-

Posts

3,267 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KeithAug

-

-

Thank you all for the good wishes re my eyes. The first one is bing replaced on Monday so I am trying to make a bit of progress before I am banned from the workshop. They do one eye then the other after 4 weeks presumably to make sure the first one works before attempting the second. Anyway I have to avoid housework / shedwork for 2 weeks after each replacement. My wife doesn't trust me to be sensible so I expect to be under close supervision for a while.

- Javelin, FriedClams, Keith Black and 4 others

-

7

7

-

The crew heads are excellent. For clarity I am referring to the heads that sit upon the bodies not the bodies that sit on the heads.

- mtaylor, Keith Black, Canute and 1 other

-

4

4

-

Great Model George. I spent an enjoyable afternoon visiting her about 30 years ago. Unfortunately I now live at the other end of the country. I remember the huge transverse beams designed to take the pressure loads from the ice pack. They crossed the hull in the accommodation areas at a most inconvenient height. She is well worth a visit but Rockville is more than an afternoon trip away. Good luck with the build.

-

51 minutes ago, Valeriy V said:

of the order of soldering parts - from large parts to smaller ones.

Thanks again Valeriy. I sort of assumed you might be using different melting point solders and heat sinks - but your method is much easier.

- FriedClams, Valeriy V, Keith Black and 3 others

-

6

6

-

37 minutes ago, Valeriy V said:

nitric acid or for a longer period into the solution NaOH.

Valeriy - thanks for the advice.

- FriedClams, Canute, mtaylor and 2 others

-

5

5

-

6 hours ago, KeithAug said:

It would be good if you were able to supply more detail on your build / soldering sequence.

Sorry Valeriy I should have been clearer. I was referring to the bulwark not the deck plates.

4 hours ago, wefalck said:need a lot of surface treatment to look smooth like the original metal.

Eberhard I agree but plasticard is always an option. Also I have found paint finishes on brass to be a bit problematic as in my experience the brsss doesn't take the paint evenly and when dry flaking tends to be a problem. It may be that I haven't prepared the surface correctly.

- FriedClams, Keith Black, shipman and 3 others

-

6

6

-

1 hour ago, Valeriy V said:

The bulwark is welded from parts and its half is installed on the forecastle.

Valeriy - As Eberhard says - I must do more brass work to develop my skills. Very inspiring. It would be good if you were able to supply more detail on your build / soldering sequence. I'm interested in how you make the later joints without unsoldering the earlier work?

Also it would be interesting to know why you chose brass for the deck planks rather than something else e.g. very thin birch ply or even card?

- Keith Black, mtaylor, Canute and 4 others

-

7

7

-

11 hours ago, bricklayer said:

Is there a glass scale or magnetic scale attached underneath the cover?

Michael - yes it's a glass DRO scale. The mill has DRO on 3 axis fitted by myself for about £200. The surgery shouldn't be a problem - it's quite routine these days and only tales about 20 minutes under local aesthetic.

-

1 hour ago, FlyingFish said:

will you be taking out a ceiling?

44 minutes ago, Keith Black said:The playroom is gonna get crowded.

Andy / Keith - I may get banished to the Garage. Plenty of room in there.

- FriedClams, Reggiemon, GrandpaPhil and 5 others

-

4

4

-

4

4

-

Well I suppose it's about time that I started to make some sawdust, even though it is only the building board. It will be 5" wide by 6' long by 3/4 inch thick. The hull beam is about 9" so the sides will overhang. The length is about 6" longer than I need. The board will be made from 2 pieces of MDF fixed end to end. This is because I don't have a 6' piece handy, however it does ease the machining on the mill which only has a nominal capacity of 18".

I started by cutting two board to give a combined length of 6'. I also drilled two/three 10mm holes in each board to take the bolts for clamping the boards to the mill table,

I then routed a 1/4" longtitudinal slot in each side of each board 1/4" deep.

Both slots were cut from the same datum edge to ensure the top and bottom slots aligned.

I then cut 2 wooden blocks to fit tightly in the mill table central slot and hammered them in place. I then drilled each block with a 1/4" hole using the same X axis setting.

Once drilled each block had a 1/4"diameter peg inserted.

These pegs fit into the lower slots in each building board, allowing the board to slide in the X direction while maintaining it at right angles to the table. This then allows the board to be cut over a much greater length that the limitation of the 18" X axis travel of the mill. (The mill table X axis handles however have to be removed for the longer of the 2 boards).

The frames are going to be cut from 1/8" ply (because I have some left from a previous project). So slots are cut across the board 1/8" wide by 1/8" deep by 5" long. The mill Y axis travel is 6" so the 5" board width is a convenient size.

Once cut the boards were cleaned up and aligned against a 6' straight edge. Side pieces were then glued in place to join the boards.

The upper central slot then had 1/4" strip wood inserted to locate the central notch in the frames.

This might all seem to be overkill but it does make the task of keeping the frames aligned and at right angles very simple. The sharp eyed among you will notice i have numbered the slots with the frame numbers. Hopefully I will put the correct frames in the correct slots.

-

Thank you all for the good wishes. My wife was done earlier this year and ever since she has hiding the mirrors and complaining about the decor. I still think she is 21. 😱

- GrandpaPhil, Keith Black, FlyingFish and 3 others

-

4

4

-

2

2

-

Very impressive. Not long now until you finish. What next?

- mbp521, FriedClams, mtaylor and 1 other

-

4

4

-

-

21 hours ago, TBlack said:

Take all the time you want,

I don't have a lot of choice art the moment Tom. I'm waiting for cataract surgery on both eyes and struggle with accuracy when cutting out stuff. I will have about 8 weeks off from dust making once the surgery takes place, in the mean time I eagerly await the appointment. Im actually looking forward to getting it done but may be less enthusiastic once I see myself in the mirror. At the moment I delude myself that I am still a bit of a catch 😁. It is good to think that at least one of the problems of aging can be reversed.

- mtaylor, Retired guy, GrandpaPhil and 3 others

-

6

6

-

-

-

-

Very smart looking model Grant. Excellent work.

-

27 minutes ago, helmarsowick said:

I was wondering if you can help me.

Helmar

You might want to get "The Gaff Rig Handbook" by John Leather. You can usually find a second hand copy at a decent price. It will give you a lot of information on rigging.

-

13 minutes ago, Jim Lad said:

About time you got back to work!

Yes sir!

- Keith Black, mtaylor and Jim Lad

-

3

3

-

50 minutes ago, Wintergreen said:

c**p weather and engine troubles.

What a pity, but there is always next year.

- mtaylor and Keith Black

-

2

2

-

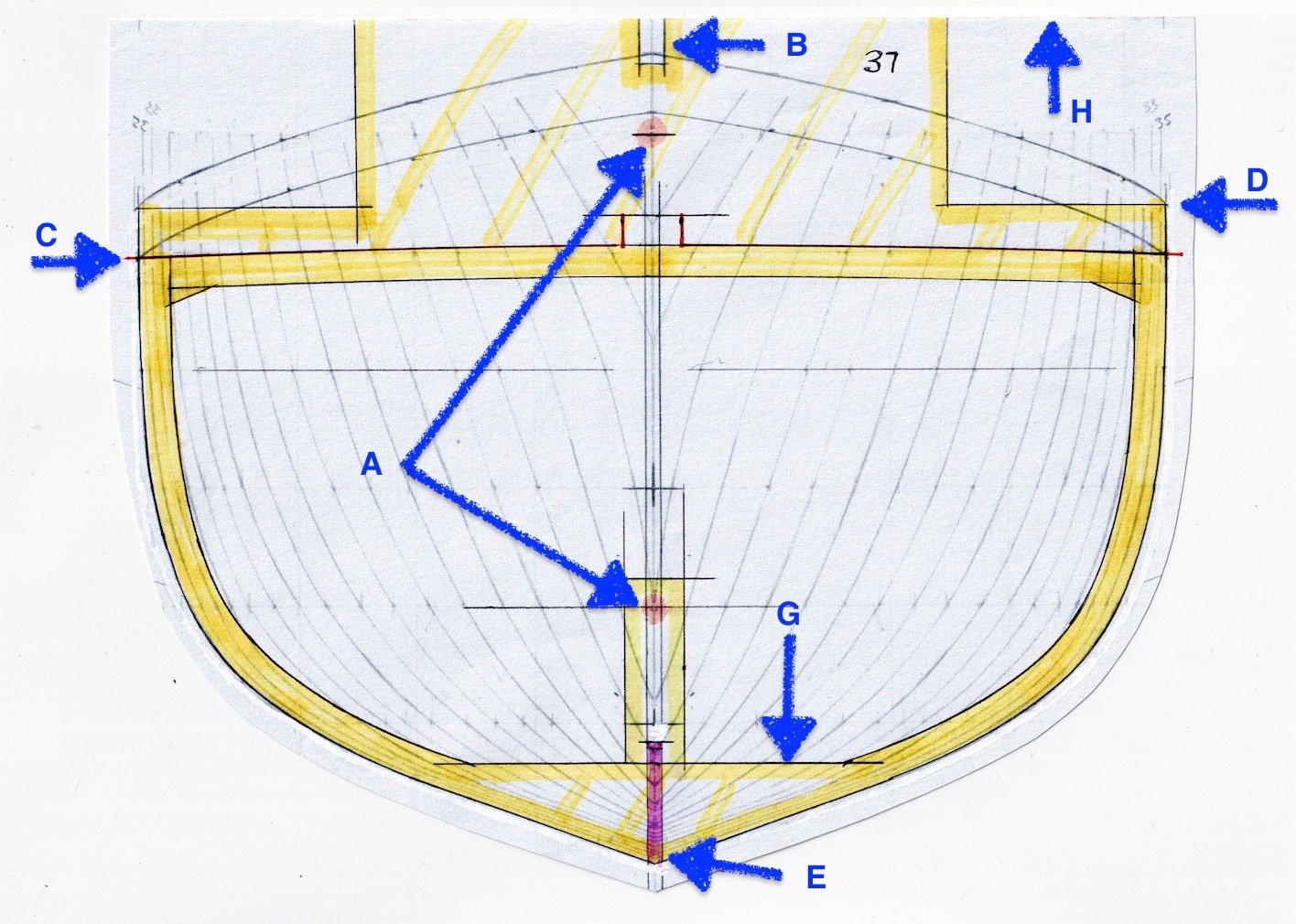

After a further shipyard layoff I return once again to building. I had now drawn all the frame templates. Some will be solid frames but most will have internal cut outs to facilitate below deck detailing. by way of example here is frame 37.

At points A and B i will drill 6mm holes to take silver steel alignment rods to me used during assembly of the skeleton.

At point B is a further alignment slot to locate the frame on the building board.

At C is the cut line for the upper edge of the deck beam. The cut will be made as far as the centre line lug, leaving only the lug to be cut through to release the building board up-stand.

D is the level of the top of the bulwark.

E is the slot for the keel.

G is the level of the interior deck (In the case of frame 37 this is the engine room floor level).

H is the datum surface for mounting on building board.

You might recall from earlier that I am only using half the frames that appear on the original. The spacing at model scale is 1.5" or 3 feet at full size. I have included all the frame cutting templates for those who might want to build Cangarda in future.

Template, 05, 07, 09,.tiffTemplate, 11, 13,.tiffTemplate, 15,.tiffTemplate, 17,.tiffTemplate, 19,.tiffTemplate, 21,.tiffTemplate, 23,.tiffTemplate, 25,.tiffTemplate, 27,.tiffTemplate, 29,.tiffTemplate, 31,.tiffTemplate, 33,.tiffTemplate, 35,.tiffTemplate, 37,.tiffTemplate, 39,.tiffTemplate, 41,.tiffTemplate, 43,.tiffTemplate, 45,.tiffTemplate, 47,.tiffTemplate, 49,.tiffTemplate, 51,.tiffTemplate, 53,.tiffTemplate, 55,.tiffTemplate, 57,.tiffTemplate, 59,.tiffTemplate, 61,.tiffTemplate, 63,.tiffTemplate, 65,.tiffTemplate, 67,.tiffTemplate, 69,.tiffTemplate, 71,.tiffTemplate, 73,.tiffTemplate, 75, 77,.tiffTemplate, 79, 81, 83,.tiffTemplate, Bow, 01,03,.tiffTemplate, Stern,.tiff

-

-

She certainly is a bit of an ugly duckling, but nevertheless quite cute. I look forward to the build.

- Ras Ambrioso, mtaylor and Canute

-

3

3

ERGENSTRASSE by Mirabell61 - FINISHED - 1:87 - steamship

in - Build logs for subjects built 1901 - Present Day

Posted

Nils - I find that the problem with scratch builds is that everyone is an experiment. I have often thought that it would-be better to build each model twice and eliminate all the inaccuacies that inevitably occur in the first version - unfortunately life is too short.