-

Posts

3,534 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by amateur

-

Strange, isn’tit? The guy who did the kit on Batavia at first had to give the ship another name, as the Batavia guys where more troubled with copy and namerights than with real content Why are they affraid of sharing? Is it while they don ‘t have the means or time to take the lines, or is it something else? Jan

-

Have you set yourself a zero-tollerance margin? I would be quite happy when my railings get out this way. Those close-ups pretty much capture the looks and feel of the pics of the original ship Jan

-

So, no margin for error.Makes it all the more challenging! Jan

- 19 replies

-

- south dakota

- battleship

-

(and 1 more)

Tagged with:

-

Sorry, missed it are you going to keep the card as is, or will you get thw grey paint ready at the end? jan

- 19 replies

-

- south dakota

- battleship

-

(and 1 more)

Tagged with:

-

Kingfisher by amateur - FINISHED - 1:1 - CARD

amateur replied to amateur's topic in Non-ship/categorised builds

Ten completely self-explanatory pics of todays work. now it needs something to sit (legs and a branch). Nextweek, perhaps..... Jan -

Kingfisher by amateur - FINISHED - 1:1 - CARD

amateur replied to amateur's topic in Non-ship/categorised builds

No, just white paper glue, appied with a small toothpick. And, by instruction, not applied to the tab, but to the opposite part. Works far better. Jan -

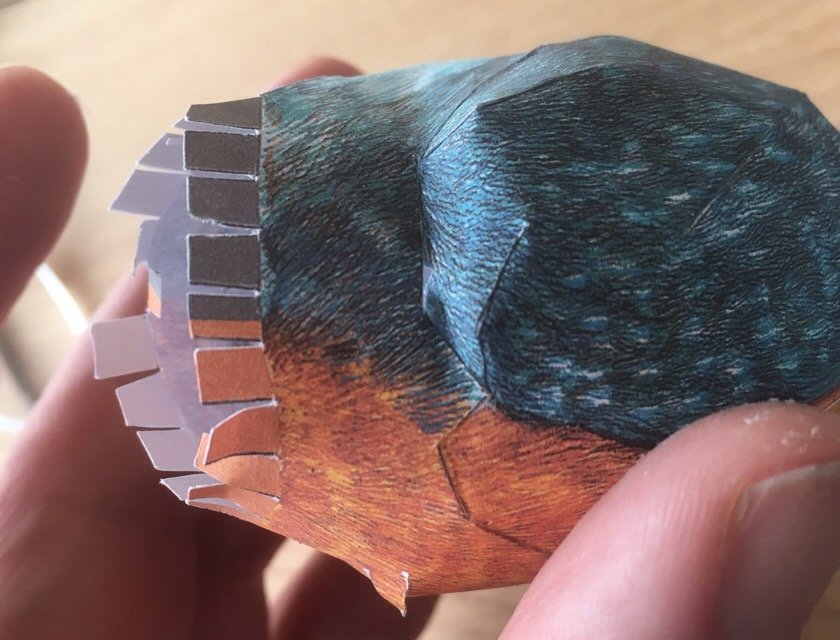

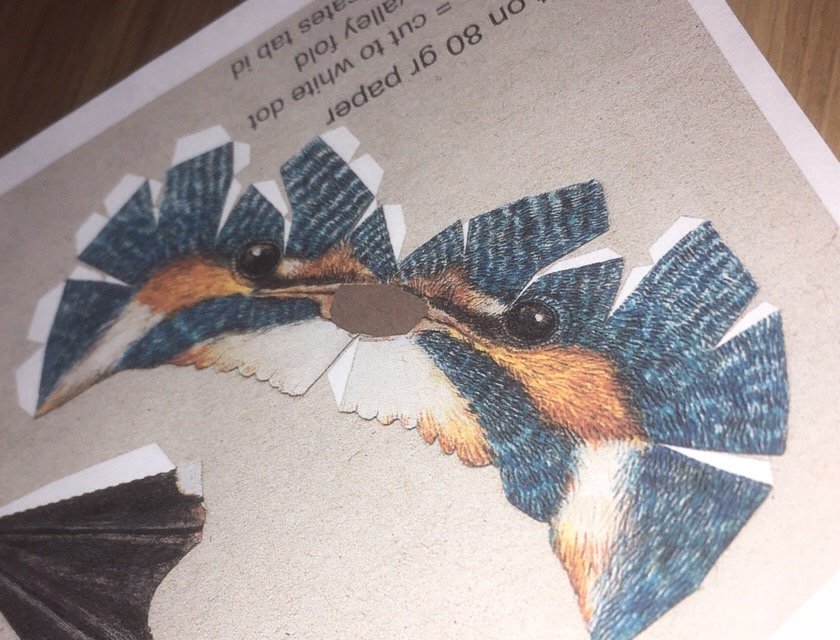

I promised a restart on the kingfisher-model. Today, I finally managed to do some work on it. It is a model designed by Johan Scherft, and the template is downloadable from his site. There is a nice you-tube video, showing how it should be done (life is not so easy as the vid suggests, but still, it is not a very complicated model with lots of tiny fiddly bits.) Time for some pics. First the template. This is all there is. (Actually, there is also a paper branche template. Did not download that for the moment) The head: template after cutting (swan morton is very usefull, although it can be done with small scissors) and all the longitudinal tabs and those above the eyes are glued. next - while the head was drying - the tail, from two parts And now for the major part: the body paper is funny stuff: I printed the bird last week, and it was very dry and rather cold here last week. After cutting, the paper startedto curl upwards.... no bug deal, as it is just normal 80 grams officepaper, the paper bends easily back when glueing. And then the process of glueing starts: tab by tab, starting with the small ones, and working towards the larger ones. Here a pic of how the bird is right now. Not too stressfull so far, just two and a half hours of fun. I hope to continue tomorrow. Jan

-

The Zeeschouw was a originally a fishing ship, Billings however took a modern yacht-versionfor its kit. Pretty acurate for what it is, but notwith the charm of a working ship. The statenjacht is modelled after a contemporarymodel in the Rijksmuseum. Problem is that the underwater part of the ship is too round, and too shalow. I guess that the kit-designer didn'tlike the 'bricklike' appearance of the model. The abovewaterline is pretty much following the contemporary model. I did the Staenjacht as my first real model, thirty-oddyears ago. I don't know whether or not Billings redesigned the kit. Jan

-

Design and accuray dpes vary between kits. Which one do you have in mind?

-

Hi Piet, Be assured, I'm not upset. Actually, I very much appreciate the fact that you are willing to share these memories with us. Would you believe me: in the Netherlands this day went by without any reference to the battle of the java-sea.... Jan

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

That X-acto knife is getting bigger and bigger Your pipes look good, as does the camo-paintwork. Jan

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Did a quick search in google books there are texts sround 1650 writimg provintien, provinsien and provincien. Can’t find any other ways of writimg the name Jan

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Hi Backer, Ik know, but still., it is not a spelling you come across often (also not in compsrable words) especially while provincie en vanantie do have their t and s sound imterchanged, y was used as alternarive for j, so I do undrstand provinciyen (again not common) but a c followed by t and y I never saw elsewhrer jan

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Given the paintings (and the large grisaille of the four-day battle) I would go for the 3D-version. What I am not sure about is the lettering on the banderole. Dik reads: De 7 Provincien the Batavia-model reads - as the Tomesen-model : De 7 Provinctye (or Provinctie, I am not sure). Depends on your interpretation, but the Tomesen-version does look a bit weird to me (never saw this way of writing the Dutch word "province" before) Jan

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Why is there an axe in all your pics It looks great. I thought 1:250 is small, but these parts are seriously tiny....Nice fix on the light. And I expect that you’ll find the missing one in a safe place where uou pit it, to make sure that uou won’t loose it Jan

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Simple Framing Question

amateur replied to t5956ws's topic in Building, Framing, Planking and plating a ships hull and deck

Is this monograph containing what you need? https://www.thenrg.org/the-galley-washington.php Jan -

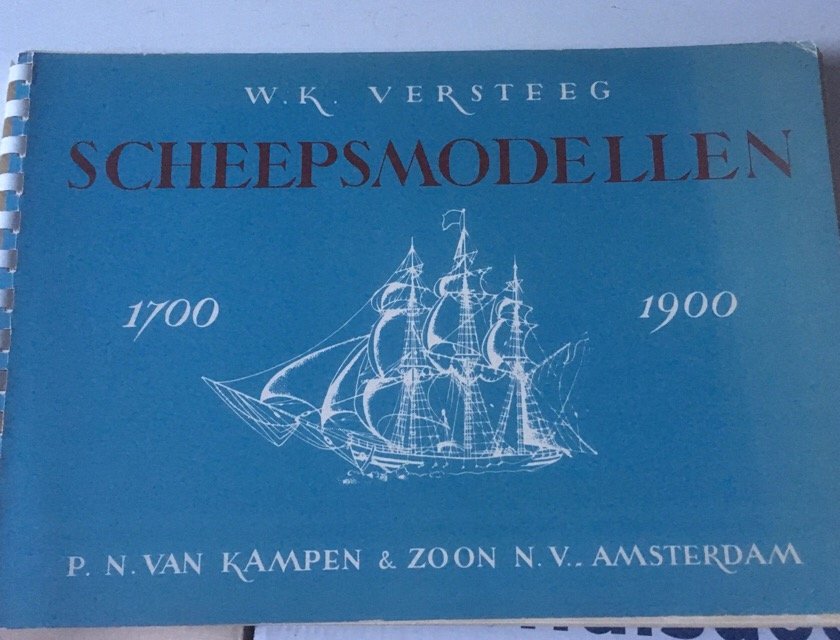

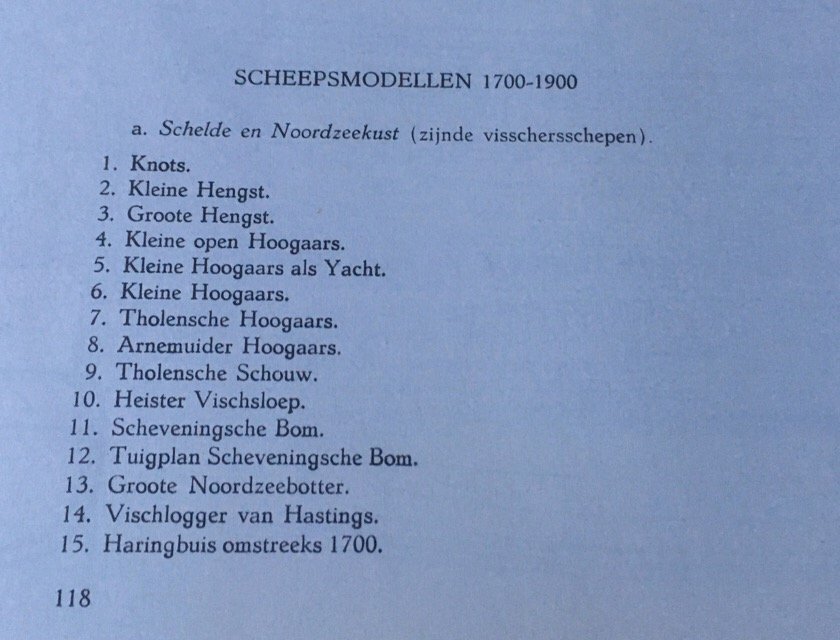

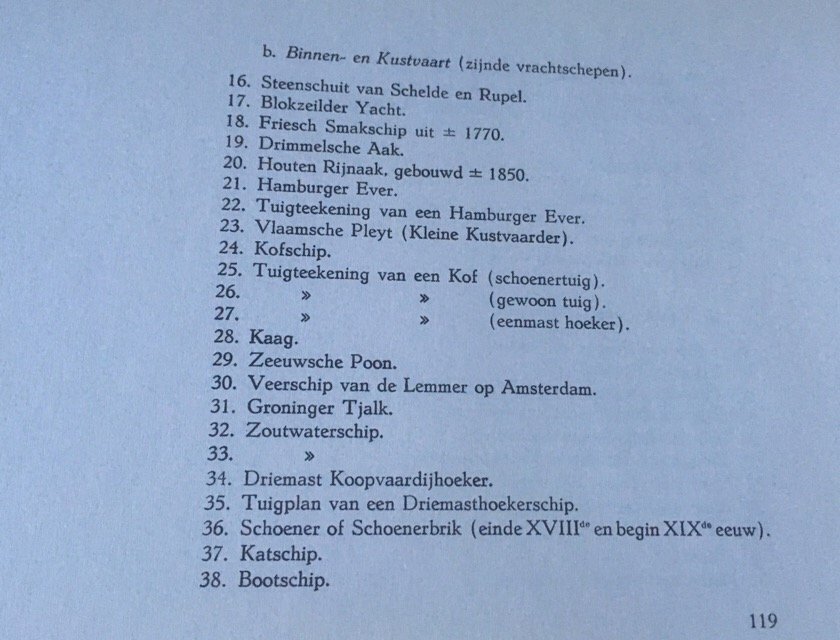

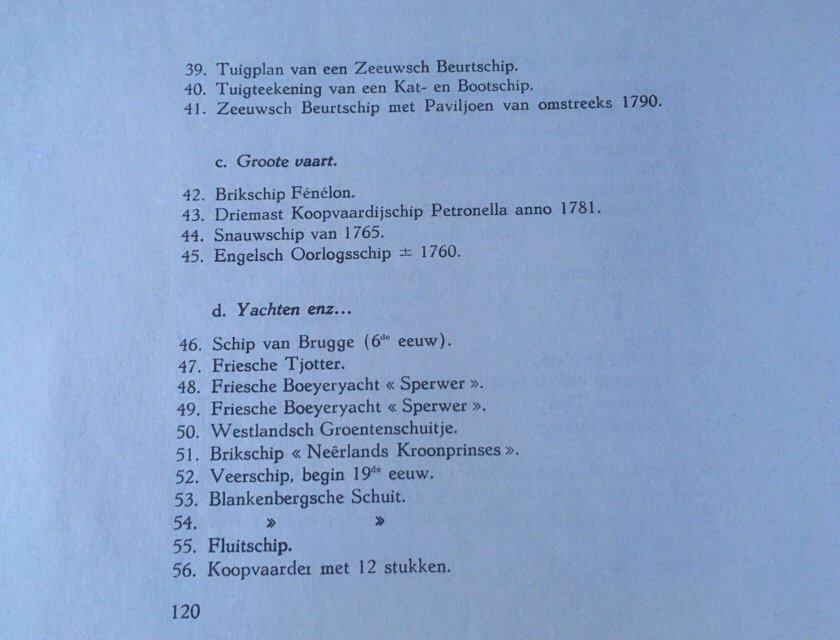

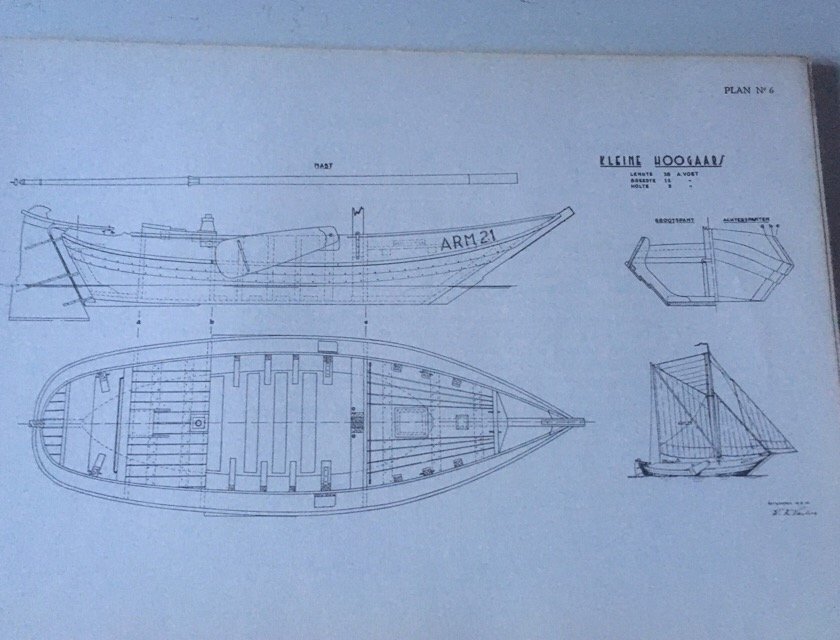

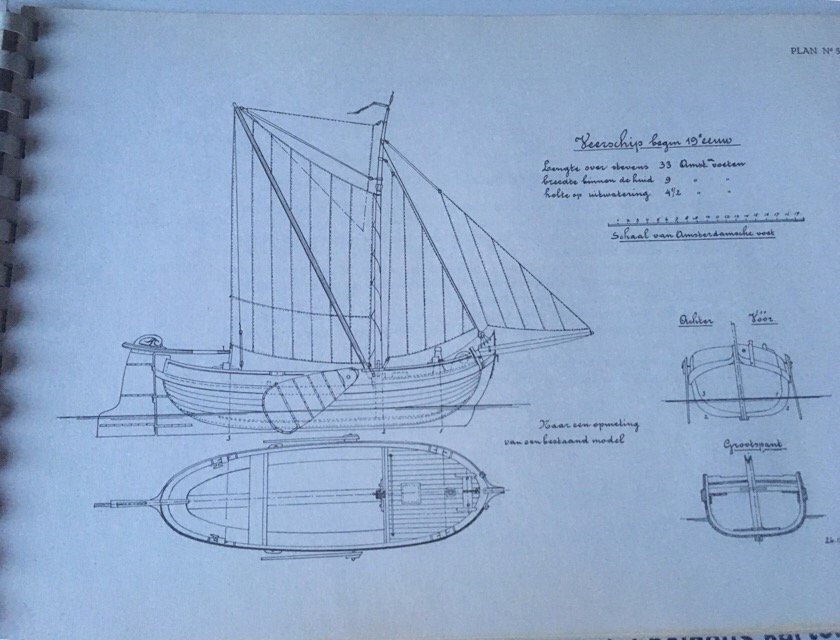

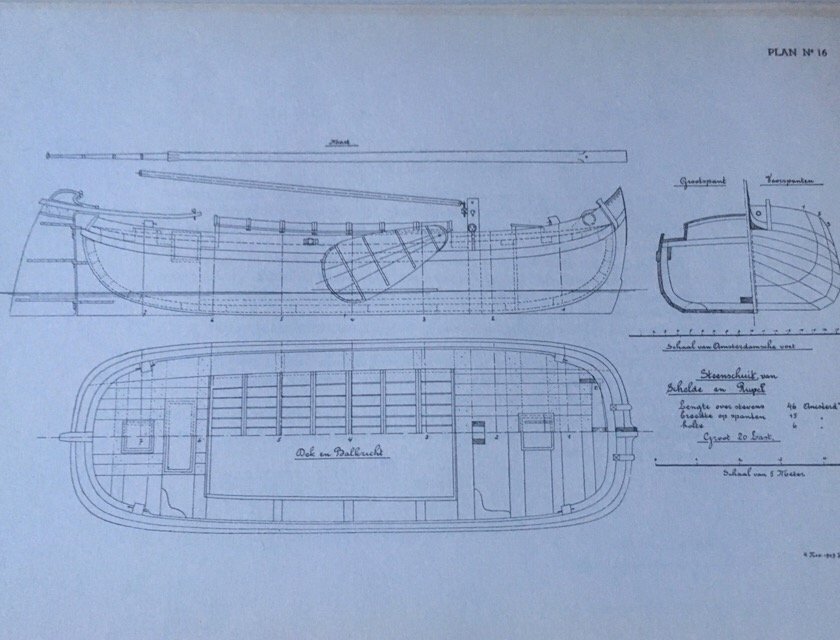

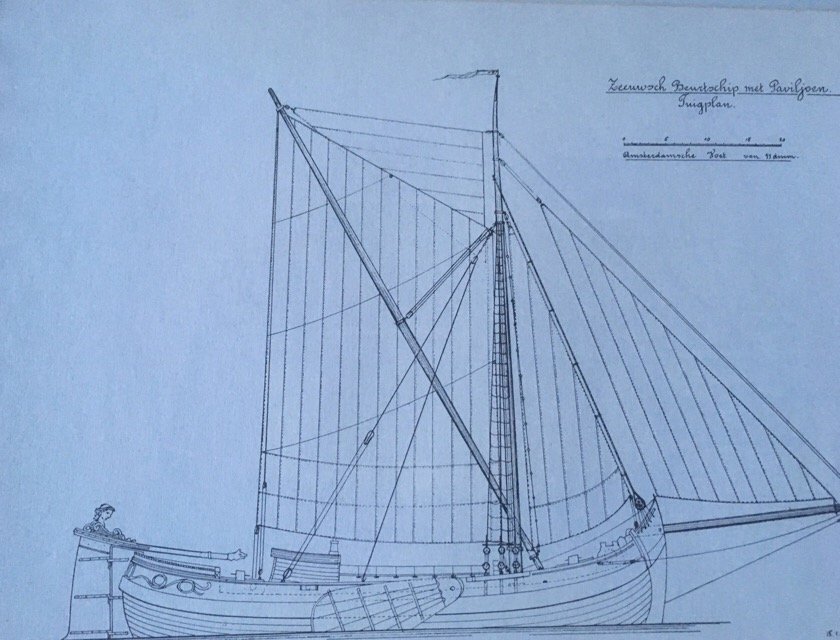

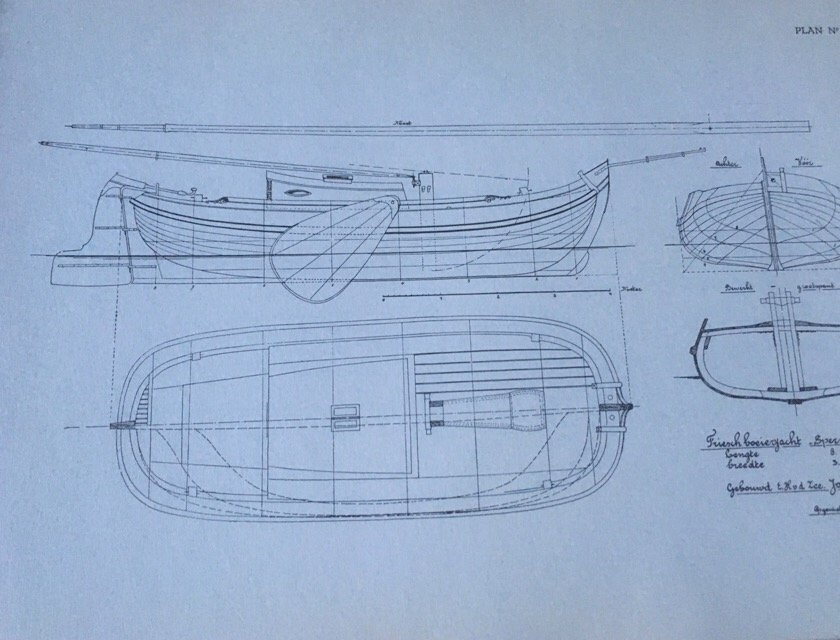

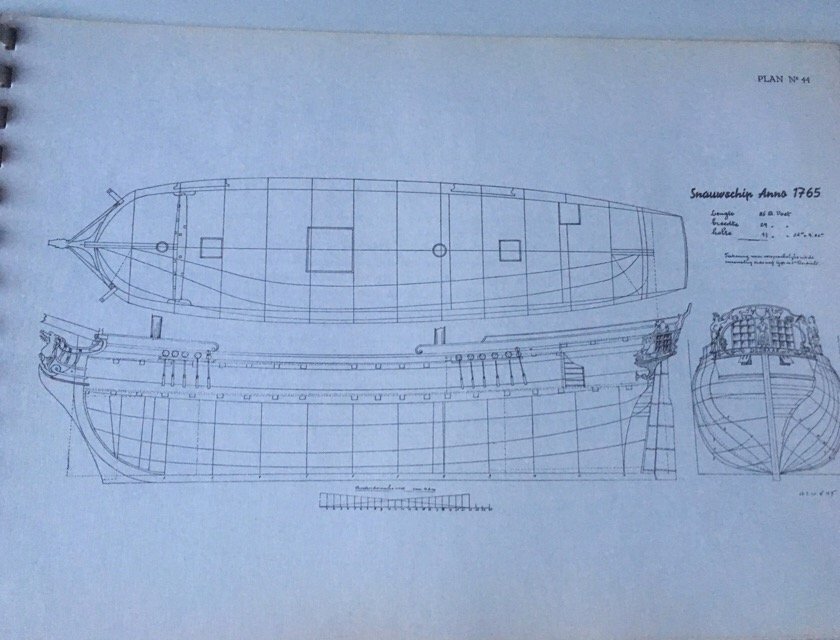

Request to admin: perhaps split this one (and the preceding ones) to a separate thread, as it is completely off topic in this thread..... I promisd to put some pics of the Versteeg booklet. Here they are, without further comments. For the smaller ships, these are more or less representative: one ship per page, some with, some without rigging plan (most of them with, but basic). The larger ships have 'chapman-like' drawings, basic, and without any useable rigging plan. Hoever, there are some nice dutch /flemish ships that van not be found elsewhere. Size of the book is A4, the right side has the drawing, the left side some bery basic info onwhere the drawings comes from (mostly own measurements from existing ship, or copy of original drawing). list of contents: (complete) And here the drawings that authentic ships used: veership: tjalk/steenschuit Boeier: Rigging plan of one of the ships (this is all you get, and this one is reasonably detailed) this one, has a more basic rigging plan And this onehas none. hope this gives an imprssion. Jan

-

But that price is rediculous for what you get..... I don't know what is happening to second hand prices, but they are rising to extremes..... this one is more realistically priced: http://www.marelibri.com/search/current.seam?maximumPrice=0.0&keywords=&firstResult=0&faceted=true&ISBN=¢ury=ALL&selectedDatasources=1021&quicksearch=Versteeg+scheepsmodellen&l=nl&matchTypeList=ALL&author=&title=&description=&minimumPrice=0.0&minimumYear=0&sorting=PRICE_ASCENDING&booksellerName=&ageFilter=ALL&keycodes=&pod=false&maximumYear=0&actionMethod=search%2Fcurrent.xhtml%3AsearchEngine.quicksearch Jan

-

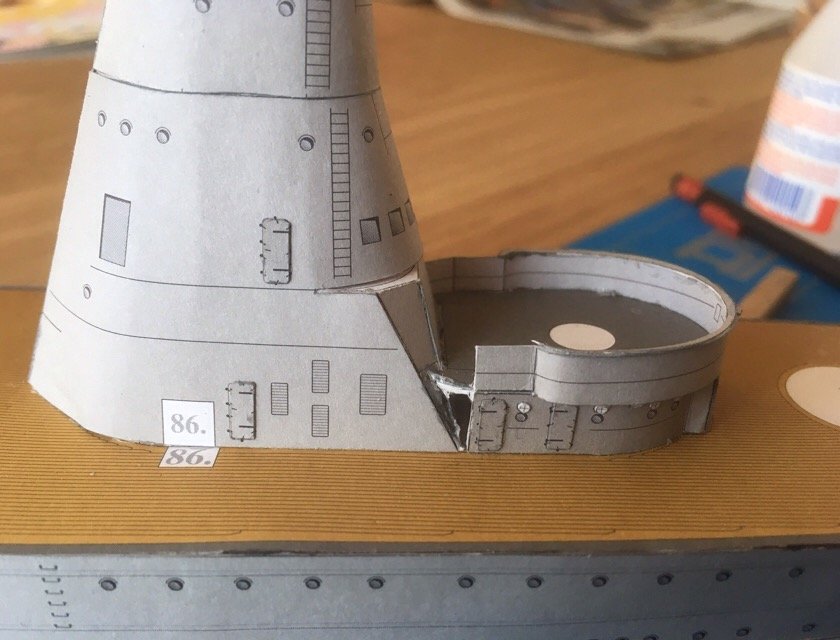

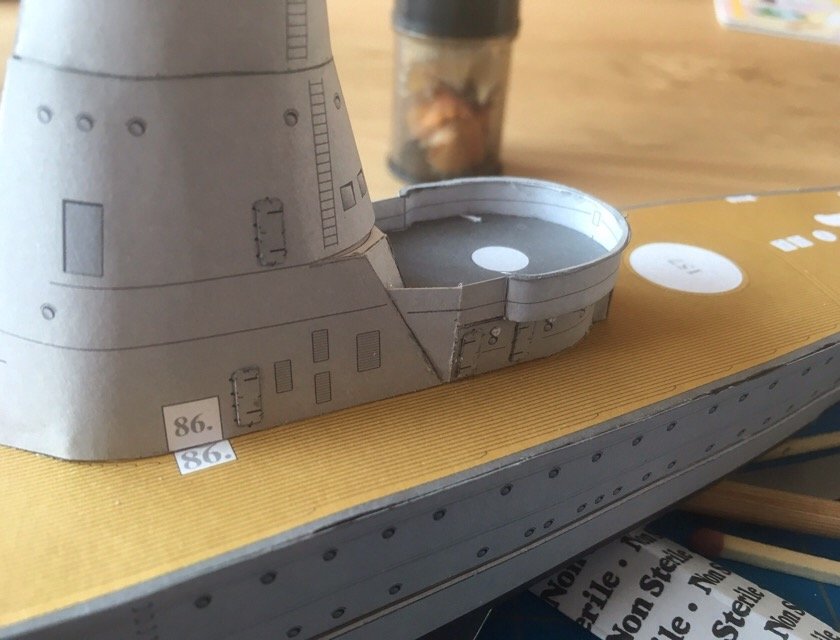

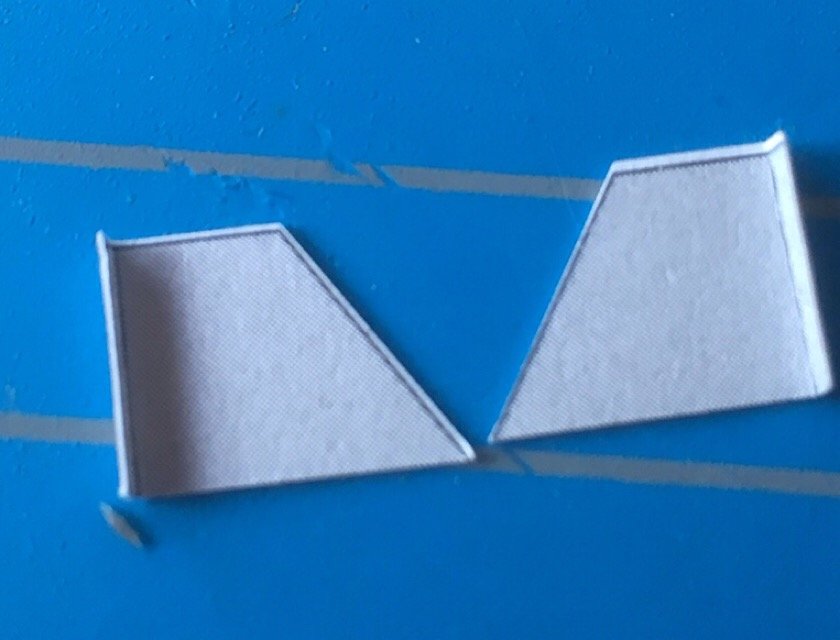

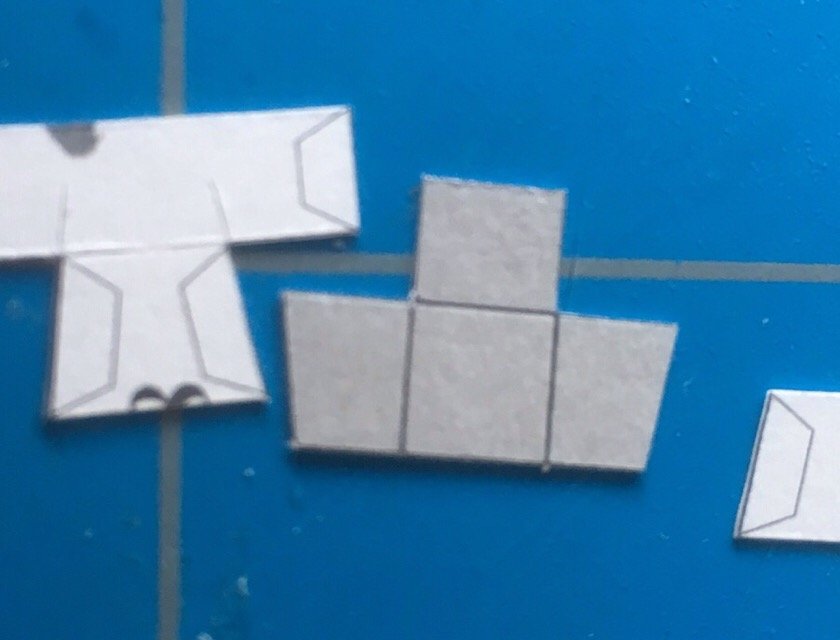

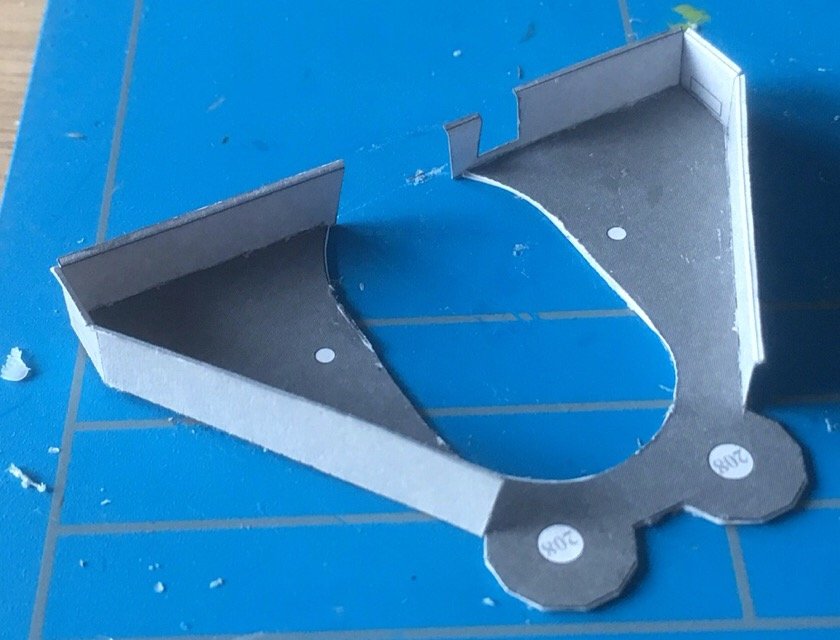

Finally...had some time to work on De Ruyter again. I decided for a fix of the sides of the conning tower. First remove the offending parts next, cut a triangle from the spare grey that is included (I put a second layer on the backside. Had some problem with that, as my printer/scanner does some weird things with the color. Dark grey turns into a very light grey 🤔 aThe black line was done with a pencil after the piece was fitter. (I discovered a second problem with the forward structure but that is for later to solve). Scaldis does two sided print, but does not always succeed in getting the colour at the correct spot some paint is needed Last both sides of the tower are some boxes. I decided to do something drastic: remove all tabs it turned out that these little boxes are far easier without tabs than with. Makes a man think..... Next was the first platform on the tower. again, although cutting at the outside of the lines, it turned out that both parts did not completely match. Hopefully The hole in the upper side matches the conning tower, if not, we need a fix again (no spare for this colour....) and finally, I decided to give myself a (rather expensive) present. Boy, does that make cutting portholes easier...:) they even get perfectly round more tomorrow (or some other time) have a nice weekend, Jan

-

No, it is not in print. I got it for about 15 euros in a second hand shop. I wouldn't have paid more for it. It is not a real ook, it is a bunch of drawings/sketches, size A4 , with a plastic binding. it has a number of (mostly) inland ships from flanders and the netherlands, and a couple of larger ships. It is a nice to have, but the drawings are ralatively small (1 ship per page), and need some work before you can build a larger scalemodel. Ican do a couple of pics if you like.

-

That boeier (as well as some other of their kits) were modellen based on drawings from this book: VERSTEEG,W.K. - Scheepsmodellen 1700 - 1900. Rather basic, solid hull models. (unfortunatedly, the milling of the hulls was not always very precise). I did this Boeier, the Tjalk, the Veerschip and the Botter. Still catching dust in my cupboard, but I still like the looks and size of these models. Rather sturdy and compact models: they survived all my moves. Jan

-

Mediaeval Cog found in River Issen

amateur replied to Louie da fly's topic in Nautical/Naval History

Yup, seen that (at least: the message, not the actual ship ) There were quite a number of wrecks on that site. Archeologists think the harbor authorities of the date tried to build some kind of dam, in order to prevent further sanding of the river mouth. The wreck was not raised, as the current practice in archeology is to preserve 'in situ'. Raising of the wreck was necessary, as the current river authorities needed to widen and deepen the rivermouth (in order to give it more capacity in times of severe rain-fall.) check this one: http://www.ijsselkogge.nl/ (partly in Dutch, but you sure can understand the pics) And: the river is called IJssel Jan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.