-

Posts

3,980 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KeithAug

-

-

- Keith Black, AJohnson, yvesvidal and 4 others

-

7

7

-

2 hours ago, FlyingFish said:

is it possible they were later additions

Keith, Andy, Richard.

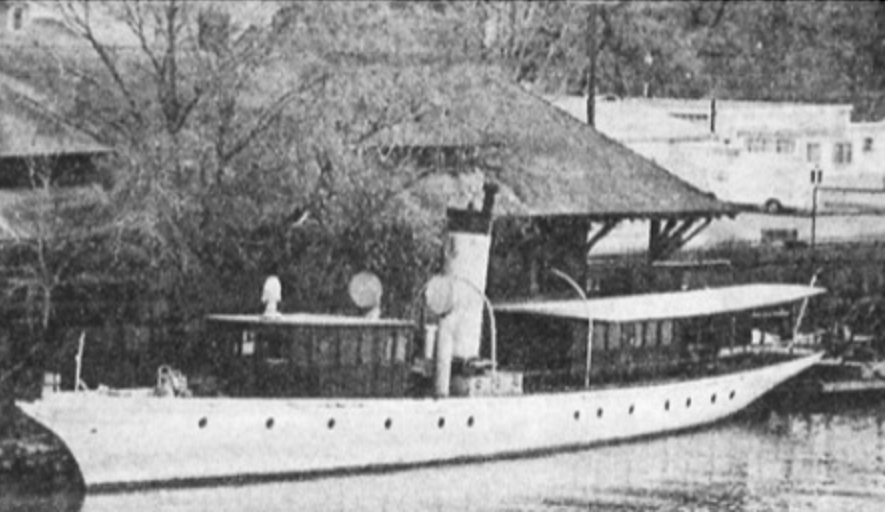

She was built with them. Here is a screenshot from a video dated 2010, only a matter of moths after launch.

Keith - I quite like the awning framework. I think its going to look real nice in polished brass.

-

6 hours ago, Richard Dunn said:

they are custom made gooseneck vents

I guess you are correct Richard, however I can think of a number of simpler / more elegant / more aesthetic ways of achieving the same objective.

-

As a measure I like feet. I have two of them.

- FlyingFish, gak1965, Canute and 2 others

-

5

5

-

7 hours ago, Jim Lad said:

look like vent pipes from tanks

I had wondered about that John but in the final photo the 2 tubes don’t seem to be connected across to form an inverted “u”.

-

36 minutes ago, FlyingFish said:

Stern Tube

A tricky little fellow.

Yes very tricky Andy. I think I would have been tempted to start with a piece of dowel and then bore it out to form a pipe. Then cut the pipe into strips before shaping / reassembling the strips to give the desired shape. However your effort looks pretty good to me.

-

These things appear at multiple positions on the deck.

In the last photo it looks like two pipes with a flat plate cap????????

- AJohnson, FriedClams, Keith Black and 2 others

-

5

5

-

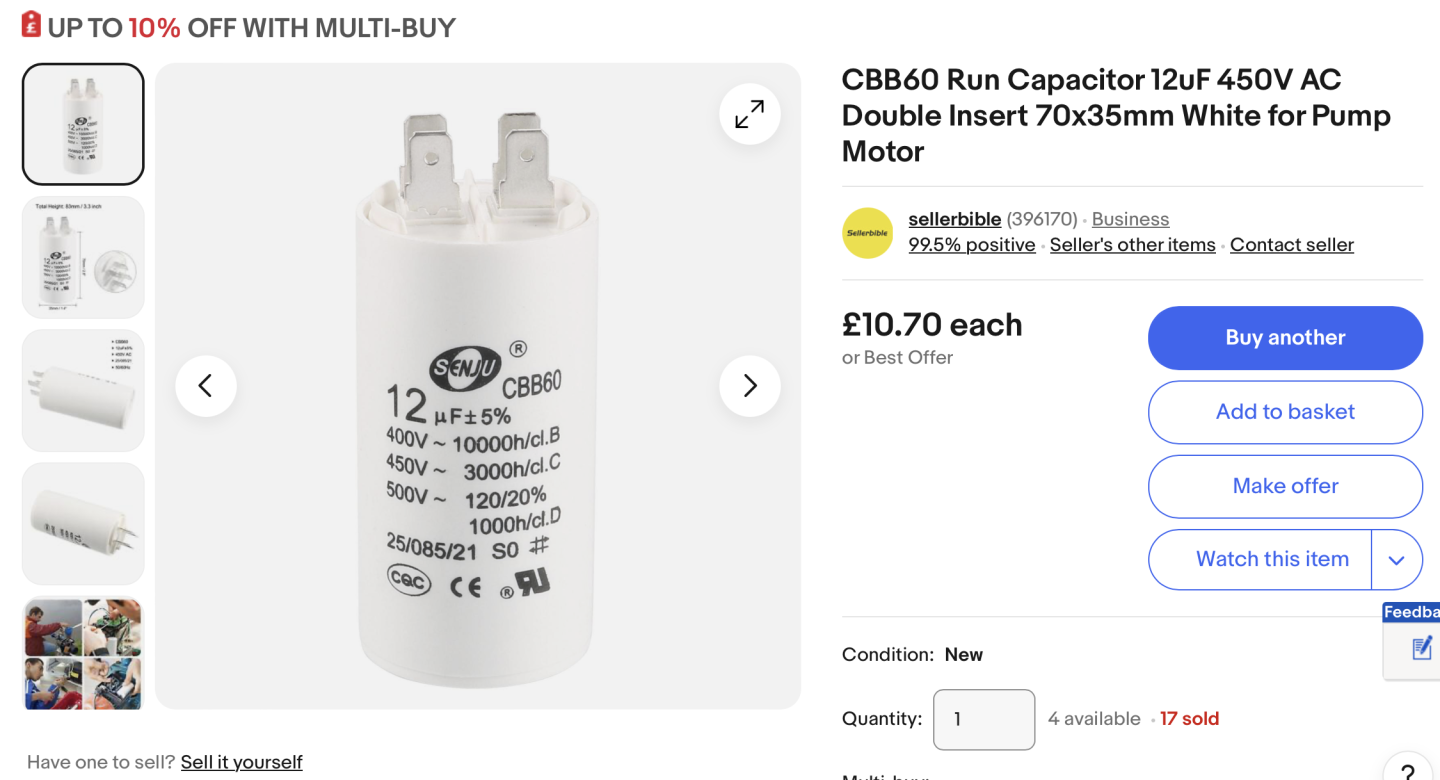

I replace the capacitor recently - The original lasted about 8 years.

I bought this on eBay and it worked fine.

The simple test for a capacitor fault is to switch the motor on and kick the blade over manually (not with fingers). If it's the capacitor that is dud this should cause the motor to run. The function of the capacitor is to facilitate starting.

-

On 7/17/2024 at 7:03 PM, Brian Glendenning said:

Brian - I thought this was a really interesting tool. In no way a replacement for a good miniature table saw but quite a useful device nevertheless.

-

-

Fascinating back story Phil. I look forward to more.

- Ras Ambrioso, vaddoc, Canute and 1 other

-

4

4

-

10 hours ago, Rick310 said:

here are some pictures of the main mast.

Rick, that is marvellous. For some reason I hadn't thought that it would be possible to get details of the masts. Information on the masts and rigging is a big black hole in my knowledge and based upon the photos I should be able to do a much better job on both masts. Many thanks.

5 hours ago, Retired guy said:Just caught up with your exceptional project

Thank you Richard.

-

I see the bow is “working out” quite nicely. Always good to find a use for a bit of weight lifting ironmongery.

- Knocklouder, Keith Black, mtaylor and 5 others

-

1

1

-

7

7

-

Beautifully done Gary.👏

- Keith Black, FriedClams and AJohnson

-

2

2

-

1

1

-

1 hour ago, gak1965 said:

And capacity in tons burthen

What about poundals and slugs, in the past measurement units had character, not like this modern SI unit stuff!

- Canute and Keith Black

-

2

2

-

-

50 minutes ago, Ras Ambrioso said:

So now I have two wheels that will rotate independently from engines that will not be capable to complete a revolution.

Ras - I always think that I should build the same boat twice to correct all the mistakes in the first one. I never do of course.

- FriedClams, Canute, Keith Black and 1 other

-

4

4

-

20 hours ago, gak1965 said:

Ah, that makes sense

All very confusing. It was much better when everything was measured in chains and furlongs.

- Canute, Keith Black and davyboy

-

3

3

-

12 hours ago, FlyingFish said:

some kind of fancy taper follower for the cross slide

I'm not that clever Andy.

10 hours ago, Jim Lad said:I'm interested to see what your cunning plan

So am I John. It tends to develop further each day on my dog walk.

10 hours ago, Rick310 said:If there are any other photos you need, especially on board, let me know and I’ll see if I can get back on board, or at least get to the top of the stairs.

Thank you Rick. It is inevitable that I find the very bit of info I need the day after Cangarda departs. The only areas where I am a bit short of info is around the bowsprit - the various deck fittings and the protrusion through the bulwark. I think these were fairly inaccessible when you were aboard due to the covers being on. Also do you know if the roofs of the deckhouses are really white or is this just a protective covering?

The details of the awning supports are very useful thank you.

- mikegr, Knocklouder, Glen McGuire and 3 others

-

6

6

-

Ras - It is funny what I miss in passing. I have only just realised Zulu has two paddle wheels. Are they on a common shaft or can they rotate independently?

- Canute and Keith Black

-

2

2

-

-

-

Very crisp work Richard - the plan looks a little daunting.

-

1 hour ago, wefalck said:

Sounds like a lot of hand-filing to come on the propeller blades

I have a cunning plan.🙂

Thank you Rick, Pat, Steve, Keith and Tom. Also thanks to everyone for the likes and visits and advice.

8 hours ago, TBlack said:Interesting piece of machinery!

Tom, I have used it before - it is also a mini pillar drill. Made from a broken camera tripod.

- Doreltomin, Keith Black and FriedClams

-

3

3

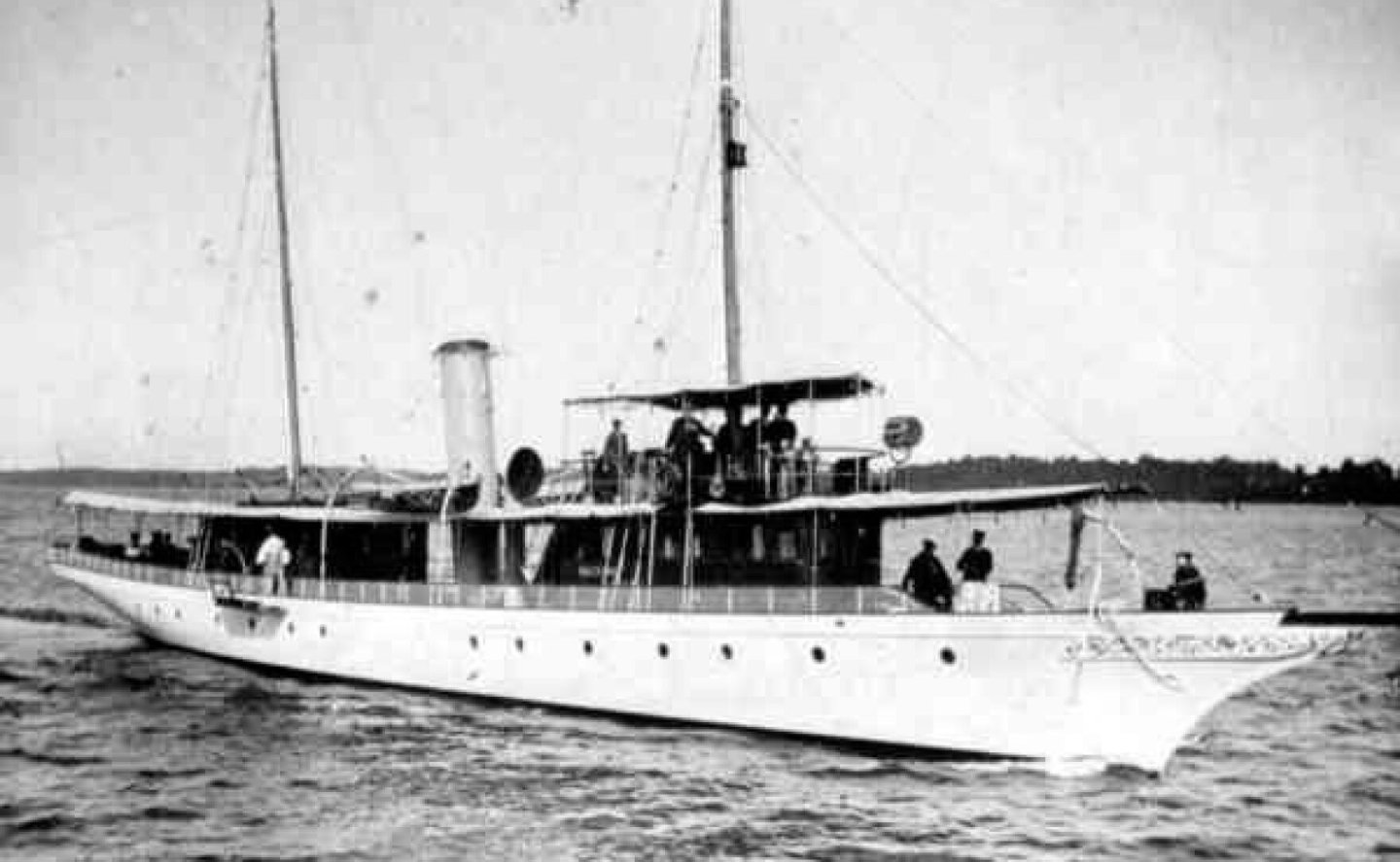

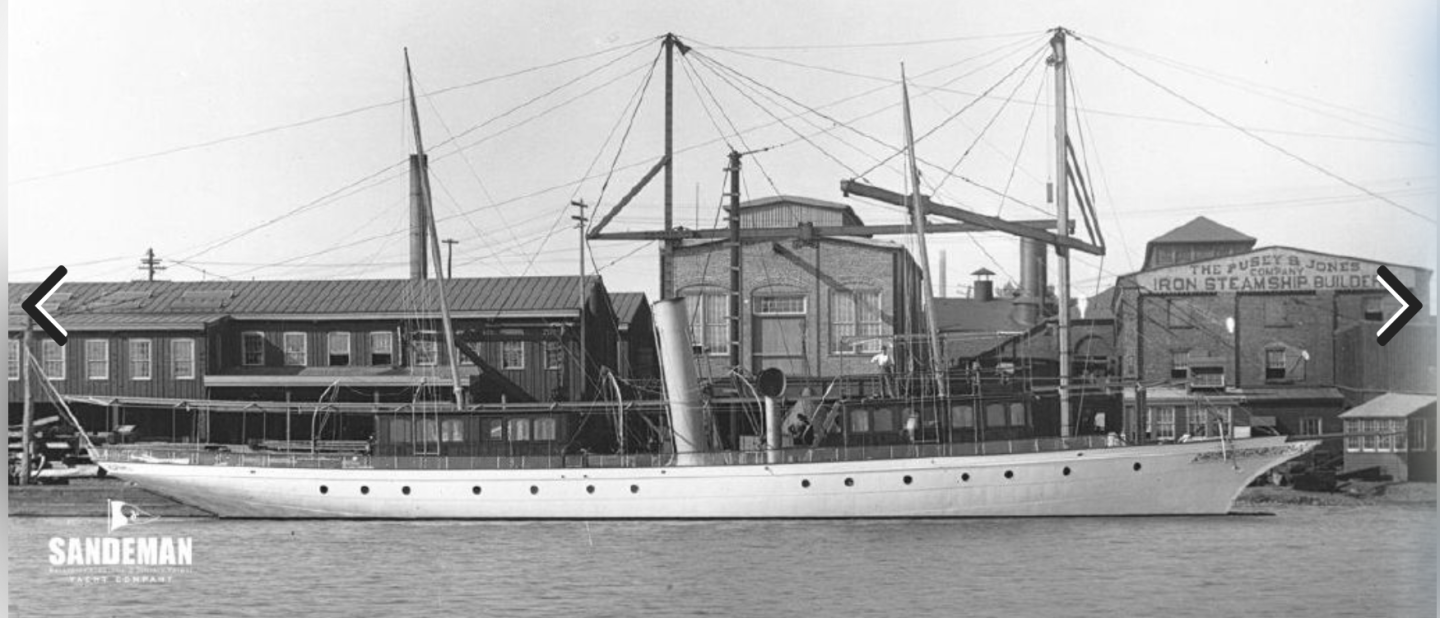

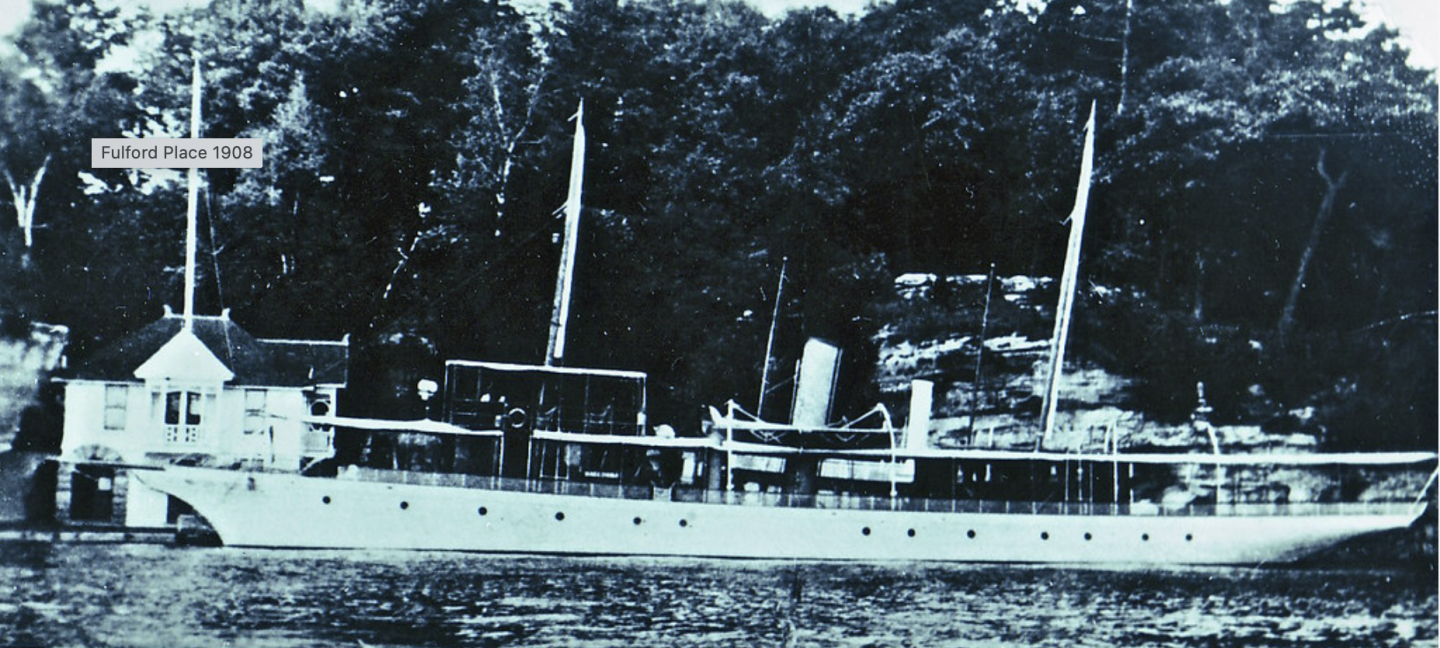

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

in - Build logs for subjects built 1901 - Present Day

Posted

Rick - thank you for the extra photos. I have a magnificent selection due to your efforts so the new owners restriction won't matter a lot. I think he / she will find that the horse has bolted if they ever find this build log!😀