-

Posts

3,547 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cathead

-

You choose the neatest prototypes! That's a really attractive vessel.

- 508 replies

-

Nice start, and I think we've all been there at some point with frustration over a missing/lost part. As for adhesives, basic wood glue works quite well for most wood-on-wood contact and will give you a longer work time.

- 23 replies

-

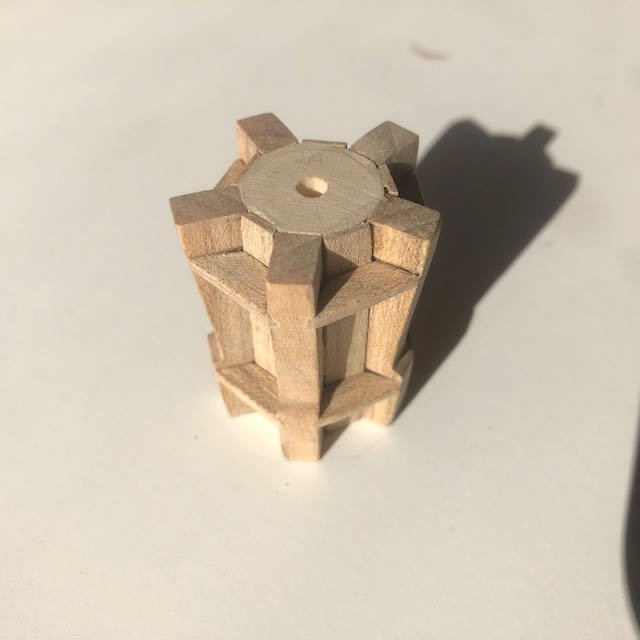

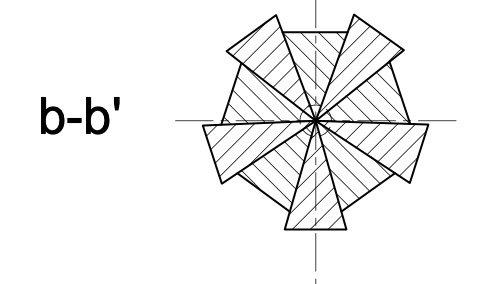

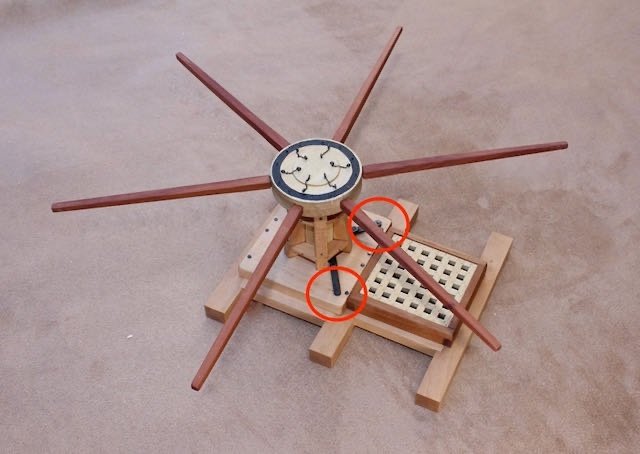

Assembly continues. With the whelps shaped, I glued them onto the barrel, using a square to get them as straight as I could: Then it was time to make the chocks, which form the two rings that fit between the whelps (what the side notches were cut to hold). Since my assembly wasn't perfectly symmetrical, I made each of these by hand to fit its specific slot. For each chock, I traced the outline of the angle between the two whelps, then cut a wider version to allow for the angled edges that fit into the notches: I then used a combination of knife and sandpaper to get the angled edges right, and test-fit the chocks. I made sure to label each chock and its corresponding location on the barrel: By now, readers who have been following this very closely are jumping up and pounding on their desks, screaming "Wait, Cathead, you've forgotten something!" Indeed, as I realized just as I was applying glue to the first chock. As you may recall, the plans show a barrel made out of wedges, creating alternating raised and lowered surfaces; the whelps fit into the recesses so there is a raised surface between them. Since I made my barrel by shaping a dowel instead, my plan was to simulate those raised surfaces with a thin veneer, which would also keep all the outer surface looking like maple. I came very, very close to forgetting this step because, of course, it wasn't in the instructions (being my own invention). So I set my chocks aside and did the veneer by cutting five thin sheets of maple and custom-fitting them between the whelps: With that done, I reshaped the chocks I'd already made (since they now needed to be smaller) and made the second ring. Once these were all glued in, I sanded them to shape, following the instructions in making the upper ring a bit convex and the lower ring a bit concave. Top view: Bottom view: You can see how the veneer simulates the raised wedges. I'm pretty pleased with this approach, it was much easier than making wedges (at least for me). The next step was to get the barrel mounted properly on the platform. Here I discovered that the 3/8" hole I'd initially drilled wasn't perfectly straight, making the capstan sit at an angle. Sigh. So I fixed this by using a 3/8" plug to fill the hole and instead drilling a new, smaller hole within that and fitting a smaller dowel as the actual axle, which was also easy to drill into the capstan base: So here's the raw capstan set on the base: And here it is with a coat of wood oil, and with the bolt holes drilled and filled with small bits of wire: You can see why I did the veneer; the dowel comes out a completely different color than the maple and I didn't want that showing through between the whelps, even if I didn't care about the raised surface (which I did): And a final photo as a reminder of 1:24 scale: On to making the drumhead...

-

I've built the Model Shipways version of this craft, so don't have direct experience with the OcCre version. I don't understand the pore-filling lacquer either. While I don't claim to be an expert, I've built a variety of wooden kits and scratchbuilds and never used anything more than basic wood oil or stain as a finish. Personally I don't like the shiny look of lacquer/varnish on a model but that's builder's choice. One thing I will say is that it's often easier/better to stain pieces before using any glue on them, as glue doesn't take up stain the same as raw wood, so any seeps or spills will show up if you stain something after assembly. On the other hand, prestaining means that if you need to sand or alter something later, you can get an uneven finish. I was surprised they have you glue the decking straight to those frames, since the frames are clearly plywood and wildly out of scale, but I guess that's their shortcut to make the model easier to build. Not having built this kit makes it hard to be more helpful, but I'll try if you have further questions!

-

Echo by tlevine - FINISHED - Cross-Section

Cathead replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Looks very nice, I'll be jumping in late. Cross-sections have always fascinated me as someone who likes to know how things work.- 52 replies

-

Steamboats and other rivercraft - general discussion

Cathead replied to Cathead's topic in Nautical/Naval History

That is so cool, thanks for sharing!- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

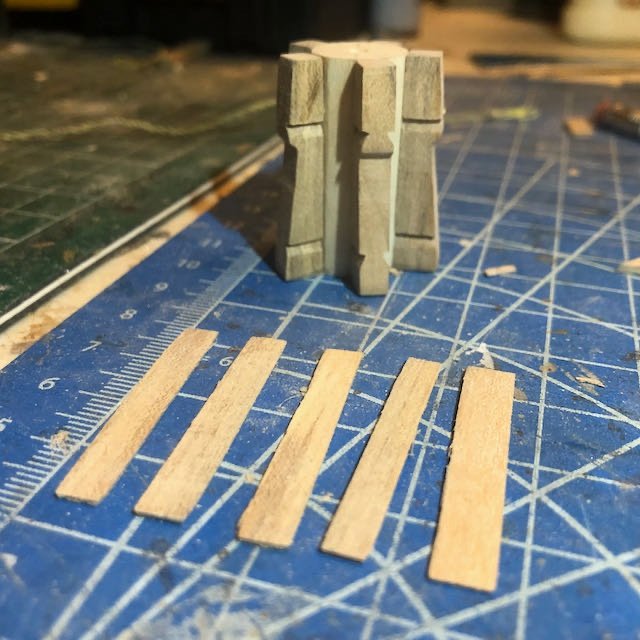

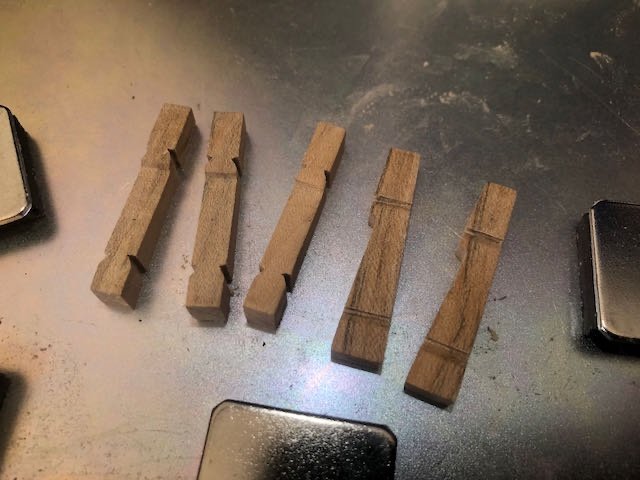

Next up, making the whelps, which turned out to be pretty straightforward even though I thought it would be more difficult because they have such a complex shape. The plans and instructions were clear and easy to follow, though I diverged from them in a few places. Here's what they're supposed to look like (from @tlevine's log): There are five of these, but I cut six blanks to account for making a mistake somewhere along the way. This was the correct decision. The instructions suggest making a paper template and cutting each out separately, but I didn't trust myself to do this consistently enough (especially with hard maple at a small scale), so I spot-glued all six together and did the basic cut on a bandsaw. This violates the "only a small table saw" rule of the Intermediate build, but I had the tool on hand so I used it. The instruction's method would work fine. I used sandpaper and files to finish the basic shaping and get the whole block consistent: Each whelp has two sets of angular grooves carved into either side, to accept some braces. I decided to think ahead and mark these across the block before I separated the whelps. So on the back (which won't be seen), I measured the grooves' locations and scribed them with a knife (one stroke went awry but this side is hidden so it doesn't matter): I soaked the block in alcohol to separate the pieces. Apparently I used too much glue in one joint, because one whelp tore away some wood from the side of another. Instead of soaking myself in alcohol, I gave thanks that I'd started with six instead of the required five. I cleaned up each piece using fine sandpaper, and in a fit of stupidity, sanded the back as well, mostly erasing my carefully scribed consistent marks. Once again I resisted soaking myself in alcohol, and clumped all six together on my magnetic board before rescribing the marks: To cut the grooves, I transferred their location to either side using a knife, then made a top cut using a razor saw: I then used a sharp hobby knife to cut the basic angle into the groove, and finished it with a triangular file. Below, the left-hand groove shows the initial saw cut, and the right-hand one has been carved out: I used my damaged sixth piece as a test case before doing the rest. And here they all are together and separate: You can see that the side grooves aren't perfect, which is entirely due to the limits of my skill set and the small scale of these pieces. Given that these are meant to accept side braces, I think it'll be ok as I can adjust both the grooves and braces as I assemble the whole thing. Also, the plans show the top grooves being ever so slightly smaller than the bottom grooves (1.75" x 0.75" vs. 2" x 1"). I'm not sure why this is, I assume something prototypical, but at 1:24 these differences measure in the hundredths of an inch range, and I just didn't think it was worth being that precise (or that I could rely on myself to be that precise consistently). So I made the grooves essentially equal and will adjust the braces to match. I realized in writing this up that I haven't drilled the bolt holes shown in the plans, but that's a minor detail. The project is back on track and I can see it taking shape. Thanks for reading and sticking with me.

-

I must agree with Michael. While the individual letters are nice, there's a pretty clear unevenness across the word that stands out to the eye, particularly when the rest of the model is so crisp and pristine. Although if his suggestion is to just cut between letters and transfer panels, I wonder if that would produce an uneven surface look that would also stand out? Here's another thought, since we're spitballing. Would it work to print out the actual lettering you want (white on a black background), then cut and transfer the entire piece of paper to the wood using something like diluted wood glue or another fixative? This would eliminate any unevenness from hand-drawing (however careful) but would give a smoother surface and perfect layout. I know you said you didn't want to print because getting the letter sizes right would be difficult, but my suggestion would be to make a number of different sizes laid out on the same page (small adjustments to the font size), print them out as blank ink on white paper to save ink, choose the size that fits best, then redo that one as white lettering on black ink within the overall outline you wanted.

-

Steamboats and other rivercraft - general discussion

Cathead replied to Cathead's topic in Nautical/Naval History

I don't know the presenter, but hope the talk is good!- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

Here's an outside-the-box suggestion on lettering: have you considered getting a lettering stencil/template 3D-printed? On my steamboat Arabia, I designed the lettering I wanted, then paid a friend's teenager to make it on his home-built 3D printer. If you don't have access to such a teenager, there are numerous websites where you can submit a design and they'll make and ship you the print.

-

Steamboats and other rivercraft - general discussion

Cathead replied to Cathead's topic in Nautical/Naval History

I'm resurrecting this thread to let interested parties know about an online steamboat talk coming up on Tuesday, February 8, at 7:00 pm US Central Time: Steamboat Disasters of the Lower Missouri River. This is hosted by Missouri River Relief, the same organization that hosted my own steamboat talk last March. It's free and open to everyone. MRR does good work in the region and I hope some of you will find the talk interesting.- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

Fantastic! Any idea how were those hatch covers held open? Some sort of prop stick from below, or some sort of chain/rope from above?

-

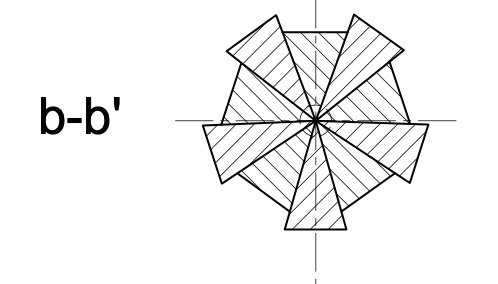

So I took a shot at carving a barrel wedge based on my best interpretation of how to go about it (essentially drawing (c) above). It was very difficult for me, especially at the smaller 1:24 scale, and using hard maple. It was a lot of work slowly chiseling down a consistent angular plane on a narrow piece only ~1.5" long, and the results were inconsistent with the need for a lot more sanding. Doing this nine more times didn't feel very inspiring. So I tried a different approach, based on the Advanced version of this project, in which the entire barrel is shaped from a single piece of wood using a power mill, rather than being assembled from 10 hand-carved blocks. I reasoned that I could probably hand-shape a ten-sided dowel at least as accurately as I could hand-carve 10 narrow wedges and fit them into a consistent circle. The Advanced plans give a barrel diameter of 13" (0.542" at 1:24). This is close to a 5/8" dowel I happened to have on hand (0.625") and I knew I'd need to remove material to get the shape right, bringing the final diameter down. First I carefully marked the center using my caliper, then used a 72º template cut from cardstock to divide the barrel into ten more or less equal wedges. Interestingly, the Advanced and Intermediate plans diverge here; the Advanced plans simply use a consistent 72º angle while the Intermediates call for different angles in the different wedges. The former seems easier to me. I used my Byrnes saw to cut a shallow notch marking the end of the barrel, to avoid tearout as I cut down the sides: I then used a sharp model chisel to flatten each "panel" (representing the outer edge of a wedge), then finished each one with sandpaper and a file, creating a ten-sided barrel (in an ironic reversal of how round masts are shaped from square stock): Now, these aren't supposed to be even like this; five should stand out while five should be recessed; the whelps fit into the recesses while the wide parts extend between them: One solution would be to sand/carve every other panel down to make this recessed pattern, which I think would still be easier than making ten wedges. But here's the crafty part, in which I kill two birds with one stone. The first bird is the need for this recessed/extended surface. The second is that this dowel is not maple and so won't look like the rest of my wood where it's exposed between the whelps. Now, each whelp is 5" wide (0.208"), but with a small bevel on the inner face to fit in between the wedges. Based on the measurements given in the plans, that means the actual whelp face making contact with the wedge is 5" - 0.38" - 0.38" = 4.24" (matching the PN027 wedge faces marked as being 4.25"). This converts to 0.177" at 1:24. I measured my 10 faces and found that they were just right: So this means I can glue accurately-sized whelps right to each alternating face of this dowel. But what about the extended wedge faces between each whelp? I simply plan to make very thin pieces of maple veneer to fit between each whelp after the latter are installed. This will create the illusion of whelps fitting into notches while making all the exposed surfaces maple. I'm feeling pretty good about this solution. Some of it is luck (that a standard 5/8" dowel happens to be so close to the needed diameter at 1:24), but even in other scales I bet a dowel could be scraped down or built up to a ten-sided shape that would work pretty well, especially as most of it is hidden and is really just an internal mounting surface for other pieces. This is the third time that I've found it easier, or at least no harder, to follow the Advanced plans rather than the Intermediate ones even though I'm only using hand tools and a Byrnes saw. The first time was when I found it easier to cut square (rather than angled) mortises for the deck beams and carlings. The second was when I found it fairly easy to make the lap joints for the capstan base rather than simply edge-gluing them (the skills needed for that were far more basic than needed for the rest of the project, so why not make it look nicer?). And the third is now when I found it easier to hand-shape a solid ten-sided capstan barrel (without needing a mill) rather than making a ten-part structure. So going forward I'm going to make a habit of always reviewing both sets of instructions and drawings, looking for the best way to achieve any given step. It wouldn't be modeling without problem-solving!

-

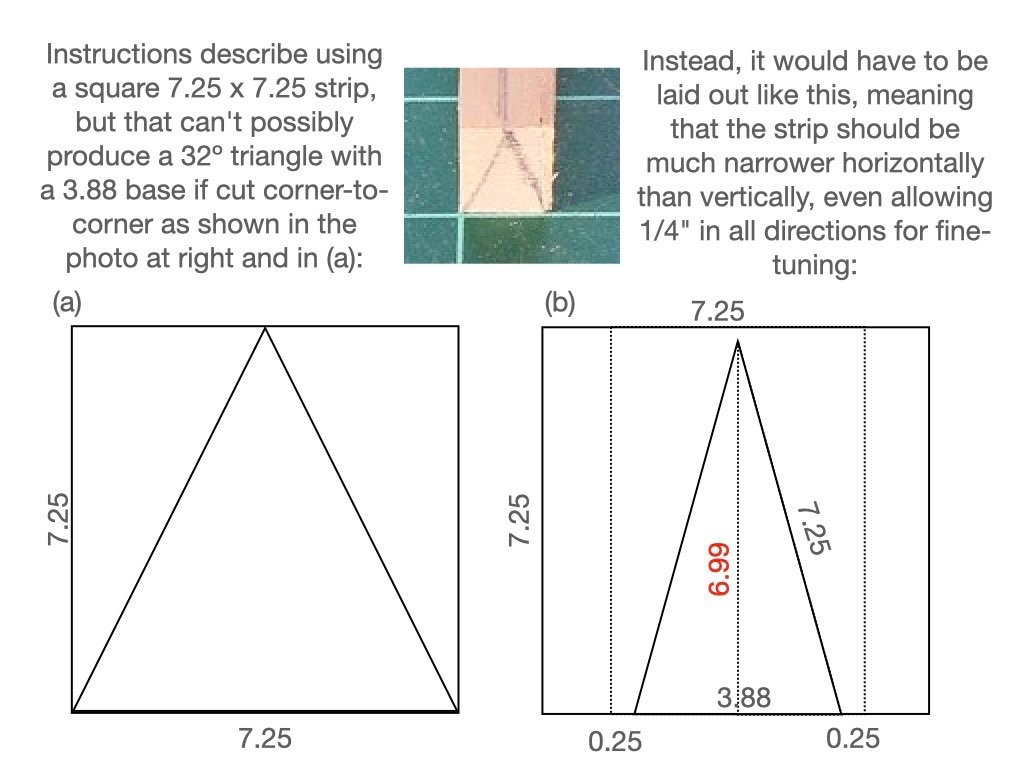

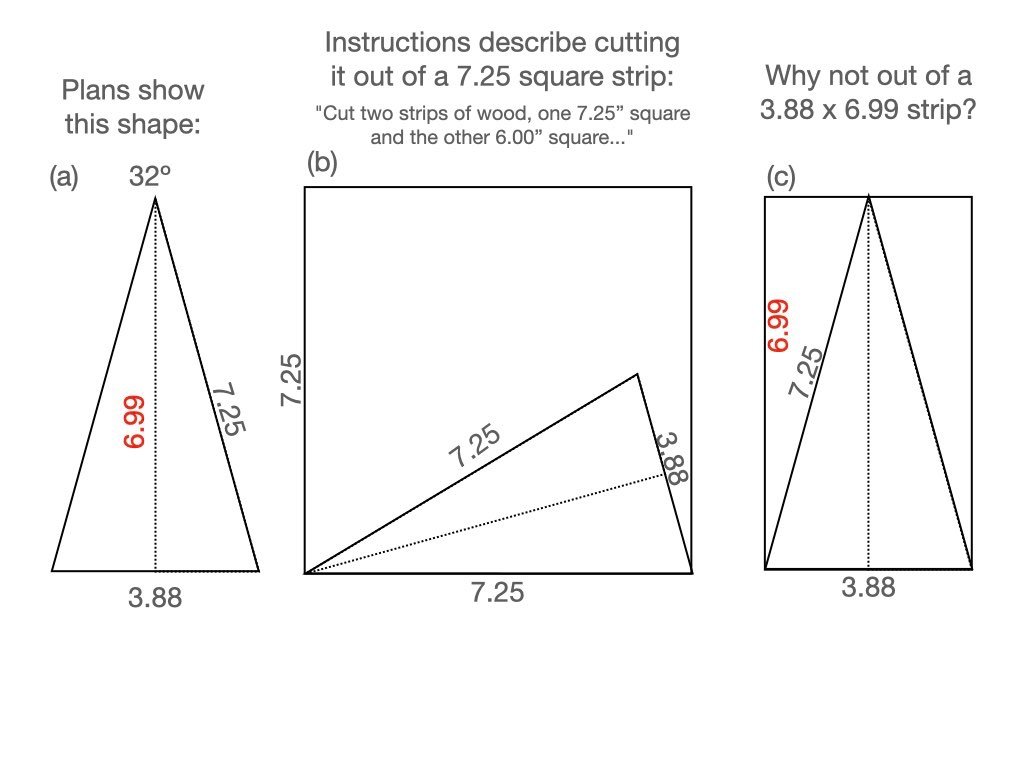

Toni, with all respect, I think you're missing the point. I don't disagree that a little wiggle room is great, but the instructions clearly say to use a square strip (i.e. 7.25 x 7.25). That's a reasonable extra .25" in the vertical direction, but an extra 2.87" in the horizontal direction (3.88+0.25+0.25 = 4.48 < 7.25), which is a lot of unnecessary extra chiseling, especially since (as the instructions rightly note) it's best to take off just a bit at a time. Nowhere do the instructions talk about wiggle room or how the square strip dimensions relate to this. And as I noted above, the plans showing the triangle lying on its 7.25" side awkwardly imply that that's one of the cut sides of the initial strip (given the coincidentally matching dimension), which is apparently incorrect but rather confusing (it would be a lot clearer to show the triangle upright, as in my drawings here). Finally, the photo supplied clearly shows the triangle being drawn from the outside corners and top edge of what looks like a square strip, which would give quite inaccurate angles and side dimensions, as I diagrammed below: This makes it very confusing for the builder to understand what's intended. You may know what you did and how it turned out, but someone who hasn't yet done the project can't easily tell which is correct: the text, the photo, or the plans, because none of them tell the same story consistently. I'm painfully aware that some of this may feel personal, and I am sorry for that. I know what it's like to receive criticism of a project I'm proud of. But as I seem to be the pioneer builder of the Intermediate project (at least on MSW), I don't see how I can avoid pointing out issues as I run across them, and doing my best to explain them so others can figure how out to approach them (or to show me where I'm wrong, where relevant). Doing so publicly allows for broader perspectives on working out the best solutions, and leaves a record for anyone who may use this build log as their guide in future. As this project is meant to be a guide to people relatively new to scratchbuilding, I feel it's especially important to be very aware of potential pitfalls in instructions and plans. As a professional editor and educator, it's my job to think about how people interact with text and learning material and to see it through the eyes of those not already familiar with it so that I can better shape that material to be relatable and clear. That's what I'm doing here.

-

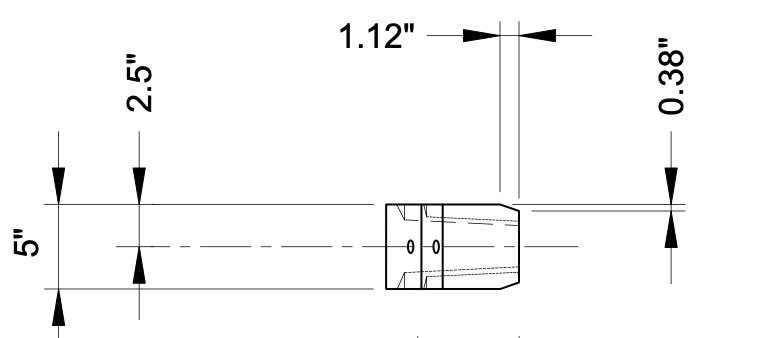

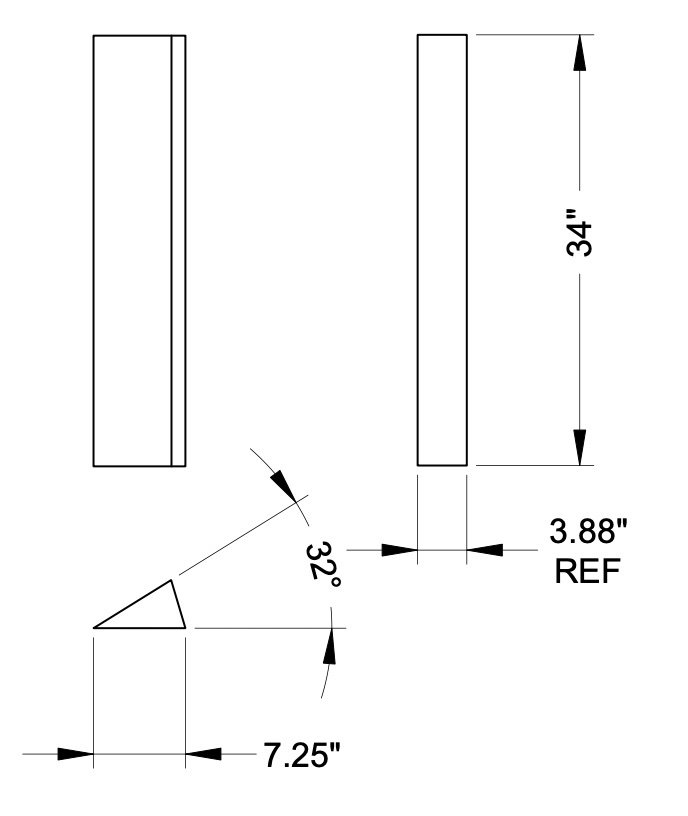

I proceeded to making the capstan barrel, and immediately encountered what I believe to be more problems with the plans/instructions, though as always I'm happy to be corrected if I've misunderstood something. I puzzled over this for a long time and took quite a while to carefully make an explanatory drawing while double-checking my calculations and thought processes. The capstan barrel is made from two sets of five wedges having subtly different measurements. Here I'm focusing on the longer/narrower set (PN026) but everything I'm about to say also applies to the shorter/fatter set (PN027): Here is the plan image for what the PN026 wedges. We have what appears to be an isosceles triangle with a base of 3.88, a peak angle of 32º, and two sides of 7.25: Now the confusion starts. The instructions say to "Cut two strips of wood, one 7.25” square [for PN026] and the other 6.00” square [for PN027] and long enough to make at least five wedges. Cut the strip into pieces a little longer than needed for the barrel and draw the shape of the wedge on both ends of the strips." Here is the relevant image provided: And this is where I started getting confused/suspicious. First, if those strips are 7.25 square, then those wedges are far too wide (note how the drawn triangle extends all the way across the base of the piece), as the base of the triangle is only supposed to be 3.88. If the base there is indeed 3.88, the instructions are wrong in saying these blanks should be cut to 7.25 square, which is way too wide. The strips also shouldn't be 7.25 tall, as that's the dimension of the angled face of the triangle, not the outer face of the strip (which would be a bit shorter, again basic geometry). The way these pieces are marked, with a line down the top-center of the piece essentially dividing it into two equal right triangles extending down to the base, makes logical sense as the easiest way to lay out and cut these. All you have to do is shave away the upper-right and upper-left bits. But it doesn't match the plans or text. Moreover, the plans give a misleading and/or inconsistent view of how to lay these pieces out. Here's a to-scale diagram I spent considerable time assembling to try and clarify this: Basic math tells us that the height of this isosceles triangle (a) should be 6.99, given the dimensions already provided. But when this triangle is laid out on its side (b), as shown in the plans, it creates a very strange relationship with a square 7.25x7.25 square block of wood that would be difficult to cut accurately and doesn't match the photo in the instructions. This photo seems to match (c) instead, but that's not what's written in the instructions or shown in the plans. It would make far more sense, at least to me, to cut a rectangular 3.88 x 6.99 strip and simply shave off each side equally, as seems to be shown in the photo above and in (c). But again, that conflicts with the written instructions, and may or may not be consistent with the plans, which at the very least are confusingly drawn with the triangle laid on its side rather than vertically as in (c). Again, the same is true for the other set of wedges, just with different numbers. I don't know what's intended here, but the resulting confusion has cost me hours of puzzling, drafting, and writing. I've also started to check and recalculate every number in the plans given the multiple errors I've encountered, costing me more time. Getting a bit frustrated, to be honest. My assumption is that I should proceed based on (c) and just ignore the strange instruction to cut a 7.25 x 7.25 block, but at this point I don't know what was intended and whether that would cause other problems later. For example, I can't know which of these numbers are right (given past errors already documented). I'm burned out on this for now, so I'm just going to set this aside and wait for @tlevine to clarify again. I need to clear my head in any case and move on to something more joy-sparking.

-

Steamboats wooded up multiple times daily. They were pretty clearly an agent of regional deforestation. I discussed this ecological context a bit in a video talk I gave on Missouri River steamboat history last year. Fantastic job on the wheels!

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

That kind of "shingling" is natural when planks get bet into complex curves. A lot of basic kits don't account for this in their instructions or materials. The only way to avoid it is to either spile the planks (cut them into curved shapes to allow for the the 3D bend) or edge-bend them (force them into the 3D curve). Or, as you found, hope there's enough thickness to sand it out!

- 132 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

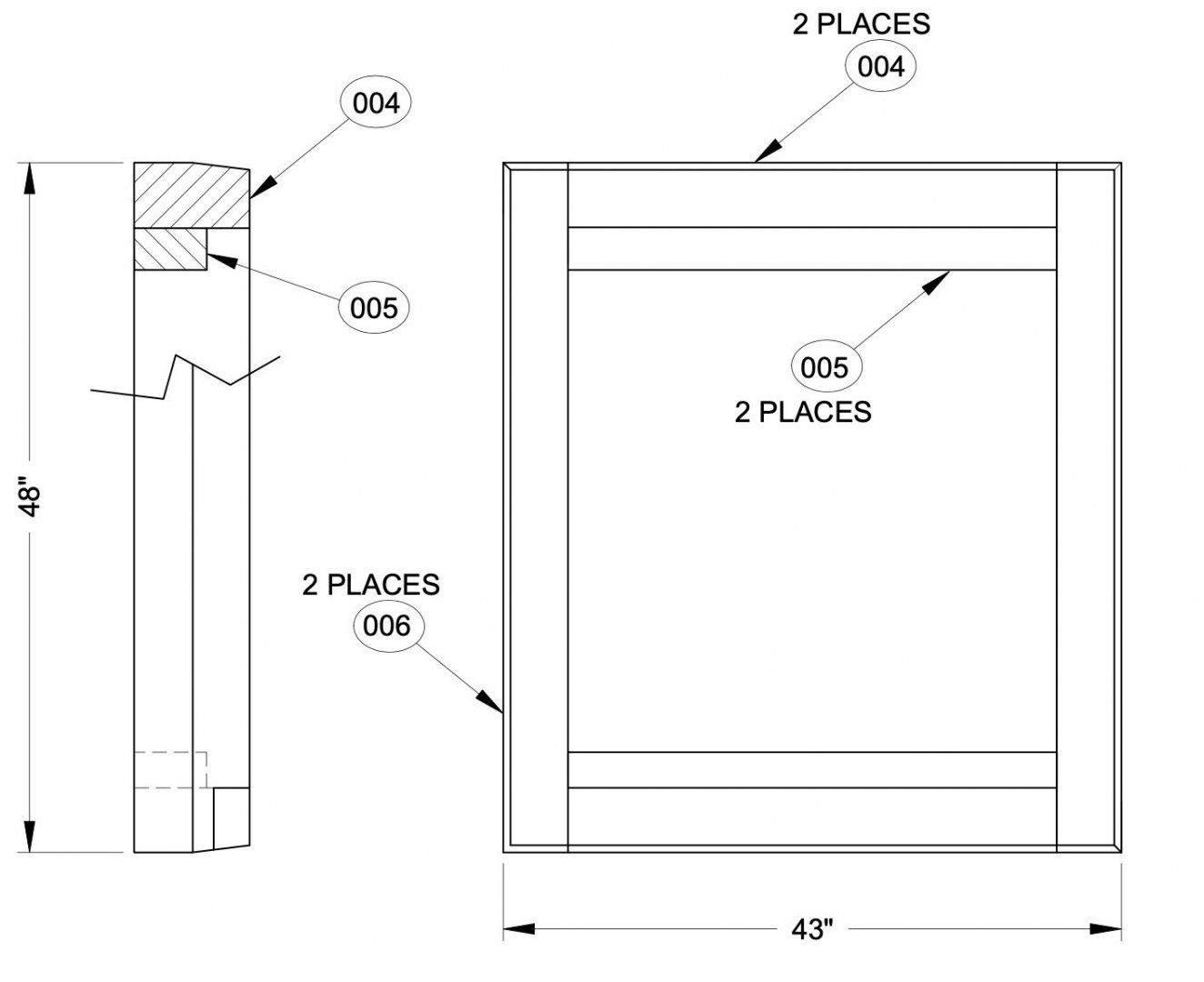

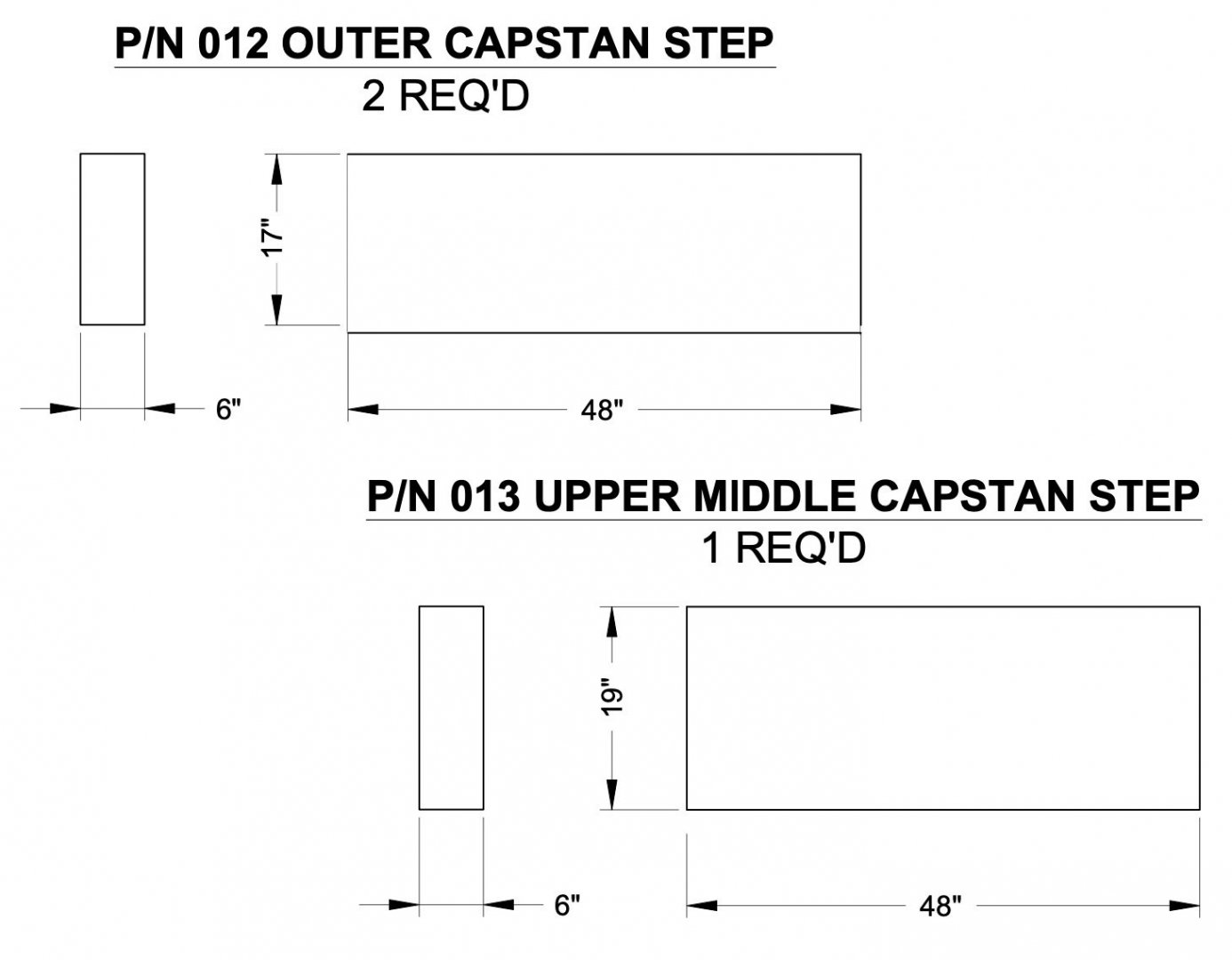

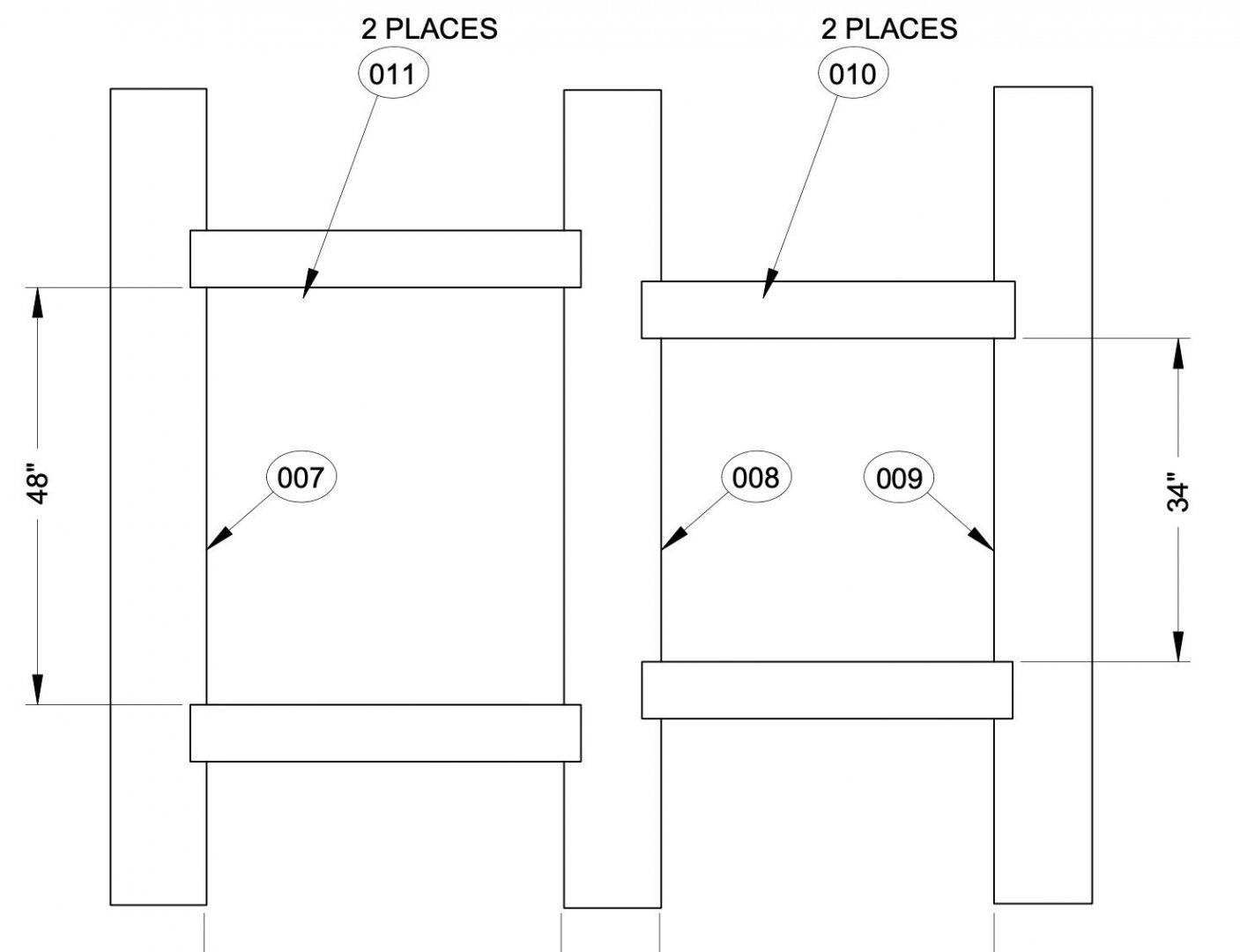

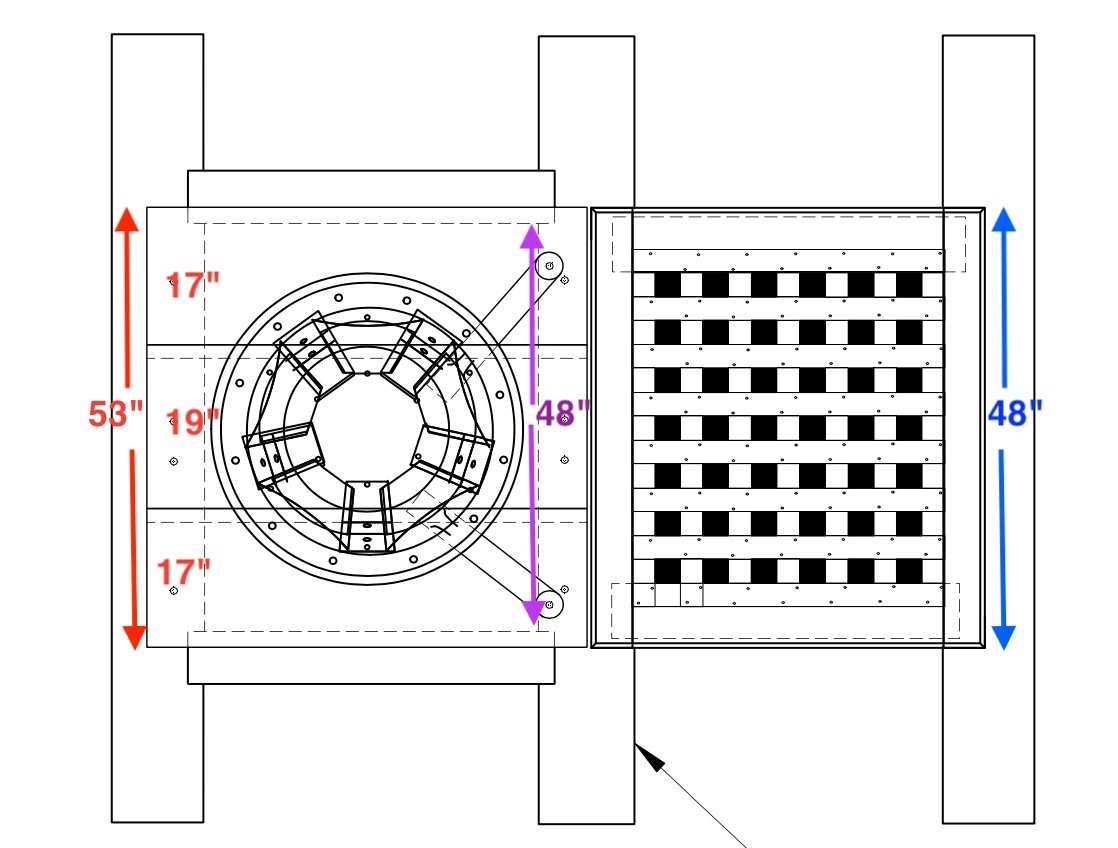

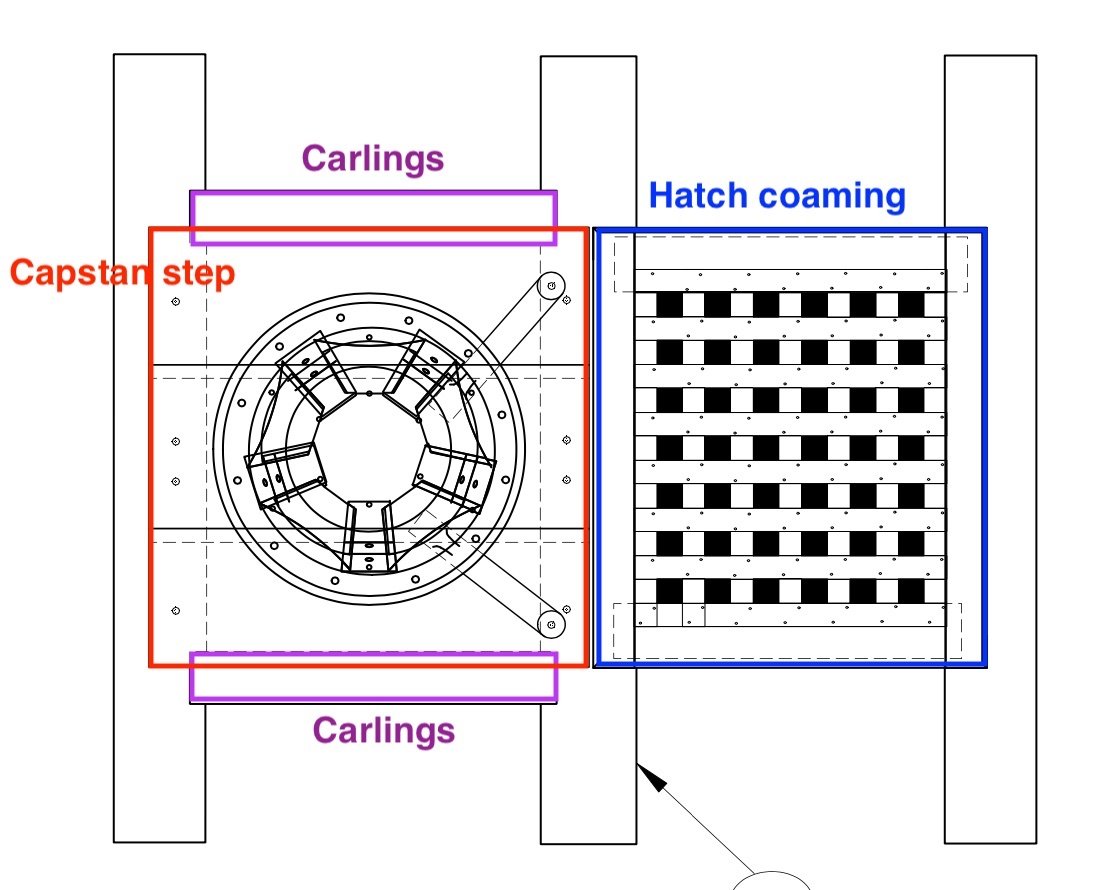

Reviewing the plans carefully made me even more confused. The plans clearly show that the deck (called the capstan step in the plans) and hatch coamings are supposed to be the same width, and that the capstan step should overlap its carlings just a bit while the hatch coaming entirely overlaps its carlings. Here I've marked up the image from above for clarity: But now let's compare measurements. The hatch coaming is supposed to be 48" x 43" along its outer edge, with the wider side being that matched up with the capstan step: The three pieces that make up the capstan step are supposed to measure 17", 19", and 17". In the intermediate version, these are edge-glued with no joinery, so the total width is 53": And the interior space between the two carlings under the capstan step is supposed to be 48": So please correct me if I'm being very dense, but none of these three measurements seems to work together, as summarized below. The outer hatch coaming (blue) and the interior space between the capstan set carlings (purple) are both individually marked as 48", but that's not what the overview plan shows; the hatch is noticeably wider. Similarly, the capstan step (red) is supposed to be 17+19+17=53", but is drawn as being the same width as the hatch coaming (blue), which is supposed to be 48". Very confusing, and possibly a factor in my messing up the drill hole at the center. Perhaps @tlevine can clarify this for future builders? I tried the easiest fix to my own specific predicament (the misaligned hole) and simply cut off one side of the capstan step to recenter the hole. Depending on how one reads the plans, this is now more accurate than it was before, making the capstan step the same width as the hatch coaming, with a slight overlap of the carlings! In other words, this matches the plans visually, just not the conflicting dimensions given. Personally, I see no reason not to keep this fix rather than the more complicated suggestions of re-making the entire step or moving the carlings (though the different ideas were welcome and helped me think through my solution). Working through all this gave me a headache, but I think I can move forward now. If I've misunderstood something, please explain! I'm also curious what it's "supposed" to look like (in terms of whether the step and hatch should be the same width or not), and whether that's based on a prototype or just designer preference.

-

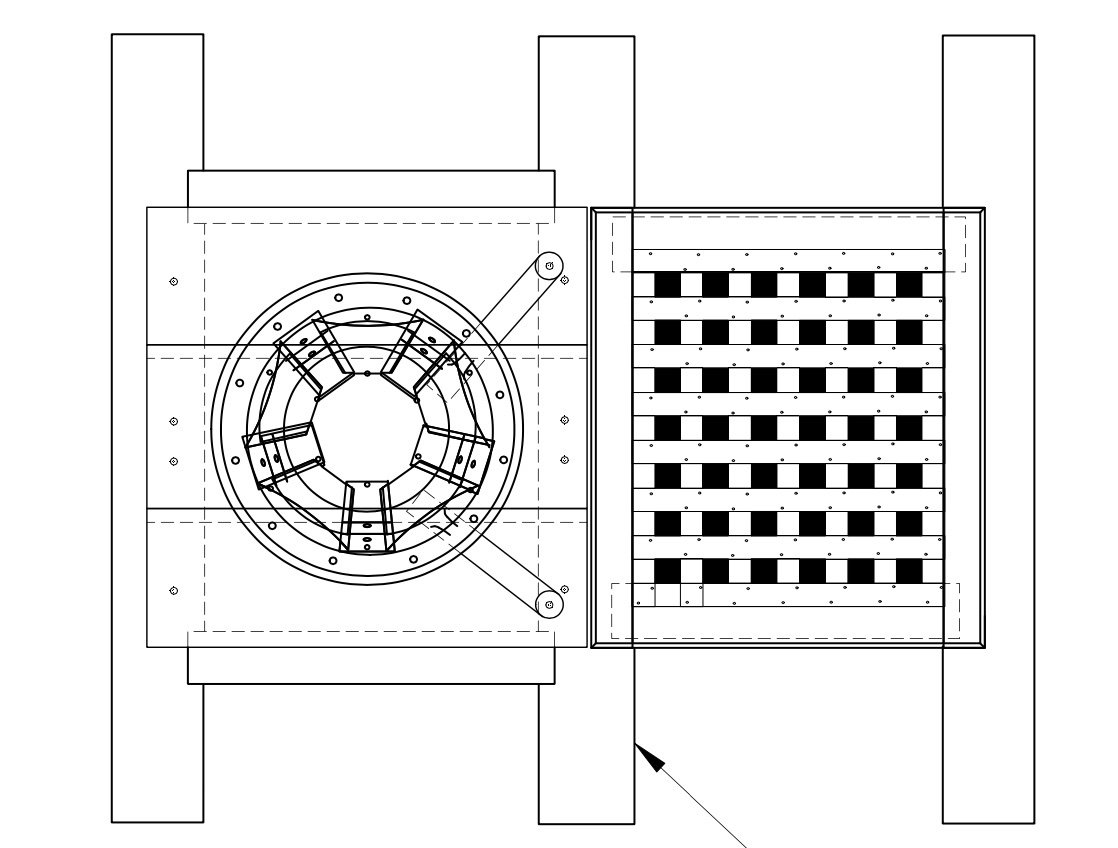

Brian, funny you should ask. I was looking at the plans again, and found an issue that I've run across before, which is that the model image shown varies significantly from the actual plans. For example, the model grating has a grid of 6x6 holes while the plan is 6x7, and the model shows the capstan base being noticeably wider than the hatch coaming while the plan shows them being the same width. Compare: Basically, it looks like the plans added an extra seventh row to the grating, making it as wide as the original capstan base. The hatch coamings are supposed to entirely cover their coamings, which my hatch does, so that's the baseline I should be working from: The base is very much NOT supposed to cover the carlings, I assume because planking is laid over them in real life. So if anything, narrowing my base to match the width of the hatch coaming makes it match the plans more accurately. Not sure how I ended up with a base wider than the coaming in the first place, as I thought I was following the measurements carefully, but I didn't notice before because I was also consulting the model image which shows that a wider base, so I didn't think anything of it. The difference here would be that I'm narrowing the base rather than widening the hatch, but the visual effect seems like it'd be very similar?

-

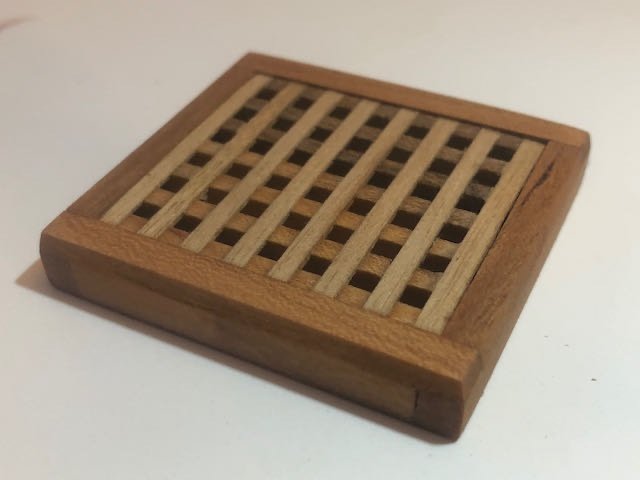

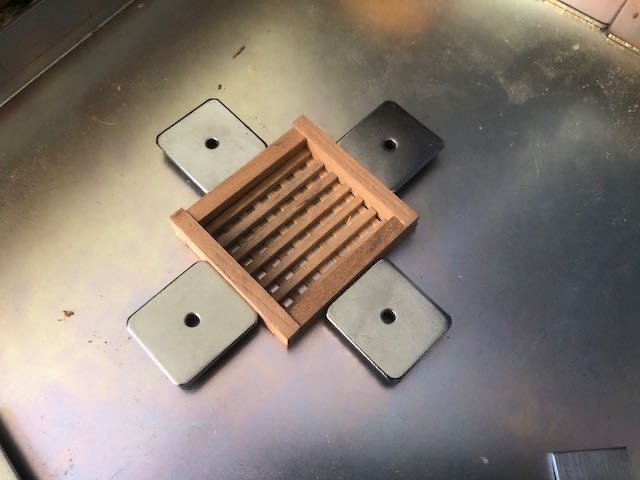

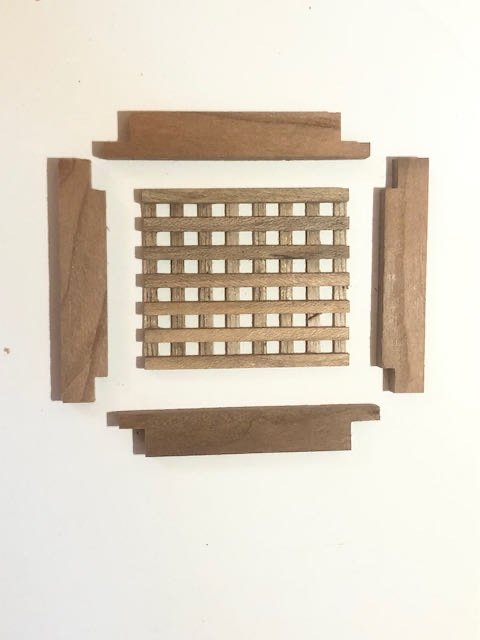

Grant, good insight. A few clarifications: first, the portion to be cut off is on the side, not the fore edge that sits against the hatch coaming. So it wouldn't change the way they meet, other than being narrower (and as far as I can tell, that's purely visual). Second, I've already finished the hatch coaming, and can confirm that they'd sit together just fine. I'll just go ahead and share the process of making the hatch and grating, then you can all judge the result and how to fix the mistake in the capstan base. The grating was very difficult for me. It took three attempts, and a fair amount of wasted wood, before I got something I was happy with. I didn't end up documenting the full process because by that point I was burned out. Basically, I followed the directions in cutting a bunch of ledges, gluing them together in a sandwich, then oh-so-carefully cutting all the batten notches out. The difficulty simply came in being accurate enough in my repetitive cutting, which I achieved by using the calipers to keep resetting the saw's fence. This took multiple passes since the saw blade's kerf (0.55) was thinner than the notch (0.104). I cut one pass in each notch, resetting the fence by 0.208 each time, then flipped the whole thing around and did it again from an adjusted starting point that widened the notches appropriately. These are at 1/24, not the suggested 1/16, so were smaller and more delicate than those done in other builds so far. Finished ledges: Ledge sandwich, grating battens (lower right), and other battens for assembly jig (upper right): I made an assembly jig by gluing extra battens to a piece of scrap wood, using the ledges as spacers. This held them firmly in place while I adjusted the battens to get the whole thing square: Finished grating before trimming the edges: After this, cutting the hatch coaming pieces, with their simple overlap joint, felt like a piece of cake and went smoothly: I glued this up using my magnetic jig, keeping the grating loose: And here's the finished product with wood oil applied (not the greatest photo, will try to do better later): Here are two shots of the assembly so far, showing the offset I'd need to do to counteract my misdrilled hole. Essentially I'd need to cut the capstan base to be almost flush with the hatch coaming: The base has not been glued to the beams, I was smart enough to hold off on that (the coaming hasn't either, and the grating is also free). So remaking is an option, as is trimming it. Even as I wrote this, I realized that one potential problem is that the capstan brakes (the little metal pieces that catch the capstan as it turns) are set right out into the corners, and trimming off one side of the base would eliminate where one of them is supposed to go. So I have to decide if it's okay to relocate them a bit, or put all the work into remaking the base. Here's what I'm talking about (hope @tlevine will forgive me for marking up her beautiful photo): Again, these would have to move a bit inward to accommodate the thinner capstan base, but I'm not sure it would be noticeable to anyone other than a very knowledgeable expert. I'll give it some thought.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.