-

Posts

9,455 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Chuck

-

-

What specifically are you looking for?? If it is one article in particular, call the NEG office and talk to Julie. She can Photocopy a particular article for a nominal fee.

585-968-8111 for Julie

Or email her.

Chuck

-

Not for several months. It really doesnt mean I have to give up the Winchelsea. In fact, I was in teh shop just now planking up her port side. Only 3 strakes to go. I just have to set aside one day for each size of blocks to start building up a stock of them. They wont be ready for a while but they will be available at some point. I have to create a website to make ordering easier and I will be putting my Rigging line and cannon up there as well.

So stay tuned. It may not be until the fall but it will get done. Looking to have the Winniw planked up this weekend so I can start treenailing.

Chuck

-

Janv, there is a company in Sweden that has extreme high quality blocks. WWW.eskader.se then change language to English. Good luck

Check out those prices though....at least in US dollars. $30 for 20 blocks. Thats nuts. Here is what they look like. I have seen these while researching my own.

-

Here is the one I would use........but its for an admiral. You can also just use the standard. But its harder to make in this scale.

http://collections.rmg.co.uk/collections/objects/668.html

Chuck

-

I have been in research and testing mode for the last three months on these. Finally have it all nailed down. I wont be able to start actual production for a while but I do have all of my earlier test runs....

I am going to bring them to my next local meeting but if there are any left over I will certainly offer them here too. They are all the small 2mm and 3/32" blocks. They are the only sizes I was testing regularly. I have about 300 in each size, singles and doubles with varying size slots and holes...some have no holes. For example...I have about 300 single 3/32" blocks with no sheave holes. They are slotted though.

After my meeting I will post what I have left. If you guys dont mind drilling your holes I have tons of those. I was testing to just get the shape and sheave slots correct. I hate to throw them away.

Chuck

-

I couldnt come up with anything for sure and thats why it was omitted from the kit. I did look at some contemporary paintings though. They had such a variety that it was impossible to choose. Go to the NMM site and search for long boat, pinnaces and cutters...it will bring up lots of paintings. Also battle scenes which showed them but you have to get creative with teh search terms.

Chuck

-

Its gonna be a while until I build up some stock....but "Chucky Blocks" are coming soon.

Its gonna be a while until I build up some stock....but "Chucky Blocks" are coming soon.

Lets take a look.

Model Expo price for 3/32" single blocks 100 QTY = $20 You know what these look like

Lloyd's price ..................................................... = $35

Jerzy's price - 2 mm .......................................... = $45

My price in boxwood will be ............................... = $27

Expo blocks compared to Warner's blocks below

My blocks compared to Jerzy;s (Jerzy's on the right) 2mm

And another shot of my 2mm blocks...the single blocks on the right have no finish on them yet the doubles have some wipe-on-poly. This is an old image that doesnt show any strop groove. I will have to take some new pics once I start up production. These were basically my tests....I have made some adjustments (sheave slots wider slightly so the holes for rigging can be larger).

Hopefully soon.....depending on how much interest in this there is out there.

-

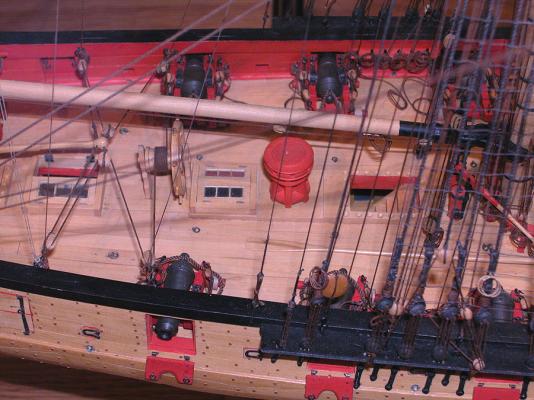

Here you go guys....some contemporary examples. Yes I used the model in the Rogers collection as my basis for rigging the tiller but you can use these also. Here are two more contemporary models that show a similar approach. Note: that even though the tiller is longer on the Rogers collection model, have a look at how the tiller rigging interferes with the last carronade in its port. After reviewing several other options, I thought it more important to make sure the rigging for the tiller is clear of the last carronade. On Syren and on Argus, the configurartion wouldnt have worked without making the last carronade useless in action.

But yes...the two blocks on the deck below the wheel should be added. I omitted them for two reasons. I found a good example in the lightley model which shows it that way...I knew folks would have access to it. The blocks supplied in the kit are huge as you know. They would have looked so out of scale and clunky that I took the aesthetic route and omitted them. If there were any kit builders that didnt take the time to reshape their blocks and just used the square ones supplied....it would have looked absolutely horrific.

The tiller is actually much too long on the Lightly model as well. It didnt match up with Chapelle's draft for the Argus or the Syren. I used his reconstruction for the inboard works with the help of English original drafts (raven and others) and contemporary models. Look at how far forward Lightly placed the ship's wheel. I saw no evidence on any other draft that this was done. Compare it to the English models. I also wanted to include the binnacle which Lightly had no place for since he moved the wheel so far forward. He has it lined up with the second port as compared to the way it is shown on the English drafts and contemporary models.

-

Beautiful work Robert

-

Wonderful wonderful looking model. I love the balance between the wood tones and painting. Thats a great wood color.

Chuck

-

Nicely done. That iron band for teh bowsprit can be a challenge. It looks well done.

Chuck

-

- maddog33, Mirabell61 and SkerryAmp

-

3

3

-

Bob

Wonderful photos.

That is exactly how I plank a hull...works a treat and saves a lot of wood. ... Instead of cutting the shaped plank from a wider sheet which ends up with to many scrap pieces. Great demo on the technique. With the strip clamped up, I use a hair dryer on the hottest setting to quickly heat and dry the plank. You can get really close to the plank so it gets really hot. After about two minutes of that, I let the strip rest for another few minutes. This locks in the bend with minimal spring-back.

Chuck

- Mirabell61, Larry Cowden, WackoWolf and 1 other

-

4

4

-

Ok folks...the registration form has been added to the bottom of the page...

http://www.thenrg.org/2013-nrg-charleston-conference-details.php

Dont forget to book your hotel separately...and use the code for the conference discount.

Chuck

-

That would be awesome. Yes it is open to non-members but with the discounts for members...you could join today for $38 and still save hundreds on the trip. There will be a 15% discount on all seminars and tours...etc for members. That includes for spouses and family members.

Chuck

-

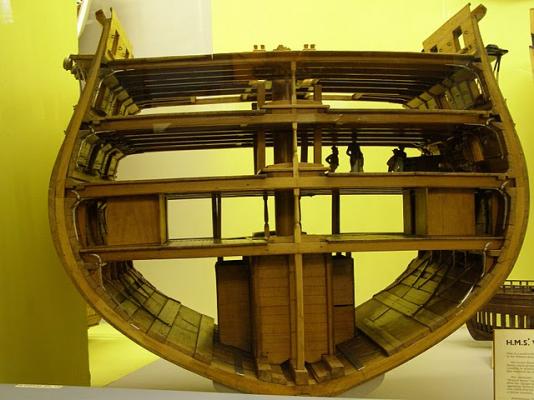

I thought I would post these two images of a cross section model from the science museum. I thought it might help or at least act as inspiration for those building teh cross section Triton. What I find very pleasing is the change in the plank thickness. Especially the outboard planking. I have no idea which ship this is as I didnt write that down when I saved it. It is one of hundreds of pictures I saved and now I am trying to organize. Based on what I see it may be a later vessel...but still worthy of inspiration.

Chuck

-

Registration forms will be on the website very soon. I will make another announcement when I add them. Hope to see many of you there.

Chuck

-

Dan

Great to see a log from you. Having seen this model first hand, I can tell you it is very sharp. Its a really interesting project and something a bit different than we usually see here on MSW.

Thanks for sharing Dan. Looking forward to those small details we were talking about!!!

-

-

Also...just give me a shout when you need a close up. I have much larger originals and possibly additional photos of what you may be working on.

Chuck

-

I agree...wonderful model.

-

-

-

Do we have a list of kits organized per scale?

in Wood ship model kits

Posted

Nope we dont.....but if you want to put one together or if someone wants to get that info in a spreadsheet...it would be awesome.

We would gladly post it. I am sure that old one that Floyd has probably needs some updating as well.

Chuck