,529 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

T-90 by Mikegr - FINISHED - AM - 1/72 - PLASTIC

ccoyle replied to mikegr's topic in Non-ship/categorised builds

Kit looks like it has a lot of detail. -

Congratulations on achieving a fine result!

- 70 replies

-

- Rattlesnake

- Model Shipways

-

(and 1 more)

Tagged with:

-

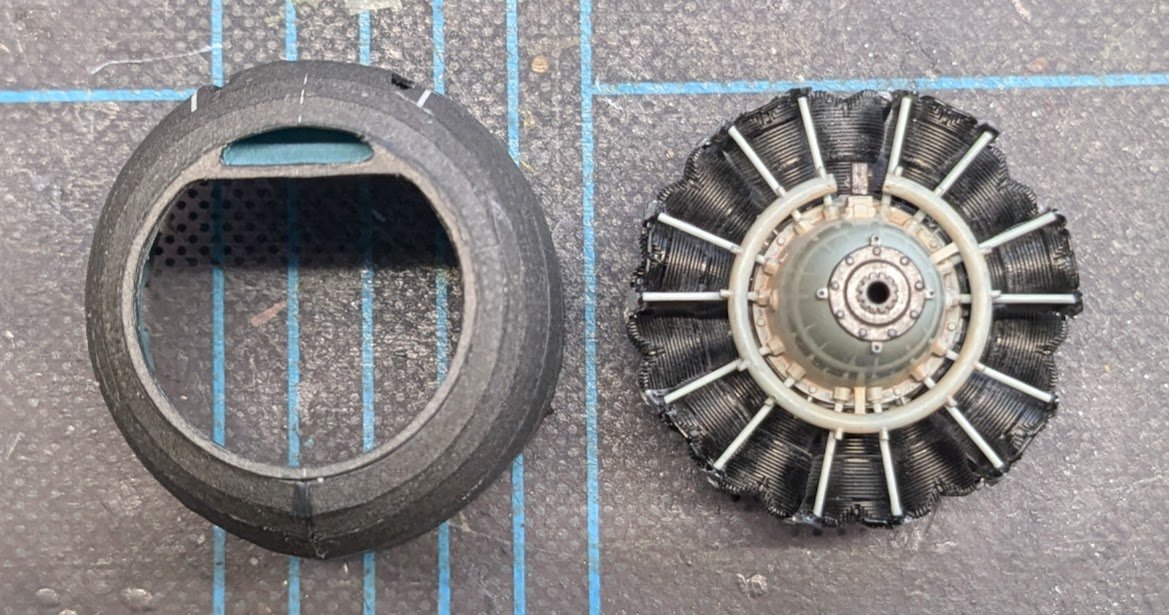

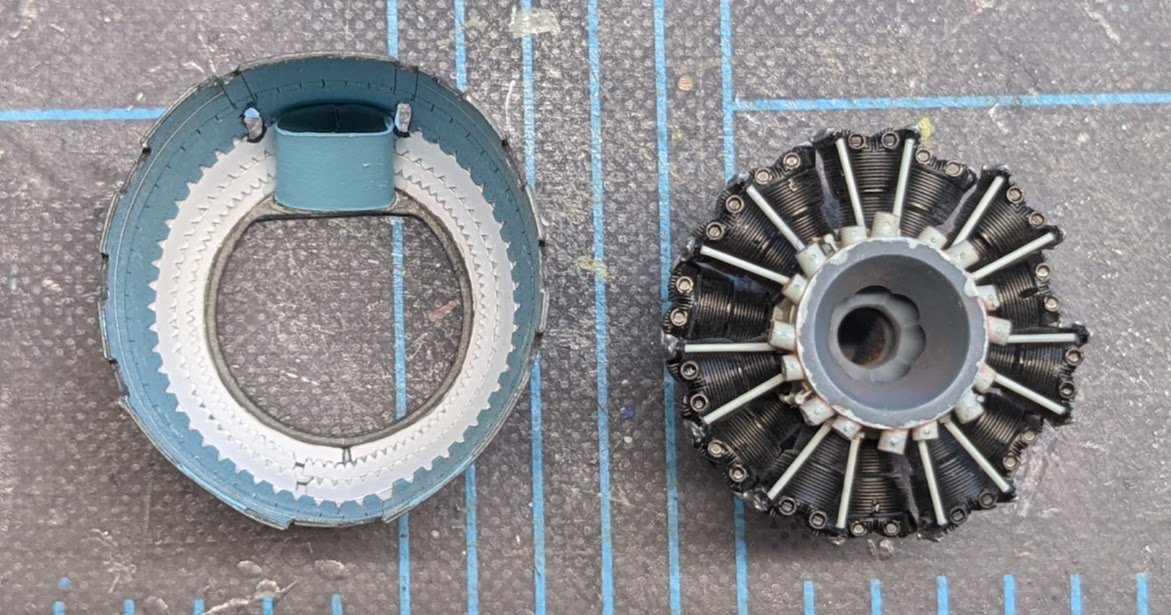

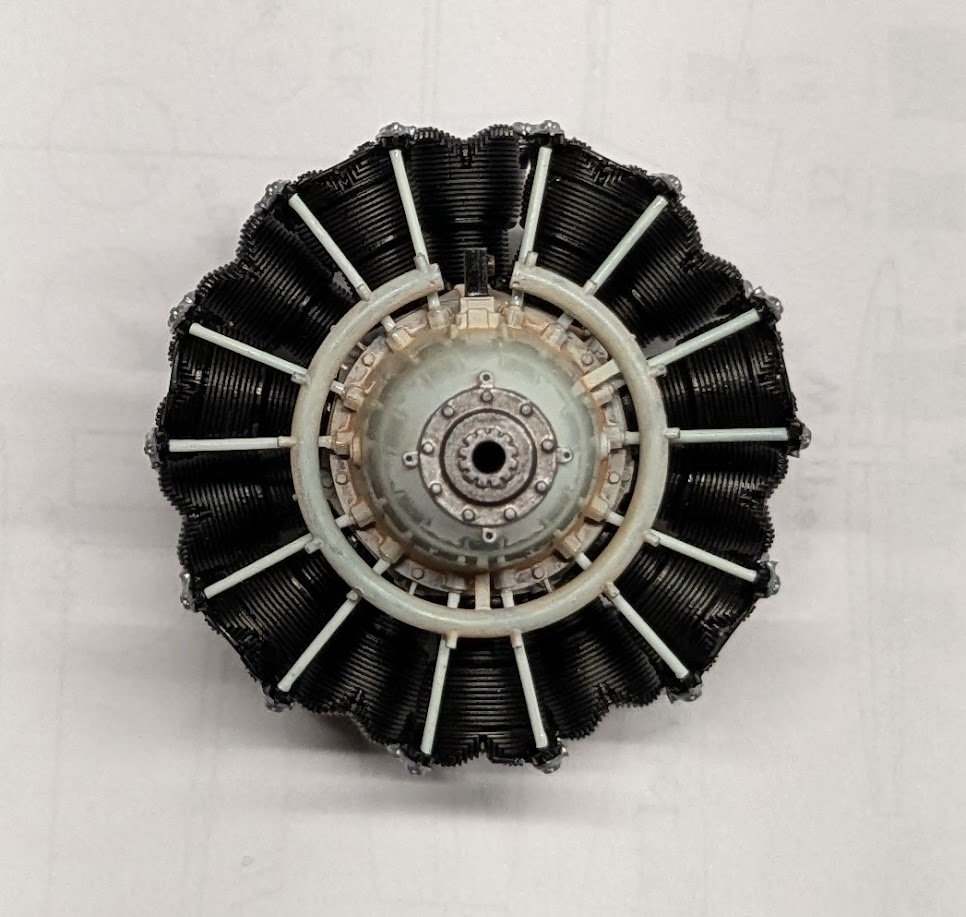

So, the outer structure of the cowl is done. The front of the crankcase should be flush with the cowl opening, so that will help me determine how to fit the rear part of the engine to the fuselage. Speaking of which . . . . . . it's a good thing I didn't fit any air intake pipes, because my initial measurements suggest that the entire portion of the molded block that includes the pipe stubs will need to be removed in order to allow the engine to fit properly. Fun!

-

Jerry, your project is coming along very nicely! The 3d-printed pieces look very neat and tidy.

- 553 replies

-

- sloop of war

- constellation

-

(and 3 more)

Tagged with:

-

Hello, Wes! Very glad to have you aboard. One side of my 'kinfolk' originally hailed from the Ellijay area (Tickanetley) -- I don't think it gets much more rural than that. Fortunately for that AL Swift kit, it has been a very popular beginner subject over the years, so we have a lot of finished build logs for it on hand. You can find them in this list. Cheers!

-

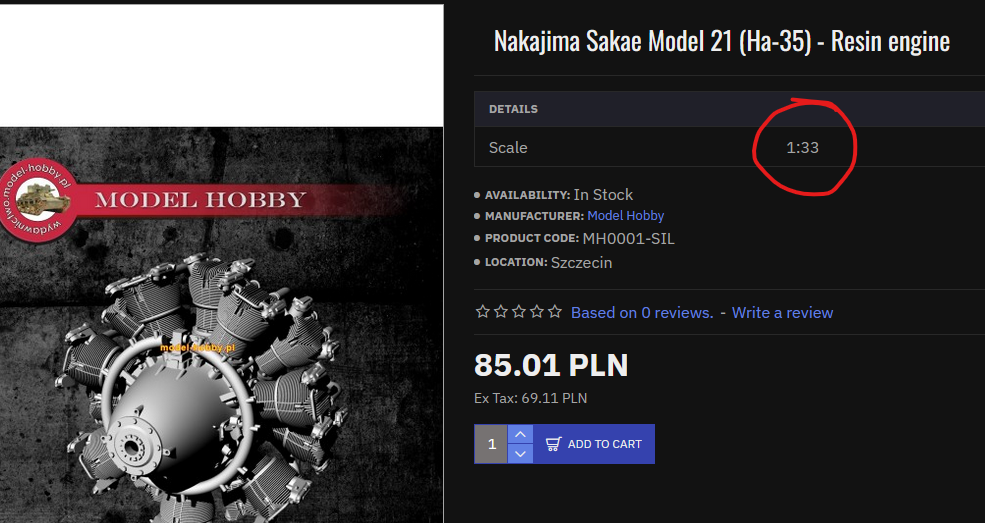

I have thought about that, but ultimately it would be an exercise of little value. If the kit engine does prove to be smaller and thus a better fit, that would suggest a wiser course would be to use the kit engine -- all 250+ parts of it. 🤮 And of course that would mean a not inconsiderable sum spent on after-market parts would be down the proverbial toilet with no return on the investment. No, I plan to start by finishing the cowling first and then calculating how much of the resin engine I will need to modify or remove in order to make it fit. As I said, the cowl opening is narrow, so it's possible that most or all of the surgically altered parts will not be visible. One step at a time!

-

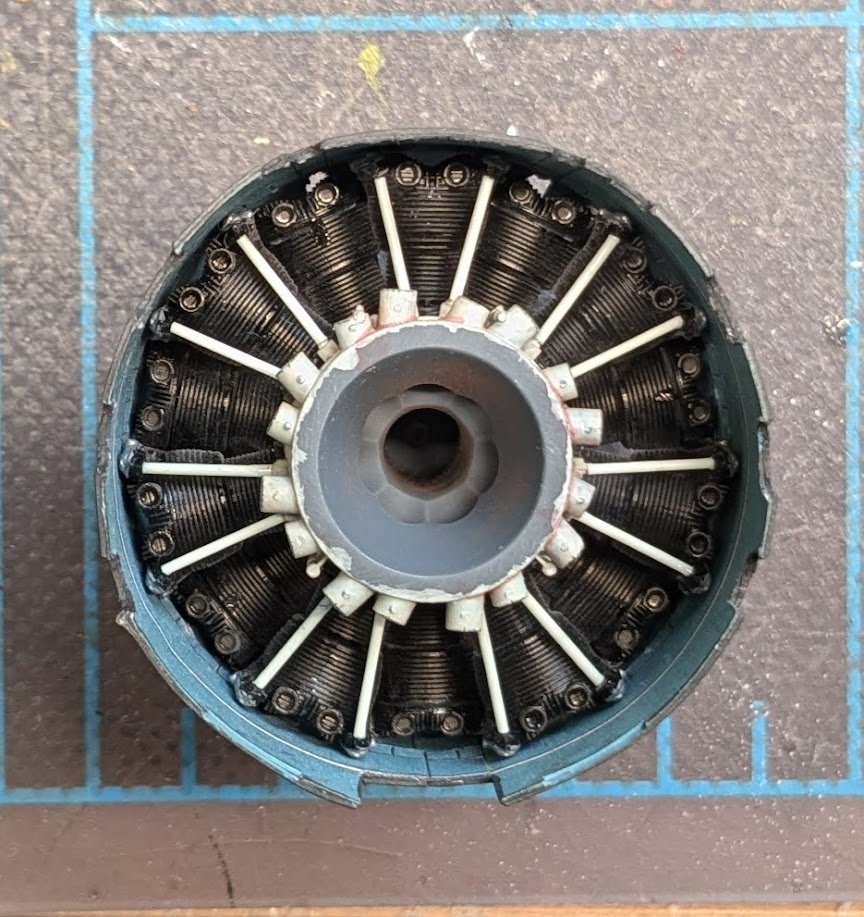

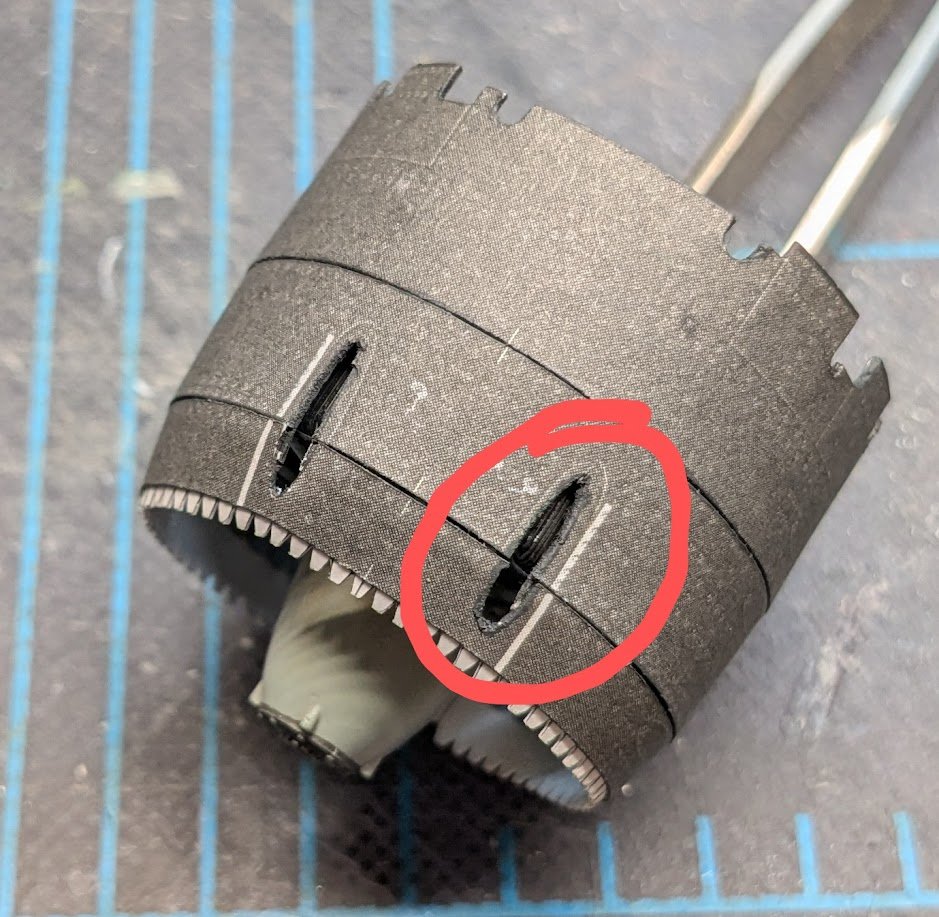

Trouble is brewing . . . First off, the resin engine is a very, very tight fit. This fact is made worse by the fact that the cowl's diameter decreases as successive rings are added. To get the engine to fit into the first three rings, I had to file off the top halves of the front cylinders' valve covers. But it gets worse . . . The engine itself is not the only thing that has to fit into the cowling. There's also the machine gun channels, and as you can see in that first picture, there's no room for them. In this next photo, you can see that cylinder heads more or less completely block the front openings for the guns -- and that's without the channels being installed. There's also an air duct that needs to fit in there as well -- don't ask me how. I'm quietly wondering whether this engine isn't actually a 1/32 scale engine rather than 1/33. It's not out of the realm of possibility.

-

Purely coincidence! I just happened to be browsing through the card logs today and noticed a few that had been quiet. I have taken the liberty of marking this log 'terminated'. We do that rather than simply deleting logs, because even unfinished logs contain information that may be of use to someone.

-

Good to hear, Jeff! My retirement is still a few years down the road -- but I can dream!

- 37 replies

-

- Baltimore

- heinkel models

-

(and 2 more)

Tagged with:

-

Welcome aboard!

-

Hey, Olli, how is this build coming along?

- 12 replies

-

- Seahorse

- Dutch Golden Age

-

(and 2 more)

Tagged with:

-

Just noticed that there was no update for May -- how's this one coming along?

- 37 replies

-

- Baltimore

- heinkel models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.